Professional Documents

Culture Documents

TUGAS-03 Metlas

Uploaded by

Mr. EverywhereOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TUGAS-03 Metlas

Uploaded by

Mr. EverywhereCopyright:

Available Formats

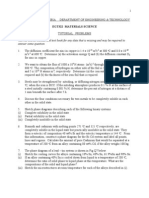

PROBLEMS CHAP.

2

2.1 In one welding experiment, 50-mm-thick steel plates were joined using electro-slag welding. The

current and voltage were 480A and 34V, respectively. The heat losses to the water-cooled copper

shoes and by radiation from the surface of the slag pool were 1275 and 375 cal/s, respectively.

Calculate the heat source efficiency.

2.2 It has been reported that the heat source efficiency in electro-slag welding increases with increasing

thickness of the work-piece. Explain why.

2.3 (a) Consider the welding of 25.4-mm-thick steel plates. Do you prefer to apply Rosenthals two- or

three-dimensional heat flow equation for full-penetration electron beam welds? What about bead-

on-plate gastungsten arc welds?

(b) Suppose you are interested in studying the solidification structure of the weld metal and you wish

to calculate the temperature distribution in the weld pool. Do you expect Rosenthals equations to

provide reliable thermal information in the pool? Why or why not?

(c) In multi-pass welding do you expect a higher or lower cooling rate in the first pass than in the

subsequent passes? Why?

2.4 Large aluminum sheets 1.6 mm thick are butt welded using GTAW with alternating current. The

current, voltage, and welding speed are 100A, 10V, and 2mm/s, respectively. Calculate the peak

temperatures at distance of 1.0 and 2.0 mm from the fusion boundary. Assume 50% arc efficiency.

2.5 Bead-on-plate welding of a thick-section carbon steel is carried out using 200A, 20V, and 2mm/s.

The preheat temperature and arc efficiency are 100C and 60%, respectively. Calculate the cross-

sectional area of the weld bead.

2.6 (a) Do you expect to have difficulty in achieving steady-state heat flow during girth (or

circumferential) welding of tubes by keeping constant heat input and welding speed? Explain

why. What is the consequence of the difficulty?

(b) Suggest two methods that help achieve steady-state heat flow during girth welding.

2.7 A cold-rolled AISI 1010 low-carbon steel sheet 0.6 mm thick was tested for surface reflectivity in

CO2 laser beam welding under the following different surface conditions:

(a) as received;

(b) oxidized in air furnace at 1000C for 20 s;

(c) oxidized in air furnace at 1000C for 40 s;

(d) covered with steel powder.

In which order does the reflectivity rank in these surface conditions and why?

2.8 It was observed in YAG laser beam welding of AISI 409 stainless steel that under the same power

the beam size affected the depthwidth ratio of the resultant welds significantly. Describe and

explain the effect.

2.9 Calculate the thermal cycle at the top surface of a very thick carbon steel plate at 5 mm away from

the centerline of the weld surface. power of the arc is 2kW, the arc efficiency 0.7, the travel speed

2mm/s, and the preheat temperature 100C.

2.10 Is the transverse cross section of the weld pool at a fixed value of x perfectly round according to

Rosenthals three-dimensional heat flow equation? Explain why or why not based on the equation.

What does your answer tell you about the shape of the transverse cross section of a weld based on

Rosenthals three-dimensional equation?

You might also like

- TUGAS-03 Metlas PDFDocument1 pageTUGAS-03 Metlas PDFyanuarNo ratings yet

- Heat Flow in Welding ExplainedDocument3 pagesHeat Flow in Welding ExplainedDavico MartinezNo ratings yet

- Previous Years GATE Questions Sub: Production Technology (Welding)Document12 pagesPrevious Years GATE Questions Sub: Production Technology (Welding)KAUSTUB CHAUHANNo ratings yet

- Resistance and Special Welding.0001Document100 pagesResistance and Special Welding.0001KKNo ratings yet

- Welding of Austenitic Stainless Steel Using Double Sided Arc Welding ProcessDocument6 pagesWelding of Austenitic Stainless Steel Using Double Sided Arc Welding ProcessShaat KumarNo ratings yet

- Tugas 03 Sri RamayantiDocument6 pagesTugas 03 Sri RamayantiSri Ramayanti SimanjuntakNo ratings yet

- Heat-Treatment of High Carbon Steel Wire - PatentingDocument4 pagesHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- MSE3094 HW#8 Solutions April 1, 2011 1) : A) The Data IsDocument5 pagesMSE3094 HW#8 Solutions April 1, 2011 1) : A) The Data IsradarskiNo ratings yet

- Tugas Metalurgi Las - Heat Flow in WeldingDocument4 pagesTugas Metalurgi Las - Heat Flow in WeldingRhidiyan Waroko100% (4)

- Transient High-Frequency Welding Simulations of Dual-Phase SteelsDocument9 pagesTransient High-Frequency Welding Simulations of Dual-Phase Steelsc131508No ratings yet

- 1 2 Resistance and Special Welding Q A For StudentsDocument10 pages1 2 Resistance and Special Welding Q A For StudentsRavinder AntilNo ratings yet

- ME2151Document6 pagesME2151Delroy JqNo ratings yet

- 로우 히트 인풋 용접으로 다중 패스 FCAW-S 용접 금속의 충격 강도 향상Document6 pages로우 히트 인풋 용접으로 다중 패스 FCAW-S 용접 금속의 충격 강도 향상Rami GhorbelNo ratings yet

- Aws Cwi QuestionDocument8 pagesAws Cwi Questionfrenskiran75% (4)

- 7 4Document8 pages7 4Izwan HassanNo ratings yet

- Thermit Welding of Chromium Vanadium RailsteelDocument8 pagesThermit Welding of Chromium Vanadium Railsteelsantu_23No ratings yet

- Resistance and Special WeldingDocument24 pagesResistance and Special WeldingKBSMANITNo ratings yet

- Materials Science problems and conceptsDocument4 pagesMaterials Science problems and conceptsaoguNo ratings yet

- Laser Beam Welding of Quenched and Tempered Astm A 517 GR.B SteelDocument7 pagesLaser Beam Welding of Quenched and Tempered Astm A 517 GR.B SteelbiancogallazziNo ratings yet

- Advanced Manufacturing ScienceDocument2 pagesAdvanced Manufacturing Sciencemukesh3021No ratings yet

- CA 6NM CastingsDocument11 pagesCA 6NM CastingsvasanthiNo ratings yet

- How Interpass Temp Affects Weld QualityDocument1 pageHow Interpass Temp Affects Weld QualityDries VandezandeNo ratings yet

- A Presentation On: Use of Copper Heat Sink To Improve Quality of Weld in AISI 304LDocument20 pagesA Presentation On: Use of Copper Heat Sink To Improve Quality of Weld in AISI 304Lrakesh ranjanNo ratings yet

- FCAW Temper Bead Iamot - OrgDocument7 pagesFCAW Temper Bead Iamot - OrgClaudia MmsNo ratings yet

- CWEng SampleQuestionsDocument8 pagesCWEng SampleQuestionsSungJun ParkNo ratings yet

- The Influence of Heat Input To Mechanical PropertiDocument7 pagesThe Influence of Heat Input To Mechanical PropertiDevran KarabulutNo ratings yet

- l'LA!MA Hot Machining For New Engineering Materials : Wear, 139 (1990) 251-267 251Document17 pagesl'LA!MA Hot Machining For New Engineering Materials : Wear, 139 (1990) 251-267 251GAURAV KUMARNo ratings yet

- Introduction CHAPTER 1Document12 pagesIntroduction CHAPTER 1Sp PatelNo ratings yet

- Creep and Creep Damage Assessment in P91 Weld JointsDocument12 pagesCreep and Creep Damage Assessment in P91 Weld JointsDeepakNo ratings yet

- Proto Type Arc FurnaceDocument5 pagesProto Type Arc FurnaceMoudeh ToumaNo ratings yet

- MMPDS-11 1 July 2016 IGH Lloy Teels 2.5.0 C H - A S: Previous PageDocument11 pagesMMPDS-11 1 July 2016 IGH Lloy Teels 2.5.0 C H - A S: Previous Pageanon_558118723No ratings yet

- Effect of welding parameters on tensile strength of 2219 aluminum alloyDocument6 pagesEffect of welding parameters on tensile strength of 2219 aluminum alloyhana haddadNo ratings yet

- Applying Computer Simulation in Improving Heat Treating Condition of Thin High-Carbon Steel PartsDocument5 pagesApplying Computer Simulation in Improving Heat Treating Condition of Thin High-Carbon Steel PartssathishelakkiyaNo ratings yet

- Erdem 2005Document7 pagesErdem 2005vinayakNo ratings yet

- Arc Welding SessionalDocument13 pagesArc Welding Sessionalnehar shubheschaNo ratings yet

- Materials Characterization: SciencedirectDocument7 pagesMaterials Characterization: SciencedirectSmruti Ranjan PattanayakNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Overheat Induced Failure of A Steel Tube in An Electric Arc Furnace (EAF) Cooling SystemDocument7 pagesOverheat Induced Failure of A Steel Tube in An Electric Arc Furnace (EAF) Cooling SystemArif Ockta100% (1)

- Optimization in Spheroidized Annealing of Two AISI 1022 Low Carbon Steels Used in Bolt IndustryDocument7 pagesOptimization in Spheroidized Annealing of Two AISI 1022 Low Carbon Steels Used in Bolt Industryenrico susantoNo ratings yet

- 4 Harden AbilityDocument12 pages4 Harden AbilityFadlin QisthiNo ratings yet

- BWRA and Séférian Model For Preheating Temperature Calculation in Case of Low Alloyed and Unalloyed SteelDocument6 pagesBWRA and Séférian Model For Preheating Temperature Calculation in Case of Low Alloyed and Unalloyed SteelChokri AtefNo ratings yet

- 114 DM 052017Document2 pages114 DM 052017Ravindra JeeviNo ratings yet

- SAE52100 VS H13 For Pilger DiesDocument2 pagesSAE52100 VS H13 For Pilger DiesTushar PachlangiaNo ratings yet

- Assignment 1 ME2820Document5 pagesAssignment 1 ME2820XNo ratings yet

- Thermographic Study of Stainless Steel Cross-Arm On Overhead Distribution SystemDocument5 pagesThermographic Study of Stainless Steel Cross-Arm On Overhead Distribution Systemhalel111No ratings yet

- Advanced Manufacturing ScienceDocument3 pagesAdvanced Manufacturing Sciencemukesh3021No ratings yet

- Metals-09-00939 OKDocument14 pagesMetals-09-00939 OKRebeca Francis Moran CamposNo ratings yet

- Case Studies in Engineering Failure Analysis: M. Ghalambaz, M. Abdollahi, A. Eslami, A. BahramiDocument11 pagesCase Studies in Engineering Failure Analysis: M. Ghalambaz, M. Abdollahi, A. Eslami, A. BahramiWarman FatraNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Ceramics for Energy Conversion, Storage, and Distribution SystemsFrom EverandCeramics for Energy Conversion, Storage, and Distribution SystemsThomas PfeiferNo ratings yet

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- Iklan Ringkasan Risalah 2019 Bhs InggrisDocument5 pagesIklan Ringkasan Risalah 2019 Bhs InggrisMr. EverywhereNo ratings yet

- The Percentage of Biomass Contribution in IndonesiaDocument6 pagesThe Percentage of Biomass Contribution in IndonesiaMr. EverywhereNo ratings yet

- Tugas Komoposit-RamzulDocument3 pagesTugas Komoposit-RamzulMr. EverywhereNo ratings yet

- Dissimilar Joint Corrosion ResistanceDocument3 pagesDissimilar Joint Corrosion ResistanceMr. EverywhereNo ratings yet

- Bioetanol As Alternative EnergyDocument5 pagesBioetanol As Alternative EnergyMr. EverywhereNo ratings yet

- Tugas IAD 1 UMSDocument2 pagesTugas IAD 1 UMSMr. EverywhereNo ratings yet

- PermutationDocument3 pagesPermutationKhairuddin MuhamadNo ratings yet

- TVL CSS11 Q4 M1Document12 pagesTVL CSS11 Q4 M1Richard SugboNo ratings yet

- Problem Set 1 CirclesDocument2 pagesProblem Set 1 Circlesapi-339611548100% (1)

- Is 4410 9 1982 PDFDocument25 pagesIs 4410 9 1982 PDFSameer Singh PatelNo ratings yet

- Chapter 3 Step Wise An Approach To Planning Software Projects 976242065Document31 pagesChapter 3 Step Wise An Approach To Planning Software Projects 976242065RiajiminNo ratings yet

- Https WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFDocument1 pageHttps WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFZainab KhatoonNo ratings yet

- Z 80 HelptopicsDocument5 pagesZ 80 HelptopicsEverly NNo ratings yet

- OptQuest User ManualDocument190 pagesOptQuest User ManualYamal E Askoul TNo ratings yet

- Rac NotesDocument16 pagesRac NotesJohnRay LominoqueNo ratings yet

- BIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022Document4 pagesBIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022balozi training InstituteNo ratings yet

- Programming structures if, for and while loopsDocument16 pagesProgramming structures if, for and while loopsFrancisco AristizabalNo ratings yet

- Inductive TransducersDocument12 pagesInductive TransducersMUKESH SUNDARARAJANNo ratings yet

- TCP Operational Overview and The TCP Finite State Machine (FSM)Document4 pagesTCP Operational Overview and The TCP Finite State Machine (FSM)Mayank JaitlyNo ratings yet

- Alcohols, Phenols and Ethers Worksheet Answer Grade 12Document6 pagesAlcohols, Phenols and Ethers Worksheet Answer Grade 12sethu100% (1)

- Innovative High Throw Copper Electrolytic ProcessDocument6 pagesInnovative High Throw Copper Electrolytic Processyonathan fausaNo ratings yet

- JasminDocument125 pagesJasminudoraboxNo ratings yet

- Iygb Gce: Mathematics MP2 Advanced LevelDocument7 pagesIygb Gce: Mathematics MP2 Advanced Levelsingh cos tanNo ratings yet

- 11 Risks and Rates of Return KEYDocument12 pages11 Risks and Rates of Return KEYkNo ratings yet

- Catalogo Carbones Helwig GDE-006Document17 pagesCatalogo Carbones Helwig GDE-006Sergio HernandezNo ratings yet

- Research BulletsDocument18 pagesResearch BulletsVong Albios DogomeoNo ratings yet

- Woodward MFR 13Document91 pagesWoodward MFR 13OryaNo ratings yet

- Ductile deformation finite strain analysisDocument27 pagesDuctile deformation finite strain analysisJorgeBarriosMurielNo ratings yet

- Fix Disk & Partition ErrorsDocument2 pagesFix Disk & Partition Errorsdownload181No ratings yet

- 34a65 PDFDocument33 pages34a65 PDFvinu100% (2)

- Pioneer Deh-1300 1350 1390mpDocument71 pagesPioneer Deh-1300 1350 1390mpJorge LavezziNo ratings yet

- Code - Aster: Multiaxial Criteria of Starting in FatigueDocument44 pagesCode - Aster: Multiaxial Criteria of Starting in FatigueYoyoNo ratings yet

- Ansoff Matrix Template User GuideDocument6 pagesAnsoff Matrix Template User Guidebernardo95No ratings yet

- Digital Image Processing TechniquesDocument34 pagesDigital Image Processing Techniquesaishuvc1822No ratings yet

- L - 1 - INTRO - Well LoggingDocument47 pagesL - 1 - INTRO - Well LoggingSaaeed Ali100% (1)

- IP46 - Guide To Use BAPCO WPS & Welding ProceduresDocument4 pagesIP46 - Guide To Use BAPCO WPS & Welding ProceduressajiNo ratings yet