Professional Documents

Culture Documents

V*SEP Membrane Filtration of Waste Oil Using New Logic Research

Uploaded by

Boulos NassarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V*SEP Membrane Filtration of Waste Oil Using New Logic Research

Uploaded by

Boulos NassarCopyright:

Available Formats

NEW LOGIC RESEARCH Case

V* SEP Membrane Filtration of Waste Oil Study

A cost-effective and environmentally sound processing solution

Overview

Used Oil Management System

A unique membrane filtration system was

installed in July 2001 at a major waste oil Site Map

re-refining operation in Portland, Oregan.

The system manufactured by New Logic Motor Oil

Research, Inc. of Emeryville, California Sales

near San Francisco, is being used to pro-

cess used crankcase waste oil and produce

filtrate that can be sold as a higher value

bunker oil. The V*SEP, (Vibratory Shear

Enhanced Process), system uses a Micro- Do-It-Yourselfer

filtration membrane module with special

construction for service with high tempera-

ture solvents and waste oils and is able to Improperly

process up to 80% of the dewatered waste Disposed Collection Center

oil. The use of high temperature polymeric

membranes has many significant advantag-

es over the conventional methods of oil re- Space Heater

refing and also over expensive ceramic and Transporter

inorganic filter media. New Logic's use of

Polymeric membranes in it's V*SEP Filter

Pack is ground breaking and has stirred Processor Re-Refiner

the interest of oil recycling companies

around the world.

End-User

Background

The waste oil re-refining operation in Port- This is done through a process Regulators have been improving

land services a large area in the Northwest of vacuum distillation. The re- incentives for recycling and have

and has several satellite transfer stations refined oil is blended with a been addressing the roadblocks to

for pick up of used oil from many customers fresh additive package to make recycling like providing more conven-

and other waste oil generators. Used oil is the finished lubricant. 75% of ient ways to drop off oil, increasing

produced by many activities including auto used oil which is reclaimed is the number of collection sites, pro-

repair, metal working, machine lubrication, reconditioned and marketed to: viding suitable containers for drop

and hydraulic equipment repair. Oil can be off, and monetary rebates similar to

recycled to make new lubricants or industrial 43% Asphalt Plants deposits paid on glass bottles.

fuels. When properly recycled, used oil is ex- 14% Industrial Boilers

cluded from regulation as a hazardous waste. 12% Power Plant Boilers

12% Steel Mills

Used oil does not wear out, it just gets dirty. 5% Cement/Lime Kilns

It can be used over and over again. 14% of 5% Marine Boilers (Bunker Fuel)

used oil that is reclaimed is re-refined to its 4% Pulp & Paper Mills

original virgin state. Re-refining base oil is the 5% Other

end product of a long process. The oil is first

Used oil that is actually reclaimed

cleaned of its contaminants, such as dirt, water,

represents a small fraction of oil

fuel, and additives.

actually sold and the majority of

this oil migrates its way into the

air and water posing a threat to

the environment.

V*SEP ... A New Standard in Rapid Separation Page 1

NEW LOGIC RESEARCH Case

Study

Recycling Programs Results using V*SEP

V*SEP's Microfiltration high The resulting filtrate has an ASTM color

temperature membrane module is index of about 8. The quality is

capable of treating used crankcase oil comparable with Marine Grade Diesel

and providing a filtrate, which is free Fuel or Bunker Fuel. Being able to sell

from suspended solids and dirt. In the oil as Marine Diesel represents a

addition, the filtration process is able to significant value added when compared

greatly reduce the levels of various to the boiler fuel quality prior to the

metals in the oil. Sulfur and Ash contents V*SEP filtration process. The VSEP

are also significantly reduced. Further process does not involve any chemical

refining to reduce Sulfur and Ash would addition and meets the criteria of

yield a Lube Oil quality product and process engineers needs for inline

methods for doing this following VSEP automated production. Both the

are currently being investigated. Permeate and Concentrate can be sold

as product.

Since the amount of used oil, which is

mysteriously lost would dwarf the Exxon

Valdez spill and is a huge environmental

problem, governments have been

looking at many ways to improve levels

of recycling. The EPA, (Environmental

Protection Agency), estimated that

210,000,000 gallons of used oil was

generated in 1991. Only about 40% of

that is recovered, with the disposition of

the remainder being unknown.

Vibratory Shear Process

V*SEPs unique separation technology

is based upon an oscillating movement

of the membrane surface with respect

to the liquid to be filtered. The result is

that binding of the membrane surface

due to the build up of solids is eliminated

and free access to the membrane pores

is provided to the liquid fraction to be

filtered. The shear created from the

lateral displacement caused suspended

solids and colloidal materials to be

repelled and held in suspension above

the membrane surface. This combined

with laminar flow of the fluid across the

membrane surface keeps the filtered

liquid homogeneous and allows very

high levels of recovery of filtrate from the

feed material. In the case of waste oil,

large storage tanks containing waste oil

are batch concentrated and volume

reduced by as much as 80% leaving

a thick viscous reject as the remaining

20% which can also be burned as a

fuel product.

V*SEP ... A New Standard in Rapid Separation Page 2

NEW LOGIC RESEARCH Case

Study

Process Description

The used oil is collected and stored in concentrated and

heated 20,000 gallons holding tanks. volume reduced in

The water is boiled off after several a process known

hours at high temperature and then the as Batch Process.

used oil is pumped into the V*SEP Multiple tanks are

system for filtration. The viscosity of used and this same

the oil plays a big part in the rate of process repeats for

filtration. Heat will help to decrease the each tank in series.

viscosity of the oil and therefore

Each V*SEP unit

improves the throughput of the V*SEP

is can process one

system. The Portland installation is

currently running at about 90C. Some 20,000 gallon tank

experimental runs have been accomp- in just under 2 days

lished at temperatures of up to 115C. One V*SEP was

The mechanical design of the V*SEP installed in

filter modules is being redesigned to Portland in 2001

handle temperatures over 120C and a second

which would double the throughput V*SEP is currently

currently provided at 90C. being brought

online to double

performance.

The Permeate flow

rate will drop off, as

the feed material in

the heated storage

tank becomes

more concentrated

and viscous. At

the end of a batch

process, the Filter

Pack is cleaned using clean diesel Fuel some configurable parameters be

out of a Clean in Place tank of about reached. The control stand contains the

350 gallons. This is done by recirculating PLC, Operator display and terminal

the diesel fuel with pressure and strips for wiring connections to

vibration to dissolve foulants that have instrumentation.

found their way to the membrane.

Months of pilot testing and also actual The Filter Pack is mounted on the

site conditions have shown that the V*SEP base unit and contains about

membrane is able to clean up very well 1100 SF, (100m2), of membrane area

and the results from batch to batch are and is constructed out of high

predictable and stable. temperature materials.

Once the oil has been heated and the

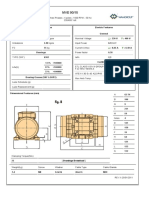

water is driven off to less than 1% by System Components The V*SEP drive system, which

volume, the feed waste oil is pumped supports and vibrates the Filter Pack is

The V*SEP system for this project was engineered using space age alloys and

into the V*SEP Filter Pack at about 60

configured for manual mode where the materials to withstand the applied stress

psi. The contents of the 20,000 gallon

feed tank are processed so that the operator would initiate all operating from a resonating frequency of about 50

filtrate is removed from the system and sequences. The unit has a PLC hz. Each base unit is fully stress tested

sent to a "Look See" holding tank and (Programmable Logic Controller) which and the factory prior to shipment. The

then a larger product storage tank. As monitors pressure, flow rate, and V*SEP drive system is made up of the

filtrate is removed by filtration and the frequency. It also provides the safety in Seismic Mass, Torsion Spring, Eccentric

reject is sent back to the feed tank, the operation by monitoring conditions and Bearing, and Lower Pressure Plate.

contents of the feed tank are then initiating an alarm shut down should

V*SEP ... A New Standard in Rapid Separation Page 3

NEW LOGIC RESEARCH Case

Study

System Throughput

Each of the V*SEP modular units for

this project is capable of processing a One - 84" V*SEP (1100SF) Permeate

20,000 gallon, (76m3) tank of used oil 6 GPM

in about 1.75 days. Since the units are 23 ppm Calcium

modular and can be used in parallel or 0.03% Ash

in series, the number of V*SEP's 0.25% Sulfur

needed can be calculated based on the Feed

amount of available used oil to be pro- 20 GPM

cessed. At 90C the membrane flux is 1179 ppm Calcium

about 8 GFD (Gallons per Square Foot 0.70% Ash

per Day) or about 13 LMH. System 0.36% Sulfur Concentrate

V*SEP

throughput is also a function of the ex- 14 GPM

tent to which the feed tank is concentrat- 1674 ppm Calcium

ed. At the beginning of a Batch run the 0.99% Ash

flux is about 15 GFD and falls to about 80% Recovery 0.44% Sulfur

4 GFD at the end of an 80% recovery of

filtrate. The system throughput shown

above is for one V*SEP unit operating As you can see the economics are The market for Oil and therefore re-

at about 90C. A second unit is being very compelling. The V*SEP is cycled oil is subject to fluctuation

installed in Portland which will double uniquely energy efficient. It comes based on supply and demand. The

the throughput. In addition, the second with a 20 HP dive motor and a 10 chief parameter for economics anal-

module will be configured for operation HP Pump Motor. Operators inter- ysis of the V*SEP process would

at 120C. The difference in performance face and maintenance a limited to be the spread in price between the

between 90C and 120C is also starting and stopping the unit and boiler fuel grade oil which is the feed

doubled. So by running at higher temp- a periodical cleaning of the mem- to the V*SEP and the Marine Grade

erature and by using 2 V*SEP units, brane after a batch run. The diesel Diesel Fuel which is the by-product of

the system throughput would be four fuel cleaning solvent can be reused the V*SEP..The Table below uses

times as high as that shown. a few times further saving costs. a spread of $0.30 per gallon of filtrate

Not only that the cleaning solution produced. This spread will vary and

Project Economics itself would have residual value can be as high at 0.50 $/gal and as

which is not shown below. The low as 0.10 $/gal. No matter what

Table 1 below shows the potential membrane replacement is the the spread, the economics for

revenue from the installation of one largest operating cost and it is V*SEP filtration of used waste oil are

V*SEP module as currently configured estimated that the life of each very compelling and can lead to

in Portland. By adding the second module is approximately 1-1.2 years. almost immediate realization of profits

machine and by operating at high temp- Operator care can improve the life from the operations.

erature, the potential revenues would and additional savings could be

also be about four times as much as yielded by having the Filter Pack In addition to the value added form

shown in the table below. last 2 years or more. of Marine Grade Diesel Fuel which is

Table 1:Waste Oil Economic Analysis currently under way, process de-

velopment is now being done to find

Description Expenses Value Added even higher value added products

that can be produced from the

V*SEP System Power Consumption $ 3,113 V*SEP including Lube Oil by reduc-

ing the Sulfur content and color index.

System Maintenance & Cleaning $ 15,095 The possible uses of the V*SEP

filtrate are wide ranging and another

use includes dust control. Additional

values and uses for the filtrate will be

Added Revenue from Oil Spread*

found in coming months.

*2,956,500 gal/year x 0.30 $/gal $ 886,950/year

V*SEP ... A New Standard in Rapid Separation Page 4

NEW LOGIC RESEARCH Case

Study

Other V*SEP Oil Applications

Oil/Water separation covers a broad

spectrum of industrial process

operations. There are many techniques

employed depending on the situation.

The oily wastewater application can be

broken down into categories determined

by the type of user of the VSEP and

the oil/ water separation desired:

a Produce Water - Drilling Operations

a Bilge Water from Drilling Derricks

a Used Coolant from Manufacturing

a Drilling Mud

a Waste Oil Haulers

There is a saying: Oil and Water dont

mix. This is true, but, they can exist as The V*SEP technology was invented by The plant has extensive equipment and

an emulsion. Oil is not soluble in water Dr. Brad Culkin in 1985. Dr. Culkin holds machinery for manufacturing nearly all the

but it can exist evenly dispersed as a Ph.D. in Chemical Engineering and was V*SEP parts. Manufacturing, assembly, and

globules in water. The concentration of formerly a senior scientist with Dorr-Oliver testing of all equipment takes place at this site.

these globules is a function of mixing or Corporation. V*SEP was originally Systems and procedures are in place and

stirring. If allowed to stand, the emulsion developed as an economic system that geared towards high standards of quality

will separate because oil is lighter than would efficiently separate plasma from control and have met the acceptance

water, although, some amount of oil whole blood. The company received a criteria of stringent applications such as

globules will remain in the water. Another contract to produce a membrane filtration nuclear waste processing.

interesting fact is that this emulsion can prototype, which later would be incorpor-

exist two ways. If the concentration of ated into a blood analyzer system. Today

Oil is less than 50%, the water will be the company has adapted the technolgy to

the suspension fluid and the oil will be address the problems that face the old tradit-

the globule. A phase transition occurs if ional membrane systems and offer com-

the oil content is more than 50%. When panies an efficient and economical way to

this happens, the oil is the suspension meet their process goals.

fluid and the water forms globules. For

this reason, hydrophilic membrane The Series i (Industrial) is a full scale model

separations will be possible only when and comes in sizes ranging from 100 Square

the oil content is less than 50%. Feet to 2000Square Feet. These units are

modular and can be used in parallel or in s For more information about the

eries. Successful VGSEP systems are in Portland Waste Oil Installation or on

Company Profile

place now world wide including Europe, VSEP technology and its potential

New Logic Research, Inc. is a privately Central Asia, Southeast Asia, Australia, application to your process, please

held corporation located in Emeryville, South America, Canada, Mexico, and of contact:

CA approximately 10 miles from San course here in the United States. New

Francisco. New Logic markets, engineers, Logic offers a strong engineering staff to New Logic Research, Inc.

and manufactures membrane dewatering

and filtration systemsused for chemical

assist customers in the design, develop- 1295 67th Street

ment, and testing of their filtration systems.

processing, waste streams, pulp & paper After outgrowing two previous locations Emeryville, CA 94608

processing, mining operations, and in the last ten years, New Logic is now (510) 655-7305 tel

drinking waterapplications. located in a 40,000 square foot manu-

facturing building in Emeryville. (510) 655-7307 fax

e-mail: info@vsep.com

web: www.vsep.com

V*SEP ... A New Standard in Rapid Separation Page 5

You might also like

- (PPT) Science Q1 Week 8 Day 1-5 (Edited Layout)Document73 pages(PPT) Science Q1 Week 8 Day 1-5 (Edited Layout)Precious Idiosolo100% (4)

- Regeneration of Waste Lubricant Oil by Extraction-Flocculation PDFDocument8 pagesRegeneration of Waste Lubricant Oil by Extraction-Flocculation PDFsasanNo ratings yet

- Revamping An Integrated Hydrocracker and Lube Base Oil UnitDocument5 pagesRevamping An Integrated Hydrocracker and Lube Base Oil UnitVyacheslavNo ratings yet

- Green Vegetable Oil Processing: Revsied First EditionFrom EverandGreen Vegetable Oil Processing: Revsied First EditionWalter E. FarrRating: 3 out of 5 stars3/5 (1)

- Lead Acid Battery Desulfator GuideDocument5 pagesLead Acid Battery Desulfator GuidetopazeusNo ratings yet

- Polyethylene - Aluminium Roof (Tetra Pak)Document6 pagesPolyethylene - Aluminium Roof (Tetra Pak)Soumendra Roy50% (2)

- Varnish in Turbine OilsDocument6 pagesVarnish in Turbine OilsToppy Toppy100% (1)

- Cracking of Waste Engine Oil in Presence of Cobalt OxalateDocument4 pagesCracking of Waste Engine Oil in Presence of Cobalt OxalateAshok RathodNo ratings yet

- Cheryan 2005Document3 pagesCheryan 2005mahesh8760No ratings yet

- Chapter - 2 Literature Review: 2.1 Regeneration of Used Lubricating OilsDocument23 pagesChapter - 2 Literature Review: 2.1 Regeneration of Used Lubricating OilsEl Sayed ZakariaNo ratings yet

- A Second Generation Biofuel PDFDocument11 pagesA Second Generation Biofuel PDFNoviNo ratings yet

- Oilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDocument10 pagesOilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDaniel DamboNo ratings yet

- Economic Feasibility Study of Biodiesel Production by Direct Esterification of Fatty Acids From The Oil and Soap Industrial SectorDocument6 pagesEconomic Feasibility Study of Biodiesel Production by Direct Esterification of Fatty Acids From The Oil and Soap Industrial SectorazNo ratings yet

- Upgrading Petroleum Residues With Solvent Deasphalting TechnologyDocument11 pagesUpgrading Petroleum Residues With Solvent Deasphalting TechnologyisleepinadrawerNo ratings yet

- STP Present Used Lube Oil Re-Refining 25anniversaryDocument89 pagesSTP Present Used Lube Oil Re-Refining 25anniversaryEng D A MaxNo ratings yet

- Green Diesel - A Second Generation BiofuelDocument11 pagesGreen Diesel - A Second Generation BiofuelChatkamol KaewbuddeeNo ratings yet

- Light, Intermediate, Heavy Distillates, and Residues. Light DistillatesDocument8 pagesLight, Intermediate, Heavy Distillates, and Residues. Light DistillatesRowel GanzonNo ratings yet

- Alfa Laval Pure Dry Waste Oil Recovery PDFDocument2 pagesAlfa Laval Pure Dry Waste Oil Recovery PDFKunjal Shah100% (1)

- Wang 2012Document7 pagesWang 2012LogamalarNo ratings yet

- Thermal Cracking of Waste Engine Oil (Lubricant) at 430oc TemperatureDocument4 pagesThermal Cracking of Waste Engine Oil (Lubricant) at 430oc TemperatureAshok RathodNo ratings yet

- Refining of Used Lube OilDocument89 pagesRefining of Used Lube OilAadarsh MouryaNo ratings yet

- Eco-Friendly Process For Re-Refining of Used Cramkcase Engine OilsDocument5 pagesEco-Friendly Process For Re-Refining of Used Cramkcase Engine OilsWaqar AhmedNo ratings yet

- Economic Bottom of the Barrel Processing to Minimize Fuel Oil ProductionDocument5 pagesEconomic Bottom of the Barrel Processing to Minimize Fuel Oil Productionfisco4rilNo ratings yet

- Revolutionary Waste Oil Refining TechnologyDocument6 pagesRevolutionary Waste Oil Refining TechnologyJohn simpson100% (1)

- Allah 2016 IOP Conf. Ser. - Mater. Sci. Eng. 147 012133 PDFDocument8 pagesAllah 2016 IOP Conf. Ser. - Mater. Sci. Eng. 147 012133 PDFFrancis AngelesNo ratings yet

- Waste Minimization Practices in The Petroleum Refining IndustryDocument9 pagesWaste Minimization Practices in The Petroleum Refining IndustryTaha Lemdjed BelahçeneNo ratings yet

- Maximizing profits from heavy crude oils and reducing fuel oil productionDocument5 pagesMaximizing profits from heavy crude oils and reducing fuel oil productionsantiagoNo ratings yet

- Olisiji Optimum DMDocument6 pagesOlisiji Optimum DMHAFIZUL FURQANNo ratings yet

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Desalination and Water TreatmentDocument9 pagesDesalination and Water TreatmentchozkmNo ratings yet

- Green Diesel Production From Vegetable Oil: September 2007Document8 pagesGreen Diesel Production From Vegetable Oil: September 2007rishikeshmandawadNo ratings yet

- Lube-Tech: Modern Base Oils & Blending For Optimal PerformanceDocument6 pagesLube-Tech: Modern Base Oils & Blending For Optimal PerformanceYesica RozoNo ratings yet

- 1 s2.0 S0016236112002736 MainDocument9 pages1 s2.0 S0016236112002736 MainRiandy PutraNo ratings yet

- Used Lube RecyclingDocument62 pagesUsed Lube RecyclingBharat SharmaNo ratings yet

- Green Diesel Production From Vegetable Oil: September 2007Document8 pagesGreen Diesel Production From Vegetable Oil: September 2007NoviNo ratings yet

- Compound Changes in Re-Refined Used Lubricating OiDocument12 pagesCompound Changes in Re-Refined Used Lubricating OiAhmad MNo ratings yet

- Thermopac Process Engineering LLPDocument3 pagesThermopac Process Engineering LLPAkshay ThermopacNo ratings yet

- Convert Bottom-Of-The-Barrel Into Diesel and Light OlefinsDocument5 pagesConvert Bottom-Of-The-Barrel Into Diesel and Light OlefinsAmjad HaniNo ratings yet

- ROSE® Process Offers Energy Savings For Solvent ExtractionDocument14 pagesROSE® Process Offers Energy Savings For Solvent Extractiona_abbaspourNo ratings yet

- Improving The Viscosity Index of Used Lubricating Oil by SolventDocument5 pagesImproving The Viscosity Index of Used Lubricating Oil by SolventJorge EliasNo ratings yet

- Thin Fil EvapDocument13 pagesThin Fil EvapimronmasfruriNo ratings yet

- Diesel From Vegetable OilDocument8 pagesDiesel From Vegetable OilSesti NugrahaNo ratings yet

- Oil Refining 04Document16 pagesOil Refining 04Nisha KrishnanNo ratings yet

- SPE 140720 Development of Environmentally Friendly Oil Based Mud Using Palm-Oil and Groundnut-OilDocument9 pagesSPE 140720 Development of Environmentally Friendly Oil Based Mud Using Palm-Oil and Groundnut-OilJaime Andres CallejasNo ratings yet

- 1 s2.0 S092041052101250X MainDocument9 pages1 s2.0 S092041052101250X Mainpetrolink2021No ratings yet

- Isom & HguDocument6 pagesIsom & HguDanish KhanNo ratings yet

- CT&Ftank PDFDocument15 pagesCT&Ftank PDFDanivian HigginsNo ratings yet

- Clay TreatmentDocument8 pagesClay TreatmentTuchitoNo ratings yet

- At 03383 WP Refinery ProfitsDocument18 pagesAt 03383 WP Refinery Profitszubair1951100% (1)

- Mahle-Mpeb Ows PDFDocument20 pagesMahle-Mpeb Ows PDFOleksii FilipovNo ratings yet

- Microwave Assisted CentrifugeDocument1 pageMicrowave Assisted CentrifugeDivya LadhaNo ratings yet

- Chemical Engineering and Processing - Process IntensificationDocument8 pagesChemical Engineering and Processing - Process Intensificationerisa mantapNo ratings yet

- Study On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDocument7 pagesStudy On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDyshelly Nurkartika PascapurnamaNo ratings yet

- Increased diesel production with selective catalysts and biomass routesDocument15 pagesIncreased diesel production with selective catalysts and biomass routesNguyễn Hoàng Bảo TrânNo ratings yet

- Lube Oil: D 1747-89 Standard Test Method For Refractive Index of Viscous MaterialsDocument3 pagesLube Oil: D 1747-89 Standard Test Method For Refractive Index of Viscous MaterialsmahsaNo ratings yet

- ISOCRACKING TECHNOLOGY FOR CLEANER FUELS AND LUBESDocument9 pagesISOCRACKING TECHNOLOGY FOR CLEANER FUELS AND LUBESAdriana MorenoNo ratings yet

- Used OilDocument11 pagesUsed Oilrvsingh100% (3)

- EOR by SNFDocument3 pagesEOR by SNFMohitNo ratings yet

- Study of Selected Petroleum Refining Residuals Industry StudyDocument60 pagesStudy of Selected Petroleum Refining Residuals Industry StudyOsama AdilNo ratings yet

- Used Engine Oil RerefiningDocument31 pagesUsed Engine Oil RerefiningMasomese Henry Kikile100% (3)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Effects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyDocument18 pagesEffects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyBoulos NassarNo ratings yet

- Leaching Spent Batteries Powder Sodium Carbonate CO2Document6 pagesLeaching Spent Batteries Powder Sodium Carbonate CO2Boulos NassarNo ratings yet

- Main Vehicle SpecificationsDocument3 pagesMain Vehicle SpecificationsBoulos NassarNo ratings yet

- ACS 355 frequency inverter quick setup guideDocument3 pagesACS 355 frequency inverter quick setup guideBoulos NassarNo ratings yet

- 19A00142Document1 page19A00142Boulos NassarNo ratings yet

- Pulse Charge With Single InductorDocument4 pagesPulse Charge With Single Inductorkcarring100% (1)

- Efficiency Package For Solar TrackerDocument2 pagesEfficiency Package For Solar TrackerBoulos NassarNo ratings yet

- Spade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Document1 pageSpade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Boulos NassarNo ratings yet

- Wiring PDFDocument13 pagesWiring PDFBoulos NassarNo ratings yet

- AOD Brochure PersulfateDocument16 pagesAOD Brochure PersulfateÖzgür SelviNo ratings yet

- Waste Handling Cranes: Power Cable Integrated With The DrumDocument1 pageWaste Handling Cranes: Power Cable Integrated With The DrumBoulos NassarNo ratings yet

- ACS 355 frequency inverter quick setup guideDocument3 pagesACS 355 frequency inverter quick setup guideBoulos NassarNo ratings yet

- Battery Desulphator: John Drake Services, IncDocument3 pagesBattery Desulphator: John Drake Services, IncBoulos NassarNo ratings yet

- DesulfatorDocument5 pagesDesulfatormad659No ratings yet

- Battery Desulphator: John Drake Services, IncDocument3 pagesBattery Desulphator: John Drake Services, IncBoulos NassarNo ratings yet

- Sadelmi Power: List of ReferencesDocument24 pagesSadelmi Power: List of ReferencesBoulos NassarNo ratings yet

- Review On Desulfation of Lead-Acid Battery For HevDocument12 pagesReview On Desulfation of Lead-Acid Battery For Hevstark2006No ratings yet

- Load Cell Cabling Setup and Trimming GuideDocument8 pagesLoad Cell Cabling Setup and Trimming GuideTong Van NgocNo ratings yet

- GBDocument2 pagesGBBoulos NassarNo ratings yet

- CAT - C15-500 - EN 500kVADocument1 pageCAT - C15-500 - EN 500kVAAmmar Lateef GakharNo ratings yet

- Split Unit MUE 18HR (6 Pieces)Document1 pageSplit Unit MUE 18HR (6 Pieces)Boulos NassarNo ratings yet

- Lowara ESV 50Hz en LDocument72 pagesLowara ESV 50Hz en LmbgprsmsNo ratings yet

- 3GAA112312 BSE M3aa 112mb 4Document2 pages3GAA112312 BSE M3aa 112mb 4Boulos NassarNo ratings yet

- 3gaa112312 AeeDocument2 pages3gaa112312 AeeBoulos NassarNo ratings yet

- 3gaa112312 BseDocument2 pages3gaa112312 BseBoulos NassarNo ratings yet

- Item ModelDocument1 pageItem ModelBoulos NassarNo ratings yet

- Silica Gel Emitter PreparationDocument2 pagesSilica Gel Emitter PreparationBoulos NassarNo ratings yet

- Mve90 15Document1 pageMve90 15Boulos NassarNo ratings yet

- Transesterification of Oil TBGDocument6 pagesTransesterification of Oil TBGSNo ratings yet

- RA 9003 Ecological Solid Waste Act SummaryDocument27 pagesRA 9003 Ecological Solid Waste Act SummaryKhryz CallëjaNo ratings yet

- Q1 Science Week 8 CherryDocument64 pagesQ1 Science Week 8 Cherrycherry faralNo ratings yet

- Advancement of Waste Segregation Through AI Trash BinsDocument14 pagesAdvancement of Waste Segregation Through AI Trash BinsTrexy HerederoNo ratings yet

- NSTP1Document1 pageNSTP1Isaac AlegaNo ratings yet

- IMX-5A - M26 - 04 - TECHNICAL Manual - ITALRAYDocument199 pagesIMX-5A - M26 - 04 - TECHNICAL Manual - ITALRAYКонстантин ПокидаевNo ratings yet

- Recycling Thesis StatementsDocument5 pagesRecycling Thesis Statementsbsgyhhnc100% (3)

- Structurix MEcoDocument12 pagesStructurix MEcoPierpaolo AparoNo ratings yet

- DLL - Science 5 - Q1 - W8Document7 pagesDLL - Science 5 - Q1 - W8Melanie De La CuestaNo ratings yet

- E Waste Management - 11.08Document24 pagesE Waste Management - 11.08Varun TomarNo ratings yet

- Waste Sorting GuideDocument22 pagesWaste Sorting GuideXiaoyu ChenNo ratings yet

- Global Sustainability Summit Brochure 2020 02 01 20 06.20 PMDocument6 pagesGlobal Sustainability Summit Brochure 2020 02 01 20 06.20 PMYogesh ChhaprooNo ratings yet

- 3rd Quarter ENGLISH-2023Document6 pages3rd Quarter ENGLISH-2023Romy Renz SanoNo ratings yet

- GCSE LLW Employability NotesDocument34 pagesGCSE LLW Employability NotesAaron Lee0% (1)

- User Manual: Teoswide 1036Document23 pagesUser Manual: Teoswide 1036Costin GrigoreNo ratings yet

- 7.seville OrangesDocument4 pages7.seville Orangeshüseyin aytekinNo ratings yet

- Waste Management ArticleDocument20 pagesWaste Management ArticleSherab ChodennNo ratings yet

- Postion Paper On Plastic PollutionDocument12 pagesPostion Paper On Plastic PollutionAngeli Alexi VitenteNo ratings yet

- Leadership Changes and Strategic Focus at Hyundai MotorDocument6 pagesLeadership Changes and Strategic Focus at Hyundai MotorALEN AUGUSTINENo ratings yet

- Apple ReportDocument14 pagesApple Reportapi-268411981No ratings yet

- Summative Assessment BlueprintDocument1 pageSummative Assessment Blueprintapi-239490164100% (1)

- Genzyme Center: Headquarters For Genzyme CorporationDocument20 pagesGenzyme Center: Headquarters For Genzyme CorporationTaynah DiasNo ratings yet

- Green Hospital Goes LEEDDocument123 pagesGreen Hospital Goes LEEDjayshree100% (2)

- Exploring An Alternative To The Chilean Textile Waste CF Assessment of A Textile Recycling ProcessDocument7 pagesExploring An Alternative To The Chilean Textile Waste CF Assessment of A Textile Recycling Processivory11136999No ratings yet

- 6 Jun 2017 IGEM 2016 Key in Enquiry 10 Oct 2016Document36 pages6 Jun 2017 IGEM 2016 Key in Enquiry 10 Oct 2016rexNo ratings yet

- Production of Pavement Tiles from Plastic WasteDocument44 pagesProduction of Pavement Tiles from Plastic WasteG3 TubeNo ratings yet

- Thermo Scientific Microphazir PC: Handheld Plastics AnalyzerDocument2 pagesThermo Scientific Microphazir PC: Handheld Plastics AnalyzerfaisalNo ratings yet

- Sustainability Fit Out Guide OfficesDocument26 pagesSustainability Fit Out Guide OfficesCalvin AdityaNo ratings yet

- E8 Unit 7Document73 pagesE8 Unit 7Фунг Тханх КуангNo ratings yet