Professional Documents

Culture Documents

Report On STP141209

Uploaded by

Manjunath HrmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report On STP141209

Uploaded by

Manjunath HrmCopyright:

Available Formats

Kaveri Watermarke Sewerage Treatment Plant Report

Report on

Sewerage Treatment Plant

CPG Consultants India Pvt Ltd., Page 1

Kaveri Watermarke Sewerage Treatment Plant Report

1.0 Introduction:

The objective of Sewage treatment plant is to stabilize decomposable organic

matter present in sewage so as to produce treated effluent which can be reused

for non-potable purposes or disposed off into the environment without causing

health hazard or nuisance.

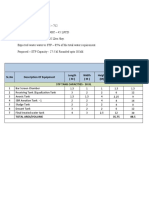

A comparison chart for various types of STP is as follows:

Convention

Sl Extended

MBR al Activated Trickling

N Feature Aeration

System Sludge Filter

o Process

Process

Less(0.15- High(0.20- High(0.20-

Area

1 Least 0.20 0.25 0.30

Requirement

sqm/person) sqm/person sqm/person

Simple but

there are

Simpler than Skilled O&M operational

Operation &

2 Most Simple activated personnel is troubles like

Maintenance

sludge. required fly and

odour

nuisance

Effluent

3 Good Good Fair Fair

Quality

Removal %

i About 98 95-98 85-92 80-90

BOD5

Removal %

ii Suspended About 98 90-95 90-95 About 80

Solids

Sludge

production &

4 Less Less High High

Sludge

handling

Power

5 Very High High High Moderate

requirement

Flexible in Flexible in Sudden Has

6 Adaptability

operation operation change in flexibility in

CPG Consultants India Pvt Ltd., Page 2

Kaveri Watermarke Sewerage Treatment Plant Report

quantity and operation

quality of

sewage

produces

adverse

effects on

the process

Capital cost

High capital Cost is less

is less but

Cost of cost but less compared to

7 high High cost

Construction expense for conventional

operational

maintenance ASP

cost

Modular Not

8 Possible Not possible Not Possible

Growth Possible

Hence we recommend a MBR type Sewage Treatment Plant.

2.0 Membrane Bio-Reactor System

The units of the MBR type STP and their function is described as follows:

a) Bar Screen: The main objective of installing screens is to remove floating

matter of comparatively large size. This unit prevents problems, which are

likely to be caused in further operation of other units. Removal of these

wastes in screens prevents clogging and chocking of pumps and other

equipments.

b) Equalization Tank: Sewage generation is not uniform and maximum quantity

comes out during morning and evening hours. The flow may be zero during

afternoon and mid night. To optimize the size of the plant, the plant is

designed for continuous operation and hence there is a need to provide a

buffer tank to store sewage during its peak hour generation and supply the

same during lean or no flow hours. Hence the plant is provided with a good

capacity of buffer tank known as EQUALISATION TANK. Screened and de-

greased sewage is then passed into the equalization tank to homogenize the

sewage quality and also even out flow fluctuations and feed sewage of

uniform quality at constant rate to subsequent treatment units. Air mixing is

also provided to mix the contents of the equalization tank. A coarse bubble

aeration grid system is provided to mix the contents of the equalization tank

CPG Consultants India Pvt Ltd., Page 3

Kaveri Watermarke Sewerage Treatment Plant Report

and also to avoid septic conditions in the tank. Hydraulic retention period here

will be 8 Hrs.

c) Aeration Tank: Biological stabilization of the waste water is carried out in the

aeration tank in the presence of microorganisms. In this tank Oxygen is given

for aeration, in order to reduce BOD and COD. The aeration devices apart

from supplying the required oxygen demand shall also provide adequate

mixing or agitation in order that the entire mixed liquor suspended solids

present in the aeration tank will be available for the biological activity. The air

containing oxygen is used by the bacteria to consume the organic matter and

convert it to carbon dioxide and water. In aeration tank, MLSS (mixed liquor

suspended solids) in the range of 3000 to 6000 mg/l or more are maintained.

The high amount of bacteria gives better and complete removal of organic

matter from the raw effluent in relatively small area. Oxygen required for the

bacteria is supplied through the blower.

Aeration: fine bubble air diffusers

MLSS: 3000 -6000Mg/ Lit

Oxygen requirement: 2 kg per kg of BOD

d) MBR Tank: The waste water (mixed liquor) with the bio mass flowing out

of the aeration is taken to an MBR tank with a hopper bottom.

Module dimension (as per design): (Immersed)

ID/OD 0.8/2mm

Material PVDF

Pore size 0.1 micron

Tensile strength >25 kg/fiber

Effective area 20 m2

Flux 15 to 70 (LMH / m2 x h)

Design Flux 25 LMH

Casing Material ABS

Operating method Suction 2 way

Operating pressure 100- 300 mm Hg

Aeration External- Bottom

Max temp 40 c

Flow Mode Out to Inside

CPG Consultants India Pvt Ltd., Page 4

Kaveri Watermarke Sewerage Treatment Plant Report

Ph 2 to 10.

MBR Module:

Each module delivers (as per design) capacity cum/day of treated

water.

No of Modules: Membrane modules of design capacity.

Cassette size : As per Design

No of cassette : As per Design

The following pumps are considered:

MBR Suction pump (1W + 1S) As per Design

MBR back wash pump (1W + 1S) - As per Design

MBR chemical cleaning pump As per Design

The MBR operation is totally done by PLC based control panel which

automatically does the suction, back washing depending on the time which is set.

MBR - CHEMICAL CLEANING (CIP)

e) Final Treated Water Tank: The water sucked from the membranes is of very

high quality with respect to BOD, COD and suspended solids, and is stored in

a final treated water tank for further use. Retention period is 10-12 hrs.

CPG Consultants India Pvt Ltd., Page 5

Kaveri Watermarke Sewerage Treatment Plant Report

f) U V STERLISER or Chlorination (for disinfection): Finally the treated MBR

product water is passed through UV sterilizer/chlorination for further

disinfection if required.

The characteristic features of raw sewage and treated sewage is as

follows:-

Characteristic of Raw Sewage

pH 7.5 8.5

TSS 400 mg/lit

BOD5 350 mg/lit

COD 500 mg/lit

IN FLOW 18 Hr

Characteristic of Treated Effluent:

pH 7.0- 8.0

TSS NIL

BOD5 < 5 mg/lit

COD <20 mg/lit

TURBIDITY <2 mg/lit

COLOR <05 hazen

ODOUR un-objectionable

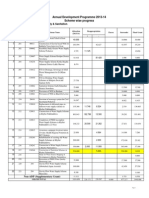

3.0 Sewerage Discharge-Total and Phase wise:

The Water demand calculation Table for the entire development is as given

below:

Add 10% Sewage

No. of No. of No. of

LPCD as for Total

Sl. units floors personn Water

Type per Unaccou Water Discharged

No per (ex.stilt el Required

CPHEEO nted Req'd/day ,

floor level) (No.s)

usage kld

1 Tower-1 8.00 14.00 1176.00 150.00 176400.0 17640.00 194040.00 164.93

2 Tower-2 21.00 14.00 1470.00 135.00 198450.0 19845.00 218295.00 185.55

Tower-3

3 (same 8.00 14.00 1176.00 150.00 176400.0 17640.00 194040.00 164.93

as 1)

CPG Consultants India Pvt Ltd., Page 6

Kaveri Watermarke Sewerage Treatment Plant Report

4 Tower-4 12.00 12.00 720.00 150.00 108000.0 10800.00 118800.00 100.98

5 Tower-5 12.00 12.00 720.00 150.00 108000.0 10800.00 118800.00 100.98

6 Tower-6 12.00 12.00 720.00 150.00 108000.0 10800.00 118800.00 100.98

7 Tower-7 22.00 11.00 1210.00 150.00 181500.0 18150.00 199650.00 169.70

8 Tower-8 25.00 12.00 1500.00 150.00 225000.0 22500.00 247500.00 210.38

Club

10 - 3.00 225.00 45.00 10125.00 1012.50 11137.50 9.47

House

7 Total 8917.00 1421062.5 1207.90

8 Treated Effluent from STP 1026.72

The water demand for Phase-I is as follows:

Sewage

No. of No. of Total

No. of LPCD as Water Add 10% for

Sl. units floors Water

Type Occupa per Required, Unaccounted Discharg

No per (ex. stilt Req'd/day

nts CPHEEO ltrs usage, ltrs ed,

floor level) , ltrs

kld

1 8.00 14.00 560.00 150.00 84000.00 8400.00 92400.00 78.54

Tower

-1

2 8.00 14.00 560.00 150.00 84000.00 8400.00 92400.00 78.54

Tower

3 8.00 6.00 240.00 135.00 32400.00 3240.00 35640.00 30.29

-2

Club

4 - 2.00 150.00 45.00 6750.00 675.00 7425.00 6.31

House

5 Total 1510.0 227865.00 193.69

6 STP Capacity 200.00

7 Treated Effluent from STP 164.63

Hence the initial sewage load is 200KLD and the total is 1.2MLD. Due to uncertainty in the time

duration of construction of towers, constructing and maintaining one single STP for the entire

development of 8 towers is not a good decision.

CPG Consultants India Pvt Ltd., Page 7

Kaveri Watermarke Sewerage Treatment Plant Report

Tower 1a 80

KLD

Tower 1b 80

KLD

STP Capacity

200 KLD

Tower 2a 30

KLD (6 floors)

Club house 10

KLD (2 floors)

Even the Phase-1 construction shall be done in various stages starting with Tower1A as

shown in the drawing.

The following points can be noted:

Tower 1A will be constructed first; hence we recommend a mobile STP of 100 KLD

capacity to be used for Tower 1A. This can take care of sewage during construction

stage for other tower as well and can even be shifted to other sites.

Since rate at which the tower is occupied will be slow initially we suggest that this

modular STP be used till tower 1B is fully occupied. By the time Tower-1A and 1B has

full occupancy a STP of 200 KLD can be constructed and can start operating with a load

of 160 KLD.

During such time if the phase 2 development is certain and is on the papers its

sewerage contribution can be envisaged and capacity of the STP can hence be decided.

We can design the STP and plan for the same at the beginning of phase 2 and ending of

phase 1.

CPG Consultants India Pvt Ltd., Page 8

Kaveri Watermarke Sewerage Treatment Plant Report

4.0 Area Requirement and Costing:

The cost of a mobile STP of 100KLD capacity is approximately 25, 75,000

INR.The area requirement for a 200 KLD STP is 230 sqm and the costing shall

be approximately 45, 00,000 INR.

CPG Consultants India Pvt Ltd., Page 9

Kaveri Watermarke Sewerage Treatment Plant Report

CPG Consultants India Pvt Ltd., Page 10

You might also like

- Design of Smoke Control Systems For Areas of Refuge 1993Document25 pagesDesign of Smoke Control Systems For Areas of Refuge 1993mingming1No ratings yet

- Water Mist CalculationDocument26 pagesWater Mist CalculationManjunath HrmNo ratings yet

- CFM Ir SizDocument1 pageCFM Ir SizManjunath HrmNo ratings yet

- Statistics: 10.1 Mean and Standard Deviation - Single DataDocument20 pagesStatistics: 10.1 Mean and Standard Deviation - Single DataManjunath HrmNo ratings yet

- Hi FogDocument36 pagesHi FogManjunath HrmNo ratings yet

- Plant CapacityDocument1 pagePlant CapacityManjunath HrmNo ratings yet

- Manual On Artificial Recharge of Ground WaterDocument198 pagesManual On Artificial Recharge of Ground WaterShyam BudhwarNo ratings yet

- Stairwell & Lift Pressurization CalculationsDocument31 pagesStairwell & Lift Pressurization CalculationsAneng2890% (10)

- Quick Guide To M: PlasticsDocument2 pagesQuick Guide To M: PlasticsManjunath Hrm100% (1)

- Grundfosliterature 3081295Document7 pagesGrundfosliterature 3081295Manjunath HrmNo ratings yet

- Design calculations for swimming pool pumps filtersDocument2 pagesDesign calculations for swimming pool pumps filtersManjunath Hrm100% (2)

- A Pump Is A Device That Moves FluidsDocument19 pagesA Pump Is A Device That Moves FluidsManjunath HrmNo ratings yet

- Gas CalculationDocument1 pageGas CalculationManjunath HrmNo ratings yet

- Dimensions of A Series Paper SizesDocument3 pagesDimensions of A Series Paper SizesRaja KathiravanNo ratings yet

- Freeware PDF UnlockerDocument116 pagesFreeware PDF UnlockerManjunath HrmNo ratings yet

- New PricelistDocument1 pageNew PricelistManjunath HrmNo ratings yet

- CAD For High Embankments-IITDocument29 pagesCAD For High Embankments-IITNAUTILUS87No ratings yet

- Typical Classroom Layout and Contents 25-08-2018Document1 pageTypical Classroom Layout and Contents 25-08-2018Manjunath HrmNo ratings yet

- British Standard: A Single Copy of This British Standard Is Licensed ToDocument13 pagesBritish Standard: A Single Copy of This British Standard Is Licensed ToManjunath HrmNo ratings yet

- The Design of Concrete Highway Bridges and Structures With External and Unbonded PrestressingDocument12 pagesThe Design of Concrete Highway Bridges and Structures With External and Unbonded PrestressingManjunath HrmNo ratings yet

- Is SP 20 1991 PDFDocument167 pagesIs SP 20 1991 PDFAnonymous 0ABCZ1bINo ratings yet

- BellDocument30 pagesBellsas999333No ratings yet

- Interview TipsDocument26 pagesInterview TipsManjunath HrmNo ratings yet

- Uniform Mechanical CodeDocument185 pagesUniform Mechanical CodeCostas Sar100% (2)

- Revenue by Quarters: Q1 Q2 Q3 Q4Document4 pagesRevenue by Quarters: Q1 Q2 Q3 Q4Manjunath HrmNo ratings yet

- Fire Requirement As Per NBCDocument1 pageFire Requirement As Per NBCManjunath HrmNo ratings yet

- Discrimination Report for Wipro Coimbatore Electrical ServiceDocument30 pagesDiscrimination Report for Wipro Coimbatore Electrical ServiceManjunath HrmNo ratings yet

- IEC 62305-2010 Tieu Chuan Chong SetDocument489 pagesIEC 62305-2010 Tieu Chuan Chong SetThuậnHồ80% (5)

- Discrimination Report for Wipro Coimbatore Electrical ServiceDocument30 pagesDiscrimination Report for Wipro Coimbatore Electrical ServiceManjunath HrmNo ratings yet

- Novec VentingoutDocument2 pagesNovec VentingoutManjunath HrmNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Drinking Water PDFDocument4 pagesDrinking Water PDFAthanasoulis KostasNo ratings yet

- Booster Sets With E-SPD Inverter: Product CatalogueDocument40 pagesBooster Sets With E-SPD Inverter: Product CatalogueDang Nguyen VuNo ratings yet

- Eastern Municipal Water District Press Release On Water DealDocument2 pagesEastern Municipal Water District Press Release On Water DealThe Press-Enterprise / pressenterprise.comNo ratings yet

- ESIA 1346 - Report - (NARSIP II) PDFDocument175 pagesESIA 1346 - Report - (NARSIP II) PDFasimNo ratings yet

- DP Booklet E D F CN-final-VersionDocument32 pagesDP Booklet E D F CN-final-VersionaernestNo ratings yet

- 11.10.2022 Sustainable Finance PlanDocument84 pages11.10.2022 Sustainable Finance PlanArifhadi Johari AffandiNo ratings yet

- Greater Kegalle Water Treatment PlantDocument9 pagesGreater Kegalle Water Treatment PlantRanjithNo ratings yet

- LWUA Tariff Setting For Septage ManagementDocument16 pagesLWUA Tariff Setting For Septage Managementchristine guardeNo ratings yet

- m1011 Jamban Cubluk Berventilasi Dan Leher AngsaDocument14 pagesm1011 Jamban Cubluk Berventilasi Dan Leher AngsaNafisa MeisaNo ratings yet

- SNV - Baseline Study To Assess FSM of Residential PremisesDocument50 pagesSNV - Baseline Study To Assess FSM of Residential PremisesrupakhasanNo ratings yet

- 1.0 Introduction, Water QualityDocument32 pages1.0 Introduction, Water QualitySyamel IzzatNo ratings yet

- Oshtemo Township Phase 1 Sewer BondDocument2 pagesOshtemo Township Phase 1 Sewer BondWWMTNo ratings yet

- Infiltration Gallery Yamna PDFDocument5 pagesInfiltration Gallery Yamna PDFshamoojeeNo ratings yet

- Mayor & SB Members: Powers, Duties &functionsDocument44 pagesMayor & SB Members: Powers, Duties &functionsJuan Paolo S. Brosas100% (1)

- Lgesp - Pura Neguma Reference Manual For Project StaffDocument62 pagesLgesp - Pura Neguma Reference Manual For Project StaffmuthunayakeNo ratings yet

- Hafeshwar-6 Volume-I Technical BidDocument122 pagesHafeshwar-6 Volume-I Technical Bidgaurang22No ratings yet

- Open DiscussionDocument10 pagesOpen DiscussionAlaa SalemNo ratings yet

- Using Graywater and Stormwater To Enhance Local Water SuppliesDocument224 pagesUsing Graywater and Stormwater To Enhance Local Water SuppliesThuong Vu ThanhNo ratings yet

- Rain Water Harvesting ProjectDocument19 pagesRain Water Harvesting ProjectManoj Janardan Jayashree Terekar100% (1)

- State Wise Dam PDFDocument207 pagesState Wise Dam PDFShahid HussainNo ratings yet

- Urban Local Body Finances: Astha AgarwallaDocument37 pagesUrban Local Body Finances: Astha AgarwallaUnmesh RajguruNo ratings yet

- Design, Estimation and Costing of Sewage Treatment PlantDocument12 pagesDesign, Estimation and Costing of Sewage Treatment Plantadarsh s100% (1)

- Sector: Drinking Water Supply & Sanitation: Annual Development Programme 2013-14 Scheme Wise ProgressDocument1 pageSector: Drinking Water Supply & Sanitation: Annual Development Programme 2013-14 Scheme Wise ProgressFazal Ahmad MarwatNo ratings yet

- Leakage AssessmentDocument7 pagesLeakage AssessmentRajesh kumarNo ratings yet

- UBMPS GIS Maps and Drawings for Urban PlanningDocument2 pagesUBMPS GIS Maps and Drawings for Urban Planninghug1515No ratings yet

- Drainage and Water Logging in Bangladesh CityDocument7 pagesDrainage and Water Logging in Bangladesh Cityতারিক বিন জিয়াদNo ratings yet

- Sewage Treatment ProcessDocument8 pagesSewage Treatment ProcessSanshlesh VermaNo ratings yet

- EPA Effluent StandardsDocument5 pagesEPA Effluent StandardsmarkhanNo ratings yet

- Water and Wastewater Engineering: Design of Water Supply System of Bahria Town Phase 1Document39 pagesWater and Wastewater Engineering: Design of Water Supply System of Bahria Town Phase 1Omaya Tariq100% (1)

- WQM 003Document4 pagesWQM 003reynaldo_777No ratings yet