Professional Documents

Culture Documents

2.1 SLMTA Floorplan v2

Uploaded by

richard mooreOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.1 SLMTA Floorplan v2

Uploaded by

richard mooreCopyright:

Available Formats

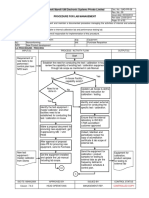

GLI Stepwise Process towards TB Laboratory Accreditation

Guiding Principles

Guiding Principles for Laboratory Floor Plan Design

Good Workflow

Laboratory space should be: Equipment should:

Adequate in size for testing needs be placed to facilitate smooth and efficient Filing

workflow printer

Organized into distinct work areas Step 4: Resulting Cabinet

sample reception have sufficient operational area Step 3:

sample preparation be safely positioned

Testing

testing avoid placement in high traffic area

results production avoid placement that requires frequent

moving for cleaning and maintenance Analyzer

results validation and release

avoid direct placement under air-

reagent and consumable storage conditioners

data / filing / records (non-testing areas) avoid nearness to sinks and wet benches

Be clean & uncluttered avoid direct proximity to heat source

Expired and unused supplies and reagents (instrument or sunlight) Step 2:

should be discarded allow adequate space between instrument Processing Step 1:

All non-functioning / out-dated equipment back and wall

should be removed from the laboratory Receiving

and store room Supplies and reagents should:

Neat and well-lit

Poor Workflow

Have dedicated cabinet or shelf space for

storage (at each workstation, if possible)

Step 1: Receiving Filing

Be arranged to facilitate compliance with the Cabinet

Electrical requirements: First-Expiry-First-Out rule

Step 4: Resulting

Step 3:

Extension chords should positioned safely

Refrigerators should: Testing

out of the walkways

All analyzers should have surge protectors be positioned to avoid disturbance and over- Analyzer

All analyzers should have UPS heating

(Uninterruptible Power Supply) be well organized and not over-stocked

Water: only hold items in use or planned for use

not have close mixing of samples and

Lab personnel should know the water type

reagents

and usage requirements for the equipment

in their labs not hold food or drink

printer Step 2:

Processing

Source: Strengthening Laboratory Management towards Accreditation

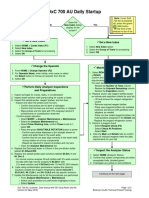

GLI Stepwise Process towards TB Laboratory Accreditation

Guiding Principles

Guiding Principles for Workstation Set-up

Required equipment and supplies All documentation readily available Optimal workstation Layout

Personal protective equipment gloves, Equipment Owners Manual Follow the sequence of the

masks, sharps containers, etc., Equipment Manufacturers Data process

Waste Disposal Containers (serial number, contact information) Place all main instruments together

Office supplies pencils, paper, stapler, Logs reagent, QC, equipment arranged in a semi-circle (or U-

scissors, etc. maintenance & service, shaped) work cell (versus

environmental (temperature, individual workstations spread in

Materials, consumables, and reagents various rooms). This arrangement

required to perform maintenance humidity, etc.) and corrective action

allows a single operator to keep all

Materials, consumables, diluents, and Standard Operating Procedures analyzers running.

reagents required to perform testing (SOPs)

Place highest-volume chemistry

Ancillary equipment required for testing Critical Values and hematology analyzers closest

(such as pipettes, pipette tips, timer, Population Reference ranges (if to laboratory entrance to minimize

mixer, vortex, rotator) available) walking.

Specimen racks to organize workload Clinician contact information Place back-up equipment, if

available, behind main analyzers.

Equipment Operators Toolkit

If more than one centrifuge is

available, decentralize and place

adjacent to the analyzers

workstation. Be aware of possible

interference to the analyzer caused

Optimal Work Process by vibrations from operating the

centrifuge.

Define the standard work / operating procedures (SOP) and specify the sequence of Specify a permanent location for

steps as well as the key actions an operator must take to ensure high quality each item (equipment, tools, and

Utilize constant workflow or small batches to decrease turn around time (TAT) and supplies). Mark the outline of each

operator waiting time item (i.e., the shape of scissors,

stapler) with colored tape so a

Analyzing specimens using a one-piece flow process (first in/first out) allows earlier

missing item will be noted & easily

detection of quality problems

replaced

Source: Strengthening Laboratory Management towards Accreditation

You might also like

- 4 CCHM Trans LecDocument8 pages4 CCHM Trans LecCRUZ, ANNA MARIELLENo ratings yet

- Housekeeping Schedule Qualification Computer System Servicing NC IiDocument2 pagesHousekeeping Schedule Qualification Computer System Servicing NC IiFritchie LouNo ratings yet

- Specifying Non-Viable Particle Monitoring For Aseptic ProcessingDocument6 pagesSpecifying Non-Viable Particle Monitoring For Aseptic ProcessingPaula LópezNo ratings yet

- Sterility Testing Lab Audit Checklist: Date: Client Name: Auditors: Site AddressDocument21 pagesSterility Testing Lab Audit Checklist: Date: Client Name: Auditors: Site AddressElena StoevaNo ratings yet

- Establishment of soil testing labDocument20 pagesEstablishment of soil testing labjishnurajkarockalNo ratings yet

- PentraDocument8 pagesPentraDV0% (1)

- Standard Operating Procedure: Department of Civil Engineering Concrete & Construction Technology LaboratoryDocument3 pagesStandard Operating Procedure: Department of Civil Engineering Concrete & Construction Technology Laboratorydpk.kushwahNo ratings yet

- The DELPHI Experiment Control SystemDocument7 pagesThe DELPHI Experiment Control Systemzhi.quarkNo ratings yet

- Lab ManualDocument9 pagesLab Manualnanda_kavalaNo ratings yet

- Day 1, Topic 1 - ActivityDocument1 pageDay 1, Topic 1 - ActivityPatrickNo ratings yet

- Office Risk Assessment Rev 1Document5 pagesOffice Risk Assessment Rev 1Abraham BarbeytoNo ratings yet

- Materi 2Document23 pagesMateri 2Murdifin SulawesiNo ratings yet

- Radiology QaqcDocument7 pagesRadiology QaqcAnn Caroline FerrerNo ratings yet

- S1126 3 NuAire Horizontal Laminar Flow Work Bench 7 08Document2 pagesS1126 3 NuAire Horizontal Laminar Flow Work Bench 7 08Krishna RajNo ratings yet

- Department of BiotechnologyDocument29 pagesDepartment of BiotechnologyPriya srivastavaNo ratings yet

- BR-51877 UniCel DxI OUS Brochure FinalDocument8 pagesBR-51877 UniCel DxI OUS Brochure FinalsantoshNo ratings yet

- OM (Project) 2019Document30 pagesOM (Project) 2019Kieron Ivan M. GutierrezNo ratings yet

- Laboratory Management Module5BDocument4 pagesLaboratory Management Module5BLezel Joy R. MontefalcoNo ratings yet

- Process Process Process Process ProcessDocument3 pagesProcess Process Process Process ProcessProcurement PardisanNo ratings yet

- Qualification of HPLCDocument10 pagesQualification of HPLCmukeshjol89% (9)

- C TASK-1 Participate in Safe Work Practices C - Task 1Document5 pagesC TASK-1 Participate in Safe Work Practices C - Task 1Mukta AktherNo ratings yet

- Enhance Laboratory Efficiency. Optimize Workflow. Trust ResultsDocument8 pagesEnhance Laboratory Efficiency. Optimize Workflow. Trust ResultsPablo Allin CañasNo ratings yet

- Path of Workflow in The Medical Microbiology Laboratory Quality ManagementDocument35 pagesPath of Workflow in The Medical Microbiology Laboratory Quality ManagementFavourNo ratings yet

- D-Ruby Installation Checklist Sura CLL 100Document14 pagesD-Ruby Installation Checklist Sura CLL 100Ana MichellNo ratings yet

- Returning To Workspace Post COVID: How To Handle Existing Facility? What Can Be Done?Document7 pagesReturning To Workspace Post COVID: How To Handle Existing Facility? What Can Be Done?Anusha AshokNo ratings yet

- Envoy 500 Operator Training Manual (L7320, Rev. - ) Low ResDocument86 pagesEnvoy 500 Operator Training Manual (L7320, Rev. - ) Low ResALONSO GARCIA100% (1)

- Jsa - Hydro Pressure Testing (2296)Document6 pagesJsa - Hydro Pressure Testing (2296)asaf ali100% (1)

- 8 Analysis Part2 Chapter5Document3 pages8 Analysis Part2 Chapter5Aldwin CantosNo ratings yet

- High and Maximum Containment LaboratoriesDocument23 pagesHigh and Maximum Containment LaboratoriesThaboJaftaNo ratings yet

- BB - Self AuditDocument18 pagesBB - Self AuditFe Rackle Pisco JamerNo ratings yet

- QAD Procedure - Lab Management P1Document1 pageQAD Procedure - Lab Management P1sumanNo ratings yet

- CBV MTFDocument13 pagesCBV MTFEduardo TomasNo ratings yet

- 1007435MTL - Indiko Plus BrochureDocument6 pages1007435MTL - Indiko Plus BrochureFerliemNo ratings yet

- Analyze Wastewater Treatment Lab ExperimentDocument1 pageAnalyze Wastewater Treatment Lab ExperimentKucing GemukNo ratings yet

- BTF1623 Process Control MonitoringDocument18 pagesBTF1623 Process Control MonitoringUMIE UMAIRA KM-PelajarNo ratings yet

- Day 7 Mindray BS 480Document2 pagesDay 7 Mindray BS 480Angelica Joy GonzalesNo ratings yet

- BR 71394 Da Gallery Analyzer Series br71394 enDocument8 pagesBR 71394 Da Gallery Analyzer Series br71394 enfvs.lacen.produtosNo ratings yet

- Refrigerated Tank TestingDocument2 pagesRefrigerated Tank TestingAnonymous 1XHScfCINo ratings yet

- Everyone in The Laboratory Is Responsible For Quality and SafetyDocument10 pagesEveryone in The Laboratory Is Responsible For Quality and SafetyAdam TaraNo ratings yet

- DC Internal Audit Done at 14Document3 pagesDC Internal Audit Done at 14oketchodoleNo ratings yet

- MolBio Lab-Act #2-Laboratory Operations-Design and EquipmentDocument8 pagesMolBio Lab-Act #2-Laboratory Operations-Design and EquipmentJhenica D. NonanNo ratings yet

- Equipping Water Testing Laboratories: Neil Durham, UKDocument4 pagesEquipping Water Testing Laboratories: Neil Durham, UKChristineNo ratings yet

- LQMS 3-5 Equipment Repair and MaintenanceDocument2 pagesLQMS 3-5 Equipment Repair and MaintenanceChristine OlivarNo ratings yet

- Alfa WassermannDocument7 pagesAlfa WassermannMiguel fuentesNo ratings yet

- Lec4 Lab AutomationDocument33 pagesLec4 Lab AutomationNehal YousryNo ratings yet

- Chapter 2 - Plant Start Up & Shut DownDocument23 pagesChapter 2 - Plant Start Up & Shut DownDharshica MohanNo ratings yet

- SOP for GLP Compliance in Quality Control LabsDocument2 pagesSOP for GLP Compliance in Quality Control LabsPrince MoniNo ratings yet

- Maintenance Schedule and Checklist - ThyRanDocument9 pagesMaintenance Schedule and Checklist - ThyRanEDMIL REBOLLOSNo ratings yet

- Transformer 1 MosDocument5 pagesTransformer 1 MosMohamedAhmedFawzyNo ratings yet

- KAMC Nurse Call and Infant Protection System CommissioningDocument12 pagesKAMC Nurse Call and Infant Protection System Commissioningmohammed naseer uddinNo ratings yet

- Tntplus Vial Tests: Expert Testing Made SimpleDocument4 pagesTntplus Vial Tests: Expert Testing Made SimpleAngelNo ratings yet

- DXC 700 Au Daily Startup: Set A New Index Set A New IndexDocument2 pagesDXC 700 Au Daily Startup: Set A New Index Set A New IndexGassem SumiliNo ratings yet

- Tba 2000FRDocument11 pagesTba 2000FRhitendra11100% (1)

- NIH BSL-3 Lab Certification ChecklistDocument23 pagesNIH BSL-3 Lab Certification ChecklistMihai TanaseNo ratings yet

- Maintain Training FacilityDocument13 pagesMaintain Training FacilityJanice TutorNo ratings yet

- 1.5 Huawei RH V3 Routine Maintenance and Troubleshooting V1 0Document27 pages1.5 Huawei RH V3 Routine Maintenance and Troubleshooting V1 0John BarretoNo ratings yet

- Benchmark ExelDocument159 pagesBenchmark ExelMAXTAR BIO-GENICSNo ratings yet

- Testing & Commissioning of Fire Alarm SystemDocument3 pagesTesting & Commissioning of Fire Alarm Systemhaytham65No ratings yet

- Laboratory Management Week 3Document3 pagesLaboratory Management Week 3tuamicaiiiNo ratings yet

- Asus Store Locations PhilippinesDocument4 pagesAsus Store Locations Philippinesrichard mooreNo ratings yet

- Radiological Health: Reporter: Ralf M. MasugodDocument17 pagesRadiological Health: Reporter: Ralf M. Masugodrichard mooreNo ratings yet

- Irrigation AldrendocxDocument1 pageIrrigation Aldrendocxrichard mooreNo ratings yet

- Concrete Testing Equipment - MatestDocument13 pagesConcrete Testing Equipment - Matestrichard mooreNo ratings yet

- Statistics On Crime & Non-Crime Related Incidents: Monthly ReportDocument1 pageStatistics On Crime & Non-Crime Related Incidents: Monthly Reportrichard mooreNo ratings yet

- HB 100 Hydraulics Bench Accessories: HB 011 Dead Weight Pressure TesterDocument1 pageHB 100 Hydraulics Bench Accessories: HB 011 Dead Weight Pressure Testerrichard mooreNo ratings yet

- 01 HE IndicatorsDocument2 pages01 HE Indicatorsrichard mooreNo ratings yet

- Lessons Grade3 Classify and Categorize Lesson 2Document5 pagesLessons Grade3 Classify and Categorize Lesson 2richard mooreNo ratings yet

- HB 012 Measures Hydrostatic Pressure ForcesDocument1 pageHB 012 Measures Hydrostatic Pressure Forcesrichard mooreNo ratings yet

- Work Flow Chart Lab PDFDocument1 pageWork Flow Chart Lab PDFrichard mooreNo ratings yet

- WBS: Work Breakdown Structure EssentialsDocument10 pagesWBS: Work Breakdown Structure Essentialsrichard mooreNo ratings yet

- Mati, Davao Region: Street View - Apr 2016Document2 pagesMati, Davao Region: Street View - Apr 2016richard mooreNo ratings yet

- Ce 159 NotesDocument3 pagesCe 159 Notesrichard mooreNo ratings yet

- Ce 159 NotesDocument3 pagesCe 159 Notesrichard mooreNo ratings yet

- 2-Story Plan 2nd FloorDocument1 page2-Story Plan 2nd Floorrichard mooreNo ratings yet

- Feasibility StudyDocument53 pagesFeasibility StudyKei Samson88% (48)

- Exer 2Document5 pagesExer 2richard mooreNo ratings yet

- Mati, Davao Region: Street View - Apr 2016Document2 pagesMati, Davao Region: Street View - Apr 2016richard mooreNo ratings yet

- Mati, Davao Region: Street View - Apr 2016Document2 pagesMati, Davao Region: Street View - Apr 2016richard mooreNo ratings yet

- Ce 159 NotesDocument3 pagesCe 159 Notesrichard mooreNo ratings yet

- Mylene Lesson PlanDocument10 pagesMylene Lesson Planrichard mooreNo ratings yet

- EVAMAEREBUCASDocument12 pagesEVAMAEREBUCASrichard mooreNo ratings yet

- Book 1Document4 pagesBook 1richard mooreNo ratings yet

- ZenFone 3 Series Product Guide V18Document85 pagesZenFone 3 Series Product Guide V18zulkifliNo ratings yet

- Mylene Lesson PlanDocument10 pagesMylene Lesson Planrichard mooreNo ratings yet

- Stream Flow ProcessesDocument8 pagesStream Flow Processesrichard mooreNo ratings yet

- Sanitaryware: Ancient Time To Modern TimeDocument17 pagesSanitaryware: Ancient Time To Modern TimeparadisegoldNo ratings yet

- Modeling Creeping Slope Movement with Visco-Hypoplastic Material LawDocument9 pagesModeling Creeping Slope Movement with Visco-Hypoplastic Material LawMilton Teran100% (1)

- Buy Uganda Build UgandaDocument36 pagesBuy Uganda Build UgandanambehelaNo ratings yet

- AdmixtureDocument6 pagesAdmixtureDunvillNo ratings yet

- Installation - Titan Power Plus-SU2 - Free Standing and Tilt (v2)Document19 pagesInstallation - Titan Power Plus-SU2 - Free Standing and Tilt (v2)SunMaxx SolarNo ratings yet

- Scope of Work For Prefab ContractorDocument4 pagesScope of Work For Prefab ContractorgodennyNo ratings yet

- Groen TDB Table Top KettleDocument2 pagesGroen TDB Table Top Kettlewsfc-ebayNo ratings yet

- Features of A Milling CutterDocument8 pagesFeatures of A Milling CutterAnuj KrNo ratings yet

- Properties of Explosive MaterialsDocument11 pagesProperties of Explosive MaterialsFrhandd MuhammadNo ratings yet

- Wear and Wear Mechanism Simulation of Heavy-Duty Engine Intake Valve and Seat InsertsDocument13 pagesWear and Wear Mechanism Simulation of Heavy-Duty Engine Intake Valve and Seat Insertsmuki10No ratings yet

- Shell Mysella S3 N 40: Performance, Features & BenefitsDocument2 pagesShell Mysella S3 N 40: Performance, Features & BenefitsironiteNo ratings yet

- Daily inspection report for PC1250-7 excavatorDocument2 pagesDaily inspection report for PC1250-7 excavatorAfrizal Bee Mei AeNo ratings yet

- 5000Q Waterblast Unit-Ver2Document2 pages5000Q Waterblast Unit-Ver2jchristoe2613No ratings yet

- 80 IN 1 Professional Computer Repair ToolDocument5 pages80 IN 1 Professional Computer Repair ToolCarlos CorreaNo ratings yet

- Building Utility System and Fire Protection EngineeringDocument16 pagesBuilding Utility System and Fire Protection EngineeringMohamad SafhireNo ratings yet

- Cebo Ycc50 ManualDocument16 pagesCebo Ycc50 ManualAngelevNo ratings yet

- Construction of Ic EngineDocument11 pagesConstruction of Ic EngineAfifah ZaynabNo ratings yet

- Notes of Velocity Triangle With ProblemsDocument23 pagesNotes of Velocity Triangle With Problemsjoseph prasanna kumar67% (3)

- 5608-09 Ugeng0000Document21 pages5608-09 Ugeng0000Morosanu Andreea-DianaNo ratings yet

- Proforma Invoice: DescriptionDocument3 pagesProforma Invoice: Descriptionanon-690278No ratings yet

- Manual Olimpus PDFDocument64 pagesManual Olimpus PDFmachine_toolsNo ratings yet

- Weaving Trials As A Customer Support Measure: Sulzer RutiDocument3 pagesWeaving Trials As A Customer Support Measure: Sulzer RutiNeelesh MishraNo ratings yet

- D Ulrich MoosheimerDocument36 pagesD Ulrich Moosheimer331623468No ratings yet

- Smart Prep Cibacron On SlavosDocument4 pagesSmart Prep Cibacron On SlavosagnberbcNo ratings yet

- Kinney Vacuum Pump OilDocument4 pagesKinney Vacuum Pump OilhibhavuNo ratings yet

- Dead Front Panels Backlit UserDocument2 pagesDead Front Panels Backlit UserBooknest CoNo ratings yet

- Mechanical Properties of Bolts and ScrewsDocument34 pagesMechanical Properties of Bolts and Screwseng.aldabeNo ratings yet

- Hazardous Area Instrumentation InformationDocument6 pagesHazardous Area Instrumentation InformationMandar PhadkeNo ratings yet

- Sieve AnalysisDocument3 pagesSieve AnalysisBibhuti B. Bhardwaj100% (1)