Professional Documents

Culture Documents

Visual Testing 12.1introduction To, Terminology, Purpose and History Of, NDT History

Uploaded by

Shahazad Shaik0 ratings0% found this document useful (0 votes)

21 views4 pagesThis document provides an overview of visual testing (VT) as a non-destructive testing (NDT) method. It discusses the history, purpose, terminology and physical principles of VT. It also describes VT equipment, testing procedures, evaluation techniques, quality aspects, and recent developments in the field. The document is intended to educate level I technicians on how to perform VT based on relevant standards and written test instructions.

Original Description:

8

Original Title

8

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of visual testing (VT) as a non-destructive testing (NDT) method. It discusses the history, purpose, terminology and physical principles of VT. It also describes VT equipment, testing procedures, evaluation techniques, quality aspects, and recent developments in the field. The document is intended to educate level I technicians on how to perform VT based on relevant standards and written test instructions.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views4 pagesVisual Testing 12.1introduction To, Terminology, Purpose and History Of, NDT History

Uploaded by

Shahazad ShaikThis document provides an overview of visual testing (VT) as a non-destructive testing (NDT) method. It discusses the history, purpose, terminology and physical principles of VT. It also describes VT equipment, testing procedures, evaluation techniques, quality aspects, and recent developments in the field. The document is intended to educate level I technicians on how to perform VT based on relevant standards and written test instructions.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Luminance:

VISUAL TESTING lighting levels;

12.1Introduction to, terminology, purpose lighting techniques;

and history of, NDT contrast.

History Optical principles:

History of visual testing (VT) operation of lenses;

Purpose of NDT operation of magnifiers;

Definition of VT image construction;

Terminology virtual images;

Terminology applicable to VT chromatic aberration

EN 1330-2 and EN 1330-10 geometric distortion;

Extended overview of VT magnification principles;

Applications Visual perception:

12.2 Physical principles of the method what the eyes see;

and associated knowledge what the mind sees;

Relevant standards: what others perceive;

EN 13018: VT General principles what the designer, engineer etc.

EN 13927: VT equipment Material attributes affecting the test:

Vision: cleanliness;

Fundamentals The eye, including operation colour;

and construction condition;

Vision limitations shape;

Adaptation and accommodation Disorders size;

Lighting: physics of light temperature;

Electromagnetic radiation texture;

Visible wavelengths type;

Fundamentals of light: surface finish;

transmission; surface preparation;

reflection; Environmental and physiological

absorption. factors:

Lighting measurements atmosphere;

comfort; cold working processes;

perspective. heat treatment processes.

distance; Material composition:

accessing; surface finishing methods;

fatigue; basic foundry technology;

health; machining and material removal

humidity; processes;

mental attitude; polymers/composites.

position; In-service aspects:

safety; service induced flaws;

temperature; mechanically;

cleanliness. thermally;

Direct and remote methods tribology;

Vision requirements & the employers wear;

Responsibility chemical;

12.3 Product knowledge and capabilities electrochemical.

of the method and its derivate techniques References:

The depth of knowledge required for EN 970

this section is as follows: EN 12454

test objects and flaws; EN 1370

basic production and EN 10163-1

degradation process; EN 10163-2

terms, origin and nature and EN 10163-3

appearance of flaws; EN ISO 5817, etc

product technology sectors; Capability and limitations of VT

basic metallurgy of the Detect ability:

process/component; flaw size;

welding/joining methods. shape;

Including cladding and buttering orientation/position;

wrought product production flaw types;

methods; surface condition effects;

equipment limitations; Image recording, transfer and storage

lighting effects. equipment:

Associated techniques: equipment selection & limitations

gauging; verification of equipment

comparators; Sizing of indications:

measurement; imaging systems;

thermographic imaging; special optical systems.

replication. Or other special equipment as

References: necessary for the test (underwater,

ISO 3057 radiation resistant, etc.)

12.4 Equipment Introduction to, and 12.5 Information prior to testing

applications of, equipment Pre-test documentation (EN 13018)

Introduction to, and applications of, Test instructions

equipment Written procedure or standard (when

Mirrors required)

Magnifiers (ISO 3058) Object to be tested

Borescopes Extent of test coverage

Fibrescopes Technique and sequence of performing test

Photographic and video: Surface condition

imaging cameras; Surface preparation

video monitors The stage of manufacture or service

light sources and special life when testing is to be carried out

lighting; The requirements of test personnel

gauges, templates, scales, The acceptance criteria

special tools, etc.; The illumination (type, level and direction)

automated systems; The visual testing equipment to be used

computer-enhanced systems; The post test documentation

demonstration test piece; A demonstration test piece &

resolution targets; inspection checkpoints

graticules. Requirement for recorded images

Development and writing of NDT

instructions for level I for a given test By comparison

specimen, from standards or codes By measurement

12.6 Testing Automated evaluation, e.g. pattern

How to set up and calibrate a test Recognition

Specifying and working with Recording

demonstration test pieces and Reporting

resolution targets 12.9 Quality aspects

Prepare written test instructions from Personnel qualification

standards or codes for given test (according to EN 473 and ISO 9712)

pieces Equipment verification

Practical training on test equipment Written instructions

and performing tests on training test Traceability of documents

pieces with known flaws to A review of applicable NDT

instructions as above including application and product standards

equipment and test parameters 12.10 Developments

12.7 Evaluation and Reporting General information

Level 1 detail plus how to control

and monitor a Level 1 test done

with your guidance

Interpretation, evaluation and

reporting of results to specifications

and standards

Objective/Subjective evaluation

Completion of calibration forms

12.8 Assessment

Classification and assessment of

observations per acceptance criteria

from the codes, standards or written

instructions, etc. or by specific

reference to a level 3 where no

codes or standards exist

You might also like

- Visual Testing Topical Outline: FundamentalsDocument2 pagesVisual Testing Topical Outline: FundamentalsGaurav ChopraNo ratings yet

- About Visual Testing (VT) : Visual Testing Is The Most Commonly Used Test Method in Industry. Because Most Test MethodsDocument1 pageAbout Visual Testing (VT) : Visual Testing Is The Most Commonly Used Test Method in Industry. Because Most Test MethodsJATINNo ratings yet

- ANDT - Student PanelDocument7 pagesANDT - Student Panelma.8840936885No ratings yet

- SECTION 11.4 Computed Radiography Procedures (Photostimulable Luminescence)Document11 pagesSECTION 11.4 Computed Radiography Procedures (Photostimulable Luminescence)Esin DenizNo ratings yet

- Level 1 IR Course Intro and OutlineDocument3 pagesLevel 1 IR Course Intro and OutlineLiam SerdeñaNo ratings yet

- 529lecture 1 Non Destructive TestingDocument120 pages529lecture 1 Non Destructive TestingLuis Eduardo Albarracin RugelesNo ratings yet

- Digital Imaging and Communication in Nondestructive Evaluation (DICONDE)Document12 pagesDigital Imaging and Communication in Nondestructive Evaluation (DICONDE)Dagi GossayeNo ratings yet

- IIWCourseNotes NDE 2002Document15 pagesIIWCourseNotes NDE 2002HabanitaConstantineFrancoNo ratings yet

- M2.2.2 Overview of NDT MethodsDocument22 pagesM2.2.2 Overview of NDT MethodsAldy Bagus PratamaNo ratings yet

- EPAS NC II - Core CompetenciesDocument15 pagesEPAS NC II - Core CompetenciesFe Marie JisonNo ratings yet

- Asnt 8Document8 pagesAsnt 8amin.adineh97No ratings yet

- AC7114-4 Rev M Final EDITORIAL 2DECDocument60 pagesAC7114-4 Rev M Final EDITORIAL 2DECRaja HoneNo ratings yet

- A C E S: Non Destructive TestingDocument25 pagesA C E S: Non Destructive TestingMahesh TamboliNo ratings yet

- NDT Unit 1to5Document373 pagesNDT Unit 1to5UdamanNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument21 pagesNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORNo ratings yet

- AWS R I C P: Adiographic Nterpreter Ertification RogramDocument4 pagesAWS R I C P: Adiographic Nterpreter Ertification RogramSharat Chandra100% (1)

- Seminar On Non-Destructive Testing: Submitted To: Submitted byDocument25 pagesSeminar On Non-Destructive Testing: Submitted To: Submitted byMahesh TamboliNo ratings yet

- Dash Utrtmtptvt Bro 2014Document6 pagesDash Utrtmtptvt Bro 2014dashNo ratings yet

- Visual Testing Level I and II Course OutlineDocument1 pageVisual Testing Level I and II Course OutlineMohammed Al-OdatNo ratings yet

- Educational Services - ES 11b ASME Section V - 1 Day - Rev August 2016Document2 pagesEducational Services - ES 11b ASME Section V - 1 Day - Rev August 2016Khalid RabbaniNo ratings yet

- NDT Facility - Magnetic Particle Testing (AC7114 - 2) Checklist - SafetyCultureDocument37 pagesNDT Facility - Magnetic Particle Testing (AC7114 - 2) Checklist - SafetyCulturevalentinNo ratings yet

- MF4092 NDT - PGDocument1 pageMF4092 NDT - PGJeganNo ratings yet

- Lesson 3 - IsO 9712Document13 pagesLesson 3 - IsO 9712Abdelaziz AbdoNo ratings yet

- MEPR205C - El 1 Metrology & Computer Aided InspectionDocument3 pagesMEPR205C - El 1 Metrology & Computer Aided Inspectionዘረአዳም ዘመንቆረርNo ratings yet

- B Gas Examination RequirementsDocument25 pagesB Gas Examination RequirementsNnamdi Celestine Nnamdi100% (1)

- Radiographic Examination: Standard Practice ForDocument17 pagesRadiographic Examination: Standard Practice ForrajeshNo ratings yet

- E 2033 - 99 (2013)Document11 pagesE 2033 - 99 (2013)Enrique Antonio100% (2)

- Radiographic Examination: Standard Practice ForDocument17 pagesRadiographic Examination: Standard Practice ForSERDARNo ratings yet

- RT Level 3 ModuleDocument8 pagesRT Level 3 ModuleArwin C. BoteNo ratings yet

- Mech NDTDocument25 pagesMech NDTArvind sharmaNo ratings yet

- Visual Testing (NDT VT) : Target CustomersDocument2 pagesVisual Testing (NDT VT) : Target Customersrejaul karimNo ratings yet

- Mech NDT PPT (1) Final..Document25 pagesMech NDT PPT (1) Final..Shahnawaz AhmedNo ratings yet

- NDT TestingDocument10 pagesNDT TestingTANISHKA VASNo ratings yet

- E1742E1742M-18 RadiographyDocument17 pagesE1742E1742M-18 Radiographydilaafadil104No ratings yet

- What To Study For The ExamsDocument6 pagesWhat To Study For The ExamsvinchandNo ratings yet

- Selection of NDE MethodsDocument6 pagesSelection of NDE MethodsNABIL HUSSAINNo ratings yet

- Radiography TestingDocument1 pageRadiography TestingGulfnde Industrial ServicesNo ratings yet

- ASTM E1742-E1742M-18 Standard Practice For Radiographic ExaminationDocument17 pagesASTM E1742-E1742M-18 Standard Practice For Radiographic Examinationdavid plata100% (1)

- NDT20 Course NotesDocument278 pagesNDT20 Course Noteshazzleraflet100% (11)

- E2339-15 Práctica Estándar para Imagen Digital y Comunicación en Evaluación No Destructiva DICONDEDocument11 pagesE2339-15 Práctica Estándar para Imagen Digital y Comunicación en Evaluación No Destructiva DICONDEfredy lopezNo ratings yet

- Asnt 9Document4 pagesAsnt 9amin.adineh97No ratings yet

- Internship Report On NDT Level 2Document34 pagesInternship Report On NDT Level 2Mohammed SafwanNo ratings yet

- Usth W2day1 Lec4 NDTDocument43 pagesUsth W2day1 Lec4 NDTTuan VuNo ratings yet

- Codes and Standards: Specific ObjectivesDocument14 pagesCodes and Standards: Specific ObjectivesJahan ZebNo ratings yet

- Asme V 2013.pdf - 3Document71 pagesAsme V 2013.pdf - 3ananth.sankar123No ratings yet

- Seminar On Non-Destructive Testing: Submitted To: Submitted byDocument25 pagesSeminar On Non-Destructive Testing: Submitted To: Submitted bysubrataNo ratings yet

- Syllabus Compendium For PCN Aerospace Sector ExaminationsDocument27 pagesSyllabus Compendium For PCN Aerospace Sector ExaminationstomcanNo ratings yet

- 0 Intro General - Nondestructive TestingDocument33 pages0 Intro General - Nondestructive TestingDavidNo ratings yet

- NDT Course WorkDocument5 pagesNDT Course Workusutyuvcf100% (2)

- NDTDocument3 pagesNDTCallvimal RamNo ratings yet

- 003 ET 2 Certification Scheme DetailDocument6 pages003 ET 2 Certification Scheme DetailadminNo ratings yet

- ASNT Nivel III ExaminationDocument6 pagesASNT Nivel III ExaminationjomsedNo ratings yet

- Fideli Thermographic MAM 6 2015Document4 pagesFideli Thermographic MAM 6 2015joelNo ratings yet

- Tec SD RS QMS 333 02 Mar 10Document59 pagesTec SD RS QMS 333 02 Mar 10Santhakrishnan AdhinarayananNo ratings yet

- Non Destructive Testing (NDT L-2) Course ContentsDocument2 pagesNon Destructive Testing (NDT L-2) Course ContentsHarminder KumarNo ratings yet

- NDT Course OutlineDocument8 pagesNDT Course OutlineChaitanya PurohitNo ratings yet

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsFrom EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsRating: 4.5 out of 5 stars4.5/5 (3)

- Medical Coatings and Deposition TechnologiesFrom EverandMedical Coatings and Deposition TechnologiesDavid GlockerNo ratings yet

- AP Single Desk Policy 2015 20Document12 pagesAP Single Desk Policy 2015 20Shahazad ShaikNo ratings yet

- A Report On StudentDocument1 pageA Report On StudentShahazad ShaikNo ratings yet

- PdfjoinerDocument57 pagesPdfjoinerShahazad ShaikNo ratings yet

- Design of BrakesDocument18 pagesDesign of BrakesShahazad ShaikNo ratings yet

- Barkhausen Noise Analysis PDFDocument4 pagesBarkhausen Noise Analysis PDFShahazad ShaikNo ratings yet

- Application Form StudentMember SMDocument5 pagesApplication Form StudentMember SMShahazad ShaikNo ratings yet

- 11 2018notification PDFDocument24 pages11 2018notification PDFShahazad ShaikNo ratings yet

- Band BrakesDocument19 pagesBand BrakesShahazad ShaikNo ratings yet

- Lab Manual For MOS LabDocument30 pagesLab Manual For MOS LabShahazad ShaikNo ratings yet

- CounsellorsDocument4 pagesCounsellorsShahazad ShaikNo ratings yet

- Basic Concepts of Descriptive Geometry: Geometry-Developed by Gaspard Monge in The Late Eighteenth Century, WhoDocument36 pagesBasic Concepts of Descriptive Geometry: Geometry-Developed by Gaspard Monge in The Late Eighteenth Century, WhoShahazad ShaikNo ratings yet

- Assignment Questions MDocument2 pagesAssignment Questions MShahazad ShaikNo ratings yet

- Assignment QuestionsDocument4 pagesAssignment QuestionsShahazad ShaikNo ratings yet

- Isometric Projections: Engineering GraphicsDocument15 pagesIsometric Projections: Engineering GraphicsShahazad ShaikNo ratings yet

- DisciplineDocument1 pageDisciplineShahazad ShaikNo ratings yet

- Rajiv Gandhi University of Knowledge Technologies, Andhra PradeshDocument1 pageRajiv Gandhi University of Knowledge Technologies, Andhra PradeshShahazad ShaikNo ratings yet

- Curves: Engineering GraphicsDocument18 pagesCurves: Engineering GraphicsShahazad ShaikNo ratings yet

- Ed SyllabusDocument1 pageEd SyllabusShahazad ShaikNo ratings yet

- Category Anantapur DistrictDocument2 pagesCategory Anantapur DistrictShahazad ShaikNo ratings yet

- ASNT L3 Exam ExperienceDocument5 pagesASNT L3 Exam ExperienceShahazad Shaik100% (1)

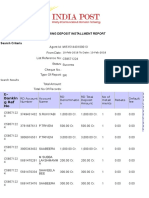

- Recurring Deposit Installment Report: E-Bankin G Ref NoDocument4 pagesRecurring Deposit Installment Report: E-Bankin G Ref NoShahazad ShaikNo ratings yet

- Hotspot (Wi Fi)Document6 pagesHotspot (Wi Fi)Shahazad ShaikNo ratings yet

- Owner's ManualDocument208 pagesOwner's ManualChantal LilouNo ratings yet

- Supply - Chain - Master - Data - SAP IBPDocument12 pagesSupply - Chain - Master - Data - SAP IBPharry4sapNo ratings yet

- Homework 15 Inside SimilarityDocument8 pagesHomework 15 Inside Similarityafeutlbet100% (1)

- KPP V1000 en Int02 0607Document24 pagesKPP V1000 en Int02 0607Abanoub Badawi MasryNo ratings yet

- Software Development Life Cycle-VDocument3 pagesSoftware Development Life Cycle-VDeepak Prakash JayaNo ratings yet

- Headphone Technology Hear-Through, Bone Conduction, Noise CancelingDocument6 pagesHeadphone Technology Hear-Through, Bone Conduction, Noise CancelingRichard HallumNo ratings yet

- Scope and Sequence of Math CurriculumDocument2 pagesScope and Sequence of Math CurriculumFaisal MunirNo ratings yet

- Bernoulli Process and Wiener ProcessDocument12 pagesBernoulli Process and Wiener Processdeary omarNo ratings yet

- Unit I. Bascis of Manufacturing ProcessesDocument30 pagesUnit I. Bascis of Manufacturing Processes070 ARITRITA BRAHMA ECENo ratings yet

- Operation & Maintenance Manual For Hypercomp CNG Compressor Model 3W815Document208 pagesOperation & Maintenance Manual For Hypercomp CNG Compressor Model 3W815Asim Riaz80% (5)

- CTS+ Configuration For PI 7.3Document23 pagesCTS+ Configuration For PI 7.3RaQNo ratings yet

- Chem301 Lab3Document5 pagesChem301 Lab3Gobe JamNo ratings yet

- Sef 0l6aeDocument144 pagesSef 0l6aezarni zarniNo ratings yet

- Jis B 1180 2004 EngDocument74 pagesJis B 1180 2004 EngAyman Hamed MalahNo ratings yet

- Virtual Memory and Demand PagingDocument50 pagesVirtual Memory and Demand PagingPrakash SinghNo ratings yet

- Ncert Class 12 Physics Current ElectricityDocument30 pagesNcert Class 12 Physics Current ElectricityfaatinNo ratings yet

- Unit 6 Chapter 1 Parallel Programming Tools Cuda - ProgrammingDocument28 pagesUnit 6 Chapter 1 Parallel Programming Tools Cuda - ProgrammingPallavi BhartiNo ratings yet

- 6.4.7 Factors Affecting Distillation Column Operation 1. Vapor Flow ConditionsDocument13 pages6.4.7 Factors Affecting Distillation Column Operation 1. Vapor Flow ConditionsAnita PanthiNo ratings yet

- Problemas Ingenieria de TransportesDocument47 pagesProblemas Ingenieria de TransportesCaio Da Silva CespedesNo ratings yet

- CBSE Sample Paper Class 7 Maths Set 1 MergedDocument21 pagesCBSE Sample Paper Class 7 Maths Set 1 MergedNAMANNo ratings yet

- δ ˆ - Closed Sets in Ideal Topological SpacesDocument12 pagesδ ˆ - Closed Sets in Ideal Topological SpacesInternational Organization of Scientific Research (IOSR)No ratings yet

- ChemDocument6 pagesChemTrisha ConcepcionNo ratings yet

- Theory of ProductionDocument24 pagesTheory of ProductionKanika BakshiNo ratings yet

- Complexity, Liking and FamiliarityDocument12 pagesComplexity, Liking and FamiliarityAjaNo ratings yet

- Must-On Board Diagnostics II PCED PDFDocument19 pagesMust-On Board Diagnostics II PCED PDFRopama BraNo ratings yet

- Sap MRP Configuration PPDocument27 pagesSap MRP Configuration PPKidana TestNo ratings yet

- Deepwater Development OverviewDocument11 pagesDeepwater Development OverviewBarry HiiNo ratings yet

- FG1100E Vs PAN 3260Document6 pagesFG1100E Vs PAN 3260Cwsta LbaumNo ratings yet

- Parte1-Description Material and ConclusionsDocument3 pagesParte1-Description Material and ConclusionsLisaNo ratings yet