Professional Documents

Culture Documents

Technical Inspection Report Due To Corrosion Ocured On LPC Pump G-2707

Uploaded by

Junie PranantaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Inspection Report Due To Corrosion Ocured On LPC Pump G-2707

Uploaded by

Junie PranantaCopyright:

Available Formats

Originated : Juni Prananta (Arrad Site Engineer)

To : Bpk. Febri Wahyudi (SRU Proc. Engineer)

Cc : Bpk. Suratno (Proc. Engineering Asst. Manager)

Bpk. Chasril Hanif (Regasification Proc. Engineer)

Bpk. Hidayatullah (Utility Proc. Engineer)

Bpk. Jusli (Arrad Acc. Manager)

Subject : Technical inspection report due to corrosion ocured on LPC pump G-2707

Dear All,

As the actually condition on G-2707A that has look corroded in maintenance shop. Arrad team and PAG

process engineer perform the inspection. As the view of corrosion that occur, there is suspection as

pitting and cavity corrosion on the pump block.

The Problems

As the system overview of condensate, steam

and BFW in SRU plant, that the G-2707A in order

as low pressure steam condensate distribution

pump. This pump is working with pressure

setting 20,3 bar steam condensate from D-2705.

Steam condensate on D-2705 (LPC storage

drum) as storage system of steam condensate

before distributing to E-2807, E-2804A/B/C/D &

E-2901 as boiler feed water. There is has no

treatment anything to oxygen dissolve

prevention. As we know the possibilities source

of oxygen in condensate can entry from

entrussion of air around leaky pump seal oxygen

can leak into a system via absorption into the

condensate in atmospheric systems (vented

receiver tanks), with raw water in leakage, and

as air drawn in through small leaks, when the

system is under a vacuum or operates

intermittently and pulls a vacuum as the equipment cools (e.g., at threaded joints, heat exchangers,

faulty steam traps, packing glands, and vented receivers).

The Reaction of oxygen attack :

4Fe + 6H2O + 3O2 4Fe(OH)3 (1)

The ferric hydroxide then generally reverts in the condensate to form particulate iron oxyde :

2Fe(OH)3 Fe2O3 + 3H2O (2)

Severe pitting caused by oxygen attack can

frequently be found at or just below the liquid

surface in partially filled vessels and pipes, and

at points above the surface where condensate

droplets are formed. Although chemical

solutions to this problem exist, air in leakage

should be solved first by making the required

system repairs.

E-2705 Sampling Point at SRU

Concern

There is unproperly sampling skid on D-2705 sample point to

check oxygen content. The analysis of oxygen in steam

condensate return storage (D-2705) is important to know

how much oxygen that dissolve in steam condensate. ARRAD

team has reported the unproperly sampling point to oxygen

content check on D-2705 to PAG (PE and Operator) since

2013 Deaerator A Sampling Point at Utilities

Discussion

Possibilities of other equipment damage by oxygen corrosion that may be occur by oxygen attack is high,

due to there is no treatment of oxygen anything in condensate return system inlet to D-2705. Addition

of oxygen removal equipment or oxygen scavanging system is important to considered

Corrosion cell mechanism

You might also like

- Troubleshooting Steam EjectorsDocument6 pagesTroubleshooting Steam EjectorsGabriel Eduardo Contreras PerozoNo ratings yet

- Air Conditioning Maintenance Procedure - RevisionDocument10 pagesAir Conditioning Maintenance Procedure - RevisionSuryo Eka FNo ratings yet

- P P NG Abbrev at Ons: AFC A F CDocument11 pagesP P NG Abbrev at Ons: AFC A F COlajide AkekeNo ratings yet

- AB-507 Installed Fired Heaters GuidelineDocument36 pagesAB-507 Installed Fired Heaters GuidelineRosa galindoNo ratings yet

- Plant Inspections PDFDocument5 pagesPlant Inspections PDFMohamedNo ratings yet

- Disomat Tersus: Instruction ManualDocument268 pagesDisomat Tersus: Instruction ManualMohamed Hamad100% (1)

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNo ratings yet

- Cleaning Balls PDFDocument8 pagesCleaning Balls PDFAlexandruNicolaNo ratings yet

- An Overview of Pipeline Leak Detection TechnologiesDocument9 pagesAn Overview of Pipeline Leak Detection TechnologiesharmlesdragonNo ratings yet

- Convection Section CleaningDocument10 pagesConvection Section CleaningSuresh RamakrishnanNo ratings yet

- Guide To Prepare WPQR According To Asme Section IxDocument5 pagesGuide To Prepare WPQR According To Asme Section IxHoque AnamulNo ratings yet

- Physical Pharmacy Answer Key-RED PACOPDocument37 pagesPhysical Pharmacy Answer Key-RED PACOPMelbhon Fabro Ramos100% (1)

- CESCO Technical ProposalDocument2 pagesCESCO Technical ProposalthmaraishriNo ratings yet

- Pre-Commissioning Check Sheet: PipingDocument1 pagePre-Commissioning Check Sheet: PipinghrimklimNo ratings yet

- Tie in MosDocument2 pagesTie in MosAAISATNo ratings yet

- Revised PPT SG HXDocument44 pagesRevised PPT SG HXskgbondNo ratings yet

- Standard Procedure For Regenerative System Chemical Cleaning 210 MWDocument9 pagesStandard Procedure For Regenerative System Chemical Cleaning 210 MWSiva KulanjiNo ratings yet

- Record of Oil Flush - KPMOG PDFDocument1 pageRecord of Oil Flush - KPMOG PDFCokro YudhaNo ratings yet

- Samsung VRF Installation Trend For BuildingDocument55 pagesSamsung VRF Installation Trend For BuildingNaseemNo ratings yet

- PPT11 12 Ic 2.3 PPT1112 Id 2.4 Realized That The Methods of Philosophy LeadDocument47 pagesPPT11 12 Ic 2.3 PPT1112 Id 2.4 Realized That The Methods of Philosophy LeadShayne Pagwagan100% (1)

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- Deaerator Brochure 01Document6 pagesDeaerator Brochure 01Rafael Cavalcanti50% (2)

- Heat Exchanger Tube Material SpecificationsDocument2 pagesHeat Exchanger Tube Material SpecificationssdrtfgNo ratings yet

- Condenser Cladding InfoDocument37 pagesCondenser Cladding Infoabhishe_reenaNo ratings yet

- 1113 Maintenance of PRVDocument63 pages1113 Maintenance of PRVhardito sussatrioNo ratings yet

- J & E Hall Refrigeration Sdn. BHD.: Dmahu Technical ReportDocument7 pagesJ & E Hall Refrigeration Sdn. BHD.: Dmahu Technical Reportamirin_kingNo ratings yet

- Hitachi Be Bic On Air CompressorDocument2 pagesHitachi Be Bic On Air CompressorFOTOPLES Digital PrintingNo ratings yet

- Castable RefractoryDocument4 pagesCastable RefractorySarbajitMannaNo ratings yet

- 1.Cooling Tower Operation & Maintenance manual 冷却塔操作维护手册-ENDocument15 pages1.Cooling Tower Operation & Maintenance manual 冷却塔操作维护手册-ENNissar Hussain100% (2)

- Compliance Statement - PPR CopraxDocument1 pageCompliance Statement - PPR CopraxAhmed HelmyNo ratings yet

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Document16 pagesDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227No ratings yet

- 345 Testing THDocument6 pages345 Testing THDjeisonSeccoNo ratings yet

- GS P&D Archsd 2012Document127 pagesGS P&D Archsd 2012Andy Lee100% (1)

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDocument27 pagesTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNo ratings yet

- Installer's Guide For Condensing Units: 2TTB0 & 2TTB2Document8 pagesInstaller's Guide For Condensing Units: 2TTB0 & 2TTB2jimbodunkyNo ratings yet

- List of Activities For A Green Field Project A. Site DevelopmentDocument2 pagesList of Activities For A Green Field Project A. Site Developmentarajamani78No ratings yet

- TCVN 4513-1988 Internal Water Supply - Design Standard PDFDocument37 pagesTCVN 4513-1988 Internal Water Supply - Design Standard PDFDoThanhTungNo ratings yet

- Installation Manual OXYFLEX® MF1100 October 2014 PDFDocument8 pagesInstallation Manual OXYFLEX® MF1100 October 2014 PDFRomuel PioquintoNo ratings yet

- PipingDocument4 pagesPipingmshkNo ratings yet

- Steam BoilerDocument3 pagesSteam BoilerMohammad AzlanNo ratings yet

- Project Report On Threading Drill PipesDocument34 pagesProject Report On Threading Drill PipesVamshi KrishnaNo ratings yet

- C1729 Is A New ASTM Standard For Aluminum JacketingDocument2 pagesC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- Fire Fighting SystemsDocument4 pagesFire Fighting SystemsUsmanNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Abilene, Inc.: An Introduction To Boiler MaintenanceDocument19 pagesAbilene, Inc.: An Introduction To Boiler MaintenanceSubbarayan SaravanakumarNo ratings yet

- Foam Monitor - F - 091318Document16 pagesFoam Monitor - F - 091318rusli bahtiarNo ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- Factors Contributing To Foarming Crude OilDocument11 pagesFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- PAL - Construction GuidelinesDocument28 pagesPAL - Construction GuidelinesCarew Mohammed AbayomiNo ratings yet

- HTR900 Inspection, Maintenance, and TestingDocument27 pagesHTR900 Inspection, Maintenance, and TestingVicente Regulez FernandezNo ratings yet

- Catalogue Tan Hung 17 (1) .9.09Document48 pagesCatalogue Tan Hung 17 (1) .9.09ngocdhxd92No ratings yet

- Interzone 954 Antifungus ReportDocument10 pagesInterzone 954 Antifungus Reportsteffy182100% (1)

- Hydrotest WaiverDocument4 pagesHydrotest Waiverbidyut100No ratings yet

- TCW Tube CleaningDocument56 pagesTCW Tube CleaningMarcela Vargas GomezNo ratings yet

- CRMS ItpDocument2 pagesCRMS Itparockiyathass100% (1)

- Mechanical Boiler Inspection ReportDocument1 pageMechanical Boiler Inspection ReportAfzal pathanNo ratings yet

- Hazards From ACCDocument3 pagesHazards From ACCS V NAGESHNo ratings yet

- Condensate ReturnDocument24 pagesCondensate Returnwaheed2286No ratings yet

- The Dangers of Uncontrolled Gases in Steam Systems: PecialDocument3 pagesThe Dangers of Uncontrolled Gases in Steam Systems: PecialOsamah AlzubadiNo ratings yet

- El GS Ad 19Document2 pagesEl GS Ad 19Ali Ahmed PathanNo ratings yet

- EP Corrosion PDFDocument57 pagesEP Corrosion PDFHatem JafouraNo ratings yet

- Wet Lay-up/Passivation - Basic Understanding of Hydrazine TreatmentDocument13 pagesWet Lay-up/Passivation - Basic Understanding of Hydrazine TreatmentAhsan Abbas100% (2)

- Steam Product March 2019Document1 pageSteam Product March 2019Junie PranantaNo ratings yet

- Steam Product March 2019Document5 pagesSteam Product March 2019Junie PranantaNo ratings yet

- Steam Product March 2019Document1 pageSteam Product March 2019Junie PranantaNo ratings yet

- HWO Tempate (Oct 12 Version)Document1 pageHWO Tempate (Oct 12 Version)Junie PranantaNo ratings yet

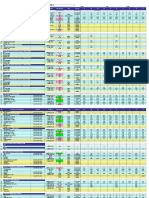

- Utility Report - 4th Week Feb 2013Document15 pagesUtility Report - 4th Week Feb 2013Junie PranantaNo ratings yet

- BIODIESEL NEGRO Black Diesel Cheap Fuel From Waste OilDocument15 pagesBIODIESEL NEGRO Black Diesel Cheap Fuel From Waste Oilambrosiofdm100% (1)

- Recomendation Letter - JINGKI MaulidinDocument1 pageRecomendation Letter - JINGKI MaulidinJunie PranantaNo ratings yet

- 062-CKL-OP-3308 Boiler-A System Line Up Rev A5Document13 pages062-CKL-OP-3308 Boiler-A System Line Up Rev A5Junie PranantaNo ratings yet

- Technical Inspection Report Due To Boiler Water Low Level On E-2804 ABCD & E-2901Document3 pagesTechnical Inspection Report Due To Boiler Water Low Level On E-2804 ABCD & E-2901Junie PranantaNo ratings yet

- Beverages, Sugars & ConfectineryDocument176 pagesBeverages, Sugars & ConfectinerynikparisNo ratings yet

- New Emulsion Fuel Production Technology Will It Save The EarthDocument13 pagesNew Emulsion Fuel Production Technology Will It Save The Earthvuongcoi102No ratings yet

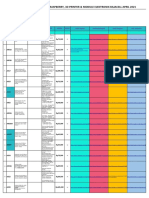

- Sow Offline Chemical Pagcs17040 Ex Pagcs17035Document10 pagesSow Offline Chemical Pagcs17040 Ex Pagcs17035Junie PranantaNo ratings yet

- News IsoDocument29 pagesNews IsoRicardo Queiroga100% (1)

- Fuel Value CalculatorDocument3 pagesFuel Value CalculatorMuhammad IrfanNo ratings yet

- Polynomials Class 9THDocument4 pagesPolynomials Class 9THAbinash KatochNo ratings yet

- Power System Analysis and Design 6Th Edition Glover Solutions Manual Full Chapter PDFDocument58 pagesPower System Analysis and Design 6Th Edition Glover Solutions Manual Full Chapter PDFDanielleNelsonxfiq100% (10)

- An Adaptive Hello Messaging Scheme For Neighbor Discovery in On-Demand MANET Routing ProtocolsDocument4 pagesAn Adaptive Hello Messaging Scheme For Neighbor Discovery in On-Demand MANET Routing ProtocolsJayraj SinghNo ratings yet

- 1 Huawei 3g Capacity OptimizationDocument39 pages1 Huawei 3g Capacity OptimizationCharles W GitahiNo ratings yet

- Bone Specific Alkaline PhophataseDocument6 pagesBone Specific Alkaline PhophataseMohan DesaiNo ratings yet

- Image - VC - Full DocumentDocument106 pagesImage - VC - Full DocumentSanthosh ShivaNo ratings yet

- Understanding Water Discounts and Lye Solution in SoapmakingDocument7 pagesUnderstanding Water Discounts and Lye Solution in SoapmakingIoanaNo ratings yet

- IMO Resuts - Science Olympiad FoundationDocument2 pagesIMO Resuts - Science Olympiad FoundationAbhinav SinghNo ratings yet

- Fisher 9500 Butterfly Control ValveDocument12 pagesFisher 9500 Butterfly Control ValveOscarNo ratings yet

- Tanaka, Murakami, Ooka - Effects of Strain Path Shapes On Non-Proportional Cyclic PlasticityDocument17 pagesTanaka, Murakami, Ooka - Effects of Strain Path Shapes On Non-Proportional Cyclic PlasticityDavid C HouserNo ratings yet

- Kathrein 80010430 PDFDocument1 pageKathrein 80010430 PDFRaúl Fernández SánchezNo ratings yet

- Periodicity in 3D Lab Report FormDocument2 pagesPeriodicity in 3D Lab Report FormZIX326100% (1)

- Mathematical Model of Transportation ProblemDocument14 pagesMathematical Model of Transportation ProblemwasimghghNo ratings yet

- TEMPLATE School Data Analysis Report 1st Periodic TestDocument3 pagesTEMPLATE School Data Analysis Report 1st Periodic TestDaisy Reyes CayabyabNo ratings yet

- Update DES Day Pit 9 Per Jam 08Document1 pageUpdate DES Day Pit 9 Per Jam 08Iccang DewiNo ratings yet

- Características Clínicas y Resultados de Los Pacientes Con COVID-19 Con Ventilación Invasiva en ArgentinaDocument10 pagesCaracterísticas Clínicas y Resultados de Los Pacientes Con COVID-19 Con Ventilación Invasiva en ArgentinaSMIBA MedicinaNo ratings yet

- STS Cat-1Document490 pagesSTS Cat-1Sri AdityaNo ratings yet

- Ranjit Kumar-Research Methodology A Step-by-Step G-15-16Document2 pagesRanjit Kumar-Research Methodology A Step-by-Step G-15-16Trendy NewsNo ratings yet

- WBSETCL Suggestive Paper..Document10 pagesWBSETCL Suggestive Paper..Pà PáïNo ratings yet

- Lipid TestDocument4 pagesLipid TestHak KubNo ratings yet

- CNS TechnicianDocument2 pagesCNS TechnicianSohailNo ratings yet

- Holiday Homework Class 12 MathematicsDocument2 pagesHoliday Homework Class 12 MathematicsKartik SharmaNo ratings yet

- Catalog Produk Arduino Rajacell Ver10.4 - End - UserDocument192 pagesCatalog Produk Arduino Rajacell Ver10.4 - End - UserSanto SetiawanNo ratings yet

- Numerical Analisis 2015Document357 pagesNumerical Analisis 2015mariaNo ratings yet

- On The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignDocument8 pagesOn The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignJiyang WangNo ratings yet