Professional Documents

Culture Documents

Dywidag Post Tensioning Catalogue 6

Uploaded by

PrateekOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dywidag Post Tensioning Catalogue 6

Uploaded by

PrateekCopyright:

Available Formats

Standard Strands

Strands are made from 7 individual

cold-drawn wires, 6 helically wound

outer wires and one center wire (king Strands are usually packaged

wire). The mechanical properties of the in so-called coils that can weigh up

strand as well as corrosion protection to 3.5 tons.

properties are most important to DSI.

Strands can be supplied either bare,

galvanized or epoxy-coated without

any loss in strength including the

wedge anchorage. For a maximum in

corrosion protection we offer electrical-

ly isolated systems using polyethylene

(PE) or polypropylene (PP) ducts. See

also page 8.

construction joint

V

D = draining V V

V = vent

V V

G = grouting S S

V S C V

V

C = coupling

S = stressing

P = post-grouting D G P D G P

E Technical Data

type 13 mm (0.5") 15 mm (0.6")

code/specification ASTM A 416 prEN 10138 ASTM A 416 prEN 10138 ASTM A 416 prEN 10138

Grade 270 BS 5896 Grade 250 BS 5896 Grade 270 BS 5896

yield strength fp0.1k N/mm2 1,6701) 1,6402) 1,5501) 1,5602) 1,6701) 1,6402)

ultimate strength fpk N/mm2 1,860 1,860 1,725 1,770 1,860 1,860

nom. diameter mm 12.70 12.90 15.20 15.70 15.24 15.70

cross-sectional area mm2 98.71 100.00 139.40 150.00 140.00 150.00

weight kg/m 0.775 0.785 1.094 1.180 1.102 1.18

ultimate load kN 183.7 186.0 240.2 265.5 260.7 279.0

modulus of elasticity N/mm2 ~195,000

relaxation3) after

1,000 h at 0.7 x % max. 2.5

ultimate strength fpk

1) yield measured at 1% effective elongation

2) yield measured at 0.1% residual elongation

3) applicable for relaxation class 2 according to Eurocode prEN 10138/BS 5896: or low relaxation complying with ASTM A 416, respectively.

6 subject to modification, August 2006

You might also like

- S1Document11 pagesS198675No ratings yet

- Design of PierDocument18 pagesDesign of PierMrinal kayalNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Technical Notes For TL (Brief)Document4 pagesTechnical Notes For TL (Brief)Dm InterioNo ratings yet

- Project Sports Complex Date: V Max ActDocument2 pagesProject Sports Complex Date: V Max ActShanil BussooaNo ratings yet

- Expt 2 - Two Way SlabDocument4 pagesExpt 2 - Two Way Slabganesh rajaNo ratings yet

- Two Way Slab Design Excel SheetDocument13 pagesTwo Way Slab Design Excel Sheetቀዳሚሃ ለጥበብ ፈሪሃ እግዚያብሔርNo ratings yet

- Fin Glass 6 PDFDocument6 pagesFin Glass 6 PDFEIWAA100% (1)

- 10T SWL Spreader Bar R2-Fos2.0Document8 pages10T SWL Spreader Bar R2-Fos2.0Snr Designer JayaNo ratings yet

- Sci Publication p387 Steel Building Desi 2Document4 pagesSci Publication p387 Steel Building Desi 2Visuvaratnam Suseendran100% (1)

- Ware House Purlin DesignDocument4 pagesWare House Purlin DesignSuhail Ahamed100% (1)

- 3.0 One Way SlabDocument20 pages3.0 One Way SlabAbhishek HulloliNo ratings yet

- Conductor Sag and Tension CalculatorDocument12 pagesConductor Sag and Tension CalculatorJetn SrisuthumNo ratings yet

- Slab DesignDocument6 pagesSlab DesignKanchan Raja SinghNo ratings yet

- StaicaseDocument4 pagesStaicaseAlex MachariaNo ratings yet

- c1b Low Voltage CoDocument16 pagesc1b Low Voltage CovizanteaNo ratings yet

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

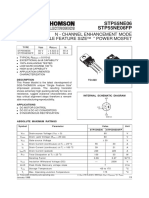

- Stp55ne06 PDFDocument9 pagesStp55ne06 PDFOmar CuevasNo ratings yet

- Two Way Slab Design Excel SheetDocument11 pagesTwo Way Slab Design Excel Sheetkshitj100% (1)

- Lift Calculation DemoDocument4 pagesLift Calculation Demoa_toups0% (1)

- Conductor Sag and Tension CalculatorDocument11 pagesConductor Sag and Tension CalculatorSanjeev KumarNo ratings yet

- 301 1C C D1Document3 pages301 1C C D1ssinokrotNo ratings yet

- Cable StructureDocument1 pageCable StructureAgnichandra SubediNo ratings yet

- 3-Design For ULS - Shear and Torsion (2016)Document22 pages3-Design For ULS - Shear and Torsion (2016)Jin PiaoNo ratings yet

- 01 - Design of One-Way SlabDocument8 pages01 - Design of One-Way Slabrmrv valdezNo ratings yet

- 01 - Design of One-Way SlabDocument8 pages01 - Design of One-Way Slabrmrv valdezNo ratings yet

- Design of Slab As Per IS:456-2000: Input Data:: Ok Ok Ok OkDocument8 pagesDesign of Slab As Per IS:456-2000: Input Data:: Ok Ok Ok OkPrakashNo ratings yet

- 6 Pile DesignDocument40 pages6 Pile DesignETHJDTJRYJ2No ratings yet

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- Crack Width Check For Water Tank BaseDocument4 pagesCrack Width Check For Water Tank BaseShamim Ahsan ZuberyNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- To Do - DS-H - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS-H - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Cable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byDocument1 pageCable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byMadhusudan ShewalkarNo ratings yet

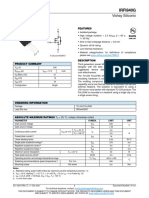

- IRFI840G: Vishay SiliconixDocument10 pagesIRFI840G: Vishay SiliconixFarhad FalahatparvarNo ratings yet

- Design of Pilecaps BS 8110Document3 pagesDesign of Pilecaps BS 8110thanigai veluNo ratings yet

- PCB Relay G8P: Ordering InformationDocument5 pagesPCB Relay G8P: Ordering Informationjombo123No ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- RCC31R Rigorous One-Way SlabsDocument389 pagesRCC31R Rigorous One-Way SlabsCioabla BogdanNo ratings yet

- Cable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byDocument1 pageCable Structure Design Based On ASCE 19-10 & AASHTO 17th: Project: Client: Design By: Job No.: Date: Review byjklo12No ratings yet

- J0231 HV TR - FINAL变压器1Document23 pagesJ0231 HV TR - FINAL变压器1SerhiiNo ratings yet

- The Dubai Chamber of Commerce and Industry Building ExtensionDocument22 pagesThe Dubai Chamber of Commerce and Industry Building ExtensionAhammad KabeerNo ratings yet

- Section Is Class 2 CompactDocument2 pagesSection Is Class 2 CompactAmmar AzmiNo ratings yet

- Design of Pad Footings BS 8110Document4 pagesDesign of Pad Footings BS 8110thanigai veluNo ratings yet

- Grid BeamDocument3 pagesGrid Beamfarzi accoNo ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Rebar CalculatorDocument11 pagesRebar CalculatorMahindaNo ratings yet

- RC Footing Design Inaccordance With BS 8110Document1 pageRC Footing Design Inaccordance With BS 8110saman2580No ratings yet

- Built Up Section Design SheetDocument12 pagesBuilt Up Section Design SheetBikal BastakotiNo ratings yet

- Ribbed SlabsDocument10 pagesRibbed SlabsAlemayehu DargeNo ratings yet

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- RDSODocument8 pagesRDSOVikasNo ratings yet

- Design Data: Design of Floor Slab ContinousDocument12 pagesDesign Data: Design of Floor Slab ContinousMohit VermaNo ratings yet

- PSC Girder-25m R0Document148 pagesPSC Girder-25m R0infra120100% (1)

- N - Channel 600V - 0.7 - 9A To-220/To220Fp Powermesh Mosfet: Stp9Nb60 Stp9Nb60FpDocument10 pagesN - Channel 600V - 0.7 - 9A To-220/To220Fp Powermesh Mosfet: Stp9Nb60 Stp9Nb60FprauloroNo ratings yet

- Calc. Fillet Weld Transverse Load-Jacket ClosureDocument6 pagesCalc. Fillet Weld Transverse Load-Jacket ClosureAsep MulyadiNo ratings yet

- 2017 Series: Features ApplicationsDocument4 pages2017 Series: Features ApplicationsCarlos MoralesNo ratings yet

- Design of Diaphragm Word FileDocument3 pagesDesign of Diaphragm Word Fileparas rahangdaleNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Abrasion Resistance Test & ASTM D968Document5 pagesAbrasion Resistance Test & ASTM D968ManukantShrotriyaNo ratings yet

- Dywidag Post Tensioning Catalogue 5Document1 pageDywidag Post Tensioning Catalogue 5PrateekNo ratings yet

- DSI-DYWIDAG Bonded PT Using Strands Eu 01 1Document1 pageDSI-DYWIDAG Bonded PT Using Strands Eu 01 1PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 8Document1 pageDywidag Post Tensioning Catalogue 8PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 7Document1 pageDywidag Post Tensioning Catalogue 7PrateekNo ratings yet

- Din ISO 1461Document24 pagesDin ISO 1461Prateek100% (3)

- Dywidag Post Tensioning Catalogue 1Document1 pageDywidag Post Tensioning Catalogue 1PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 3 PDFDocument1 pageDywidag Post Tensioning Catalogue 3 PDFPrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 2Document1 pageDywidag Post Tensioning Catalogue 2PrateekNo ratings yet

- BS en Iso 15630-3-2010Document38 pagesBS en Iso 15630-3-2010Prateek50% (2)

- Catalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 8Document1 pageCatalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 8PrateekNo ratings yet

- Catalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 10Document1 pageCatalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 10PrateekNo ratings yet

- BS en Iso 15630-3-2010 38 PDFDocument1 pageBS en Iso 15630-3-2010 38 PDFPrateekNo ratings yet

- Catalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 11Document1 pageCatalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 11PrateekNo ratings yet

- Catalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 10Document1 pageCatalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 10PrateekNo ratings yet

- Catalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 7Document1 pageCatalogue DSI DYWIDAG Multistrand Stay Cable Systems ENG 7PrateekNo ratings yet

- Significant Changes in ACI 318-19Document72 pagesSignificant Changes in ACI 318-19Dana PomaresNo ratings yet

- Chapter 5-Traffic Loading & VolumeDocument19 pagesChapter 5-Traffic Loading & VolumenatiNo ratings yet

- Introduction To Seismic Analysis of Irregular BridgesDocument22 pagesIntroduction To Seismic Analysis of Irregular BridgeslawanNo ratings yet

- PT Slab DesignDocument18 pagesPT Slab DesignwelwelNo ratings yet

- BS en 1998-2 BridgesDocument33 pagesBS en 1998-2 BridgesVlog NVC100% (1)

- Drill String FailureDocument44 pagesDrill String FailureUsama Bin Sabir88% (8)

- Low Cycle Fatigue Life Prediction of 316 L (N) Stainless Steel Based On CyclicDocument7 pagesLow Cycle Fatigue Life Prediction of 316 L (N) Stainless Steel Based On CyclicidrissNo ratings yet

- Dynamic Design For AnchorsDocument44 pagesDynamic Design For AnchorshoustonhimselfNo ratings yet

- V - Theory of Compressive Stress in Aluminum of ACSRDocument12 pagesV - Theory of Compressive Stress in Aluminum of ACSRgvsbabu63No ratings yet

- Strut and Tie MethodDocument6 pagesStrut and Tie MethodJohn Richard NelsonNo ratings yet

- Design of Isolated Square Footing: 2-Storey Residential BLDG.: Poblacion Initao, Mis. orDocument35 pagesDesign of Isolated Square Footing: 2-Storey Residential BLDG.: Poblacion Initao, Mis. orJoseph Cloyd L. LamberteNo ratings yet

- Plate 6Document3 pagesPlate 6XDXDXDNo ratings yet

- Experimental Investigation of Composite Ultra-High-Performance Fiber-Reinforced Concrete and Conventional Concrete MembersDocument9 pagesExperimental Investigation of Composite Ultra-High-Performance Fiber-Reinforced Concrete and Conventional Concrete MemberszainabNo ratings yet

- Concrete Centre Scheme Manual To EC2 PDFDocument140 pagesConcrete Centre Scheme Manual To EC2 PDFDeRudyNo ratings yet

- Damage and Fracture in GeomaterialsDocument85 pagesDamage and Fracture in GeomaterialsYongliang LiuNo ratings yet

- 1-3 Simple Stresses 1-3-1 Axial StressDocument32 pages1-3 Simple Stresses 1-3-1 Axial StressHazim KhalilNo ratings yet

- Sample Size CalculationDocument101 pagesSample Size CalculationFaNo ratings yet

- Chapter 6 - Fatigue Failure Theories - Part 1Document12 pagesChapter 6 - Fatigue Failure Theories - Part 1Divyanshu KumarNo ratings yet

- 2 2axial LoadingDocument43 pages2 2axial LoadingshohaimNo ratings yet

- Búsqueda de Información - Michael Jesus Camargo MezaDocument2 pagesBúsqueda de Información - Michael Jesus Camargo MezaMichael Jesus Camargo MezaNo ratings yet

- Bangcola, Yusoph Salahaddin Pat A. Materials Testing 1. Tensile TestDocument2 pagesBangcola, Yusoph Salahaddin Pat A. Materials Testing 1. Tensile TestIvandelist XNo ratings yet

- LectureNote (Practical Analyses of Local Earthquakes)Document58 pagesLectureNote (Practical Analyses of Local Earthquakes)Muhammad Irpan KusumaNo ratings yet

- Lifting Lug Stress AnalysisDocument10 pagesLifting Lug Stress AnalysisChaitanya Sai TNo ratings yet

- Basic Design Value AISCDocument4 pagesBasic Design Value AISCmrajansubramanian100% (2)

- Shear Strength of SoilDocument5 pagesShear Strength of SoilDupio German IINo ratings yet

- Nist Ir 8005 PDFDocument17 pagesNist Ir 8005 PDFRaj RajeshNo ratings yet

- Example 3.2 - Continuous Beam-Updated 010812Document15 pagesExample 3.2 - Continuous Beam-Updated 010812Muhammad Farhan Gul100% (3)

- ABV - Brochure - Colour New (2016) PDFDocument28 pagesABV - Brochure - Colour New (2016) PDFSewGuanNo ratings yet

- 123 CCM 191 197Document6 pages123 CCM 191 197Pablo Cesar TrejoNo ratings yet

- Gusset Plate Connection To Round HSS Tension MembersDocument7 pagesGusset Plate Connection To Round HSS Tension Membersglav1309No ratings yet