Professional Documents

Culture Documents

HAZOP Final

Uploaded by

chiang95Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZOP Final

Uploaded by

chiang95Copyright:

Available Formats

HAZARD AND OPERABILITY STUDY REPORT

PROJECT TITLE DESIGN OF HEAT EXCHANGER USING FLOW OF STEAM DATE 12/12/2016

LIM CHIEN CHIANG 19789

STUDY NODE 1 PROCESS HEATING OF VOLATILE SUBSTANCE STUDY TEAM PATRICK ANTHONEY LOUIS 19707

VANESSA YANJAN HARRY 19638

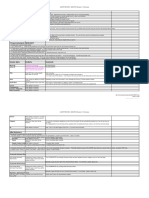

GUIDE POSSIBLE

NO. STUDY NODE PARAMETER DEVIATION CONSEQUENCES SAFEGUARDS RECOMMENDATION

WORD CAUSES

1 Pump faulty. 1 No heat exchange 1 Fail open valve. 1 Create an emergency

occurs. response.

NO NO FLOW

Check the condition

Pipe

2 2 Economic loss. 2 Flow indicator. 2 of the equipments

blockage. and the pipeline.

Feed control Regular inspection of

Less yield of Flow control

1 valve partially 1 1 1 the flow control

desired product. valve.

closed valve.

1 HEAT EXCHANGER FLOW LESS LESS FLOW

Install low flow

Leakage in 2 2 Lowsystem.

flow alarm 2 alarm

2 inlet Production loss. at inlet of the

pipeline. steam flow.

Feed control Set the limit flow

1 Change in product 1 Composition

1 valve fail 1 control at the

composition. indicator.

open. maximum value.

MORE MORE FLOW

2 Controller is Desired conditions 2 High flow alarm 2 Switch valve to

saturated. 2 not achieved. system. manual control.

Check

More maintenance Regular pipe

1 pressure in 1 Off-spec product 1 procedures and 1 maintenance

reactor schedules

REACTOR

AS WELL AS PRODUCT IN

COILS

Alter gas inlet

attached to high

2 Contaminant Debris build-up in 2 Replace corroded

2 level flow 2 equipment

debris piping and valve

indicator and

alarm

1 HEAT EXCHANGER FLOW

Backflow Perform regular

from Product yield Install check

1 downstream 1 1 1 inspection on

affected valve equipment and valve

line

REVERSE

REVERSE FLOW

Install pressure

2 Water source 2 Desired flow rate 2 indicator Replace faulty

at inlet 2 equipment

failure not achieved and valve

stream

You might also like

- HAZOP for R-101 Reactor Process ParametersDocument2 pagesHAZOP for R-101 Reactor Process ParametersHudaNo ratings yet

- HAZOP Write UpDocument3 pagesHAZOP Write UpGlacier RamkissoonNo ratings yet

- No-Flow Process Deviations GuideDocument5 pagesNo-Flow Process Deviations GuideAnonymous QqE5tcEa100% (5)

- Hazop.1092475 Appendix 30.hazopDocument67 pagesHazop.1092475 Appendix 30.hazopAudrey Patrick Kalla50% (2)

- HAZOP ReactorDocument9 pagesHAZOP ReactorChadGayle100% (9)

- HAZOPDocument18 pagesHAZOPMark GuevarraNo ratings yet

- Hazop ExampleDocument2 pagesHazop ExampleMARCOPOLO24No ratings yet

- 01-HAZOP Worksheet Formaldehyde - (Corrosion)Document8 pages01-HAZOP Worksheet Formaldehyde - (Corrosion)Muhammad Zarif Amir100% (1)

- Separator Drum HAZOP ExerciseDocument1 pageSeparator Drum HAZOP Exercisevijaymoorthy140% (1)

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDocument39 pagesHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (1)

- HAZOPDocument32 pagesHAZOPMaximiano Ferraz71% (14)

- HAZOP ExerciseDocument12 pagesHAZOP Exerciseshawalina07No ratings yet

- Safety: Table 1: Safe Equipment. Authors: Cango. P, Espinoza. A, Lopez. C. (2019)Document4 pagesSafety: Table 1: Safe Equipment. Authors: Cango. P, Espinoza. A, Lopez. C. (2019)Alexander EspinozaNo ratings yet

- HAZOPDocument11 pagesHAZOPNathan Naelz Sandy100% (1)

- HAZOP Study (Part II)Document18 pagesHAZOP Study (Part II)Saad Ahmed100% (14)

- Hazop of FurnaceDocument2 pagesHazop of FurnaceTouhidBinAnwarNo ratings yet

- HAZOP Flash DrumDocument3 pagesHAZOP Flash DrumNurshahirahSapian75% (4)

- HAZOP Study (Part I)Document4 pagesHAZOP Study (Part I)Saad Ahmed100% (1)

- HAZOP Analysis of Oil Storage TankDocument2 pagesHAZOP Analysis of Oil Storage Tankvijaymoorthy14No ratings yet

- Chapter 7 HazopDocument11 pagesChapter 7 HazopMohd Azman Suwandi50% (2)

- HazopDocument8 pagesHazopferrari.indiaNo ratings yet

- HAZOP Worksheets: Item Guide Word Deviation Possible Causes ConsequencesDocument8 pagesHAZOP Worksheets: Item Guide Word Deviation Possible Causes Consequencesdvian50% (2)

- HAZOP AnalysisDocument35 pagesHAZOP AnalysisGopi Krish100% (3)

- Pre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuDocument18 pagesPre-Start Up Safety Review (PSSR) : Akamigas Balongan IndramayuRifky Haikal RamadhanNo ratings yet

- Tutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredDocument3 pagesTutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredSyafiyatulMunawarahNo ratings yet

- HAZOP Study of Methanol, Ethanol, and Water Distillation ColumnDocument7 pagesHAZOP Study of Methanol, Ethanol, and Water Distillation ColumnEng MohammedNo ratings yet

- HAZOP study of methanol production plant equipmentDocument12 pagesHAZOP study of methanol production plant equipmentAin SyuhadaNo ratings yet

- Hazop EvaporatorDocument2 pagesHazop Evaporatorchemeng22033% (3)

- Hazop Example PDFDocument2 pagesHazop Example PDFhappale200286% (7)

- HAZOP ExerciseDocument8 pagesHAZOP Exercisekefeinzel0% (1)

- Design Project HAZOP Draft 6Document6 pagesDesign Project HAZOP Draft 6Aleksei SukhovNo ratings yet

- C-102 Distillation Column Process Parameters and DeviationsDocument5 pagesC-102 Distillation Column Process Parameters and DeviationsPutri SaidatinaNo ratings yet

- Sample HAZOP Study Worksheet (P&ID 100-002)Document5 pagesSample HAZOP Study Worksheet (P&ID 100-002)Mikee Felipe88% (8)

- HAZOP On Distillation ColumnDocument1 pageHAZOP On Distillation Columnmuhammad arslan100% (1)

- Hazop For CSTRDocument3 pagesHazop For CSTRRomel Leo100% (1)

- Distillation Column Operation GuideDocument2 pagesDistillation Column Operation GuideRaffi Richard83% (53)

- V-103 HAZOP Study Nodes and ParametersDocument15 pagesV-103 HAZOP Study Nodes and ParametersEdna TanNo ratings yet

- Pump HazopDocument3 pagesPump HazopNick100% (1)

- HazopDocument2 pagesHazopapi-292058494100% (1)

- Basics of HAZOPDocument26 pagesBasics of HAZOPNg JoshuaNo ratings yet

- Hazop & HazidDocument18 pagesHazop & HazidRizqi Pandu SudarmawanNo ratings yet

- COOLER REACTOR hAZOPDocument2 pagesCOOLER REACTOR hAZOPAmirul NazrenNo ratings yet

- Safety HAZOP CourseworkDocument31 pagesSafety HAZOP CourseworkMaximiano Ferraz0% (1)

- Day 5 - Hazop Procedure For CompanyDocument57 pagesDay 5 - Hazop Procedure For Companyamidi5555913100% (1)

- HAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaDocument15 pagesHAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaMatthew BennettNo ratings yet

- HazopDocument75 pagesHazopSaima Saima89% (9)

- Hazop Basic ConceptsDocument14 pagesHazop Basic ConceptsClaudio Sobarzo100% (1)

- Senior HazopDocument113 pagesSenior HazopKongWeiHern100% (7)

- Hazop Study TemplateDocument3 pagesHazop Study TemplateLunga Dan Patso100% (1)

- HAZOPDocument43 pagesHAZOPChemsys Mail100% (1)

- Process Hazard Analysis Handbook - Seek-A-PeekDocument23 pagesProcess Hazard Analysis Handbook - Seek-A-PeekIcarusORM100% (8)

- Hazop Analysis Worksheet (Ammonia High Level)Document2 pagesHazop Analysis Worksheet (Ammonia High Level)Kenneth Teow100% (1)

- HAZOP Study Report TemplateDocument1 pageHAZOP Study Report TemplateSatria Antariksa RamadhanNo ratings yet

- HAZOP WorksheetDocument5 pagesHAZOP WorksheetchristyleneNo ratings yet

- Cdu Hazop PRL Sep 2014Document102 pagesCdu Hazop PRL Sep 2014amar yunisNo ratings yet

- UniSim Design Tutorial 2Document63 pagesUniSim Design Tutorial 2solo66No ratings yet

- HAZOP Workbook-Distillation Column 101-102Document4 pagesHAZOP Workbook-Distillation Column 101-102Ibrahim Nick DibalNo ratings yet

- Appendix-1 (HAZOPWorksheets)Document37 pagesAppendix-1 (HAZOPWorksheets)zohaib_farooq100% (1)

- Quantitative Risk Assessment A Complete Guide - 2020 EditionFrom EverandQuantitative Risk Assessment A Complete Guide - 2020 EditionNo ratings yet

- Appendix 1 HAZOPWorksheets 1 PDFDocument37 pagesAppendix 1 HAZOPWorksheets 1 PDFSDP02No ratings yet

- Petcoke Mass PercentDocument2 pagesPetcoke Mass Percentchiang95No ratings yet

- Experiment 5: Ratio Control: CDB 3062 - Chemical Engineering Laboratory III September 2016 SemesterDocument11 pagesExperiment 5: Ratio Control: CDB 3062 - Chemical Engineering Laboratory III September 2016 Semesterchiang95No ratings yet

- Model Liquid Release from Pipeline LeakDocument45 pagesModel Liquid Release from Pipeline Leakchiang95100% (1)

- Vanadium Pentoxide MsdsDocument6 pagesVanadium Pentoxide Msdschiang95No ratings yet

- Occupational Safety and Health Act 1994 (Act 514) Ve - OSHADocument31 pagesOccupational Safety and Health Act 1994 (Act 514) Ve - OSHAExsan OthmanNo ratings yet

- Syah Hafiz SIT Report PPM PDFDocument44 pagesSyah Hafiz SIT Report PPM PDFchiang95No ratings yet

- CDB 3033 Transport Phenomena: 1. Introduction To Transport Phenomena 2. Introduction To Momentum TransportDocument34 pagesCDB 3033 Transport Phenomena: 1. Introduction To Transport Phenomena 2. Introduction To Momentum Transportchiang95No ratings yet

- Unfair Commercial Practices DirectiveDocument1 pageUnfair Commercial Practices Directivechiang95No ratings yet

- CDB2043 Course Outline and Planning Sept 2015Document4 pagesCDB2043 Course Outline and Planning Sept 2015chiang95No ratings yet

- G22 Exp12Document12 pagesG22 Exp12chiang95No ratings yet

- May 2014 SemesterDocument2 pagesMay 2014 Semesterchiang95No ratings yet

- L4 Energy Balance Reactive SystemDocument29 pagesL4 Energy Balance Reactive Systemchiang95No ratings yet

- Outline PCSDocument6 pagesOutline PCSchiang95No ratings yet

- LipidsDocument8 pagesLipidschiang95No ratings yet

- L3 Energy Balance Reactive SystemDocument16 pagesL3 Energy Balance Reactive Systemchiang95No ratings yet

- Property Tables and Charts (Si Units)Document50 pagesProperty Tables and Charts (Si Units)Q_TNo ratings yet

- Module 3Document37 pagesModule 3Rozaini OthmanNo ratings yet

- Chemistry Perfect Score Module 2010Document91 pagesChemistry Perfect Score Module 2010rajadahlanNo ratings yet

- 4TH ED Pagess From Vol. Text B 31 Chapters 37 38 PROPIETARY ASME 3-26-13Document72 pages4TH ED Pagess From Vol. Text B 31 Chapters 37 38 PROPIETARY ASME 3-26-13namasralNo ratings yet

- Walnut Creek California 091104 PDFDocument20 pagesWalnut Creek California 091104 PDFknarf320No ratings yet

- Study On Waxy Crude Oil Pipeline Restart Simulation: Tian Jingwu, Ren Xidong, Zhang BaoxinDocument4 pagesStudy On Waxy Crude Oil Pipeline Restart Simulation: Tian Jingwu, Ren Xidong, Zhang BaoxinAYAUWU LOVEDAYNo ratings yet

- Pipeline Transient StudyDocument98 pagesPipeline Transient StudyNAMITA MODAK100% (1)

- Adil Naseer Khawaja's 25+ Years Piping Engineering ExperienceDocument5 pagesAdil Naseer Khawaja's 25+ Years Piping Engineering ExperienceAdil KhawajaNo ratings yet

- 18 Inch Gas Pipeline Data PDFDocument2 pages18 Inch Gas Pipeline Data PDFAliZenatiNo ratings yet

- Pipeline Pigging Incident: Dave Shepherd Aug, 2005Document7 pagesPipeline Pigging Incident: Dave Shepherd Aug, 2005mostafa_1000No ratings yet

- List of QP StandardsDocument4 pagesList of QP StandardsGalfarqatar MEPNo ratings yet

- PSM 2 - Flooding, Cleaning, Gauging & Hydrotesting During Pre-Comm ProcessDocument29 pagesPSM 2 - Flooding, Cleaning, Gauging & Hydrotesting During Pre-Comm ProcessMohamad Shukri100% (1)

- Surge Suppression Air ValvesDocument2 pagesSurge Suppression Air ValvesjyothiprakashNo ratings yet

- Hole Size SelectionDocument3 pagesHole Size SelectionGreg_Knight_8525No ratings yet

- Pipeline Protection and Stabilisation SLP The Submat Bitumen Mattress CanDocument19 pagesPipeline Protection and Stabilisation SLP The Submat Bitumen Mattress CanArianta RianNo ratings yet

- Astm F1743Document8 pagesAstm F1743Hernando Andrés Ramírez GilNo ratings yet

- Remoteness of Impressed Current Anode Ground - UnlockedDocument13 pagesRemoteness of Impressed Current Anode Ground - UnlockedJorge LunaNo ratings yet

- Van Oord UK LTD & Anor V Allseas UK LTD (2015) EWHC 3074 (TCC) (12 November 2015)Document85 pagesVan Oord UK LTD & Anor V Allseas UK LTD (2015) EWHC 3074 (TCC) (12 November 2015)harrydrivesucrazyNo ratings yet

- Procedure For The Design Construction of Distribution SysteDocument189 pagesProcedure For The Design Construction of Distribution SystemgyoonNo ratings yet

- Design of Natural Gas Transmission Pipeline A Case Study of A Typical Marginal Oil and Gas Field in Niger Delta NigeriaDocument13 pagesDesign of Natural Gas Transmission Pipeline A Case Study of A Typical Marginal Oil and Gas Field in Niger Delta NigeriaTivani MphiniNo ratings yet

- Save £150/US$240 by Applying for Pipeline Engineering Course by 4 AprilDocument4 pagesSave £150/US$240 by Applying for Pipeline Engineering Course by 4 AprilMehedi HasanNo ratings yet

- Pipeline Wall Thickness Calculation With Example (With PDFDocument21 pagesPipeline Wall Thickness Calculation With Example (With PDFALINo ratings yet

- GRP 104 - Introduction To Human Geography Ii A. Introduction/PreambleDocument18 pagesGRP 104 - Introduction To Human Geography Ii A. Introduction/PreambleDa-silvaNo ratings yet

- New Mexico OCD RulesDocument161 pagesNew Mexico OCD RulesMatt GuisingerNo ratings yet

- Advantages of Long Length PE Pipes for Marine PipelinesDocument86 pagesAdvantages of Long Length PE Pipes for Marine PipelinesA_ValsamisNo ratings yet

- Medical Gas Pipeline RequirementsDocument20 pagesMedical Gas Pipeline RequirementsJoe_AverageNo ratings yet

- Direct Assessment CescorDocument4 pagesDirect Assessment CescorIndraNo ratings yet

- Piping EngineerDocument4 pagesPiping EngineerMasoodMiyanNo ratings yet

- Asme 31 GDocument48 pagesAsme 31 GShriram Avasarkar100% (2)

- 9R4944 - 0411 - EPC BD Vol I - Invitation To Bidder FINAL Rev0 20090623Document164 pages9R4944 - 0411 - EPC BD Vol I - Invitation To Bidder FINAL Rev0 20090623masahin100% (1)

- PMGS Couse Note RevDocument83 pagesPMGS Couse Note RevfisplNo ratings yet

- BMT Offshore Oil and Gas - Services and SolutionsDocument12 pagesBMT Offshore Oil and Gas - Services and SolutionsmiguelfensterseiferNo ratings yet

- Redubar A Register of All Gas RegulationsDocument64 pagesRedubar A Register of All Gas RegulationsMilos BajicNo ratings yet