Professional Documents

Culture Documents

H GR For Mercury Removal

Uploaded by

mohamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H GR For Mercury Removal

Uploaded by

mohamedCopyright:

Available Formats

HGR for Mercury Removal

Granular Activated Carbon

Description Impact of Moisture

Calgon Carbon HGR granular activated carbon is a sulfur 10,000

impregnated carbon. The base carbon is made from select

1,000

grades of bituminous coal and suitable binders to create the

unique pore structure and superior hardness necessary for the 100

Hg Concentration (g/Nm3)

intended service. Activation is controlled to impart a pore

structure that will both accept substantial quantities of 10

impregnant and maintain access for the gas being treated to the

1

complex pore structure. After activation, the sulfur is distributed

in a thin layer over the extensive internal surface area of the 0.1

carbon. This provides it with the unique properties required for

the removal of elemental and organic mercury from natural gas, 0.01 H2O Saturated Gas

air, and by-product hydrogen streams. Dry Gas

0.001

0.0001

The Mercury Removal Process 0

Mercury removal with HGR activated carbon is an established

process for removal of mercury from natural gas and by-product Carbon Bed Depth

hydrogen streams. The mercury is removed from natural gas

feedstocks to LNG and LPG plants to protect aluminum heat Impact of Temperature

exchangers from corrosion. The exhaust air from mercury cell

chlorine plants or metallurgical processing equipment can be 10,000

treated to provide an environmentally safe atmosphere for 1,000

employees and delicate instruments. Type HGR is also used in

mercury cell chloralkali plants to remove mercury from 100

by-product hydrogen streams.

10

The mercury removal process employs a single or dual

vessel adsorption system designed to reduce concentrations 1

to <0.01 g/Nm3 in the treated gas. During the adsorption

process, mercury is attracted to the activated carbon surface 0.1

160F

where a chemical reaction converts the mercury to mercuric

0.01

sulfide. The sulfide product is then retained in the pores of the 100F

carbon granule. Mercury capacity of Type HGR activated 0.001

carbon can be as high as 20% by weight.

0.0001

In a properly designed HGR carbon system, the maximum 0

attainable mercury concentration in treated gas is not affected

by changing the pressure or inlet mercury concentration of the Carbon Bed Depth

gas. However, lowering the gas temperature or moisture content

of the inlet gas will improve the process and further reduce the

mercury concentration in the treated gas. For instance, a gas

Specifications

stream at 150F saturated with moisture will result in a treated

gas containing 0.1 g/Nm3 of mercury. The mercury level in Apparent Density 37 lb./ft3 (approx.)

the treated gas can be further reduced to <0.01 g/Nm3 by Sulfur Content by weight 10% (min)

reducing the temperature to 70F and the moisture to trace

levels. Screen Size by weight, U.S. Sieve Series

On 4 mesh 5.0% (max)

Through 10 mesh 5.0% (max)

Making Water and Air Safer and Cleaner

HGR for Mercury Removal

Granular Activated Carbon

Packaging Limitations of Liability

225 lb. (55 gal.) steel drum, net wt. The Suppliers liability and the Purchasers exclusive remedy for

any cause of action arising out of this transaction, including, but

not limited to, breach of warranty, negligence and/or

Safety Message indemnification, is expressly limited to a maximum of the

Wet activated carbon preferentially removes oxygen from purchase price of spare parts or equipment sold hereunder. All

air. In closed or partially closed containers and vessels, claims of whatsoever nature shall be deemed waived unless

oxygen depletion may reach hazardous levels. If workers made in writing within forty-five (45) days of the occurrence

are to enter a vessel containing carbon, appropriate giving rise to the claim. In no event shall the Supplier, for any

sampling and work procedures for potentially low oxygen reason or pursuant to any provision of the warranty, be liable for

spaces should be followed, including all applicable Federal and incidental or consequential damages or damages in excess of

State requirements. the purchase price, nor shall the Supplier be liable for loss of

profits or fines imposed by governmental agencies.

Your local representative

Making Water and Air Safer and Cleaner

Calgon Carbon Corporation Chemviron Carbon Calgon Carbon Asia

P.O. Box 717 European Operations of 65 Chulia Street

Pittsburgh, PA USA 15230-0717 Calgon Carbon Corporation #37-03 OCBC Centre

1-800-422-7266 Zoning Industriel C de Feluy Singapore 049513

Tel: 412-787-6700 B-7181 Feluy, Belgium Tel: +65 6 221 3500

Fx: 412-787-6713 Tel: + 32 (0) 64 51 18 11 Fx: +65 6 221 3554

Fx: + 32 (0) 64 54 15 91

Copyright 2006 Calgon Carbon Corporation, all rights reserved. CPM-PB1047-0406 www.calgoncarbon.com

You might also like

- 55 Zorflex WovenDocument2 pages55 Zorflex WovenHerik AziziNo ratings yet

- Activated Carbon For Biogas TreatmentDocument8 pagesActivated Carbon For Biogas TreatmentVipul JainNo ratings yet

- 053 Harrison Woca2017pDocument4 pages053 Harrison Woca2017pJuliano. PQMNo ratings yet

- MERSORBDocument3 pagesMERSORBaccofaceNo ratings yet

- Mercury removal from coal via mild thermal treatmentDocument9 pagesMercury removal from coal via mild thermal treatmentvannesaNo ratings yet

- Activated CarbonDocument10 pagesActivated CarbonMurugesh100% (2)

- Filtrasorb 100 PDFDocument2 pagesFiltrasorb 100 PDFHerik AziziNo ratings yet

- CO2 Capture at Ambient Temperature in A Fixed Bed With CaO Based Sorbents 2015 Applied EnergyDocument7 pagesCO2 Capture at Ambient Temperature in A Fixed Bed With CaO Based Sorbents 2015 Applied EnergyserchNo ratings yet

- Flue Gas Cleaning 2017 ENDocument6 pagesFlue Gas Cleaning 2017 ENXhfhhNo ratings yet

- Activated Carbon in Biomethane ProductionDocument31 pagesActivated Carbon in Biomethane ProductionDian Alberto100% (1)

- UOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFDocument9 pagesUOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFPedraza Velandia JhonNo ratings yet

- Coal Gasification and Coal CharacterizationDocument10 pagesCoal Gasification and Coal CharacterizationAnunay JainNo ratings yet

- Exhaust System Inspection and Catalytic Converter OperationDocument4 pagesExhaust System Inspection and Catalytic Converter OperationyermainNo ratings yet

- Accepted ManuscriptDocument29 pagesAccepted ManuscriptAlek KrótkiNo ratings yet

- Activated Carbon and Its Application E 2012Document16 pagesActivated Carbon and Its Application E 2012luis ramirez osccoNo ratings yet

- Specification: (1) Fastener Tightening SpecificationsDocument4 pagesSpecification: (1) Fastener Tightening SpecificationsLuis AlfonsoNo ratings yet

- Coal Quality DeterminationDocument17 pagesCoal Quality DeterminationWulan Dwikusuma Asih100% (1)

- Coconut Activated Carbon: Product BulletinDocument1 pageCoconut Activated Carbon: Product BulletinAbduol llyNo ratings yet

- EP0435008A1 UreaDocument8 pagesEP0435008A1 UreaRuchita PoilkarNo ratings yet

- Coro CleanDocument18 pagesCoro Cleanlaminar ersNo ratings yet

- Flue Gas Cleaning Systems-A Review Paper: December 2017Document9 pagesFlue Gas Cleaning Systems-A Review Paper: December 2017Ali LakhoNo ratings yet

- BIOMASS GASIFICATION PROCESS OVERVIEWDocument23 pagesBIOMASS GASIFICATION PROCESS OVERVIEWbharatNo ratings yet

- Voc PDFDocument4 pagesVoc PDFrkhandelwal9604No ratings yet

- H2S-Removal v2 NDocument6 pagesH2S-Removal v2 NHenry WicaksanaNo ratings yet

- 4-Emission ControlDocument27 pages4-Emission ControlRASHEED MUHAMMADNo ratings yet

- SGL Group'S Outstanding Expertise - HCL Synthesis Units With Steam GenerationDocument45 pagesSGL Group'S Outstanding Expertise - HCL Synthesis Units With Steam GenerationRatan Lal SethNo ratings yet

- SGL8 X 30Document2 pagesSGL8 X 30DucVikingNo ratings yet

- ArtigoDocument9 pagesArtigo1986crisNo ratings yet

- Handout Jacobs Css - Superclaus ProcessDocument1 pageHandout Jacobs Css - Superclaus ProcessJose Juan ViopNo ratings yet

- Shell Cansolv CO2 Capture System Fact SheetDocument2 pagesShell Cansolv CO2 Capture System Fact SheetIrfanNo ratings yet

- Cement Manufacturing: Environmental Guidelines ForDocument4 pagesCement Manufacturing: Environmental Guidelines FornathabbuNo ratings yet

- Production: Activated Carbon, Also Called Activated Charcoal or Activated Coal Is A Form of Carbon ThatDocument13 pagesProduction: Activated Carbon, Also Called Activated Charcoal or Activated Coal Is A Form of Carbon ThatShanmugam RameshNo ratings yet

- Cal TR12x40Document2 pagesCal TR12x40Herik AziziNo ratings yet

- Axens AdsorbentsDocument19 pagesAxens AdsorbentsfloretotesoroNo ratings yet

- 08 - FGD by Ammonia Scrubbing in CFB Power PlantDocument4 pages08 - FGD by Ammonia Scrubbing in CFB Power PlantNishantNo ratings yet

- Activated Carbon Adsorption: Toggle Sub Menusub Menutoggle Main Menumain MenuDocument7 pagesActivated Carbon Adsorption: Toggle Sub Menusub Menutoggle Main Menumain MenuVamsi YashodaNo ratings yet

- Purge Gas RecoveryDocument9 pagesPurge Gas RecoveryMithilesh ShamkuwarNo ratings yet

- Argon Fire Systems The Simple Solution: ExtinguishingDocument10 pagesArgon Fire Systems The Simple Solution: ExtinguishingJuhar MohammedNo ratings yet

- Natural Gas ProcessingDocument24 pagesNatural Gas ProcessingMuhammad Shariq KhanNo ratings yet

- Korpi El 1997Document7 pagesKorpi El 1997Daniell MvrIlloNo ratings yet

- Flue Gas Cleaning Systems-A Review Paper: December 2017Document9 pagesFlue Gas Cleaning Systems-A Review Paper: December 2017Muhammad Hamza LodhiNo ratings yet

- Svendsen CATO Amsterdam June 2014Document43 pagesSvendsen CATO Amsterdam June 2014jiangshencaoNo ratings yet

- Duan at Al. 2019 InglêsDocument11 pagesDuan at Al. 2019 InglêsLuanna CamposNo ratings yet

- Active CharcoalDocument12 pagesActive CharcoalMitko100% (1)

- Problems Associated With MercuryDocument3 pagesProblems Associated With MercuryMuhammad Ihsan AljabbarNo ratings yet

- Preparation of Sorbents. The PotassiumDocument5 pagesPreparation of Sorbents. The PotassiumFarah TalibNo ratings yet

- CO2 CaptureDocument5 pagesCO2 CaptureSarvesh JaiswalNo ratings yet

- Chemical Engineering Journal: A.S. González, M.G. Plaza, F. Rubiera, C. PevidaDocument10 pagesChemical Engineering Journal: A.S. González, M.G. Plaza, F. Rubiera, C. PevidaClara RojasNo ratings yet

- AMMONIA Syn Gas Drying With Z4-01Document4 pagesAMMONIA Syn Gas Drying With Z4-01raghu4594No ratings yet

- NAWTEC - New Trends On Flue Gas CleaningDocument14 pagesNAWTEC - New Trends On Flue Gas CleaningADalPozzoNo ratings yet

- Coal Gamification Technology SCGDocument4 pagesCoal Gamification Technology SCGSambit DashNo ratings yet

- Technology selection for a natural gas plantDocument13 pagesTechnology selection for a natural gas plantsoheilkhosh3311No ratings yet

- UltraCat Ceramic BrochureDocument4 pagesUltraCat Ceramic BrochureMarco TorreNo ratings yet

- Methanation CatalystDocument4 pagesMethanation CatalystBạch Trung Phú100% (2)

- Granular Activated Carbon and Powdered Activated CarbonDocument6 pagesGranular Activated Carbon and Powdered Activated CarbonAnjali Kothe100% (1)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 01 - X - Appendix 1-C - Project Closeout ChecklistDocument6 pages01 - X - Appendix 1-C - Project Closeout ChecklistmohamedNo ratings yet

- PF - Passavant Shut-Off DevicesDocument4 pagesPF - Passavant Shut-Off DevicesmohamedNo ratings yet

- Project-Closeout-Checklist - Structural SlabDocument2 pagesProject-Closeout-Checklist - Structural SlabmohamedNo ratings yet

- Contractor Project Closeout Procedure and ChecklistDocument1 pageContractor Project Closeout Procedure and ChecklistmohamedNo ratings yet

- PF - Johnson Screens Multi Rake Bar Screen Defender DuoDocument2 pagesPF - Johnson Screens Multi Rake Bar Screen Defender DuomohamedNo ratings yet

- PF - PASSAVANT Bar Screen With Grab Cleaner SGRDocument2 pagesPF - PASSAVANT Bar Screen With Grab Cleaner SGRmohamedNo ratings yet

- PF - Geiger Climber Screen KRCDocument2 pagesPF - Geiger Climber Screen KRCmohamedNo ratings yet

- PF - Passavant Revolving Chain Screen Kur-CDocument2 pagesPF - Passavant Revolving Chain Screen Kur-Cmohamed100% (1)

- CourseBook Semester1 AlTarbyiahDocument94 pagesCourseBook Semester1 AlTarbyiahmohamedNo ratings yet

- Bilfinger Water Technologies - Solutions For Fine and Micro-SievingDocument8 pagesBilfinger Water Technologies - Solutions For Fine and Micro-SievingmohamedNo ratings yet

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- PF - PASSAVANT Cable Operated Bar Screen RMGWDocument2 pagesPF - PASSAVANT Cable Operated Bar Screen RMGWmohamedNo ratings yet

- What Is An Oil and Natural Gas ReservoirDocument104 pagesWhat Is An Oil and Natural Gas ReservoirmohamedNo ratings yet

- Bilfinger Water Technologies - Solutions For Sludge TreatmentDocument8 pagesBilfinger Water Technologies - Solutions For Sludge TreatmentmohamedNo ratings yet

- Bilfinger Water Technologies - Solutions For Biological TreatmentDocument12 pagesBilfinger Water Technologies - Solutions For Biological TreatmentmohamedNo ratings yet

- Oil and Gas FormationDocument5 pagesOil and Gas FormationmohamedNo ratings yet

- PF - Geiger Climber Screen KRCDocument2 pagesPF - Geiger Climber Screen KRCmohamedNo ratings yet

- Natural Gas Production: FormationDocument11 pagesNatural Gas Production: FormationmohamedNo ratings yet

- Bilfinger Water Technologies - Solutions For Inlet Works - HeadworksDocument20 pagesBilfinger Water Technologies - Solutions For Inlet Works - HeadworksmohamedNo ratings yet

- Bilfinger Water Technologies - Global Unit Water Treatment - EDocument40 pagesBilfinger Water Technologies - Global Unit Water Treatment - EmohamedNo ratings yet

- What Is Natural GasDocument7 pagesWhat Is Natural GasmohamedNo ratings yet

- Turbo Expander FinalDocument25 pagesTurbo Expander Finalmohamed100% (2)

- Natural Gasprocessing TopicstDocument2 pagesNatural Gasprocessing TopicstmohamedNo ratings yet

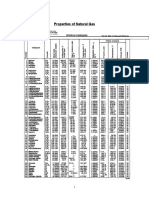

- Properties of Natural GasDocument9 pagesProperties of Natural GasmohamedNo ratings yet

- Thermal Design of Shell and Tube Heat ExchangersDocument5 pagesThermal Design of Shell and Tube Heat ExchangersmohamedNo ratings yet

- NATURAL GAS PROCESSING TROUBLESHOOTINGDocument17 pagesNATURAL GAS PROCESSING TROUBLESHOOTINGmohamedNo ratings yet

- Natural Gas TreatmentDocument33 pagesNatural Gas Treatmentmohamed100% (1)

- Natural Gasprocessing TopicstDocument2 pagesNatural Gasprocessing TopicstmohamedNo ratings yet

- NATURAL GAS SPECIFIC COURSEDocument17 pagesNATURAL GAS SPECIFIC COURSEmohamedNo ratings yet

- NATURAL GAS SPECIFIC COURSEDocument28 pagesNATURAL GAS SPECIFIC COURSEmohamed100% (1)

- DMVPN TutorialDocument10 pagesDMVPN TutorialwahyuabadiNo ratings yet

- 5phaseinterface Lead With Electrical IsolationDocument40 pages5phaseinterface Lead With Electrical IsolationsiromexNo ratings yet

- 4N35 OptocouplersDocument7 pages4N35 OptocouplersattapapaNo ratings yet

- Oracle HRMS Work StructureDocument36 pagesOracle HRMS Work StructureshrinawNo ratings yet

- ME 311 Problems on Exact Solutions of Navier-Stokes EquationDocument2 pagesME 311 Problems on Exact Solutions of Navier-Stokes EquationMukesh MalviyaNo ratings yet

- Network Forensic System For Port Scanning Attack: Atul Kant Kaushik, Emmanuel S. Pilli, R.C. JoshiDocument6 pagesNetwork Forensic System For Port Scanning Attack: Atul Kant Kaushik, Emmanuel S. Pilli, R.C. JoshigrandsunilNo ratings yet

- Amm 26-00 General 01Document38 pagesAmm 26-00 General 01Adhemir De León100% (1)

- Solar Farm Construction Schedule (Smartsheet)Document5 pagesSolar Farm Construction Schedule (Smartsheet)Adam SH0% (1)

- Digital GovernansiDocument32 pagesDigital GovernansiAnonymous kpND1j8hNo ratings yet

- IOM-P14-R0 Quarter Turn BVDocument9 pagesIOM-P14-R0 Quarter Turn BVDonovan BonnerNo ratings yet

- John Berry ResumeDocument3 pagesJohn Berry Resumeapi-230798470No ratings yet

- Latches & Flip-Flops: EE 2730 Fall 2010Document60 pagesLatches & Flip-Flops: EE 2730 Fall 2010lsu225No ratings yet

- Mentorpaper 102908Document79 pagesMentorpaper 102908rohan357No ratings yet

- Making Definitions Daily Lesson LogDocument2 pagesMaking Definitions Daily Lesson LogMa-Anne Joyce RodiNo ratings yet

- Geo-E2010 Advanced Soil Mechanics L Wojciech Sołowski: 14 March 2017Document75 pagesGeo-E2010 Advanced Soil Mechanics L Wojciech Sołowski: 14 March 2017Anonymous D5s00DdU100% (1)

- 901 User ManualDocument23 pages901 User ManualHappy DaysNo ratings yet

- Schematic Diagram For Model 2216: All VersionsDocument1 pageSchematic Diagram For Model 2216: All VersionsZa RacsoNo ratings yet

- Jsa Installation of Supports and Cable Racks1Document16 pagesJsa Installation of Supports and Cable Racks1loveson709100% (3)

- Nails Big Book 2012 13Document32 pagesNails Big Book 2012 13John100% (1)

- F3B-07!01!2014 Gearbox ManualDocument39 pagesF3B-07!01!2014 Gearbox ManualMartin PayneNo ratings yet

- Art of Theatre On New Media Platform & Audience Viewing ExperienceDocument20 pagesArt of Theatre On New Media Platform & Audience Viewing ExperienceYvonne KayNo ratings yet

- View TendDocument125 pagesView TendYin ThoNo ratings yet

- Bond Strength of Mortar To Masonry Units: Standard Test Method ForDocument8 pagesBond Strength of Mortar To Masonry Units: Standard Test Method ForFranky HernandezNo ratings yet

- Oracle Banking Platform Extensibility GuideDocument330 pagesOracle Banking Platform Extensibility Guidekiran100% (1)

- Shell Impact Plate SimulationDocument16 pagesShell Impact Plate Simulationsravis69No ratings yet

- Procedure ITP Austenitic SS Rev.0.3Document13 pagesProcedure ITP Austenitic SS Rev.0.3Ferdie OSNo ratings yet

- Ericsson - Multi Band CellDocument36 pagesEricsson - Multi Band CellDzung Tran Viet100% (6)

- UHU Servo Controller 300 enDocument13 pagesUHU Servo Controller 300 enZoltán NémetNo ratings yet

- 01-Toy Product DesignDocument54 pages01-Toy Product DesignJuanNo ratings yet

- Inspecting ammonia storage tank welds with non-intrusive ultrasonic robotDocument13 pagesInspecting ammonia storage tank welds with non-intrusive ultrasonic robotMechNo ratings yet