Professional Documents

Culture Documents

10'

Uploaded by

Faisal MumtazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10'

Uploaded by

Faisal MumtazCopyright:

Available Formats

International Research Journal of Environment Sciences________________________________ ISSN 23191414

Vol. 4(7), 24-28, July (2015) Int. Res. J. Environment Sci.

Use of Catalyst in Pyrolysis of Polypropylene Waste into Liquid Fuel

Sonawane YB, Shindikar MR and Khaladkar MY

Department of Applied Science, College of Engineering, Pune, 411005, INDIA

Available online at: www.isca.in, www.isca.me

Received 16th April 2015, revised 22nd May 2015, accepted 14th June 2015

Abstract

Pyrolysis of polypropylene (PP) waste was carried out by developing lab scale borosilicate glass reactor of one litre

capacity. Reactions were carried out by using about 200 grams of PP waste. The nitrogen gas was purged in required

quantity in the reactor to create pyrolytic condition. The maximum temperature in a reactor was kept about 4500C.

Reactions were carried out with and without using natural zeolite (NZ) as a catalyst. It was found that, time required for

completion of the pyrolysis process was 90 minutes without catalyst and 65 minutes with natural zeolite. Results showed

that in absence of catalyst, process gives about 80.82% of liquid fuel and in presence of 10 % natural zeolite, about 86.40

% yield is obtained. It is observed that by using natural zeolite, oil percent can be enhanced and one can obtain high

calorific value fuel than that of oil without catalyst. GC-MS results of oil samples showed presence of petroleum fractions

(C5-C20) with some high molecular weight fractions from C20-C30.

Keywords: Catalyst, pyrolysis, polypropylene, natural zeolite, calorific value, GC-MS.

Introduction industries as an alternative fuel for running boilers, generators,

and turbines. By using suitable catalyst, process yield can be

Plastics are made up of long chain molecules called polymers1. enhanced and reaction time can be minimized which ultimately

They are light weight polymers of carbon along with hydrogen, achieves efficiency in the process.

nitrogen, sulphur and other organic and inorganic elements. The

main drawbacks for utility of plastics are they are manufactured Production of hydrogen and carbon nanotubes is possible by

from fossil fuel which is a non-renewable source and their non - catalytic pyrolysis of waste polypropylene8. Pyrolysis of

biodegradable nature2-3. polypropylene waste material gives petroleum fuel grade liquid

product without using catalyst9-10. Catalytic cracking of

Plastic waste pollution is increasing day by day in developed polypropylene (PP) waste by using zeolite beta (BEA) catalyst

and developing countries because of their non-biodegradable enhances percent of oil as compared to that of without

nature. In India, plastic waste generated per day is about ten catalyst11. Use of synthesized catalysts from fly ash also gives

thousand tons that of total municipal solid waste4. Due to good results in pyrolysis process of plastic waste12. Kaolin

improper segregation and recycling system for these plastic catalyst found effective for thermo degradation of

wastes, load on landfill sites increases which ultimately cause polypropylene waste for conversion into fuel13. Some authors

environmental pollution and affects marine biodiversity5. studied pyrolysis process for converting mixture of waste tyre

and polypropylene into petroleum fuel by using ZnO as a

Thermoplastic waste mainly consists of polyethylene catalyst14. Present research work focuses on use of natural

terephthalate, high density polyethylene, polyvinyl chloride, low zeolite catalyst in pyrolysis of polypropylene waste into liquid

density polyethylene, polypropylene and polystyrene. For food fuel.

packaging, generally polyethylene and polypropylene materials

are used. As polypropylene is more resistant to heat, harder, Material and Methods

denser and more transparent than polyethylene, it is used for

microwavable packaging and sauce or salad dressing bottles6. In present research study, experiments were performed without

These types of thermoplastic waste can be recycled by using catalyst and by using 10 percent of natural zeolite.

different methods like mechanical recycling, chemical Polypropylene waste was collected from canteens, mess, ice-

recycling, incineration, pyrolysis etc. cream parlors etc. Washing, shredding and drying was done

manually. Waste quantity of about 200 gram was used as a

Pyrolysis is one of the recycling options for plastic waste which feedstock for reaction. Natural zeolite was selected as a catalyst

involves heating of organic material at elevated temperature in due to its cost effectiveness, easy availability and chemical

absence of oxygen7. It is one of the best methods to reduce load properties. It was heated upto 2000C in an oven for an hour to

of plastic waste on available landfills. It converts plastic waste remove impurities.

into different petroleum fractions which can be used in many

International Science Congress Association 24

International Research Journal of Environment Sciences______________________________________________ ISSN 23191414

Vol. 4(7), 24-28, July (2015) Int. Res. J. Environment Sci.

The whole pyrolysis reactor set up has following parts: i.

Nitrogen gas cylinder ii. heating mantle iii. Borosilicate glass

reactor with recovery bend iv. Thermocouple with temperature

indicator v. Condenser and vi. Collection flask.

Before starting reaction, 200 grams shredded plastic waste was

fed into a reactor and nitrogen gas was purged into it for 5

seconds with pressure of 5kgf/cm2 to make pyrolytic condition.

Reactions were carried out at maximum temperature of 4500C.

Vapours generated after depolymerisation of material were

passed through condenser and oil obtained was collected in a

flask. Uncondensed gases produced during the experiment were

passed in cold water bath.

Figure-3

Oil obtained by pyrolysis without catalyst

Figure-1

Polypropylene plastic waste

Figure-4

Oil obtained by pyrolysis with 10 % NZ

Results and Discussion

Polypropylene waste started melting at temperature about

1350C. So melting point was recorded 1350C. Pure

polypropylene material has a melting point of about 1300C.

Small difference in melting point may be due to presence of

additives and other materials in polypropylene waste. The

maximum yield was observed at a temperature range of about

400 to 4500C. Process required 25 minutes to start receiving

distillate in a collection flask without using catalyst whereas by

using NZ process required only 20 minutes. In absence of

catalyst about 90 minutes were required to complete the process

and with the help of NZ, it has been completed in 65 minutes

only.

Percent oil obtained by pyrolysis process with and without

Figure-2 catalyst was calculated by using following formula:

Pyrolysis reactor set up for plastic waste recycling

International Science Congress Association 25

International Research Journal of Environment Sciences______________________________________________ ISSN 23191414

Vol. 4(7), 24-28, July (2015) Int. Res. J. Environment Sci.

Oil obtained in grams minimized which ultimately saves energy required for the

Percent oil obtained = 100 process.

Weight of plastic waste taken

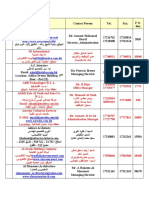

Specific gravity of oil samples were determined by using Table-1

specific gravity bottle. Calorific value of oil samples Digital Percent yield of oil and wax obtained without catalyst and

bomb calorimeter with make model RSB-3 by Rico Scientific with 10 % NZ

was used to determine calorific value of obtained oil samples in Oil Wax Reaction

PP Material

the process. obtained obtained time

(200 g)

(%) (%) (Minutes)

GC make model Agilent-7890, with FID detector was used and Without

80.82 18.64 90

MS make model Jeol Accu TOF GCV with mass range 10-2000 catalyst

amu and mass resolution 6000 was used. Results showed With 10 % NZ

86.41 11.34 65

presence of gasoline, kerosene and diesel fractions with some catalyst

higher molecular weight fractions.

Table-2

Table-1 displays values of oil and wax percent obtained for PP Calorific values of oil with and without catalyst

and reaction time required for the process in absence of catalyst PP Calorific value (KJ/Kg)

and by using NZ. PP without catalyst 25794

PP with 10 % NZ 27167

In absence of catalyst, oil obtained from the process is about

80% and with the help of 10 % NZ, process gives about 86% Table-2 Displays calorific values of oil samples in absence of

oil. With 10 % natural zeolite, time span for completion of NZ and with NZ. Increase in calorific value of oil with NZ

process is reduced by 25 minutes with that of in absence of catalyst broadens its applications as an energy source.

catalyst. By using natural zeolite, yield percent and physical

appearance can be enhanced and time required can be

C:\XCALIBUR\...\Data\EXT_E01CEP_PPWC 4/5/2014 6:22:43 PM

RT: 0.00 - 31.01

4.17 NL:

100 3.80E9

90 TIC MS

EXT_E01C

80 EP_PPWC

Relative Abundance

70

60

10.94 11.19

50

40 7.66

30 13.74 14.62 16.22 16.57

4.44 20.35 22.18

20 3.25 11.90 23.47

8.73 19.38

4.83 6.55 23.01

10 3.15 9.07 12.13 14.92 17.57 24.90

5.86 25.07 26.83 28.46 29.75

0 r

MXU\J >1T r r l i r

T i T I I 1 T i T T T i i

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

Time (min)

EXT_E01CEP_PPWC #77 RT: 4.17 AV: 1 NL: 7.00E8

T: + c Full ms [50.00-500.00]

55.02 70.10

100

80

Relative Abundance

60

83.10

40

126.11

20

84.12

111.06 127.16 153.19 167.17 193.09 207.11

85.14 239.55 267.17 281.10 328.39 341.23 354.97 386.86 418.31 442.77 457.56 490.80

i.

0 T T T T T T T T T T T T T T T T T T T T T T T

50 100 150 200 250 300 350 400 450 500

m/z

Figure-5

GC-MS of oil sample without catalyst

International Science Congress Association 26

International Research Journal of Environment Sciences______________________________________________ ISSN 23191414

Vol. 4(7), 24-28, July (2015) Int. Res. J. Environment Sci.

C:\Xcalibur\...\Data\EXT_E01CEP_PPNZ10 4/5/2014 5:01:53 PM

RT: 0.00 - 31.01

4.17 NL:

100 3.81E9

90 TIC MS

EXT_E01C

80 EP_PPNZ1

Relative Abundance

70 0

60

50 10.94 11.19

40

7.66

30 4.44 16.22 16.58

13.74

14.62 20.35 22.18

20 3.23 11.90 17.17

8.73 19.38 23.47

10 4.83 6.55

3.14 9.07 12.13 14.94 17.57 24.31 25.07

26.83 28.49 29.20

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

Time (min)

EXT _E01CEP_PPNZ10 #77 RT : 4.17 AV: 1 NL: 7.43E8

T : + c Full ms [50.00-500.00]

55.02

100

70.10

80

Relative Abundance

60

83.10

40

20 126.10

84.13

85.14 111.12 127.16 153.11 193.15 207.02 241.30 267.02 281.23 295.43 328.07 357.09 367.47 397.18 415.85 432.26 460.97 474.66 491.16

0

50 100 150 200 250 300 350 400 450 500

m/z

Figure-6

GC-MS plot for oil sample with 10% natural zeolite

GC-MS plot of oil samples obtained without catalyst and by References

using natural zeolite show presence of petroleum fractions (C4

to C20) which include alkanes e.g. heptanes, dodecane, alkenes 1. http://www.cleanup.org.au/PDF/au/cua_plastic_recycling_f

e.g. 2, 4 dimethyl 1-heptene, 3 hexadecene, esters e.g. act_sheet.pdf 2, (2015)

pentadecyl ester and few high molecular weight fractions (C20- 2. Kumari, N.A., Kumari, P., Murthy, N.S., A Novel,

C30) e.g. 9 eicosene, hexadecyl ester etc. which shows their Mathematical Approach for Optimization of Plastic

usefulness for fuel in different industrial sectors. Degradation, Int. J. Engg. Trends and Tech., 4(8), 3539-

3542 (2013)

Conclusion 3. Kathiresan K., Polythene and Plastics-degrading

Polypropylene waste can be converted into useful liquid, gas microbes from the mangrove soil, Rev. Biol. Trop., 51(3),

and waxy hydrocarbon fractions by using pyrolysis technique. 629-634 (2003)

Optimum temperature range of about 400-4500C maximize 4. Raja A. and Murali A., Conversion of plastic wastes into

percent of oil and lessen the yield of wax. With the help of fuels, J. of Mat. Sci. Eng., B1: 86-89, (2011)

natural zeolite in the pyrolysis process, one can reduce the

reaction time upto 25 minutes for 200 grams of PP waste. The 5. Thompson R.C., Olsen Y. and Mitchell R.P., Lost at Sea:

oil obtained by using natural zeolite has higher calorific value Where is all the plastic, Science, 7, 838 (2004)

which broadens its applications. From obtained results, it is 6. http://www.foodsmart.govt.nz/whats-in-our-food/

concluded that 10 % natural zeolite enhances oil percent in chemicals-nutrients-additives-toxins/plastic-packaging,

pyrolysis process and reduces reaction time proves its utility in (2015)

recycling of PP waste. The oil obtained without catalyst and

with natural zeolite has variety of low to high molecular weight 7. Plastic industry statistics. http://www.cipet.gov.in/

hydrocarbon fractions which can be used as an energy source. plastics_statics.html, (2015)

8. Lu J., Jiang Z.W., Yu H. and Tang T., Production of

hydrogen and carbon nanotubes by catalytic pyrolysis of

International Science Congress Association 27

International Research Journal of Environment Sciences______________________________________________ ISSN 23191414

Vol. 4(7), 24-28, July (2015) Int. Res. J. Environment Sci.

waste polypropylene in a two-step process, Fifth ISFR, 12. http://www.netl.doe.gov/publications/proceedings/99/99k

Chengdu, China (2009) orea/shchung.pdf, (2015)

9. Obali Z., Sezgi N.A. and Dogu T., Catalytic degradation 13. Panda A.K. and Singh R.K., Experimental optimization

of polypropylene over alumina loaded mesoporous of process for the thermo-catalytic degradation of waste

catalysts, Chem. Eng. J., 207-208 (2012) polypropylene to liquid fuel, Adv. in Energy Eng., 1(3),

10. Nishino J., Itoh M., Ishinomori T., Kubota N. and 74-84 (2013)

Uemichi Y., Development of a catalytic cracking process 14. Sarker M. and Rashid M.M., Waste tyre and

for converting waste plastics to petrochemicals, J. of Mat. polypropylene mixture into petroleum fuel using ZnO,

Cycles Waste Manage, 5, 8993 (2003) International J. of Sci. Mod. Eng., 1(2), 1-8 (2013)

11. Wanchai K. and Chaisuwan A., Catalytic Cracking of

Polypropylene Waste over Zeolite Beta, Chem. Mater.

Res., 3(4), 31-41 (2013)

International Science Congress Association 28

You might also like

- Hydrolysis of Salt and The Action of Buffer SolutionDocument5 pagesHydrolysis of Salt and The Action of Buffer SolutionFaisal MumtazNo ratings yet

- Kinetics of The Hydrolysis of Ethyl Acetate by Sodium Hydroxide by A Conductivity MethodDocument4 pagesKinetics of The Hydrolysis of Ethyl Acetate by Sodium Hydroxide by A Conductivity MethodFaisal MumtazNo ratings yet

- Chemy102 Lab ManualDocument53 pagesChemy102 Lab ManualGhazanfar IqbalNo ratings yet

- Enthalpy Change of Reaction: Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 1Document4 pagesEnthalpy Change of Reaction: Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 1Faisal MumtazNo ratings yet

- Determination of The Dissociation Constant and Concentration of A Weak AcidDocument4 pagesDetermination of The Dissociation Constant and Concentration of A Weak AcidFaisal MumtazNo ratings yet

- Rate of Chemical Reaction: The Iodination of AcetoneDocument7 pagesRate of Chemical Reaction: The Iodination of AcetoneFaisal MumtazNo ratings yet

- Oxidation-Reduction Titration: Determination of OxalateDocument4 pagesOxidation-Reduction Titration: Determination of OxalateFaisal MumtazNo ratings yet

- Acid-Base Titration Curves ": Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 4Document6 pagesAcid-Base Titration Curves ": Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 4Faisal MumtazNo ratings yet

- Acid-Base Titration Curves ": Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 4Document6 pagesAcid-Base Titration Curves ": Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 4Faisal MumtazNo ratings yet

- Kinetics of The Hydrolysis of Ethyl Acetate by Sodium Hydroxide by A Conductivity MethodDocument4 pagesKinetics of The Hydrolysis of Ethyl Acetate by Sodium Hydroxide by A Conductivity MethodFaisal MumtazNo ratings yet

- Chemy102 Lab ManualDocument53 pagesChemy102 Lab ManualGhazanfar IqbalNo ratings yet

- Determination of The Solubility Product Constant For A Sparingly Soluble SaltDocument3 pagesDetermination of The Solubility Product Constant For A Sparingly Soluble SaltFaisal MumtazNo ratings yet

- Determination of The Dissociation Constant and Concentration of A Weak AcidDocument4 pagesDetermination of The Dissociation Constant and Concentration of A Weak AcidFaisal MumtazNo ratings yet

- Determination of The Solubility Product Constant For A Sparingly Soluble SaltDocument3 pagesDetermination of The Solubility Product Constant For A Sparingly Soluble SaltFaisal MumtazNo ratings yet

- Hydrolysis of Salt and The Action of Buffer SolutionDocument5 pagesHydrolysis of Salt and The Action of Buffer SolutionFaisal MumtazNo ratings yet

- Oxidation-Reduction Titration: Determination of OxalateDocument4 pagesOxidation-Reduction Titration: Determination of OxalateFaisal MumtazNo ratings yet

- KETO 14 Day Meal PlanDocument25 pagesKETO 14 Day Meal Planpinkyhead99No ratings yet

- Shakeel CV-Electrical Electronics EngineerDocument3 pagesShakeel CV-Electrical Electronics EngineerFaisal MumtazNo ratings yet

- Rate of Chemical Reaction: The Iodination of AcetoneDocument7 pagesRate of Chemical Reaction: The Iodination of AcetoneFaisal MumtazNo ratings yet

- R. K. Jain Production Technology Khanna PublishersDocument4 pagesR. K. Jain Production Technology Khanna PublishersAniket SankpalNo ratings yet

- Feasibility Study For The Expansion of Existing (PPP) Sewage Treatment Plant at Muharraq (MSTP)Document1 pageFeasibility Study For The Expansion of Existing (PPP) Sewage Treatment Plant at Muharraq (MSTP)Faisal MumtazNo ratings yet

- Sustainability 09 01126 v3 PDFDocument13 pagesSustainability 09 01126 v3 PDFAsma DurraniNo ratings yet

- Adkhar BookletDocument8 pagesAdkhar BookletAuliya DsNo ratings yet

- Enthalpy Change of Reaction: Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 1Document4 pagesEnthalpy Change of Reaction: Name: Lujain Mohammed Alsyouf ID: 20100429 Section: 1 Course: 2 Experiment: 1Faisal MumtazNo ratings yet

- SustaiinableDocument7 pagesSustaiinableFaisal MumtazNo ratings yet

- The Ketogenic Diet: Understanding The Ketogenic Diet. For The Moment, Be Reassured, The High Fat Content of TheDocument6 pagesThe Ketogenic Diet: Understanding The Ketogenic Diet. For The Moment, Be Reassured, The High Fat Content of TheM. GuidoNo ratings yet

- Graduate Brochure CHENG PDFDocument2 pagesGraduate Brochure CHENG PDFFaisal MumtazNo ratings yet

- ReadMeMapV8iSS3 April2012 PDFDocument44 pagesReadMeMapV8iSS3 April2012 PDFFaisal MumtazNo ratings yet

- MET2487 Ketogenic Program Guide IPAD PDFDocument20 pagesMET2487 Ketogenic Program Guide IPAD PDFCássia BothNo ratings yet

- ContactsDocument14 pagesContactsFaisal MumtazNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- What Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Document2 pagesWhat Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Darlene PanisaNo ratings yet

- ECE 4400 Performance Analysis Local Computer Networks HomeworkDocument2 pagesECE 4400 Performance Analysis Local Computer Networks HomeworkNguyen Phi HungNo ratings yet

- Family Preparedness PlanDocument6 pagesFamily Preparedness PlanSabrinaelyza UyNo ratings yet

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDocument2 pagesKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyNo ratings yet

- Effectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting OperationDocument10 pagesEffectiveness of Using High Gas Pressure in A Blast Furnace As A Means of Intensifying The Smelting Operationchandan kumar100% (1)

- Morpho Full Fix 2Document9 pagesMorpho Full Fix 2Dayu AnaNo ratings yet

- Monetary System 1Document6 pagesMonetary System 1priyankabgNo ratings yet

- Lorain Schools CEO Finalist Lloyd MartinDocument14 pagesLorain Schools CEO Finalist Lloyd MartinThe Morning JournalNo ratings yet

- GEd 105 Midterm ReviewerDocument17 pagesGEd 105 Midterm ReviewerAndryl MedallionNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary EducationAdaaan AfzalNo ratings yet

- I Am Sharing 'Pregnancy Shady' With YouDocument48 pagesI Am Sharing 'Pregnancy Shady' With YouNouran AlaaNo ratings yet

- Physics MCQ Solid State PhysicsDocument15 pagesPhysics MCQ Solid State PhysicsRams Chander88% (25)

- Assessing Khazaria-Serpent PeopleDocument1 pageAssessing Khazaria-Serpent PeopleJoao JoseNo ratings yet

- Impact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityDocument14 pagesImpact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityYo Vivo Fit Pablo y KarlaNo ratings yet

- Valentine Gifting - Accessories EditionDocument25 pagesValentine Gifting - Accessories EditionPriyanath PaulNo ratings yet

- Internal auditing multiple choice questionsDocument4 pagesInternal auditing multiple choice questionsSantos Gigantoca Jr.No ratings yet

- Karate Writing AssessmentDocument2 pagesKarate Writing AssessmentLeeann RandallNo ratings yet

- UntitledDocument21 pagesUntitledRoberto RamosNo ratings yet

- Footprints 080311 For All Basic IcsDocument18 pagesFootprints 080311 For All Basic IcsAmit PujarNo ratings yet

- Timoshenko Beam TheoryDocument8 pagesTimoshenko Beam Theoryksheikh777No ratings yet

- 1 CAT O&M Manual G3500 Engine 0Document126 pages1 CAT O&M Manual G3500 Engine 0Hassan100% (1)

- Assessing Student Learning OutcomesDocument20 pagesAssessing Student Learning Outcomesapi-619738021No ratings yet

- Mega Goal 4Document52 pagesMega Goal 4mahgoubkamel0% (1)

- Exploratory Data Analysis: M. SrinathDocument19 pagesExploratory Data Analysis: M. SrinathromaNo ratings yet

- Graphs & Charts SummariesDocument20 pagesGraphs & Charts SummariesMaj Ma Salvador-Bandiola100% (1)

- Hearing God Through Biblical Meditation - 1 PDFDocument20 pagesHearing God Through Biblical Meditation - 1 PDFAlexander PeñaNo ratings yet

- Makerwys - Exe Version 4.891: by Pete Dowson © 2019 InstructionsDocument11 pagesMakerwys - Exe Version 4.891: by Pete Dowson © 2019 InstructionsRafrol RamonNo ratings yet

- New Microwave Lab ManualDocument35 pagesNew Microwave Lab ManualRadhikaNo ratings yet

- Chapter-5 Contract ManagementDocument43 pagesChapter-5 Contract Managementprem kumarNo ratings yet

- CELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesDocument4 pagesCELTA Pre-Interview Grammar, Vocabulary and Pronunciation ExercisesMichelJorge100% (2)