Professional Documents

Culture Documents

Canal Syphon Programme

Uploaded by

Mukhlish AkhatarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Canal Syphon Programme

Uploaded by

Mukhlish AkhatarCopyright:

Available Formats

Office of Director Dam

368513587.xls

I.D.R., Jaipur

DESIGN OF A CANAL SYPHON

NAME OF PROJECT : Case study, Design example 9.4/p394

DESIGN INPUT DATA :

(a) Canal

(i) Full supply discharge of canal 40.00 Cumec

(ii) Bed width of canal 18.00 m

(iii) Full supply depth of canal 2.10 m

(iv) Bed level of canal (C.B.L.) at D/S 250.00 m

(v) Side slope of canal (s) 1.50 :1

(vi) Free board of canal 0.75 m

(b) Drain

(i) Max. observed flood discharge 100.00 cumec

(ii) Bank level 254.00 m

(iii) Bed level 251.80 m

(iv) Highest Flood Level (H.F.L.) 253.25 m

(v) slope 1/600

HYDRAULIC DESIGN :

(1) Section of the drainage channel

According to Lacey's formula

P = 4.83 X Q 1/2

= 4.83 X 10

= 48.3

Provide bed width of the drain at the crossing = 44.50 m.

(2) Canal waterway

Bed width of canal = 18.00 m.

Normal X-area of the channel = BD + sD 2

(A) = 44.42 Sq.m.

Velocity in the normal section = Q/A

= 0.90 m/sec

Adopt size of the barrel as

Width = 3.00 m, Wall thickness = 0.30 m

Program by- Sunil K Goyal Hydraulic 1 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

Height = 2.50 m, No. of barrels = 2 No.

Program by- Sunil K Goyal Hydraulic 2 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

Reduce the canal waterway from 18.00 m to 6.30 m

40

Velocity through the barrels = = 2.67 m/sec

15

< 6.00 m/sec

The velocity is within the recommended range

The size of the barrel is, therefore okay

It should be checked that the flow is subcritical in the barrel, .i.e., Froude number (F) should

be less than unity

Now F = V/(gd)1/2

Where,

V = 2.67 m/sec

g = 9.81 m/sec

d = 2.50 m

Therefore,

F = 0.538

Since the value of F is less than 1 the flow will be subcritical in the barrel

(3) Head loss and bed levels at different sections :

Width of canal in the flumed portion = 6.3 m

Provide 2 in 1splay in contraction and 3 in 1 splay in expansion transition

11.70

Length of contraction transition =

-------- X 2 = 11.7 m

2

11.70

Length of expansion transition = -------- X 3 = 17.55 m

2

Assume,Length of the barrels in the flumed portion= 70.0 m > 68.50 m

assumed length is O.K.

In the transitions, the side slopes of the section shall be warped from 1.50 : 1 to vertical.

1 2 3 4

0.3 m Thick wall

Canal

18.0 6.3 18.0

R.C.C. barrels

11.70 70.00 17.55

1 2 3 4

Canal waterway (All dim in meter)

Program by- Sunil K Goyal Hydraulic 3 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

At section 4-4

Area of section = 44.42 Sq.m.

(Normal channel section)

Velocity = Q/A = 0.901 m/sec

Velocity head = V /2g =

2

0.0414 m

R.L. of bed = 250.00 m (given)

R.L. of water surface = 250.00 + 2.1

= 252.10 m

R.L. of T.E.L. = 252.10 + 0.0414

= 252.141 m

At section 3-3

Water depth at the entry and exit of the barrel should be kept slightly higher than the depth

of the barrels so as to keep the ends of the barrel submerged for proper syphoning

Provide water depth equal to 3.00 m

Area of section = 3.00 X 6.3

= 18.9 Sq.m.

Velocity = Q/A = 2.116 m/sec

Velocity head = V /2g =

2

0.228 m

Loss of head in expansion from section 3-3 to section 4-4

= 0.3 (V22 - V12) /2g

= 0.056 m

Hence elevation of T.E.L. at section 3-3

= 252.141 + 0.056

= 252.197 m

R.L. of water surface = 252.197 - 0.228

= 251.969 m

R.L. of bed = 251.969 - 3.00

= 248.969 m

From section 3 - 3 to section 2 - 2, area and velocity are constant.

Head loss through barrels

Head loss through barrels is given by

= ( 1 + f1 + f2 xL/R )V 2/2g

Where, f1 = 0.080 ,for bell mouthed syphon

f2 = a(1+b/R)

Where, a = 0.00316 , b = 0.10000

L = 70.0 m

R = A/P

= 0.682 m

Hence,

f2 = 0.00362

Therefore loss of head in barrels = 0.526 m

Program by- Sunil K Goyal Hydraulic 4 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

At section 2-2

R.L. of T.E.L. = T.E.L. at section 3-3 + head loss through barrels

= 252.197 + 0.526

= 252.724 m

R.L.of water surface = R.L. of T.E.L. - Velocity head at section 3-3

= 252.724 - 0.228

= 252.495 m

R.L. of bed = 252.495 - 3.00

= 249.495 m

At section 1-1

Loss of head in contraction transition from section 1-1 to section 2-2

= 0.2 (V22 - V12) /2g

= 0.037 m

R.L. of T.E.L. = T.E.L. at section 2-2 + head loss in contraction transition

= 252.724 + 0.037

= 252.76 m

R.L. of water surface = 252.76 - 0.041

= 252.72 m

R.L. of bed = 252.72 - 2.10

= 250.62 m

(4) Transitions

The general method of Hinds shall be applied for designing the transitions, as the water depths in

the transitions vary from 2.10 m to 3.00 m

(a) Contraction transition

w.s.profile

1

R.L. 252.72 2

y1 = 0.112

x1= 5.85 R.L. 252.50

1

11.70 2

(All dim in m)

Contraction transition

Water level at section 1-1 - Water level at section 2-2

y1 =

2

252.72 - 252.50

=

2

= 0.1122

x1 Length of contraction transition

=

2

11.70

=

2

= 5.85 m

Program by- Sunil K Goyal Hydraulic 5 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

y1 0.112

C = = = 0.00328

x12 34.223

y = 0.00328 x2 (equation of water surface profile in contraction transition)

The details of the contraction transition have been worked out in Table 1

(b) Expansion transition

w.s.profile 4

3 R.L. 252.10

y1 = 0.065

R.L. 251.97

x1= 8.775

17.55 4

3

Expansion transition

Water level at section 4-4 - Water level at section 3-3

y1 =

2

252.10 - 251.97

=

2

= 0.0654 m

x1 Length of expansion transition

=

2

17.55

=

2

= 8.775 m

Hence,

y1 0.06541

C = = = 0.00085

x12 77.0006

y = 0.00085 x2 (equation of water surface profile in expansion transition )

The details of expansion transition have been worked out in Table 1

Program by- Sunil K Goyal Hydraulic 6 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

Table 1

water Elevation Velocity Velocity side Area A= Bed Depth(D) Bed

Distance y=cx2 surface of head (hV) V= 2ghV slope 's' Q/V Level Col.(3) width

elevation T.E.L. (4) - (3) -Col(9) B = A/D

m m m m -sD

1 2 3 4 5 6 7 8 9 10 11

From section 1-1 to 2-2 CONTRACTION TRANSITION

0 0.0000 252.720 252.761 0.041 0.901 1.500 :1 44.392 250.62 2.10 18.00

3.0 0.0295 252.690 252.752 0.062 1.099 1.115 :1 36.406 250.34 2.35 12.86

5.85 0.1122 252.608 252.742 0.135 1.627 0.750 :1 24.593 250.06 2.55 7.73

8.7 0.0295 252.525 252.733 0.208 2.021 0.385 :1 19.794 249.78 2.75 6.30

11.7 0.0000 252.495 252.724 0.228 2.116 0.00 :1 18.900 249.50 3.00 6.30

From section 3-3 to 4-4 EXPANSION TRANSITION

0 0.0000 251.969 252.197 0.228 2.116 0 :1 18.900 248.969 3.00 6.30

3 0.0076 251.977 252.188 0.211 2.035 0.256 :1 19.656 249.145 2.83 6.30

6 0.0306 252.000 252.178 0.179 1.872 0.513 :1 21.372 249.322 2.68 6.61

8.775 0.0654 252.035 252.169 0.135 1.627 0.750 :1 24.593 249.485 2.55 7.73

11.55 0.0306 252.069 252.161 0.091 1.337 0.987 :1 29.913 249.648 2.42 9.96

14.55 0.0076 252.092 252.151 0.059 1.072 1.244 :1 37.300 249.824 2.27 13.62

17.55 0.0000 252.100 252.141 0.041 0.901 1.500 :1 44.392 250.00 2.10 18.00

(5) Invert level

Bed level of drain = 251.80 m

Provide 0.30 m thick concrete slab and 0.60 m thick earth fill over the slab

Invert level of the concrete = 251.80 - ( 0.6 + 0.3 + 2.5 )

= 248.40 m

Invert level at the entrance and exit of the barrel shall be the same as the bed levels already

worked out at sections 2-2 and 3-3 respectively.

Thus the invert level at the entry = 249.495 m

The invert level at the exit = 248.969 m

The invert level of the barrel would be kept at 248.40 m in a length of 44.5 m

(under base of drain) after which it would meet the respective bed levels at the entrance and

exit, so as to obtain a slope of about 1in 15 in the barrel at either side.

Thus, Length of barrel upstream = 16.00 m

Length of barrel downstream = 8.00 m

The length of the pucca floor on either end should be adequate to provide safe hydraulic gradient

and its thickness sufficient to counterbalance the total uplift pressure by gravity. The barrel shall

be made of reinforced concrete box construction and its structural design is given subsequently.

Program by- Sunil K Goyal Hydraulic 7 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

(6) Pucca Floor

Provide pucca floor in half the transition length in the upstream and 3/4 th the length of expansion

transition in the downstream.

Length of pucca floor upstream = 1/2 X 11.7

= 5.85 m

say 6.00 m

Length of pucca floor downstream = 3/4 X 17.55

= 13.16 m

= say 13.00 m

The floor shall be subjected to static uplift and seepage head; it is maximum when high flood is

passing through the drain and there is no flow in the barrel. The seepage head would be

calculated by Bligh's theory.

(7) Uplift pressures on the barrel floor and pucca floor

(a) Static pressure

At bottom of barrel floor

Deepest invert level of the barrel = 248.40 m

The thickness of the barrel is = 0.30 m

The bottom level of the barrel floor = 248.10 m

Assuming the sub-soil water level upto the bed level i.e.at R.L. 250.00 m, the maximum

static head = 250.00 - 248.10

= 1.90 m

At the downstream end of barrel

Floor level at d/s end of barrel = 248.969 m

Assuming floor thickness at this point 2.00 m,

The bottom level of pucca floor = 248.969 - 2.00

= 246.969 m

Hence,

Static head = 250.00 - 246.969

= 3.031 m

At the upstream end of barrel

Floor level at u/s end of barrel = 249.495 m

Assuming floor thickness at this point 1.50 m,

The bottom level of pucca floor = 249.495 - 1.50

= 247.995 m

Hence,

Static head = 250.62 - 247.995

= 2.624 m

(b) Seepage head

The seepage head will be maximum when the drain is running full and there is

no flow in the canal. Thus total seepage head =

= H.F.L. in the drain - Bed level of canal

Program by- Sunil K Goyal Hydraulic 8 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

= 253.25 - 250.00

= 3.25 m

Program by- Sunil K Goyal Hydraulic 9 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

At bottom of barrel floor

The residual seepage head at point 'a' in the centre of the first barrel has been calculated by

Bligh's theory. The seepage line would follow the path indicated by the line x a b y. Its total length

(neglecting floor depression or thickness) is the sum of the following

(i) Half the barrel span = 1.5 m

(ii) Length of barrel in indicated portion = 8.00 m

(iii) Length of pucca floor = 13.00 m

Thus total creep length = 22.50 m and creep length upto point 'a' i.e. centre of first

barreel= 1.5 m

c.c.floor

c.c.cutoff

8 13.00

a b

1.5 y

x

R.C.C.Barrel

Barrel Plan

Residual seepage head point 'a' = 3.033 m

Thus total uplift in the barrel = 1.90 + 3.033

= 4.93 m

say 4.93 t/m2

At the downstream end of barrel floor

total creep length upto the end of barrel floor i.e. at point b

= 1.5 + 8.0

= 9.5 m

Hence ,

Residual seepage head at this point = 1.88 m

Thus total uplift = Static uplift + residual seepage head

= 3.031 + 1.88

= 4.909 m

4.909

The floor thickness required (sp.gr.=2.22) = ----------- = 2.211 m

2.22

Say 2.20 m

Provide 2.20 m thick c.c.floor d/s and reduce it to thickness 0.90 m at the end of floor

Program by- Sunil K Goyal Hydraulic 10 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R., Jaipur

At the upstream end of barrel floor

total creep length upto the end of barrel floor

= 1.5 + 16.00

= 17.5 m

Hence ,

Residual seepage head at this point = 0.83 m

Thus total uplift = Static uplift + residual seepage head

= 2.624 + 0.83

= 3.454 m

3.454

The floor thickness required (sp.gr.=2.22) = ----------- = 1.556 m

2.22

Say 1.60 m

Provide 1.60 m thick c.c.floor u/s and reduce it to thickness 0.70 m at the end of floor

********************** **********************

Program by- Sunil K Goyal Hydraulic 11 Checked by - P.P.Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

DRAIN

TRANSITION WING TRANSITION WING

4.28 4.28

B

R.C.C. BARRELS 0.30 M THICK

A A

3.00

18.00

18.00

CANAL 3.00

B

4.28 16.00 44.50 8.00 4.28

CONTRACTION TRANSITION EXPANSION TRANSITION

11.7 68.50 17.55

PLAN

0.60 TH. EARTH FILL

TOP OF WING WALL TOP OF WING WALL

R.L. 253.47 254.00 R.L. 252.85

R.L. 254.00 H.F.L. 253.25

U/S F.S.L. 252.72 D/S F.S.L. 252.10

CANAL

U/S BED R.L. 250.62 D/S R.L. 250.00

249.50 2.50 248.97

248.40

U/S TOE WALL U/S CUT OFF C.C. BLOCK 0.30 TH. R.C.C. BARREL LEAN CONCRETE C.C. BLOCK D/S CUT OFF D/S TOE WALL

DRY BRICK PITCHING 5.70 6.00 16.00 44.50 8.00 13.00 4.55 D.B. PITCHING

11.7 68.50 17.55

TOP OF BANK 254.00 SECTION AT A-A

H.F.L. OF DRAIN 253.25 DETAILS OF PROTECTION WORKS

BED LEVEL OF DRAIN 251.80 TOP OF BARREL ROOF 1 U/S TOE WALL 0.40 X 0.80

R.L. 251.20 2 U/S CUT OFF 0.50 X 1.00

3.10 3 C.C. BLOCK 0.50 X 0.50

R.L. 248.40

4 D/S CUT OFF 0.50 X 1.50

6.90 5 D/S TOE WALL 0.40 X 1.00

Program by - Sunil K Goyal Drawing 12 Checked by- P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

SECTION AT B-B 6 LEAN CONCRETE 0.15 M THICK

7 D.B.PITCHING 0.40 M THICK

M THICK

DETAILS OF TRANSITION WINGS

TRANSITION WING TRANSITION WING

4.275 4.275

18.00

13.62

18.00

7.73

6.30

6.30

6.30

6.61

7.73

9.96

###

6.00

3.00 8.78

5.85 11.55

4.275 8.70 14.55 4.275

11.70 17.55

CONTRACTION TRANSITION EXPANSION TRANSITION

DETAILS OF PUCCA FLOOR

0.70 0.90

1.15

1.30

1.60

1.70

2.20

2.00

4.00 3.25 3.25 3.25 3.25

6.00

13.00

U/S PUCCA FLOOR D/S PUCCA FLOOR

Program by - Sunil K Goyal Drawing 13 Checked by- P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

Program by - Sunil K Goyal Drawing 14 Checked by- P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

STRUCURAL DESIGN OF A CANAL SYPHON

NAME OF PROJECT : Case study, Design example 9.4/p394

DESIGN DATA :

1 UNIT WEIGHT OF DRY EARTH 1.60 t/m3

2 UNIT WEIGHT OF SATURATED EARTH 2.00 t/m3

3 UNIT WEIGHT OF SUBMERGED EARTH 1.00 t/m3

4 UNIT WEIGHT OF CONCRETE 2.40 t/m3

5 ANGLE OF INTERNAL FRICTION ( f ) 30 Degree

6 GRADE OF STEEL Fe 415

7 GRADE OF CONCRETE M 20

6 DIAMETER OF REINF. BARS Main 16 F

Dist 12 F

7 NUMBER OF BARRELS 2 Nos.

8 WIDTH OF EACH BARREL 3.00 m

9 HEIGHT OF EACH BARREL 2.50 m

10 THICKNESS OF BARREL 0.30 m

11 BANK LEVEL 254.00 m

11 DRAIN H.F.L. 253.25 m

12 LEVEL AT TOP OF BARREL 251.20 M

13 UPLIFT AT BASE OF BARREL 4.93 t/m2

Program by- Sunil K Goyal Structural 15 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

(1) Critical section of the barrel

The barrel shall be subjected to maximum loading under the bank at the lowest possible

level of the barrel as indicated below in the following section:-

Bank level 254.00 m

Saturation line 253.25 m

R.L. 251.20 m

2.50

R.L. 248.40 m

R.L. 248.10 m

6.90

(2) Design features

Following cosiderations have been made in the design of barrels :

(i) Bottom slab : This design is for uplift pressure and reaction from soil resulting from

the loading on the foundations. Theoretically, the soil reaction is not uniform but for

simplification it is assumed uniform.

(ii) side walls : Side walls would be tested in the following two critical conditions

(a) High flood in the drain while barrels are empty

(b) No water in the drain while barrels are full

(iii) Partition walls : The partition walls are subjected to equal pressures on either side, and

therefore,no reinforcement is required. Nominal reinforcement is, however,

provided to take care of contingency arising due to unequal pressures

resulting from chocking up of any of the barrels.

(iv) Top slab : The loads considered for design of top slab are :

(a) Earth load,

(b) Weight of water below saturation line

As there is no roadway along the drain, no live load due to traffic shall be considered.

(3) Design

As the barrels are rigidly joined, they should be designed as a continuous structure. Hardy Cross

method of moment distribution shall be used for design.

The effective length of horizontal member = 3.30 m

The effective length of vertical member = 2.80 m

Distribution factors

At joint A

2.8

For member AB = = 0.46

2.8 + 3.3

3.3

For member AD = = 0.54

2.8 + 3.3

Program by- Sunil K Goyal Structural 16 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

At joint D

3.3

For member DA = = 0.54

2.8 + 3.3

2.8

For member DC = = 0.46

2.8 + 3.3

(i) Dead loads

Consider one meter length of barrel

Depth of dry earth over barrel = 254.00 - 253.25 = 0.75 m

Depth of saturated earth = 253.25 - 251.20 = 2.05 m

Weight of dry and saturard earth = 0.75 X 1.60 + 2.05 X 2.00

= 5.3 t/m2

Weight of top slab = 0.30 X 2.40 = 0.72 t/m2

Weight on the top slab including its own weight = 5.3 + 0.72

= 6.02 t/m2

Weight of the barrels per metre of length

=( 4 X 3.3 + 3 X 2.8 ) X 0.30 X 2.40

= 15.55 t

Total dead load/m length of barrels = 15.55 + 5.3 X 6.90

= 52.12 t

Uplift/m length = 4.93 X 6.90 = 34.04 t

Net vertical load acting on foundation = 52.122 - 34.04

= 18.08 t

18.082

Pressure on foundation soil = = 2.62 t/m2

6.90

Pressure acting on the base slab = Soil reaction + uplift

= 2.62 + 4.93

= 7.55 t/m 2

Net upward pressure on the base slab = 7.55 - 0.72

= 6.83 t/m2

(ii) Earth pressure

The earth pressure shall comprise of the following :

(a) dry earth pressure above saturation line from R.L. 253.25 to 254.00

(b) saturated earth pressure from R.L. 253.25 to 248.25

Program by- Sunil K Goyal Structural 17 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

Corresponding to f = 30 degree , Cp = 1/3

The pressure at A= Surcharge due to dry earth + Surcharge due to saturated earth

= Cp X wd X 0.75 + Cp X ws X 2.20

+ w X 2.20

= 1/3 X 1.60 X 0.75 + 1/3 X 1.0 X 2.20

+ 1 X 2.20

= 3.33 t/m2

Pressure at D = 3.33 + Cp X ws X 2.8 + w X 2.8

= 3.33 + 1/3 X 1.00 X 2.8 + 1 X 2.8

= 7.07 t/m2

Loads acting on different members are shown below :

6.02 t/m2

3.33 t/m 2

3.33 t/m2

A B E

3.30 3.30

2.80

D C F

7.07 t/m2 D 7.07 t/m2

6.83 t/m 2

(iii) Fixing moments

wl2 6.02 X 3.3 2

(i) On span AB = 12 = 12

= 5.46 t-m

wl2 6.83 X 3.3 2

(ii) On span CD = 12 = 12

= 6.20 t-m

(iii) On span AD fixed end moments in the wall at each end due to rectangular portion

wl2 3.33 X 2.8 2

= 12 = 12

= 2.178 t-m

Fixed end moments due to triangular portion

3.73 X 2.8 2

MAD = 30

= 0.9756 t-m

MDA = 3.73 X 2.8 2

20

Program by- Sunil K Goyal Structural 18 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

= 1.4635 t-m

Program by- Sunil K Goyal Structural 19 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

Total fixed end moments at A = 2.178 + 0.976

= 3.15 t-m

Total fixed end moments at D = 2.178 + 1.4635

= 3.64 t-m

(iv) Distribution of moments

Joints C D A B

Distribution 0.46 0.54 0.54 0.46

factors

Fixed end -6.20 6.20 -3.64 3.15 -5.46 5.46

moments

Balance -1.18 -1.39 1.25 1.06

Carry over -0.59 0.62 -0.69 0.53

Balance -0.29 -0.34 0.37 0.32

Carry over -0.14 0.19 -0.17 0.16

Balance -0.09 -0.10 0.09 0.08

Carry over -0.04 0.05 -0.05 0.04

Balance -0.02 -0.02 0.03 0.02

Total -6.98 4.63 -4.63 3.98 -3.98 6.19

(v) Net moments at centre and face

Span AB

6.02 X 3.3 6.02 X 0.15 2

Sagging moments at face = ------------------- X 0.15 - -----------------------------

2 2

= 1.4222 t-m

3.15

Fixing moments at face= 3.98 + ( 6.19 - 3.98 )

3.3

= 6.0907 t-m

Net fixing moments at face = 6.0907 - 1.422

= 4.6685 t-m

Sagging moments at centre = 6.02 X 3.3 2

8

= 8.1947 t-m

Fixing moments at centre = 3.98 + 6.19

2

= 5.0876 t-m

Net sagging moments at centre = 8.195 - 5.088

= 3.107 t-m

Program by- Sunil K Goyal Structural 20 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

Span CD

6.83 X 3.3 6.83 X 0.15 2

Sagging moments at face = -------------------- X 0.15 - ----------------------------

2 2

= 1.6145 t-m

Fixing moments at face= 3.15

4.63 + ( 6.98 - 4.63 )

3.3

= 6.8693 t-m

Net fixing moments at face = 6.8693 - 1.61451

= 5.2548 t-m

Sagging moments at centre = 6.83 X 3.3 2

= 9.3027 t-m

Fixing moments at centre = 6.98 + 4.63

2

= 5.8043 t-m

Net sagging moments at centre = 9.303 - 5.804

= 3.498 t-m

Span AD

(a) Due to rectangular portion

3.33 X 2.8 3.33 X 0.15 2

= X 0.15 -

2 2

= 0.6625 t-m

(a) Due to triangular portion

3.73 X 2.8 1 0.2 X 0.15

= X X 0.15 - X 0.05

2 3 2

= 0.2606 t-m

Total sagging moments at face = 0.662 + 0.261

= 0.92 t-m

Fixing moments at face = 3.98 + 2.65 ( 4.63 - 3.98 )

2.8

= 4.598 t-m

Program by- Sunil K Goyal Structural 21 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

Net fixing moments at face = 4.598 - 0.92

= 3.67 t-m

Sagging moments at centre

(a) Due to rectangular portion = 3.33 X 2.80 2

8

= 3.27 t-m

(b) Due to triangular portion = 3.73 X 2.80 1

X 2.8 X

2 7.81

= 1.87 t-m

Total sagging moments at centre = 3.27 + 1.87

= 5.14 t-m

4.63 + 3.98

Fixing moments at centre =

2

= 4.31 t-m

Net sagging moments at centre = 5.14 - 4.31

= 0.83 t-m

The net moments at face and centre of the different spans are tabulated below :

MOMENTS

Span

At face At centre

AB 4.67 t-m (hogging) 3.11 t-m (sagging)

CD 5.25 t-m (hogging) 3.50 t-m (sagging)

AD 3.67 t-m (hogging) 0.83 t-m (sagging)

(vi) Thickness of members

The maximum moment in the barrels is 5.25 t-m

For M 20 grade concrete and steel of Fe 415

scbc = 70 Kg/cm2 s st

= 1500.00 Kg/cm2

m = 13

k = 0.378

j = 0.874

Q = 11.552

The minimum effective thickness (d) required for bending moment

M 5.25 X 105

d = =

bQ 100 X 11.552

= 21.33 cm

Adopt overall thickness of all the members = 30.0 cm

Then effective thickness = 25.20 cm

Program by- Sunil K Goyal Structural 22 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

(clear cover = 4.0 cm )

Program by- Sunil K Goyal Structural 23 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

The reinforcement required at various points is given below :

(vii) Reinforcement

Span AB & BE

Moments in t-m Reinforcement required

At face 4.67 t-m (hogging) At = 14.13 Cm2

Provide 16 mm bars @ 14.0 cm c/c

At centre 3.11 t-m (sagging) At = 9.40 Cm2

Provide 16 mm bars @ 21.0 cm c/c

Span CD & CF

Moments in t-m Reinforcement required

At face 5.25 t-m (hogging) At = 15.90 Cm2

Provide 16 mm bars @ 12.0 cm c/c

At centre 3.50 t-m (sagging) At = 10.59 Cm2

Provide 16 mm bars @ 18.0 cm c/c

Span AD & EF

Moments in t-m Reinforcement required

At face 3.67 t-m (hogging) At = 11.12 Cm2

Provide 16 mm bars @ 18.0 cm c/c

At centre 0.83 t-m (sagging) At = 2.52 Cm2

Provide 16 mm bars @ 25.0 cm c/c

Nominal steel shall also be provided on the outer face of the walls for the condition when there is

no water in the drain and barrels are running full. The details of reinforcement are shown below

16 mm f @ 14.0 cm c/c

16 mm f @ 14.0 cm c/c

12 mm f @ 25.0 cm c/c

16 mm f @ 21.0 cm c/c

C.C. M - 20 16 mm f @ 25.0 cm c/c 12 mm f @ 25.0 cm c/c

16 mm f @ 18.0 cm c/c

16 mm f @ 12.0 cm c/c clear cover = 4.00 cm

16 mm f @ 18.0 cm c/c

0.30 3.00 m 0.30 3.00 0.30

DETAILS OF REINFORCEMENT IN SYPHON BARRELS

Program by- Sunil K Goyal Structural 24 Checked by - P P Pareek

Office of Director Dam

368513587.xls

I.D.R.,Jaipur

************* *************

Program by- Sunil K Goyal Structural 25 Checked by - P P Pareek

You might also like

- Civil TechDocument358 pagesCivil TechGunaNo ratings yet

- ADocument1 pageAMukhlish AkhatarNo ratings yet

- Controls & Planning Management PlanDocument14 pagesControls & Planning Management PlanmukhleshNo ratings yet

- AbDocument1 pageAbMukhlish AkhatarNo ratings yet

- IuiuioiioDocument1 pageIuiuioiioMukhlish AkhatarNo ratings yet

- Civil Delhi24-7 PDFDocument142 pagesCivil Delhi24-7 PDFMukhlish AkhatarNo ratings yet

- JHGGGGDocument1 pageJHGGGGMukhlish AkhatarNo ratings yet

- Business Structure Selector1Document3 pagesBusiness Structure Selector1mukhleshNo ratings yet

- Employee Shift Schedule1Document2 pagesEmployee Shift Schedule1kg1240No ratings yet

- Column Design LinkDocument10 pagesColumn Design LinkMukhlish AkhatarNo ratings yet

- 12 Month Cash Flow Statement1AZXDocument2 pages12 Month Cash Flow Statement1AZXmukhleshNo ratings yet

- Water Tank Design As Per Moody ChartDocument20 pagesWater Tank Design As Per Moody ChartMukhlish AkhatarNo ratings yet

- 12 Month Cash Flow Statement1AZXDocument6 pages12 Month Cash Flow Statement1AZXMukhlish AkhatarNo ratings yet

- RCC Rate AnalsysisDocument2 pagesRCC Rate AnalsysisjowarNo ratings yet

- Start Up CapitalDocument1 pageStart Up Capitalshegel100% (4)

- Opening Day Balance SheetDocument2 pagesOpening Day Balance Sheetapi-3809857No ratings yet

- Corbel: 25 415 Bearing in Steel Plate Cast 0.8Document3 pagesCorbel: 25 415 Bearing in Steel Plate Cast 0.8mukhleshNo ratings yet

- Cantilever SlabDocument16 pagesCantilever SlabMukhlish AkhatarNo ratings yet

- Petty Cash Request4Document1 pagePetty Cash Request4Mukhlish AkhatarNo ratings yet

- LRFD Compression Member DesignDocument248 pagesLRFD Compression Member DesignMukhlish Akhatar100% (1)

- Project Performance Tracking and ReportingDocument9 pagesProject Performance Tracking and ReportingUbuntu LinuxNo ratings yet

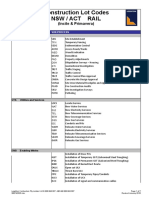

- NSW & ACT Construction Rail Codes V1.1Document7 pagesNSW & ACT Construction Rail Codes V1.1Mukhlish AkhatarNo ratings yet

- Purchase Order With Sales Tax4Document1 pagePurchase Order With Sales Tax4Mukhlish AkhatarNo ratings yet

- General Ledger1Document8 pagesGeneral Ledger1Mukhlish AkhatarNo ratings yet

- Petty Cash Request4Document1 pagePetty Cash Request4Mukhlish AkhatarNo ratings yet

- Customers Pivot TableDocument71 pagesCustomers Pivot TableAdie MorganNo ratings yet

- Income StatementDocument19 pagesIncome StatementiPakistan67% (3)

- KPM Uncertainty Input SheetDocument210 pagesKPM Uncertainty Input SheetMukhlish AkhatarNo ratings yet

- Idprd 281298Document2 pagesIdprd 281298Mukhlish AkhatarNo ratings yet

- Profit and Loss Summary: Budget Summary ReportDocument6 pagesProfit and Loss Summary: Budget Summary ReportIslam Ayman AbdelwahabNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- To Water Supply and Sanitation: Submitted By: RUBY JANGRA (18001006057) SAHIL REDHU (18001006060)Document33 pagesTo Water Supply and Sanitation: Submitted By: RUBY JANGRA (18001006057) SAHIL REDHU (18001006060)sahilNo ratings yet

- Budget & Service Highlights: Durham RegionDocument4 pagesBudget & Service Highlights: Durham RegionlindaNo ratings yet

- Plumbing Fitting Joints and FixtureDocument61 pagesPlumbing Fitting Joints and FixtureManjeet Cingh100% (1)

- LDL Design GuideDocument18 pagesLDL Design GuidebhupsjangirNo ratings yet

- PART 1B Tech SpecificationDocument98 pagesPART 1B Tech SpecificationChandrashekar PatigeNo ratings yet

- Hidraulika Saluran TerbukaDocument110 pagesHidraulika Saluran Terbukasekar_mayangNo ratings yet

- Differential Head Flowmeters (Usbr - Gov) (ISO-5167 Stolz Equation) .HTMLDocument7 pagesDifferential Head Flowmeters (Usbr - Gov) (ISO-5167 Stolz Equation) .HTMLempanadaNo ratings yet

- Method Statement For Plumbing Piping Works Rev 01 PDFDocument46 pagesMethod Statement For Plumbing Piping Works Rev 01 PDFjaianit8980% (5)

- Service Ariston 081313462267Document12 pagesService Ariston 081313462267Service Pemanas AirNo ratings yet

- Improvement of The Drainage System in Poblacion BulaDocument37 pagesImprovement of The Drainage System in Poblacion BulaLester Ave BermidoNo ratings yet

- Hubbell Model GXDocument6 pagesHubbell Model GXast654No ratings yet

- SOLAR POWER SYSTEM RoanDocument34 pagesSOLAR POWER SYSTEM RoanroanNo ratings yet

- 2016 FullVol5LIDManualDocument258 pages2016 FullVol5LIDManualalikoleiniNo ratings yet

- Usp 38-1231Document27 pagesUsp 38-1231spiderman00No ratings yet

- Flow SumpitDocument1 pageFlow SumpitMuhammad Fiqi SyaifuddinNo ratings yet

- Government Polytechnic Ghari Shyampur RishikeshDocument14 pagesGovernment Polytechnic Ghari Shyampur RishikeshNaveen SinghNo ratings yet

- 2.2.3. TSF Embankment Seepage Analysis - 114001.06-M002 - Eng PDFDocument7 pages2.2.3. TSF Embankment Seepage Analysis - 114001.06-M002 - Eng PDFFernando TorresNo ratings yet

- Chapter Six Urban Hydrology 6. Urban Hydrology: Engineering Hydrology Lecture NoteDocument8 pagesChapter Six Urban Hydrology 6. Urban Hydrology: Engineering Hydrology Lecture NoteKefene GurmessaNo ratings yet

- Management of Lakes in India 10mar04Document20 pagesManagement of Lakes in India 10mar04Chinglen KhunNo ratings yet

- Is 458 - 2003Document33 pagesIs 458 - 2003Milind Gupta50% (4)

- Plumbing Inspection Checklist - Form 11.7Document1 pagePlumbing Inspection Checklist - Form 11.7Justin Rolfe0% (1)

- Water - A Precious ResourceDocument15 pagesWater - A Precious ResourceHarshita RanjanNo ratings yet

- Geberit MRP CatalogueDocument35 pagesGeberit MRP Catalogueinquiry.surfacesplusNo ratings yet

- Fagc - Aerodrome Chart - Ad-01Document1 pageFagc - Aerodrome Chart - Ad-01KHUSHAL BANSALNo ratings yet

- Water2buy Water Softener Owners ManualDocument110 pagesWater2buy Water Softener Owners ManualSalomon SalomonNo ratings yet

- SedimentationDocument26 pagesSedimentationDavid Charles Meissner100% (1)

- Golf WaterDocument6 pagesGolf WaterZainalNo ratings yet

- Hydraulic Jump-1Document14 pagesHydraulic Jump-1Manny Anthony TagubaNo ratings yet

- Commercial Softener Install Apr2010Document3 pagesCommercial Softener Install Apr2010nermeen ahmedNo ratings yet

- KKKZDocument76 pagesKKKZMahesh ShindeNo ratings yet