Professional Documents

Culture Documents

9000-0020

Uploaded by

2791957Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9000-0020

Uploaded by

2791957Copyright:

Available Formats

OPERATING INSTRUCTIONS for

IGNITION TESTER AND

TACH CALIBRATOR

Part Number 1000-1000

For more information, see www.cranecams.com

CAUTION: READ INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION.

INTRODUCTION 1. Remove the trigger source from the ignition under test.

The Crane Ignition Tester and Tach Calibrator part num- 2. Connect the test spark plug to a good engine ground.

ber 1000-1000 is a hand held device designed to perform

3. Remove the coil high voltage lead from the distributor

quick operational tests of an ignition system on a vehicle

and attach it to the test plug. If the distributor has a

without running the engine. The unit can also be used to

female type coil terminal, use a spark plug lead with

check and calibrate tachometers.

the correct terminals for both the coil and the test plug.

BASIC OPERATION 4. Connect the red tester lead to battery positive and

The unit features precise quartz crystal controlled black tester lead to chassis ground near the ignition.

signal generation with an accuracy of 30 RPM over 5. Connect the appropriate tester trigger signal lead to

the entire operating range of the tester. Pushwheel the trigger input on the ignition (white lead for points

switches set the maximum RPM value from 300 to type or orange lead for magnetic trigger).

14,990 RPM in 10 RPM steps. An RPM adjust knob

allows sweeping the RPM from 200 RPM up to the FINAL CHECK

maximum RPM value set on the pushwheel switches.

When the maximum RPM value is reached, the MAX Before turning the tester and ignition switch on, double

RPM LED lights up. check all connections. Pay particular attention to the coil

and test spark plug connections.

All connections are made by means of leads with alliga-

tor clips to facilitate quick hookup. Connections include OPERATION

12-18V power (red lead), ground (black lead), points/

module trigger output (white lead), and magnetic trigger WARNING: Do not run drag race ignition systems at

output (orange lead). high RPM for extended periods. The following test

times should not be exceeded:

TEST CONNECTIONS

2 minutes at 6,000 RPM

WARNING: Turn off ignition switch before

30 seconds at 8,500 RPM.

making any test connections. Do not come

into contact with the coil primary wires or

the secondary plug wires while the engine is

After testing an ignition at high RPM, allow the ignition to

running. Do not connect a timing light or other

become cool to the touch before retesting.

test equipment to any coil terminal while the

engine is running. Never crank the engine with

the coil high voltage terminal disconnected.

BASIC IGNITION TESTS

Refer to Figures 1-3. Follow the procedures listed below.

The following steps are required to test any ignition sys- 1. Set the MAX RPM SELECT switches 200 RPM below

tem. Refer to Figures 1-7 for additional details. the rev limit setting for the ignition. If the ignition has

no rev limit, set the switches between 6,000 and 8,000

Daytona Beach, FL 32117

www.cranecams.com / Phone: 866-388-5120 / Fax: 608-627-0480

7/10 1 9000-0020 REV A

RPM. Set the RPM ADJUST knob full counterclockwise. limiting will be indicated by an audible change in spark

frequency or complete disappearance of the spark.

2 Turn the ignition and tester power on. The tester switch setting should be within 100 RPM

of the selected rev limit setting.

3. Verify spark at the test plug before proceeding. If no

spark is present, turn all power off immediately. Refer 6. If the DEC9000/DEC9500 is suspect, remove it from

to the troubleshooting section for more details. the ignition system. Test the ignition module by itself.

4. Rotate the RPM ADJUST knob clockwise to MAX TACH CALIBRATION PROCEDURES

(indicated by the MAX RPM LED). If the spark across

the test plug is clearly visible and generates an audi- 1. Choose an RPM value for tach calibration. In most

ble buzz, the ignition system is functioning properly. cases this will be a critical RPM value, such as the

If the spark is weak, there may be a problem with the engine redline or a shift point. The RPM value you

ignition system. Refer to the troubleshooting section choose must be below the rev limit of the ignition or

for more details. engine control. Set the MAX RPM SELECT switches

at the value you selected. Rotate the RPM ADJUST

5. Increase the MAX RPM SELECT switches in incre- knob to the MAX position (full clockwise).

ments of 10 RPM until the rev limit is reached (make

sure the RPM ADJUST knob is full clockwise). Rev 2. Turn the ignition and tester power on.

limiting will be indicated by an audible change in spark

frequency or complete disappearance of the spark. 3. The tach reading should be within 100 RPM of the

The tester switch setting should be within 100 RPM tester setting for a professional racing tach. Original

of the ignition rev limit setting. equipment and low cost aftermarket tachs commonly

have errors in excess of 250 RPM. If the accuracy

TESTING IGNITIONS SYSTEMS is not satisfactory, contact the tach manufacturer for

INCLUDING THE DEC9000 OR calibration or repair procedures. Some aftermarket

DEC9500 tachs provide a calibration trimpot. First turn off all

power. Remove the back cover of the tach and locate

Refer to Figures 4-6. The figures show the DEC9000. the adjustment trimpot. Repeat the tach accuracy test

DEC9500 hookup is similar. listed above and adjust the trimpot as required. Keep

the tach oriented as close as possible to the normal

1. Set the MAX RPM SELECT switches 200 RPM below mounting position during the procedure. Note that

the maximum RPM limit or stage RPM limit setting performing the tach calibration may void the warranty.

on the DEC9000/9500 (depending on which rev limit

is selected). Note that 12 volts must be applied to a TROUBLESHOOTING WITH THE

stage limit input to select that stage limit, otherwise the TESTER

maximum limit will be active. Set the RPM ADJUST

knob full counterclockwise. Is the spark at the test spark plug weak? If so, inspect the

test spark plug. Measure the resistance from the terminal

2. Turn the ignition and tester power on. Verify that the to the center electrode with an Ohmmeter. The reading

status LEDs are operating. The TRIGGER LED should should be less than 1 Ohm. Also check the resistance of

be blinking at low RPM. For the DEC9000, the status the test spark plug wire, referring to the specification for

LEDs also show which rev limit is selected. wire resistance values. Check the coil primary and sec-

ondary resistance. If the coil is suspect, replace it with a

3. Verify spark at the test plug before proceeding. If no

known good unit and retest the system.

spark is present, turn all power off immediately. Refer

to the troubleshooting section for more details. Did the ignition system ever work? If so, Carefully check

all wiring and verify that the system is receiving power.

4. Rotate the RPM ADJUST knob clockwise to MAX

Use the status LEDs on the tester, ignition, and engine

(indicated by the MAX RPM LED). If the spark across

controller to aid in diagnosing the problem.

the test plug is clearly visible and generates an audi-

ble buzz, the ignition system is functioning properly. Is the ignition or engine controller rev limit functioning? If

If the spark is weak, there may be a problem with the not, carefully read the installation instructions for the sus-

ignition system. Refer to the troubleshooting section pect device. Check the rev limit setting on the ignition or

for more details. controller. Try different settings and retest. For additional

assistance, call the Crane Tech Line listed at the bottom

5. Increase the MAX RPM SELECT switches in incre-

of page 1.

ments of 10 RPM until the rev limit is reached (make

sure the RPM ADJUST knob is full clockwise). Rev

7/10 2 9000-0020 REV A

Figure 1. HI-6 Points/Module Trigger Test Hookup

IGNITION START

VEHICLE

SWITCH TACHOMETER

RUN

+12V BALLAST GREEN

TACH

M

RESISTOR

F

(not always used)

+

RPMX100

THIN RED

12 VOLT

IGNITION

BATTERY

HEAVY RED

BAT+ MAGNETIC

TRIGGER CABLE

TAPE UP

TEST SPARK

PLUG PLUG

WIRE

ENGINE ORANGE COIL

GROUND COIL+ CABLE HI-6

BLACK

COIL- WHITE

POINTS

HEAVY BLACK

CHASSIS GROUND

LX-91

M

BLACK

DISCONNECT

WHITE FROM POINTS

RED

LINE

F

TRIGGER

IGNITION TESTER/

SOURCE

TACH CALIBRATOR

POWER RPM ADJUST

O.E.

ELECTRONIC

ON

MAX

IGNITION MODULE

0 9 5 0 0

RPM

OFF

MIN MAX

MAX RPM SELECT

ORANGE

(NOT USED)

Daytona Beach, FL PN 1000-1000

7/10 3 9000-0020 REV A

Figure 2. HI-6 Magnetic Trigger Test Hookup

IGNITION START

VEHICLE

SWITCH TACHOMETER

RUN

+12V BALLAST GREEN

TACH

M

RESISTOR

F

(not always used)

+

RPMX100

THIN RED

12 VOLT

IGNITION

BATTERY

HEAVY RED

BAT+

TEST SPARK

PLUG PLUG

WIRE

ENGINE ORANGE COIL

GROUND COIL+ CABLE HI-6

BLACK

MAGNETIC

COIL-

TRIGGER

CABLE

WHITE HEAVY BLACK

F

POINTS CHASSIS GROUND

BLACK RED (NOT USED)

LX-91 MAG MAG +

M

ORANGE

RED (BOTH)

WHITE

(NOT USED) DISCONNECT

MAGNETIC

PICKUP

M

IGNITION TESTER/ PURPLE

TACH CALIBRATOR

POWER RPM ADJUST

MAGNETIC

ON

MAX PICKUP DISTRIBUTOR

0 9 5 0 0

RPM

(FORD COLOR CODES SHOWN)

OFF

MIN MAX

MAX RPM SELECT

Daytona Beach, FL PN 1000-1000

7/10 4 9000-0020 REV A

Figure 3. HI-7/HI-8 Test Hookup

CRANK TRIGGER WHEEL

TACHOMETER

RPMX100

BLACK IGNITION

MAG- SWITCH

RED

MAG+

DISCONNECT MAG PICKUP

FROM IGNITION TO

+12V

SHIELDED PICKUP CABLE

RED

IF PICKUP CABLE 18 AWG

BLACK RED

IS SUSPECT,

MAG MAG +

TEST HERE

CRANE

STATUS

POINTS

SHIELD

AUX IN

MAG +

MAG

TACH

IGN +

ORANGE

HI-7

or

JUMPER WHEN

USING POINTS INPUT

HI-8

BLACK

IGNITION TESTER/

TACH CALIBRATOR

POWER RPM ADJUST SPARK PLUG

WIRE

ON TEST

0 9 5 0 0

MAX

PLUG

RPM

OFF

MIN MAX

MAX RPM SELECT

Daytona Beach, FL PN 1000-1000

BLACK

COIL-

ORANGE ENGINE

COIL+ GROUND

WHITE

(NOT USED)

RED

TO BATTERY + LX-92

7/10 5 9000-0020 REV A

Figure 4. DEC9000 and HI-7/HI-8 Test Hookup

TEST 1:

NOTE:

Remove Mag pickup leads from DEC9000. MAG+ must be jumpered to IGN+

TO SWITCHED +12V

Connect tester orange & black leads to when using POINTS input on HI-7/HI-8

DEC9000 MAG+ & MAG- inputs

respectively.

Tester white lead is not used.

GREEN

TEST 2: CRANE

STATUS

POINTS

SHIELD

AUX IN

MAG +

MAG

TACH

IGN +

Remove POINTS & AUX IN wires from HI-7

HI-7/HI-8. TEST 2 or

Connect tester white lead to HI-7/HI-8

JUMPER WHEN

USING POINTS INPUT

HI-8

POINTS input, and tester black lead to

chassis ground.

Tester orange lead is not used.

BLUE

CRANK TRIGGER WHEEL

OTHER SYSTEMS

MSD ONLY

FIRING

HIGH

AUX OUT SEQUENCE

INITIAL GEAR

HALL OUT CONTROL STAGE RPM LIMIT MAX RPM LIMIT TIMING RETARD

POINTS

TACH 1 1 1 1 00 1 1 1 00 1 1

+12V

GROUND

START RTD

HIGH GEAR

HIGH GEAR RETARD

START RETARD

CRANE

STAGE

MAG + TRIGGER INPUT

MAG - +12V POWER OK

SHIELD DEC9000 DIGITAL ENGINE CONTROL

TEST 1 OTHER CONNECTIONS

NOT SHOWN FOR CLARITY

TO BATTERY +

RED

IGNITION TESTER/

TACH CALIBRATOR

TEST

POWER RPM ADJUST

PLUG

ON

SPARK PLUG

MAX

WIRE

0 9 5 0 0

RPM

OFF BLACK

MAX RPM SELECT

MIN MAX

COIL-

Daytona Beach, FL PN 1000-1000

ORANGE ENGINE

COIL+ GROUND

WHITE BLACK ORANGE

TESTER LEAD CONNECTIONS DEPEND

ON WHICH TEST IS BEING PERFORMED LX-92

7/10 6 9000-0020 REV A

Figure 5. DEC9000 and MSD-7 Test Hookup

TEST 1: TO SWITCHED +12V

Remove Mag pickup leads from DEC9000.

Connect tester orange & black leads to MSD-7AL IGNITION

DEC9000 MAG+ & MAG- inputs respectively. TO

Tester white lead is not used. BATTERY C+

C-

TEST 2: IGN

Remove wire from MSD-7AL POINTS input RPM TEST 2

MODULE PTS

and connector from RPM module socket. PLUG

T

Note the orientation of the plug for A M+ NOT

C

reinstallation. H M- USED

Connect the tester white lead to the MSD-7AL GROUND

POINTS input and the tester black lead to

chassis ground.

Tester orange lead is not used.

GREEN

BLUE

CRANK TRIGGER WHEEL

OTHER SYSTEMS

MSD ONLY

FIRING

HIGH

AUX OUT SEQUENCE

INITIAL GEAR

HALL OUT CONTROL STAGE RPM LIMIT MAX RPM LIMIT TIMING RETARD

POINTS

TACH 1 1 1 1 00 1 1 1 00 1 1

+12V

GROUND

START RTD

HIGH GEAR

HIGH GEAR RETARD

START RETARD

CRANE

STAGE

MAG + TRIGGER INPUT

MAG - +12V POWER OK

SHIELD DEC9000 DIGITAL ENGINE CONTROL

TEST 1 OTHER CONNECTIONS

NOT SHOWN FOR CLARITY

TO BATTERY +

RED

IGNITION TESTER/ SPARK PLUG

TACH CALIBRATOR WIRE

POWER RPM ADJUST

ON

MAX

0 9 5 0 0

RPM

OFF

MIN MAX

MAX RPM SELECT

Daytona Beach, FL PN 1000-1000 TEST

PLUG

WHITE BLACK ORANGE

ENGINE

TESTER LEAD CONNECTIONS DEPEND GROUND

ON WHICH TEST IS BEING PERFORMED

7/10 7 9000-0020 REV A

Figure 6. DEC9000 and MSD-8 Test Hookup

TEST 1: TO TO SWITCHED +12V

Remove magnetic pickup wires from DEC9000 BATTERY

MAG+, MAG-, and SHIELD.

Connect tester orange & black leads to the DEC9000 MSD-8 IGNITION

MAG+ and MAG- respectively.

Tester white lead is not used. C+

C-

TEST 2: IGN

Remove ADAPTER green & blue wires from DEC9000

POINTS & AUX OUT. GND

Connect tester white lead to adapter green wire, and tester M+

TACH

black lead to chassis ground. M-

Tester orange lead is not used.

TEST 3: TEST 2

Disconnect MSD-8 weatherpack (6-pin)

connector & remove white ADAPTER line from MSD-8 TEST 3

GREEN PLUG WHITE

MSD-8 MAG+. DEC9000

Connect tester orange & black leads to MSD-8 TO MSD-8

BLUE ADAPTER

MAG+ & MAG- terminals respectively.

Tester white lead is not used.

CRANK TRIGGER WHEEL OTHER SYSTEMS

MSD ONLY

FIRING

HIGH

AUX OUT SEQUENCE

INITIAL GEAR

HALL OUT CONTROL STAGE RPM LIMIT MAX RPM LIMIT TIMING RETARD

POINTS

TACH 1 1 1 1 00 1 1 1 00 1 1

+12V

GROUND

START RTD

HIGH GEAR

HIGH GEAR RETARD

START RETARD

CRANE

STAGE

MAG + TRIGGER INPUT

MAG - +12V POWER OK

SHIELD DEC9000 DIGITAL ENGINE CONTROL

TEST 1 OTHER CONNECTIONS

NOT SHOWN FOR CLARITY

TO BATTERY +

RED

IGNITION TESTER/ SPARK PLUG

TACH CALIBRATOR WIRE

POWER RPM ADJUST

ON

MAX

0 9 5 0 0

RPM

OFF

MIN MAX

MAX RPM SELECT

Daytona Beach, FL PN 1000-1000 TEST

PLUG

WHITE BLACK ORANGE

ENGINE

TESTER LEAD CONNECTIONS DEPEND GROUND

ON WHICH TEST IS BEING PERFORMED

7/10 8 9000-0020 REV A

Figure 7. Tach Test and Calibration Hookup

DASH

+12V LIGHTS

RED

WHITE

NOTES: 8 9 10

7

1. Autometer tach hookup shown. WHITE 6

F RPM

2. Other aftermarket units similiar. GREEN 5

4

3

3. Check tach instructions for wire colors. REMOVE FROM 2 1 0

IGNITION TO

TEST & CALIBRATE

BLACK

GROUND

IGNITION TESTER/

TACH CALIBRATOR

POWER RPM ADJUST

ON

MAX

0 9 5 0 0

RPM

OFF

MIN MAX

MAX RPM SELECT

Daytona Beach, FL PN 1000-1000

RED

BLACK

TO BATTERY + ORANGE

NOT USED

CHASSIS

GROUND

7/10 9 9000-0020 REV A

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Automotive Steering SuspensionDocument1 pageAutomotive Steering Suspension2791957No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- IJESE 1119 Article 5808a2438fd89Document14 pagesIJESE 1119 Article 5808a2438fd892791957No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 10 Electric Power Steering GB Druck PDFDocument2 pages10 Electric Power Steering GB Druck PDF2791957No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- A Smart Way To Drive Ecu ConsolidationDocument4 pagesA Smart Way To Drive Ecu Consolidation2791957No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Automotive (Small Engine)Document2 pagesAutomotive (Small Engine)2791957No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Testing OBD interfaces and CAN busesDocument3 pagesTesting OBD interfaces and CAN buses2791957No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

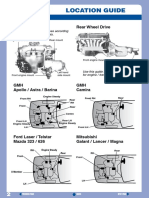

- Wheel Drive and Mount Location GuideDocument107 pagesWheel Drive and Mount Location Guide27919570% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Engine troubleshooting guideDocument1 pageEngine troubleshooting guide2791957No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- ToolsCat 74Document58 pagesToolsCat 742791957No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Determining Battery Capacity3 PDFDocument37 pagesDetermining Battery Capacity3 PDF2791957No ratings yet

- Swift - June 09 - 03 Instrument PanelDocument56 pagesSwift - June 09 - 03 Instrument Panel2791957No ratings yet

- Battery Control System: DescriptionDocument3 pagesBattery Control System: Description2791957100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- BATTERY TESTING AND CHARGING GUIDEDocument6 pagesBATTERY TESTING AND CHARGING GUIDE2791957No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Application Note AN06 - ELM327L and The PL-2303HX: Installing SoftwareDocument2 pagesApplication Note AN06 - ELM327L and The PL-2303HX: Installing Software2791957No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- SM-AFRGen2 User GuideDocument2 pagesSM-AFRGen2 User Guide2791957No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- LDV 200 300 400Document108 pagesLDV 200 300 4002791957No ratings yet

- Q 117R2Document2 pagesQ 117R22791957No ratings yet

- Sample: Diagram 1 Early Ford C-Max Wiring DiagramsDocument4 pagesSample: Diagram 1 Early Ford C-Max Wiring Diagrams2791957No ratings yet

- 05ivm EseriesDocument56 pages05ivm Eseries27919570% (1)

- Marine Generator Set with Gasoline EngineDocument4 pagesMarine Generator Set with Gasoline Engine2791957No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Emergency Response Guide-ToyotaDocument143 pagesEmergency Response Guide-Toyota2791957100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Module 2 Mechanics of Machining Lesson 8 Forces and Merchant's Circle DiagramDocument15 pagesModule 2 Mechanics of Machining Lesson 8 Forces and Merchant's Circle DiagramSUBHASH ANURAGNo ratings yet

- Focus WiresDocument816 pagesFocus Wiresionutnespus100% (2)

- 5.2combustion and Combustion Chamber For SI EnginesDocument53 pages5.2combustion and Combustion Chamber For SI EnginesTamene Tesfaye100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Alto2011 CatalogDocument538 pagesAlto2011 CatalogIsa Restrepo Fernandez0% (1)

- Eng Trouble Diag Aug 09Document48 pagesEng Trouble Diag Aug 09279195750% (2)

- Chap 17Document96 pagesChap 172791957No ratings yet

- 1GR-FE Engine Cooling System GuideDocument77 pages1GR-FE Engine Cooling System GuideMauricio Andrés Montenegro71% (7)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Ford Wiring Diagram 1994 9404Document11 pagesFord Wiring Diagram 1994 94042791957No ratings yet

- Operating Manual Parts List: 1000Vmc (Siemens)Document226 pagesOperating Manual Parts List: 1000Vmc (Siemens)apodshNo ratings yet

- Manual E-Claw EngDocument18 pagesManual E-Claw Engshyampillai2007No ratings yet

- Tank Size CalculatorDocument6 pagesTank Size CalculatorVijayakumar Chandrasekaran100% (2)

- Micom p343Document66 pagesMicom p343kjfenNo ratings yet

- 7 Inch Liner Cementing ProgramDocument44 pages7 Inch Liner Cementing ProgramMarvin OmañaNo ratings yet

- Software Testing Types, Levels, Roles & Best PracticesDocument3 pagesSoftware Testing Types, Levels, Roles & Best PracticesAbhinav DakshaNo ratings yet

- Design and Development of Swashplate-Less HelicopterDocument68 pagesDesign and Development of Swashplate-Less HelicopterNsv DineshNo ratings yet

- Direct Stiffness Method for Truss AnalysisDocument28 pagesDirect Stiffness Method for Truss Analysisgilberthufana446877No ratings yet

- Distillation Is Defined As:: How Does Distillation Work?Document35 pagesDistillation Is Defined As:: How Does Distillation Work?sankalpnambiarNo ratings yet

- Assist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Document49 pagesAssist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Hundee HundumaaNo ratings yet

- ECOSYS M6526cdn Fax SetupDocument204 pagesECOSYS M6526cdn Fax SetupAnonymous gn8qxxNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Degaussing N Magnetic MinesDocument3 pagesDegaussing N Magnetic MinesGus MellonNo ratings yet

- Gaspardo MAESTRA 2004-02 (19530520)Document78 pagesGaspardo MAESTRA 2004-02 (19530520)costelchelariuNo ratings yet

- 9040 - User ManualDocument236 pages9040 - User ManualWallie Billingsley77% (13)

- Fobasv 6Document3 pagesFobasv 6Satyabrat Gaan100% (3)

- Magic Quadrant For Identity Governance and AdministrationDocument18 pagesMagic Quadrant For Identity Governance and AdministrationmilosvblNo ratings yet

- Cloud Radio Access Network Architecture Towards 5G NetworkDocument171 pagesCloud Radio Access Network Architecture Towards 5G NetworkwobblegobbleNo ratings yet

- Ijso 2012Document5 pagesIjso 2012bhaskarNo ratings yet

- PV Elite (Construccion de Recipiente) MDMTDocument8 pagesPV Elite (Construccion de Recipiente) MDMTAlejandro CanoNo ratings yet

- Finite Element Analysis of The In-Service-Welding of T Joint Pipe ConnectionDocument12 pagesFinite Element Analysis of The In-Service-Welding of T Joint Pipe ConnectionMohamed SamyNo ratings yet

- Nba Sar B.tech. Electronics UgDocument171 pagesNba Sar B.tech. Electronics UgSaurabh BhiseNo ratings yet

- Bondek Design & Construct ManualDocument131 pagesBondek Design & Construct ManualAkuma.Gokai7328100% (12)

- Silo Fluidizer: Keep Dry Bulk Materials MovingDocument2 pagesSilo Fluidizer: Keep Dry Bulk Materials MovingHùng Thanh NguyễnNo ratings yet

- Inspection Checklist For Lifting Tools & TacklesDocument2 pagesInspection Checklist For Lifting Tools & Tacklesnil thaeu100% (1)

- CS5001 CourseworkDocument9 pagesCS5001 CourseworkpeteligijusNo ratings yet

- P0562-Battery Voltage LowDocument7 pagesP0562-Battery Voltage Lowguillermoal539100% (1)

- PuleyDocument9 pagesPuleynicolasNo ratings yet

- DP TV Aver 15022 DriversDocument94 pagesDP TV Aver 15022 DriversMohammed Tahver Farooqi QuadriNo ratings yet

- NUVE EN 032-055-120 Incubators BrochureDocument2 pagesNUVE EN 032-055-120 Incubators BrochureDinhtrung TruongNo ratings yet

- NPS-1 Piano Stand Lnstallation Guide: List of PartsDocument2 pagesNPS-1 Piano Stand Lnstallation Guide: List of PartsFian PanekenanNo ratings yet