Professional Documents

Culture Documents

Subject Outline

Uploaded by

MuhammadTanzeeLUsmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Subject Outline

Uploaded by

MuhammadTanzeeLUsmanCopyright:

Available Formats

Title of Subject : SIMULTANEOUS HEAT & MASS TRANSFER

OPERATIONS

Course Code : CH-355

Disciplines : B.E. (Chemical Engineering)

Semester : Sixth

Effective : Batch 2016 onwards

Pre-requisites : Mass Transfer, Heat Transfer

Assessment : 20% Sessional Work, 20%, Mid Semester, 60% Final Semester

Examination

Marks : Theory: 100 Practical: 50

Credit Hours : 3 1

Teaching Scheme : 3Hrs/Week 3Hrs/Week

1. COURSE OBJECTIVES:

To provide understanding of design strategies of separation equipment involving simultaneous

heat and mass transfer operations.

2. COURSE OUTLINE:

HUMIDIFICATION AND COOLING TOWERS: Humidification terms, wet-bulb and

adiabatic saturation temperature, Humidity data for the air-water system, temperature-humidity

chart, enthalpy-humidity chart, determination of humidity, humidification and dehumidification.

Cooling Towers: Basic principles, types, features and operation of various cooling towers.

Cooling tower design. Alternative sinks for waste heat. Design of equipment based on worst case

studies. Water and air based systems. Environmental effects

DRYING: General principles, Rate of drying, The mechanism of moisture movement during

drying, Diffusion and Capillary theory of drying, Classification and selection of dryers(Tray,

tunnel, rotary, drum, spray, pneumatic, fluidized beds, turbo-shelf, disc and centrifuge dryers),

solvent drying, superheated steam drying, freeze drying, flash drying, partial-recycle dryers, The

drying of gases.

DISTILLATION: The fractionating column. Concept of constant molal overflow. Calculation

of number of plates required for binary separations. Lewis-Sorel, McCabe-Thiele methods.

Concept of operating lines. Intersection of operating lines and location of feed plate. Importance

of the reflux ratio. Calculation of minimum reflux ratio. Number of plates at total reflux.

Underwood and Fenske methods. Selection of economic reflux ratio. Effect of multiple feeds and

sidestreams. Plate efficiency and Murphrees formula. Concept of a theoretical plate and HETP.

Method of transfer units and HTU. Multi-component distillation: Degrees of freedom in separation

specifications. Key components in multi-component mixtures and recovery fraction. Continuous

flash distillation with heat balancing. Equilibrium and enthalpy expressions. Multi-stage

distillation Numerical examples of multi-component separation problems. Side streams and partial

condensers. Column Design: Tray design; hydraulics and performance.

BATCH DISTILLATION: operation at constant product composition or constant reflux ratio.

Calculation of column, diameter and height.

AZEOTROPIC AND EXTRACTIVE DISTILLATION: Heterogeneous azeotropes.

Illustrative examples of azeotropic distillations. Reactive distillation.

3. PRACTICAL WORK IN THE LABS:

Practicals based upon the theory studied in studied in theory class

4. RECOMMENDED BOOKS:

1. McCabe Warren L., Smith Julian C., Harriott peter Unit Operations of chemical

Engineering 7th Ed. 2005. McGraw Hill Inc.

2. Coulson J.M., Richardson J.F. Chemical Engineering Vol-II, 5th Ed. 2002. The English

Book Society and Pergamon Press.

3. Coulson J.M., Richardson J.F. Chemical Engineering Vol-I, 1999. The English Book

Society and Pergamon Press

4. Foust Alan S., Wenzel Leonard A., Clump Curtis W., Maus Louis and Anderen L. Bryce

Principles of Unit Operations 2nd Ed. , 1963, John Wiley and sons.

5. Incropera Frank P., De Witt David P. Fundamentals of Heat and Mass Transfer 3rd Ed.

1990. John Wiley and Sons.

6. Treybal Robert E. Mass Transfer Operations , 1981, McGraw Hill Book Company.

5. LEARNING OUTCOMES

1. Able to apply principles of heat and mass transfer to basic engineering systems. Use

individual mass transfer coefficients to obtain overall mass transfer coefficient in multi-phase

systems and apply in a variety of design applications.

2. Design packed-columns for simultaneous heat- and mass-transfer (i.e. cooling towers,

distillation etc.) in terms of number and height of transfer units (NTU & HTU).

3. Work with others on solution strategies but solve the actual problem on their own thorough

homework assignments.

4. Students will be able to solve simple problems where heat and mass transfer are coupled.

5. Students will learn about chemical processes, units, and corresponding equipment related to

heat and mass transfer.

6. MAPPING OF PROGRAM OUTCOMES TO COURSE LEARNING OUTCOMES

Course Program Outcomes

Learning

Objectives A B C D E F G H I J K L

1 E E E I I I I E E I E E

2 P P P I I I I E P E E P

3 P P E P P P P P P P E P

Course Program Outcomes

Learning

Objectives A B C D E F G H I J K L

4 P P E P P P P P P P E P

5 P P E P P P P P P P E P

(I: introduced; P: practiced; E: emphasized)

Approval:

Board of studies Chemical Engineering Res. No. Agenda Item No. 05. Dated: 16th

July 2013

Academic Council Res. No. 05 Dated April 2015

You might also like

- Lect 3 2Document61 pagesLect 3 2MuhammadTanzeeLUsmanNo ratings yet

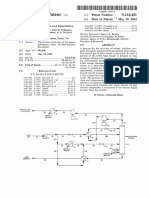

- United States Patent: Denton Et A1. (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Denton Et A1. (10) Patent N0.: (45) Date of PatentMuhammadTanzeeLUsmanNo ratings yet

- Lect 2Document13 pagesLect 2MuhammadTanzeeLUsmanNo ratings yet

- US5114451Document10 pagesUS5114451MuhammadTanzeeLUsmanNo ratings yet

- Production of Iso-Propyle Alcohol by Direct Hydration ProcessDocument2 pagesProduction of Iso-Propyle Alcohol by Direct Hydration ProcessMuhammadTanzeeLUsmanNo ratings yet

- Lecture Plan: Week Lectures Topics Assignment / Quizzes % Course CoverageDocument3 pagesLecture Plan: Week Lectures Topics Assignment / Quizzes % Course CoverageMuhammadTanzeeLUsmanNo ratings yet

- Internship LetterDocument1 pageInternship LetterMuhammadTanzeeLUsmanNo ratings yet

- Z - Peng RobinsonDocument1 pageZ - Peng RobinsonMuhammadTanzeeLUsmanNo ratings yet

- Atm Thefts: in Our First Slide You See An Individual Who Apparently Is Making A Bank Transaction at The AtmDocument17 pagesAtm Thefts: in Our First Slide You See An Individual Who Apparently Is Making A Bank Transaction at The AtmMuhammadTanzeeLUsmanNo ratings yet

- RFM PDFDocument221 pagesRFM PDFMuhammadTanzeeLUsmanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Week 1Document10 pagesWeek 1Ghonel RootNo ratings yet

- Enfriador Electrico Panel Sec-2001bDocument1 pageEnfriador Electrico Panel Sec-2001braul salinasNo ratings yet

- Velocity Diagram Impulse Turbine StageDocument5 pagesVelocity Diagram Impulse Turbine Stagedevang_panchal899600No ratings yet

- CH 2Document46 pagesCH 2جلال بولادNo ratings yet

- Butadine Extraction Unit: FC LC TIDocument1 pageButadine Extraction Unit: FC LC TIAtwadin SatriadaniNo ratings yet

- Advanced Modern Engineering Mathematics 3rd Ed Glyn James Solutions ManualDocument23 pagesAdvanced Modern Engineering Mathematics 3rd Ed Glyn James Solutions ManualIman ArzmanNo ratings yet

- Unit 6 - Week 03: Mass Transfer Coefficient and Interface Mass TransferDocument3 pagesUnit 6 - Week 03: Mass Transfer Coefficient and Interface Mass TransferSandra GilbertNo ratings yet

- The Mass Effect of Refrigerant R600a On Household Refrigerator Energy ConsumptionDocument7 pagesThe Mass Effect of Refrigerant R600a On Household Refrigerator Energy ConsumptionEdy MesinNo ratings yet

- D5470-12 Standard Test Method For Thermal Transmission Properties of Thermally Conductive Electrical Insulation MaterialsDocument6 pagesD5470-12 Standard Test Method For Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materialsastewayb_964354182No ratings yet

- Simple and Fractional Distillation Repaired)Document4 pagesSimple and Fractional Distillation Repaired)Janine LauretaNo ratings yet

- WS2-Chapter 09 Guidelines and Codes That Affect DesignDocument2 pagesWS2-Chapter 09 Guidelines and Codes That Affect DesignJCNo ratings yet

- Thermodynamics Lesson 1-5Document43 pagesThermodynamics Lesson 1-5Cristel Shane DuranNo ratings yet

- Transport ProcessDocument32 pagesTransport Processpidexhitam67% (3)

- Natural Convection Heat Transfer On A Vertical C 2014 International JournalDocument8 pagesNatural Convection Heat Transfer On A Vertical C 2014 International JournalAnonymous vVsidh3nNo ratings yet

- ME 2121 Module RevisedDocument96 pagesME 2121 Module Revisedpanger moooNo ratings yet

- Thermo Products Dealer Price Book OnlineDocument64 pagesThermo Products Dealer Price Book OnlineRobert OramNo ratings yet

- Thermodynamics 1 Module 5Document20 pagesThermodynamics 1 Module 5Andrea AlejandrinoNo ratings yet

- Marble-Hand (II) ADocument15 pagesMarble-Hand (II) AmohammedetaNo ratings yet

- L1 - Heat and Mass TransferDocument13 pagesL1 - Heat and Mass Transfershamiul himelNo ratings yet

- TKR - Calculation AC HeatLoad - Rev1Document15 pagesTKR - Calculation AC HeatLoad - Rev1giatuan85_728400728No ratings yet

- TNPSC Engineering Services SyllabusDocument4 pagesTNPSC Engineering Services SyllabusGOPALAKRISHNAN RAGOTHAMANNo ratings yet

- Effects of Particle Size On DryingDocument4 pagesEffects of Particle Size On DryingAshley Perida50% (2)

- Thermo-Review PENT PDFDocument31 pagesThermo-Review PENT PDFDzuhri Ferianto100% (1)

- PP ManualDocument50 pagesPP ManualMohammad RehmanNo ratings yet

- ThermodynamicsDocument60 pagesThermodynamicsMahender ThotakuriNo ratings yet

- ASHRAE-Chart No1 PDFDocument2 pagesASHRAE-Chart No1 PDFaukanaiiNo ratings yet

- Handbook of Thermal Analysis (1999,0471983632, T. Hatakeyama, Liu Zhenhai)Document471 pagesHandbook of Thermal Analysis (1999,0471983632, T. Hatakeyama, Liu Zhenhai)rafael_nicolay9196100% (3)

- Thermophysical Properties of Carbon DioxideDocument4 pagesThermophysical Properties of Carbon DioxideAnonymous 6cQRWqNo ratings yet

- LG LW8012ER Air Conditioner Spec SheetDocument2 pagesLG LW8012ER Air Conditioner Spec SheetAbin MeetuNo ratings yet