Professional Documents

Culture Documents

Ford 7.3 Diesel

Uploaded by

Jose Antonio Tano CisnerosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ford 7.3 Diesel

Uploaded by

Jose Antonio Tano CisnerosCopyright:

Available Formats

10-21 7.

3L Engine 12/1/06 9:19 AM Page 10

by Roy Berndt,

Contributing Editor

rberndt@engine-builder.com

W ith our present situation of

gasoline prices hovering at $3

per gallon; a four wheel drive

truck, with a large displacement gasoline

engine becomes a very expensive vehicle to

average John Q. Public American. There

are over 3.5 million of these engines out

there in vehicles ranging from contractors

pick-up trucks to airport vans and school

buses that transport your children. All of

operate. these vehicles are in the target market that

One solution to that problem is the diesel typically will purchase one or more

engine with more torque, horsepower and reman/rebuilt engines This is great news

better fuel economy. This applies not only for the reman/builder industry.

to heavy-duty applications but small dis- The early 6.9L and 7.3L engines were

placement turbocharged, intercooled indirect ignition (IDI) engines with cylinder

diesels as well. The diesel engine will play heads that used pre-combustion chambers.

just as important part of the future of the Then later in 1994 the 7.3L with direct

automotive industry as the Hybrid. injection (DI) and turbocharging carried

If you have any doubt about the per- the label Powerstroke that everyone is

formance and reliability factors of modern familiar with.

diesel engines, just look at the first and The proliferation of the IDI engines is

third place finishers of the 2006 24 hour pretty simple to understand but things get

race at Le Mans. They were Audi diesel real interesting when you move into the DI

powered racing vehicles. engines. Here, the front covers also

For the first time ever diesel powered become key in the mix of all the changes.

vehicles accounted for more than 50 per- So lets take a look at all of the compo-

cent of the vehicles registered in the nents year by year and give you the insights

European market. and images needed to understand all of

The International 6.9L and later the them. One thing critical to identification of

7.3L diesel engines, found largely in Ford diesels in general is remembering that seri-

pick-up trucks of the 80s and through the al number breaks rather than the year of

millennium, are considered by many as the production are most important. If you

first diesel engine to break the barrier of keep that in mind you should never make a

being widely accepted and embraced by the mistake as to when to use what.

10 FORD TECH GUIDE 11 2006 www.engine-builder.com

10-21 7.3L Engine 12/1/06 9:19 AM Page 12

Rebuilding The Ford 7.3L Powerstroke Engine

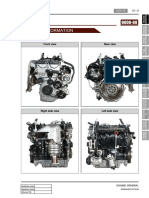

CYLINDER BLOCKS

6.9L IDI 1983-1987

Starting at the beginning, the 6.9L IDI engine

was introduced in 1983 with the first series block

(c/n 1805440C1). This is considered by most as

not a viable block casting for rebuilding. It is

easily recognized by the lightweight or narrow

gusseting across the upper area in the front of the

block (Figure 1). Figure 1 This is a 6.9L first design casting with a nar-

In 1984 the second series block (c/n row gusset across the top of the block. Unfortunately, its

1807996C1) was introduced. With improved not considered a viable casting for rebuilding by most.

structural integrity, this is considered the block

to use for all applications of 6.9L engines. To rap-

idly identify it, look at the same area in the front

of the block (Figure 2) with the wide gusseting.

The 6.9L was never turbocharged, therefore you

will only require one long block part number for

all 6.9L applications.

Figure 3 and Figure 4 The coolant port on the corner

of the cylinder head deck is triangular on the 6.9L

engine (left). The coolant port on the corner of the the

cylinder head deck is circular on the 7.3L engine (right).

deck. The 6.9L has triangular coolant ports

(Figure 3), while the 7.3L coolant ports are

round (Figure 4).

7.3L IDIT 1992-1994

Block c/n 10809000C3 is the turbo block and the

Figure 2 The second design 6.9L casting has a wide end of the IDI chapter. These engines carried

gusset across the top front of the block. This casting is serial numbers 1,116,331 to the end of produc-

considered the only viable casting for rebuilding by tion for the family. Note that the casting number

most. is identical to the non-turbo block other than the

C3 at the end. Make no mistake: this is a differ-

7.3L IDI 1988-1994 ent and stronger block which you may certainly

Block c/n 10809000C1 was used for the entire use for IDI applications but do not attempt to do

7.3L IDI years of production. The serial numbers it the other way around. You will regret it.

for naturally aspirated applications are 500,079 One of the key differences is that the main

through 1,116,330. webs on the turbo blocks are approximately .100

This block was prone to cavitation damage on thicker. The visual aid for this block can be

the exterior of the cylinder walls on the left bank found at the rear of the engine. The turbo block

thrust/valley side of the cylinders. For more has a 1/4 pipe-threaded hole for the oil feed for

details about cavitation see Core Corner: turbo applications (Figure 5). This same port on

Fighting Truth Decay About Cavitation (Engine the non-turbo block is just 1/8 and is used for

Builder, January 2006, page 38). the oil pressure gauge. There are non-turbo

These walls were recorded as moving as much blocks out in the field that have been drilled and

as .004. Since this block looks nearly identical tapped to 1/4 so it is always a good idea to veri-

to the 6.9L, the quick visual for identification are fy serial and casting numbers.

the coolant ports at the corners of the cylinder

12 FORD TECH GUIDE 11 2006 www.engine-builder.com

10-21 7.3L Engine 12/1/06 9:19 AM Page 13

Rebuilding The Ford 7.3L Powerstroke Engine

1/4 Pipe Thread

Turbo Block Only

Figure 6 First series 7.3L DIT blocks had a large

opening at the upper valley area of the cylinder head

Non-Turbo 1/8 deck.

Figure 5 The 7.3L IDIT block is stronger, with a 1/4

pipe thread for the turbo oil feed. The non-turbocharged

block has a 1/8 hole for the oil pressure gauge.

7.3L DIT 1994-2004

Figure 7 The second series 7.3L DIT block casting has

The first series block for the DIT Powerstroke solid casting support areas between each cylinder bore

(c/n 1818270C2) runs from serial number 501 as well as additional crank counterweight clearance in

through 661,973 and fits applications from 1994 the lower block.

to mid-1998. You can see why the serial number

breaks are important now. All engines from this

point forward are turbocharged and had direct

injection. The blocks are noticeably different

than the IDI version so there is no confusion of

identification.

There are, however, two different DI blocks.

The first series design is readily identified by Figure 8 All IDI and IDIT engines in both 6.9L and 7.3L

the lack of solid webbing in the valley up to the sizes use the same crankshaft (c/n 1085420C1).

deck of the block (Figure 6). So if youre look-

ing down on the deck toward the lifter bores it is 9-hole rear flange and the thrust flange located

one big opening. on No. 3 main journal (Figure 8).

The second series block (c/n 1825849C2) is

used from mid-1998-2004 with serial number 7.3L DIT 1994-1998.5

661,974 through 2,030,402. This block received The direct injection engines get a little more

some structural improvements such as addition- interesting. Riddle me this: when are three dif-

al crank counterweight clearance in the lower ferent crankshafts actually two? When they are

crankcase. The visual identifiers are the full used in the 7.3L DIT engine.

casting separations between each cylinder in the The first two crankshafts are considered the

lifter valley to the block deck (Figure 7). same product. The only difference between them

is the size of the hole bored into the rod throws.

One (c/n 1818200C1) has 1-1/8 bore balance

CRANKSHAFTS holes in the rod throws and the other (c/n

1818200C3) has 1 bore balance holes drilled in

6.9L IDI, 7.3L IDI and them. The diameter of the balance hole was

7.3L IDIT 1983-1994 changed for better strength and reliability.

Despite this difference, these cranks are consid-

Crankshafts for the indirect injection engines ered the same and are fully interchangeable

used from 1983-1994 are easy to identify (Figure 9). Use either of these cranks in serial

because they are all the same. They all used a number engines 501 through 661,973.

forged steel crankshaft (c/n 1805420C1) with a

www.engine-builder.com 11 2006 FORD TECH GUIDE 13

10-21 7.3L Engine 12/1/06 9:19 AM Page 14

Rebuilding The Ford 7.3L Powerstroke Engine

7.3L DIT 1998.5-2004

The third crank (which is actu-

ally the second design) has no

balance hole in the rod throw at

all and has a slightly different

configured counterweight. This

crank can only be used in the

later block casting (c/n

1825849C1) which has the

clearance (Figure 10). This

crank is used in serial number

661,974 through 2,030,402

May be 1-1/8 or 1 Diameter

CAMSHAFTS

Figure 9 The 7.3L DIT first series crank may have either a 1-1/8 bore hole

(the first design) or a 1 diameter hole (the second design). However, both 7.3L DIT 1994-mid-1998

are interchangeable.

Ford Standard Duty and

International

The stamping number on the

back of the camshaft is

181062C1 and was used in

both Ford and International

applications from serial num-

ber 501 through 661,973. It is

the upper most cam shown in

Figure 11.

7.3L DIT 1998.5-2004

Figure 10 The third design second series crankshaft for the 7.3L DIT Ford Standard Duty

engines has no balance hole in the rod throw area at all. The standard duty cam has

stamping number 1825912C1

Figure 11 Three camshafts were used in the 7.3L DIT engine application. The top two cams are the standard duty

camshafts, while the bottom one is for heavy duty Ford and Internationals from s/n 661,0974-2,030,402. Note the

absence of the pump lobe.

14 FORD TECH GUIDE 11 2006 www.engine-builder.com

10-21 7.3L Engine 12/1/06 9:19 AM Page 15

Rebuilding The Ford 7.3L Powerstroke Engine

Casting #

EDS G3# Front View Rear View Flange 1 Flange 2 Flange 3

Year/s Used

2

3

1815915C1

FIN 7301

1994-1995

1 1 2 3

1824378C1

FIN 7302

1996

1823536C1

FIN 7303

1997-1998.5

1831654C2

FIN 7304

1998.5-2004

Chart 1 7.3L Ford/International direct injection engine casting identification chart.

Casting #

EDS G3# Front View Rear View Flange 1 Flange 2 Flange 3

Year/s Used

2

3

1820508C1

FIN 7305

1994-1995

1 1 2 3

1824379C1

FIN 7306

1996

1825378C1

FIN 7307

1997-1998.5

1828179C2

FIN 7308

1998.5-2004

Chart 2 7.3L Ford/International indirect injection engine casting identification chart.

www.engine-builder.com 11 2006 FORD TECH GUIDE 15

10-21 7.3L Engine 12/1/06 9:19 AM Page 18

Rebuilding The Ford 7.3L Powerstroke Engine

7.3L DIT 1998.5-2004

and was used in engines with serial number

661,974 through 2,030,402. It no longer has a Heavy Duty Ford and International

fuel rail pressure pump eccentric. The middle camshaft in Figure 11 is the cam

Ford Heavy Duty (F 650-750) and used for Ford F650-750 applications and

International went different ways here and con- International trucks. This camshaft continued to

tinued to use the mechanical pump. Ford went to maintain the mechanical rail pressure pump and

a frame mounted fuel conditioning module that carries the stamping number of 1826779C1.

does everything but put perfume in the cab. They I found no posted serial numbers for these

went to an electric pressure pump; it is the bot- engines but since their applications are unique it

tom camshaft shown in Figure 11. really makes no difference.

CONNECTING RODS

6.9L IDI, 7.3L IDI 1983-1994

The same connecting rod (c/n 1816619C1) was

Non-Turbo used for all the 6.9L and 7.3L IDI non-turbo

apps (Figure 12).

Turbo PM-Crack 1998.5-04

Forged 1994-98.5

Figure 12 The rod on top was used for all 6.9L and

7.3L non-turbo IDI applications from 1983-1994. The

rod on the bottom was used in all turbo IDIT 7.3L

engines from 1993-1994. Note the two boss areas for

visual identification. The turbo also has a larger piston Figure 14 The upper rod is a powder metal cracked

pin. rod for use with the late 7.3L DIT block and crank.

The lower rod is forged and used with both early

cranks and the early block.

7.3L 1992 -1994 IDIT

The 7.3L IDIT turbo connecting rod (c/n

Non-Turbo Turbo 1805615C1) has two bosses on the side of the rod

and has a larger piston pin than the non-turbo

(Figures 12 and 13).

7.3L DIT 1994-1998.5

The first design is a forged connecting rod (c/n

1812003C2) that would be used with either of the

crankshafts that have balance holes in the rod

Figure 13 The IDIT turbo piston on the right has a throws regardless of the size (Figure 14). It is

considerably larger piston pin than the naturally aspi- easily differentiated from the second design

rated one on the left. which is made of powder metal.

Circle 36 for more information

18 FORD TECH GUIDE 11 2006 www.engine-builder.com

10-21 7.3L Engine 12/1/06 9:19 AM Page 19

Rebuilding The Ford 7.3L Powerstroke Engine

7.3L DIT 1998.5-2004

The second design is a powder metal connecting

rod with a cracked parting line for the rod cap

and bolts. It has a tapered piston pin, and the

casting number is printed in ink so unless it is

new out of the box you wont know the number

(Figure 14 page 18).

CYLINDER HEADS

Figure 15 One of the second design 6.9L IDI head

castings has the as-cast numbers ground off and the

6.9L IDI 1983

new one stamped in. This cylinder head (c/n 1805296C1 and

1809199C1) was used for only one year and is

very prone to cracking. It is considered by most

to be not viable for rebuilding.

6.9L IDI 1984-1987

The second design is identical to the first in

appearance but is a bit heavier and a more stable

casting. This head (c/n 1805855C1 and

1809215C91) is considered the only heads

viable for rebuilding.

The 6.9L engines use 7/16 head bolts. The

215 heads have the as cast number ground off

and the 215 number stamped in (Figure 15).

7.3L IDI 1988 1994,

IDIT 1993-1994

All 7.3L heads have head bolt holes for 1/2 head

bolts and carry casting number 1809030C3. This

casting comes in two flavors: one that has soft

Figure 16 7.3L IDI and IDIT cylinder head castings

plugs on the intake side of the head and one that

may have two different shaped coolant ports. One is cir- just has a port.

cular and uses a soft plug (top) and one is oblong without Both get covered by the gasket so it really

a plug (bottom). Both get covered by the gasket and both does not make any difference which is used. Yet

have c/n 1809030C3. They are fully interchangeable. if a technician with a sharp eye sees it you might

Figure 17 This is the 10-bolt intake manifold cylinder head from the 7.3L (s/n 896,813 to end). Earlier 8-bolt cylin-

der heads did not have the two bolt bosses circled above.

www.engine-builder.com 11 2006 FORD TECH GUIDE 19

10-21 7.3L Engine 12/1/06 9:20 AM Page 20

Rebuilding The Ford 7.3L Powerstroke Engine

Figure 18 At right (reading left to

right) a comparison of the four differ-

ent pistons used from the start of pro-

duction to the end of production.

From left: 6.9L, IDI non-turbo; 7.3L

IDI non-turbo; 7.3L IDIT; and 7.3

DIT turbo.

want to have the explanation industry changes, one thing will part of the process.

(Figure 16). always remain the same. Today the front cover has

Identifying what type of engine become such an integral part of

7.3L DIT 1994-1995 on which youre working will be application identification that it

This was the first series direct an important and challenging has become as important as any

injection cylinder head (c/n

1821727C92). The identifier

to this cylinder head is the 8

bolts (Figure 17) for the

intake manifold. Use this head

from serial number 501

through 375,548.

7.3 DIT 1995-2004

This is the second series direct

injection head (c/n 11825113C1)

and is easily identified by the 10

bolts (Figure 17) for the intake

manifold. It was used from serial

number 375,549 through

2,030,402. A 10 bolt cylinder

head may be converted into an

eight bolt by filling the two bolt Figure 19 Franklin Powers cell production means everyone can do every-

holes circled in Figure 17. The one elses job.

heads are identical other than

the bolts.

PISTONS

There were four distinctly differ-

ent pistons used for the various

iterations of the 6.9L/7.3L

engine. Each is unique and all

are easily identifiable by their

appearance. See Figure 18 for

the identification of each.

FRONT

COVERS

No matter how much the engine

Figure 20 Technological advancements in remanufacturing now border on

remanufacturing and building that of the OEM.

20 FORD TECH GUIDE 11 2006 www.engine-builder.com

10-21 7.3L Engine 12/1/06 9:20 AM Page 21

Rebuilding The Ford 7.3L Powerstroke Engine

of the major component cast- A special thanks must be center. Franklin gradually

ings. Thats extremely impor- extended to Franklin Power evolved from producing gaso-

tant to remember when working Products in Franklin, IN, an line engines to being one of the

on the Powerstroke engine. As authorized OE reman for these leading remanufacturers of mid-

youll see in the charts on page engines. Franklin has just range diesel engines and fuel

15, knowing which cover goes moved into a new 300,000 sq. systems, with over 500 employ-

with which application can save ft. facility that is steeped in tra- ees. In 1995 Franklin became a

you a lot of headaches. Not dition but also contains some of part of Remy International,

knowing can cost you time and the most advanced technology which has a strong presence in

money. available in remanufacturing. the OE market.

The company was originally The company recently

CREDITS AND founded by International moved away from line produc-

SPECIAL THANKS Harvester as a remanufacturing tion to cell remanufacturing, a

move that is cutting edge in

this ever-changing industry.

Over 200,000 engines have

been recycled through

Franklin (Figures 19-22).

For additional detailed

information about the 6.9L

and 7.3L engines and many

more images visit www.

engine-builder.com. Or visit

EngineDataSource.com and

sign up for a free 30-day trial

period. Contact EDS at

info@EngineDataSource.com

for more information. EB

Figure 21 All Powerstroke engines built at Franklin are dyno tested and all

the information is housed in a database in case any information on any engine About the Author

is needed in the future. Roy Berndt has been in the

Automotive Rebuilding and

Remanufac-

turing industry

for over 30

years. He is an

ASE Master

Machinist and

co-author of

SAE docu-

ments and Standards. He is the

EDS Project Director for the

Production Engine Reman-ufac-

turers Association (PERA), and

monthly columnist of Core

Corner for Engine Builder maga-

zine. Contact him at

royberndt@pera.org.

Figure 22 When it needs to be sealed right every time, a robot is used to

apply the exact amount of sealer.

www.engine-builder.com 11 2006 FORD TECH GUIDE 21

You might also like

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)

- 7.3 DIT Powerstroke Part 1 PDFDocument6 pages7.3 DIT Powerstroke Part 1 PDFFEF777100% (2)

- Power Stroke Engine: Technician High Pressure Pump Guide For The 7.3Document8 pagesPower Stroke Engine: Technician High Pressure Pump Guide For The 7.3Abysmal67% (3)

- How to Build Max-Performance Chevy LT1/LT4 EnginesFrom EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesRating: 3 out of 5 stars3/5 (1)

- 2000 7.3L Diesel SupplementDocument39 pages2000 7.3L Diesel SupplementInventour100% (1)

- OEM Ford 7.3 Litre Diesel OBD II DiagnosticsDocument26 pagesOEM Ford 7.3 Litre Diesel OBD II DiagnosticsTigxMig75% (8)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Ford 7.3L 94-03 DiagnosticsDocument9 pagesFord 7.3L 94-03 DiagnosticsColoray Borthwick75% (8)

- Oldsmobile V-8 Engines 1964–1990: How to Rebuild: How to RebuildFrom EverandOldsmobile V-8 Engines 1964–1990: How to Rebuild: How to RebuildRating: 2 out of 5 stars2/5 (1)

- IDI Fuel Injection ServiceingDocument9 pagesIDI Fuel Injection ServiceingPeter Stam100% (3)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Power Stroke Diesel NavistarDocument126 pagesPower Stroke Diesel NavistarAlex Salas87% (15)

- 1997 OBD 7.3 Diesel SYStem OperationDocument25 pages1997 OBD 7.3 Diesel SYStem Operationroachmech100% (6)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- Ford Diesel Diagnostics Oregon Fuel InjectionDocument1 pageFord Diesel Diagnostics Oregon Fuel InjectionWilliam Peele0% (1)

- Fuel Injection: Ford Powerstroke Diagnostics 1994-2003Document11 pagesFuel Injection: Ford Powerstroke Diagnostics 1994-2003Lojan Coronel José Humberto100% (1)

- Ford Y-Block Engines: How to Rebuild & ModifyFrom EverandFord Y-Block Engines: How to Rebuild & ModifyRating: 4.5 out of 5 stars4.5/5 (3)

- Ford 6.9 and 7.3 IDI Diesel Stall After Starting Troubleshooting HelpDocument2 pagesFord 6.9 and 7.3 IDI Diesel Stall After Starting Troubleshooting Helpcrawdoogie100% (1)

- How to Swap Ford Modular Engines into Mustangs, Torinos and MoreFrom EverandHow to Swap Ford Modular Engines into Mustangs, Torinos and MoreRating: 4 out of 5 stars4/5 (6)

- Diesel Sales Reference ManualDocument150 pagesDiesel Sales Reference Manualrabitosan83% (6)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Chevy 6.5 EFIDocument114 pagesChevy 6.5 EFIJerad Bixler100% (3)

- Building 4.6/5.4L Ford Horsepower on the DynoFrom EverandBuilding 4.6/5.4L Ford Horsepower on the DynoRating: 5 out of 5 stars5/5 (1)

- WWW - Incar.tw-1989 Ford F250 Diesel Repair Manual PDFDocument5 pagesWWW - Incar.tw-1989 Ford F250 Diesel Repair Manual PDFkenneth0% (3)

- 7.3L TurboDocument60 pages7.3L TurboIsmaelOrdoñez100% (2)

- 6.4L - Power Stroke EngineDocument16 pages6.4L - Power Stroke EngineRuben Michel100% (2)

- 6.0 Powerstroke Fuel Pressure Testing and Tips 1webDocument19 pages6.0 Powerstroke Fuel Pressure Testing and Tips 1webDavid Fuentes100% (6)

- 2000 Super Duty F-250, F-350, F-450, F-550 Owner GuideDocument256 pages2000 Super Duty F-250, F-350, F-450, F-550 Owner GuideMatthew Case100% (6)

- 7 3 Idi Repair ManualDocument2 pages7 3 Idi Repair ManualDeniGrams10% (31)

- 6.0L Power Stroke Tech Manual (2004 Update)Document80 pages6.0L Power Stroke Tech Manual (2004 Update)dustyboner96% (48)

- 73 Dit Power StrokeDocument78 pages73 Dit Power StrokeNic Price100% (1)

- DB2 Conv Guide For GM 6.5 Turbo DieselDocument29 pagesDB2 Conv Guide For GM 6.5 Turbo Dieselbolink65483% (6)

- 303-01c-I Engine - 6.0L Diesel 303-01c-IDocument13 pages303-01c-I Engine - 6.0L Diesel 303-01c-Iradius1188100% (1)

- Ford Axle Lube ChartDocument2 pagesFord Axle Lube Chartkernol20No ratings yet

- PCM Pinout - Ford Truck Enthusiasts ForumsDocument4 pagesPCM Pinout - Ford Truck Enthusiasts ForumsAdolfo Moscoso75% (4)

- Iinternational 7.6LDocument80 pagesIinternational 7.6LJehuty88No ratings yet

- Ford 6.7 11 15 DiagnosticDocument13 pagesFord 6.7 11 15 DiagnosticAlberto Gutierrez100% (2)

- 7.3L Powerstroke Powertrain SystemDocument4 pages7.3L Powerstroke Powertrain SystemFEF77757% (7)

- Intake Manifold - 5.4L: SECTION 303-01B: Engine - 4.6L and 5.4L 2001 F-150 Workshop Manual In-Vehicle RepairDocument12 pagesIntake Manifold - 5.4L: SECTION 303-01B: Engine - 4.6L and 5.4L 2001 F-150 Workshop Manual In-Vehicle RepairAlexander Avila SumoyaNo ratings yet

- ManualDocument20 pagesManualpepw67% (3)

- 2003 Ford 6.0 DITDocument106 pages2003 Ford 6.0 DITPhil B.95% (20)

- 6.0 Late 2004 Hardstart - Nostart - DiagnosticsDocument1 page6.0 Late 2004 Hardstart - Nostart - DiagnosticsvixentdNo ratings yet

- 1998 1999 F-Series Powertrain Control Emissions Diagnosis Powertraincontro017724mbpDocument509 pages1998 1999 F-Series Powertrain Control Emissions Diagnosis Powertraincontro017724mbpldmitch100% (3)

- 6L Power Stroke ManualDocument101 pages6L Power Stroke Manualstupidfingcar75% (4)

- 6.0l Ficm GuideDocument16 pages6.0l Ficm GuidePSDPlayer100% (10)

- Catalogo Ford PDFDocument44 pagesCatalogo Ford PDFEfren PalaciosNo ratings yet

- 2.4l EngineDocument237 pages2.4l EngineRene SanchezNo ratings yet

- Navi Star Powerstroke Diesel Engine PartsDocument35 pagesNavi Star Powerstroke Diesel Engine PartsJonathan Carlson100% (1)

- (TM) Ford Manual de Taller Ford Super Duty 2007 2008 en InglesDocument747 pages(TM) Ford Manual de Taller Ford Super Duty 2007 2008 en Inglesjuan carlos delgadoNo ratings yet

- 93 94 7.3 IDITurbochargedDieselEngineDocument72 pages93 94 7.3 IDITurbochargedDieselEngineBrian Kyser100% (3)

- Fuel System Dakota Dodge 1995Document94 pagesFuel System Dakota Dodge 1995Jorge MorenoNo ratings yet

- 6.0L Power Stroke SpecsDocument2 pages6.0L Power Stroke SpecszaidsantoyoNo ratings yet

- 4.2L EngineDocument28 pages4.2L Engineadnmb100% (6)

- S10 Service ManualDocument53 pagesS10 Service ManualDave M67% (3)

- Chevy Engine Casting NumbersDocument41 pagesChevy Engine Casting Numberswyofreeride100% (1)

- Superduty 6.0L Powerstroke Engine: Removal/Installation Service TipsDocument21 pagesSuperduty 6.0L Powerstroke Engine: Removal/Installation Service Tipsvixentd100% (1)

- Tsubaki Emerson Gearmotor HypoidDocument228 pagesTsubaki Emerson Gearmotor HypoidDillan Stwart Quintero ParraNo ratings yet

- Traulsen RDT - ADT Refrigerator-FreezerDocument4 pagesTraulsen RDT - ADT Refrigerator-Freezerwsfc-ebayNo ratings yet

- t6010 PDFDocument412 pagest6010 PDFPapy Plus100% (1)

- Portable Turmeric Boiling System: Project Review 2Document12 pagesPortable Turmeric Boiling System: Project Review 2Akash JaiswalNo ratings yet

- Robex 210LC 7 Manual de Partes PDFDocument1,312 pagesRobex 210LC 7 Manual de Partes PDFmohammed barghothiNo ratings yet

- Rotary Valve Functions BookletDocument17 pagesRotary Valve Functions Bookletamahmoud3No ratings yet

- Exam PaperDocument11 pagesExam PaperSi JampangNo ratings yet

- Nano Ic EngineDocument24 pagesNano Ic EngineUjjwal Kumar0% (1)

- 08 Plasticity 03 Yield CriteriaDocument21 pages08 Plasticity 03 Yield Criteria한종훈100% (1)

- Finite Element Simulation of Conventional and High Speed Machining of Ti6Al4V AlloyDocument9 pagesFinite Element Simulation of Conventional and High Speed Machining of Ti6Al4V AlloyArul KirubakaranNo ratings yet

- Flat Spiral SpringsDocument2 pagesFlat Spiral SpringsBharani DaranNo ratings yet

- (Ricardo, Ponce) 16-Essential Hydraulic Components - Maintenance R2Document27 pages(Ricardo, Ponce) 16-Essential Hydraulic Components - Maintenance R2Raúl Marcelo Veloz100% (1)

- Operacion de Sistemas Power Shift - D4EDocument6 pagesOperacion de Sistemas Power Shift - D4ERenato LicettiNo ratings yet

- Seamless Dimensional Range: Wall ThicknessDocument1 pageSeamless Dimensional Range: Wall ThicknessFilipNo ratings yet

- Layout: Rear View Front ViewDocument14 pagesLayout: Rear View Front ViewRms AutomotrizNo ratings yet

- GS Ep PVV 146Document8 pagesGS Ep PVV 146SangaranNo ratings yet

- IFC Series Y-Strainers: NotesDocument30 pagesIFC Series Y-Strainers: Notesmarsha.fsdNo ratings yet

- Kasinski Mirage 150Document106 pagesKasinski Mirage 150Karolaay B.No ratings yet

- Comparativo Llegada Stock de Seguridad 14012023Document6 pagesComparativo Llegada Stock de Seguridad 14012023Jesus Sarmiento VillanuevaNo ratings yet

- Stability-Calculation For PipelineDocument2 pagesStability-Calculation For PipelineGeorge100% (1)

- Baja Be 500 Owners ManualDocument29 pagesBaja Be 500 Owners ManualDragos EnacheNo ratings yet

- Almera n16 Europa Ec-K9kDocument214 pagesAlmera n16 Europa Ec-K9kMARK llNo ratings yet

- Atb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesDocument4 pagesAtb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesAleNo ratings yet

- Andras Iosif 1 - Anale 2016Document6 pagesAndras Iosif 1 - Anale 2016Augustin AghiorghioaieNo ratings yet

- Use of Fiber-Reinforced Soil For Blast ProtectionDocument16 pagesUse of Fiber-Reinforced Soil For Blast ProtectionSameer ShashwatNo ratings yet

- Camion Articulado 730C2 Plano HYD 2016 SISDocument2 pagesCamion Articulado 730C2 Plano HYD 2016 SISFabrizio Jesus Morales SalirrosasNo ratings yet

- Condition Based Monitoring - Mining Equipment's - Monthly Check Sheet (MCL & SAIL Barsua)Document14 pagesCondition Based Monitoring - Mining Equipment's - Monthly Check Sheet (MCL & SAIL Barsua)Soumyaranjan NayakNo ratings yet

- Valve Range Strainer SupplierDocument8 pagesValve Range Strainer SupplierRAVIKIRAN BARDENo ratings yet

- DMBF Full en Metric LetterDocument4 pagesDMBF Full en Metric LetterRonaldNo ratings yet

- Screw Jack Calculations PDFDocument6 pagesScrew Jack Calculations PDFVero FeloNo ratings yet

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyFrom EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyRating: 3.5 out of 5 stars3.5/5 (111)

- Cyber War: The Next Threat to National Security and What to Do About ItFrom EverandCyber War: The Next Threat to National Security and What to Do About ItRating: 3.5 out of 5 stars3.5/5 (66)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (227)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (55)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldFrom EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldRating: 4.5 out of 5 stars4.5/5 (107)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewFrom EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (104)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideFrom EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideRating: 5 out of 5 stars5/5 (2)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziFrom Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziNo ratings yet

- Dark Data: Why What You Don’t Know MattersFrom EverandDark Data: Why What You Don’t Know MattersRating: 4.5 out of 5 stars4.5/5 (3)

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceFrom EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceNo ratings yet

- Four Battlegrounds: Power in the Age of Artificial IntelligenceFrom EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceRating: 5 out of 5 stars5/5 (5)

- AI Prompting Mastery: Strategies and Techniques for Effective PromptingFrom EverandAI Prompting Mastery: Strategies and Techniques for Effective PromptingNo ratings yet

- How to Do Nothing: Resisting the Attention EconomyFrom EverandHow to Do Nothing: Resisting the Attention EconomyRating: 4 out of 5 stars4/5 (421)

- Working with AI: Real Stories of Human-Machine Collaboration (Management on the Cutting Edge)From EverandWorking with AI: Real Stories of Human-Machine Collaboration (Management on the Cutting Edge)Rating: 5 out of 5 stars5/5 (5)

- The AI Advantage: How to Put the Artificial Intelligence Revolution to WorkFrom EverandThe AI Advantage: How to Put the Artificial Intelligence Revolution to WorkRating: 4 out of 5 stars4/5 (7)

- Everybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really AreFrom EverandEverybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really AreRating: 4.5 out of 5 stars4.5/5 (913)

- Artificial Intelligence & Generative AI for Beginners: The Complete GuideFrom EverandArtificial Intelligence & Generative AI for Beginners: The Complete GuideRating: 5 out of 5 stars5/5 (1)