Professional Documents

Culture Documents

QW 483

Uploaded by

delta lab sangliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QW 483

Uploaded by

delta lab sangliCopyright:

Available Formats

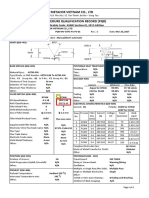

QW-483 SUGGESTED FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR)

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)

Record of the Actual Conditions Used to Weld Test Coupon

Company Name

Procedure Qualification Record No. Date

WPS No.

Welding Process (es)

Types (Manual, Automatic, Semi-auto) Semi-auto

JOINTS (QW-402)

Groove Design of Test Coupon (sketch, figure or reference)

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used.)

BASE METALS (QW-403) POST WELD HEAT TREATMENT (QW-407)

Material Specification Temperature

Type or Grade or UNS Number Time

P No. Group No. to P No. Group No. Other

Thickness of Test Coupon

Diameter of Test Coupon

Maximum Pass Thickness

Other GAS (QW-408)

Percent Composition

FILLER METALS (QW-404) Gas (es) (Mixture) Flow Rate

Layer (combination welds) 1 2 3 Shielding

SFA Specification Trailing

AWS Classification Backing

Filler Metal F No. Other

Weld Metal Analysis A No.

Size of Filler Metal

Filer Metal Product Form ELECTRICAL CHARACTERISTICS (QW-409)

Supplemental Filler Metal Current

Electrode Flux Classification Polarity

Flux Type Amps Volts

Flux Trade Name Tungsten Electrode Size

Weld Metal Thickness Transfer Mode for GMAW (FCAW)

Other Other

POSITION (QW-405)

Position of Groove

Weld Progression (Uphill, Downhill) TECHNIQUE (QW-410)

Other Travel Speed

String or Weave Bead

Oscillation

PREHEAT (QW-406) Multipass or Singles Pass (per side)

Preheat Temperature Single or Multiple Electrodes

Interpass Temperature Other

Other

QW-483 (Back)

PQR No.

Tensile Test (QW-150)

Type of

Specimen Ultimate Ultimate

Width Thickness Area Failure &

No. Total Load Unit Stress

Location

Guided Bend Tests (QW-160)

Type and Figure No. Result

Toughness Tests (QW-170)

Specimen Notch Specimen Test

Impact Values Drop Weight Break

Number Location Size Temperature

Ft-lb or J % Shear Mils (in.) or mm (Yes/No)

Comments

Fillet Weld Test (QW-180)

Result- Satisfactory: Yes No Penetration into Parent Metal: Yes No

Macro - Results

Other Tests

Type of Test

Deposit Analysis

Other

Welders Name Clock No. Stamp No.

Tests Conducted by Laboratory Test Number

We certify that statements made in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

Requirements of Section IX of the ASME Boiler and Pressure Vessel Code

Manufacturer or Contractor

Date Certified By

You might also like

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- WPS-Nozzle With Reinforcement Pad (CS-CS) .Document1 pageWPS-Nozzle With Reinforcement Pad (CS-CS) .suria qaqcNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroNo ratings yet

- WPSDocument42 pagesWPSjoehodoh100% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Document3 pagesAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzHNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad RizkiNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- QW-403.2 InterpretationDocument1 pageQW-403.2 Interpretationlaz_kNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Qualified Welder List Valid Until - 03-12-2019Document2 pagesQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- WPS Updated PDFDocument2 pagesWPS Updated PDFRaja Muaz Ahmad KhanNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- NoticeDocument1 pageNoticeAnirban Sen SharmaNo ratings yet

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Procedure Qualification RecordDocument2 pagesProcedure Qualification RecordDan ClarkeNo ratings yet

- Suggested Format PQRDocument2 pagesSuggested Format PQRAngel RebolloNo ratings yet

- SC PTSS PQRDocument3 pagesSC PTSS PQRprayogaNo ratings yet

- Fillet Inspection SheetDocument2 pagesFillet Inspection SheetShankey JAlanNo ratings yet

- SAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Document2 pagesSAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Lovedeep SinghNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFEmma DNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFEmma DNo ratings yet

- Measuring Fast-Neutron Reaction Rates by Radioactivation of IronDocument4 pagesMeasuring Fast-Neutron Reaction Rates by Radioactivation of Irondelta lab sangliNo ratings yet

- Designation: E 264 - 92 (Reapproved 1996)Document5 pagesDesignation: E 264 - 92 (Reapproved 1996)delta lab sangliNo ratings yet

- Measuring Neutron Fluence and Average Energy From H He Neutron Generators by Radioactivation TechniquesDocument12 pagesMeasuring Neutron Fluence and Average Energy From H He Neutron Generators by Radioactivation Techniquesdelta lab sangliNo ratings yet

- D 5662 - 99 - Rdu2Document19 pagesD 5662 - 99 - Rdu2delta lab sangliNo ratings yet

- D 5762 - 98 - Rdu3njitoDocument6 pagesD 5762 - 98 - Rdu3njitodelta lab sangliNo ratings yet

- Detector Calibration and Analysis of Radionuclides: Standard Test Methods ForDocument21 pagesDetector Calibration and Analysis of Radionuclides: Standard Test Methods Fordelta lab sangliNo ratings yet

- Evaluation of Corrosiveness of Diesel Engine Oil at 121°C: Standard Test Method ForDocument17 pagesEvaluation of Corrosiveness of Diesel Engine Oil at 121°C: Standard Test Method Fordelta lab sangliNo ratings yet

- Specific Gravity of Water and Brine: Standard Test Methods ForDocument6 pagesSpecific Gravity of Water and Brine: Standard Test Methods Fordelta lab sangliNo ratings yet

- D 2331 - 80 R99 - RdizmzetodbsotkDocument5 pagesD 2331 - 80 R99 - Rdizmzetodbsotkdelta lab sangliNo ratings yet

- Nickel in Water: Standard Test Methods ForDocument14 pagesNickel in Water: Standard Test Methods Fordelta lab sangliNo ratings yet

- Residual Chlorine in Water: Standard Test Method ForDocument6 pagesResidual Chlorine in Water: Standard Test Method Fordelta lab sangliNo ratings yet

- Electrical Conductivity and Resistivity of Water: Standard Test Methods ForDocument7 pagesElectrical Conductivity and Resistivity of Water: Standard Test Methods Fordelta lab sangliNo ratings yet

- D 1291 - 89 R94 - RdeyotetukveDocument5 pagesD 1291 - 89 R94 - Rdeyotetukvedelta lab sangliNo ratings yet

- D 2513 - 03 - Rdi1mtmtmdnc PDFDocument24 pagesD 2513 - 03 - Rdi1mtmtmdnc PDFdelta lab sangliNo ratings yet

- E 1405 - 98 R99 - Rte0mdutotDocument3 pagesE 1405 - 98 R99 - Rte0mdutotdelta lab sangliNo ratings yet

- E 1354 - 02 - Rtezntqtmdm - PDFDocument18 pagesE 1354 - 02 - Rtezntqtmdm - PDFdelta lab sangliNo ratings yet

- Isocyanate Groups in Urethane Materials or Prepolymers: Standard Test Method ForDocument2 pagesIsocyanate Groups in Urethane Materials or Prepolymers: Standard Test Method Fordelta lab sangliNo ratings yet

- D 2598 - 96 R01 - Rdi1otgtotzDocument2 pagesD 2598 - 96 R01 - Rdi1otgtotzdelta lab sangliNo ratings yet

- A 533 - A 533M - 93 R99 Qtuzmy9bntmztqDocument4 pagesA 533 - A 533M - 93 R99 Qtuzmy9bntmztqdelta lab sangliNo ratings yet

- A 808 - A 808M - 00 Qtgwoc9boda4ts1sruqDocument3 pagesA 808 - A 808M - 00 Qtgwoc9boda4ts1sruqdelta lab sangliNo ratings yet

- A 421 - A 421M - 02 Qtqyms9bndixtqDocument4 pagesA 421 - A 421M - 02 Qtqyms9bndixtqdelta lab sangliNo ratings yet

- A 704 - A 704M - 96 Qtcwnc9bnza0ts1sruqDocument4 pagesA 704 - A 704M - 96 Qtcwnc9bnza0ts1sruqdelta lab sangliNo ratings yet

- A 514 - A514m - 00 Qtuxnc9bnte0ts1sruqDocument4 pagesA 514 - A514m - 00 Qtuxnc9bnte0ts1sruqdelta lab sangliNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Asme Sec Ix 2019 380Document1 pageAsme Sec Ix 2019 380Balkishan DyavanapellyNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Rke PQR 01Document2 pagesRke PQR 01Satish KeskarNo ratings yet

- Asme Ix PT QB Article Xi QB 100 Brazing General RequirementsDocument5 pagesAsme Ix PT QB Article Xi QB 100 Brazing General RequirementsGabriel Giampietro de AndradeNo ratings yet

- Nasa STD 5006aDocument33 pagesNasa STD 5006atoadstooll100% (1)

- Use of Welding in Bridges and Structures Subject To Dynamic Loading - Code of Practice (Document18 pagesUse of Welding in Bridges and Structures Subject To Dynamic Loading - Code of Practice (KrunalNo ratings yet

- Corrosion Resistant AlloysDocument40 pagesCorrosion Resistant Alloysmiker100No ratings yet

- Determining The Cost of WeldingDocument7 pagesDetermining The Cost of WeldingSriram VjNo ratings yet

- Ice Plant Test RigDocument58 pagesIce Plant Test Rigjuned shaikhNo ratings yet

- Welding Inspection PDFDocument15 pagesWelding Inspection PDFzsmithNo ratings yet

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Tube To Tubesheet WeldingDocument8 pagesTube To Tubesheet WeldingManjadi Maverick100% (1)

- WPS - 003 BDocument7 pagesWPS - 003 BMAT-LIONNo ratings yet

- Welding Lecture1 2Document34 pagesWelding Lecture1 2Dr Abhijeet GangulyNo ratings yet

- Aws A5.1 (1991) PDFDocument57 pagesAws A5.1 (1991) PDFRenier KoenNo ratings yet

- Welding Procedure Specification - TemplateDocument2 pagesWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- D1.8 Seismic Supplement Welding ManualDocument48 pagesD1.8 Seismic Supplement Welding Manualmariovalenti100% (1)

- Internship Report CRDocument22 pagesInternship Report CRRockyXYZNo ratings yet

- ESDEP ConnectionsDocument268 pagesESDEP ConnectionsrabeeabuahmadNo ratings yet

- Is - 2825.1969Document286 pagesIs - 2825.1969karthickmectrNo ratings yet

- PQRDocument2 pagesPQRHoangNo ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- Fcaw SSDocument5 pagesFcaw SSAhmad ShaheenNo ratings yet

- BMP - Other Welding ProcessesDocument76 pagesBMP - Other Welding Processessujay nayakNo ratings yet

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1Document14 pagesWelding Procedure Specification Register (Structural Steel) : AWS D1.1murshid badshah100% (2)