Professional Documents

Culture Documents

Computer Aided Design For Additive Manufacturing of Cellular Structures

Uploaded by

thlpapOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Aided Design For Additive Manufacturing of Cellular Structures

Uploaded by

thlpapCopyright:

Available Formats

Computer-Aided Design and Applications

ISSN: (Print) 1686-4360 (Online) Journal homepage: http://www.tandfonline.com/loi/tcad20

Computer-Aided Design for Additive

Manufacturing of Cellular Structures

David W. Rosen

To cite this article: David W. Rosen (2007) Computer-Aided Design for Additive Manufacturing

of Cellular Structures, Computer-Aided Design and Applications, 4:5, 585-594, DOI:

10.1080/16864360.2007.10738493

To link to this article: http://dx.doi.org/10.1080/16864360.2007.10738493

Published online: 05 Aug 2013.

Submit your article to this journal

Article views: 900

View related articles

Citing articles: 12 View citing articles

Full Terms & Conditions of access and use can be found at

http://www.tandfonline.com/action/journalInformation?journalCode=tcad20

Download by: [University of Bath] Date: 24 April 2017, At: 09:54

585

Computer-Aided Design for Additive Manufacturing of Cellular Structures

David W. Rosen

Georgia Institute of Technology, david.rosen@me.gatech.edu

ABSTRACT

Additive Manufacturing (AM) technologies, informally called rapid prototyping, enable the

fabrication of parts and devices that are geometrically complex, have graded material compositions,

and can be customized. In this paper, we focus on cellular materials and structures, which can lead

to designs that are very geometrically complex. In order to take advantage of AM capabilities, new

design and CAD methods must be developed. Two advances are reported in this paper. First, a

new Design for Additive Manufacturing (DFAM) method is proposed that supports part and

specification modeling, process planning, and manufacturing simulations. The method is based on

the process-structure-property-behavior model that is common in the materials design literature.

Second, Manufacturable ELements (MELs) are proposed as an intermediate representation for

supporting the manufacturing related aspects of the method. These MELs represent process

planning information for discrete geometric regions of a part and also enable process simulation.

An example of a cover plate with over 14,000 shape features is used to illustrate the DFAM method

and design-manufacturing integration achievable with MELs.

Keywords: Additive Manufacturing, Rapid Prototyping, Design for Manufacture, Cellular

Structures.

1. INTRODUCTION

1.1 Design for Additive Manufacturing

Design for manufacturing (DFM) has typically meant that designers should tailor their designs to eliminate

manufacturing difficulties and minimize costs. However, the improvement of rapid prototyping, or Additive

Manufacturing (AM), technologies provides an opportunity to re-think DFM to take advantage of the unique

capabilities of these technologies. Several companies are now using AM technologies for production manufacturing.

For example, Siemens, Phonak, Widex, and the other hearing aid manufacturers use selective laser sintering and

stereolithography (SL) machines to produce hearing aid shells, Align Technology uses stereolithography to fabricate

molds for producing clear braces (aligners), and Boeing and its suppliers use selective laser sintering to produce

ducts and similar parts for F-18 fighter jets. In the first three cases, AM machines enable one-off, custom

manufacturing of 10s to 100s of thousands of parts. In the last case, AM technology enables low volume

manufacturing and, at least as importantly, piece part reductions to greatly simplify product assembly. More generally,

the unique capabilities of AM technologies enable new opportunities for customization, very significant improvements

in product performance, multi-functionality, and lower overall manufacturing costs. These unique capabilities include:

Shape complexity: it is possible to build virtually any shape, lot sizes of one are practical, customized geometries

are achieved readily, and shape optimization is enabled.

Material complexity: material can be processed one point, or one layer, at a time, enabling the manufacture of

parts with complex material compositions and designed property gradients.

Hierarchical complexity: hierarchical multi-scale structures can be designed and fabricated from the

microstructure through geometric mesostructure (sizes in the millimeter range) to the part-scale macrostructure.

New CAD and DFM methods are needed in order to take advantage of these capabilities. In the hearing aid and

aligner cases, new CAD systems had to be developed to enable efficient shape modeling and part design. During a

U.S. government sponsored study of European researcher groups [11], many researchers said that they foresaw the

lack of capable CAD tools as a serious impediment for their research and for the utilization of AM technologies for

production manufacturing applications. However, if suitable CAD and DFM methods and tools can be developed,

designers can design devices with significantly improved performance that fully utilize material, and with efficient

manufacturing processes. With the shape, material, and hierarchical complexity capabilities, DFM can move from an

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

586

emphasis on cost minimization to a focus on achieving heretofore unrealizable capabilities. Hence, a new definition of

DFM can be proposed. DFM for Additive Manufacturing (DFAM) is the:

Synthesis of shapes, sizes, geometric mesostructures, and material compositions and microstructures to best

utilize manufacturing process capabilities to achieve desired performance and other life-cycle objectives.

In order to achieve this new concept of DFAM and enable wide ranges of new applications, new approaches,

methods, and tools are needed. The focus in this paper is on the application of cellular materials to replace bulk

materials. Cellular materials provide many more design variables, but with those variables comes more complexity.

New design, analysis, and manufacturing technologies are needed as a result.

1.2 Cellular Materials

The concept of designed cellular materials is motivated by the desire to put material only where it is needed for a

specific application. From a mechanical engineering viewpoint, a key advantage offered by cellular materials is high

strength accompanied by a relatively low mass. These materials can provide good energy absorption characteristics

and good thermal and acoustic insulation properties as well [4]. Cellular materials include foams, honeycombs,

lattices, and similar constructions. When the characteristic lengths of the cells are in the range of 0.1 to 10 mm, we

refer to these materials as mesostructured materials. Mesostructured materials that are not produced using stochastic

processes (e.g. foaming) are called designed cellular materials. In this paper, we focus on designed lattice materials.

In the past 10 years, the area of lattice materials has received considerable attention due to their inherent advantages

over foams in providing light, stiff, and strong materials [1]. Lattice structures tend to have geometry variations in

three dimensions; some of our designs are shown in Figure 1. As pointed out in [2], the strength of foams scales as

1.5, whereas lattice structure strength scales as , where is the volumetric density of the material. As a result, lattices

with a = 0.1 are about 3 times stronger than a typical foam. The strength differences lie in the nature of material

deformation: the foam is governed by cell wall bending, while lattice elements stretch and compress. The examples in

Fig. 1 utilize the octet-truss (shown on the left), but many other lattice structures have been developed and studied

(e.g., kagome, Kelvin foam). We have developed methods for designing lattice mesostructure for parts [15] and have

developed design-for-manufacturing rules for their fabrication in SL.

d

w

v

u

Fig. 1: Octet-truss unit cell and example parts with octet-truss mesostructures.

Methods of continuum mechanics have been applied to various mesostructured materials. Ashby and co-workers

wrote a book on metal foam design and analysis [1]. They and others have applied similar methods to the analysis of

lattice structures. The octet truss in Fig. 1 has been extensively analyzed. Deshpande et al. [4] treated the octet truss

unit cell as a collection of tension-compression bars that are pin-jointed at vertices and derived analytical models of

their collapse behavior for many combinations of stresses. Their results match finite element model behavior well, but

tend to under-predict the strength and stiffness of octet trusses due to their assumption of pin-jointed vertices. Wang

and McDowell [16] extended this study to include several other lattice cells. Recently, we have been developing a

more general analytical model of lattice behavior [7]. From our general model, models for octet and other lattice

structures can be derived. We base our model on a single vertex with a collection of struts incident on that vertex.

This vertex model will be our base unit cell for representation and modeling purposes.

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

587

1.3 Requirements for DFAM

The concept of mesostructured materials is motivated by the desire to put material only where it is needed for a

specific application. Achieving high stiffness or strength and minimal weight are typical objectives. Multifunctional

requirements are also common, such as structural strength and vibration absorption. The area of compliant

mechanisms shares the same motivation, where the local compliance of the structure enables the mechanism to

perform specified motions.

We hypothesize that designed mesostructures will enable structures and mechanisms to be designed that perform

better than parts with bulk or non-designed mesostructures, particularly for multifunctional applications. Testing this

hypothesis requires the ability to bridge the meso to macro size scales. To do this, we need to first recognize some

requirements on DFAM methods and CAD-DFAM tools that will be developed, with a related objective of utilizing the

unique capabilities of AM technologies. The requirements that we propose include the capability to:

R1: Represent and design with hundreds of thousands of shape elements, enabling large complex design

problems as well as designed material mesostructures.

R2: Represent complex material compositions and ensure that they are physically meaningful.

R3: Determine mechanical properties from material compositions and mesostructures across length scales.

R4: Ensure that specified shapes, material structures, and properties are manufacturable.

R5: Ensure that as-manufactured designs achieve requirements.

In order to achieve these requirements, several new technologies are required. Our approach has five main elements

(requirements that they address are appended):

Implicit representations of shapes and specifications of desired distributions of materials and physical properties

(e.g., density, refractive index, elastic modulus). Implicit representations are of two types, implicit modeling and

non-manifold modeling of shape skeletons. With implicit modeling, evaluations of designs need only be

decomposed to the resolution needed for the most detailed analysis. R1, R2, R3

Manufacturable Elements (MELs) that contain geometry, material, properties, and uncertainties in these

quantities that are produced by elementary manufacturing operations. R2, R3, R4

Inverse design methods for process planning that effectively and efficiently determine values of process variables

from MEL representations of parts. R4

Manufacturing simulations that are performed by composing MELs according to their interaction rules, where

composition is achieved by solving simultaneous implicit equations. R2, R3, R4, R5

DFAM templates that enable formulation and solution of typical DFM problems. R4, R5

Each of these five new technologies is addressed, at least in part, in this paper. In the next section, the formal

framework for our DFAM approach is presented, providing the larger context for this research. In Section 3, the

technologies being developed for DFAM are presented, with an emphasis on the problem formulations and

Manufacturing Elements. An example is presented in Section 4 that covers part design, manufacturability analysis,

process planning, and process simulation. Conclusions are drawn in the final section.

2. FORMAL FRAMEWORK FOR DFAM

It is helpful to introduce a formal notation for the subsequent discussion. Let a solid model with material composition

and other material-related attributes be denoted as S = (G, M), where G is the solid geometric model and M is the

attribute space, with some attributes being applied only to regions of G. S denotes the structure of the design. We will

borrow the process-structure-property relationships framework from the materials science field to model a design [8].

The manufacturing process space, P, consists of process plans with sequences of operations and values of process

variables. Property space T contains information about part properties that are derivable from S using physical

principles; e.g., mechanical, thermal, and electrical properties. Finally, we will add behavior space, B, which contains

information about a parts actual and desired behavior given some loading and boundary conditions. The

relationships among these spaces are shown in Fig. 2.

Mappings are defined among these spaces. Mapping represents a manufacturing analysis that determines material

composition and microstructure, and possibly as-manufactured part shape from a process plan. Mapping represents

a material science analysis of a material, and possibly part geometry, to arrive at a set of mechanical and other

properties. It is possible that this mapping can be determined once, then reused for different applications (not design-

or part-specific). Some standard engineering tasks can be described using this notation.

: (S,T) B Engineering analysis

-1: S P Process planning

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

588

: (S,B) (S*, P, T) Design and DFAM

Design

Process Structure Property Behavior

P S T B

Material Composition Mechanical, Electrical, Actual and desired

Microstructure Thermal, Properties behavior

Analysis

Fig. 2: Process-Structure-Property-Behavior Mappings.

The mappings shown in Fig. 2 capture important relationships among design attributes across several size scales.

However, additional richness enables the multi-scale aspects of both geometric and material models to be captured.

The process, structure, and property models will be divided into geometric and material models in order to emphasize

their different decompositions. Fig. 3 shows the framework from Fig. 2 with separate Material and Geometry levels.

As one moves from right to left, the relevant size scales decrease. Similarly, when one moves from top to bottom,

smaller size scales become important. These levels and size scales will be further explained in the next section.

PG SG TG B Behavior

Geometry

Decreasing size scale

Material

PM SM TM

Process Structure Property

Decreasing size scale

Fig. 3: Expanded CADfAM Framework with Geometry and Material Layers.

3. DFAM METHOD, SYSTEM, AND TECHNOLOGIES

3.1 DFAM Method and System

The overall DFAM method consists of a traversal of the frameworks in Figs. 2 and 3 from Behavior to Process, then

back again to Behavior. The traversal from Behavior to Process can be called design, where functional requirements

are mapped to properties and geometry that satisfy those requirements to structures and through process planning to

arrive at a potential manufacturing process. Going in the reverse direction, one can simulate the designed device and

its manufacturing process to determine how well it satisfies the original requirements.

Fig. 4 shows the proposed DFAM system that embodies the method outlined above. To the right in Fig. 4, the

designer can define the DFAM synthesis problem, using an existing problem template if desired. For different problem

types, different solution methods and algorithms will be available. Analysis codes, including FEA, boundary element,

and specialty codes, will be integrated to determine design behavior. In the middle of Fig. 4, the heterogeneous solid

modeler (HSM) is illustrated (heterogeneous denotes that material and other property information will be modeled).

Libraries of materials and mesostructures enable rapid construction of design models. To the left, the manufacturing

modules are shown. Both process planning and simulation modules will be included. After planning a manufacturing

process, the idea is that the process will be simulated on the current design to determine the as-manufactured shapes,

sizes, mesostructures, and microstructures. The as-manufactured model will then by analyzed to determine whether or

not it actually meets design objectives.

At present, elements of all indicated modules have been developed. The CAD system itself is limited in that material

composition and most property distributions cannot be modeled directly. Most modules have limitations and their

integration is limited. However, enough of the system has been developed in order to illustrate the potential of the

system and to conduct some example design problems with complex cellular structures, as will be seen in Section 4.

3.2 CAD = Structure + Property

The CAD system proposed here consists of the Structure and Property elements of Figs. 2 and 3. Our proposed

geometric representation is a combination of implicit, non-manifold, and parametric modeling, with the capability of

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

589

generating BReps when needed. Implicit modeling is used to represent overall part geometry, while non-manifold

modeling is used to represent shape skeletons. Parametric modeling is necessary when decomposing the overall part

geometry into cellular structures; each cell type will be represented as a parametric model.

2 Process 1

Planning DFAM

Manufacturing Implicit

Solution

Process Solid

Planner Modeler Methods

3 4

Manufacturing Analysis

Determine Materials,

Simulator Microstructure, Codes

as-manufactured

shapes, properties Mesostructure

DFAM

Mfg Processes Materials Mesostructures

Templates

Fig. 4: DFAM System and Overall Method.

Implicit modeling has many advantages over conventional BRep, CSG, cellular decomposition, and hybrid

approaches, including its conciseness, ability to model with any analytic surface models, and its avoidance of complex

geometric and topological representations [3]. The primary disadvantage is that an explicit boundary representation is

not maintained, making visualization and other evaluations more difficult than with some representation types. For

HSM, additional advantages are apparent. Implicit modeling offers a unified approach for representing geometry,

materials, and distributions of any physical quantity. A common solution method can be used to solve for material

compositions, analysis results (e.g., deflections, stresses, temperatures), and for spatial decompositions if they can be

modeled as boundary value problems [13]. Furthermore, it provides a method for decomposing geometry and other

properties to arbitrary resolutions which is useful for generating visualizations and manufacturing process plans.

Cellular structures are represented parametrically. The octet lattice unit cell shown in Fig. 1 includes spatial

parameters u, v, w and size parameter d for strut diameters. That is, one can think of a unit cell as a primitive that can

be mapped into a trivariate volume. Such primitives can be used to fill (tile) a volume that is modeled as a trivariate

Bezier or B-spline volume. The mapping -1(TG) SG is a spatial decomposition of a volume into a collection of unit

cells. The decompositions of interest here are essentially mapped hexahedral meshes, with each element of the mesh

consisting of an appropriate unit cell. In this manner, lattice and other cellular structures can be generated readily.

Non-manifold modeling is used to represent shape skeletons. For lattice structures, it is often sufficient to represent

struts as line segments terminated by nodes. Radius parameters are associated with struts and nodes to enable

reasoning about the 3D geometry of lattices and enable generation of 3D solid models, analysis models, and

manufacturing models. We use a simple non-manifold model based on that of Gursoz et al. [5], which is particularly

useful when representing lattices with skins. Such models are represented by the centerlines of the lattice struts and

the mid-plane of the skin (surface). Non-manifold capability enables the determination of which side of the skin the

truss is on, among other reasoning tasks.

3.3 Manufacturable Elements

A Manufacturable ELement (MEL) is a predefined, parameterized decomposition of a volumetric region of a part. For

the lattice structures under investigation in this paper, MEL definition is straightforward: scan patterns and scan

variables are associated with each strut in a unit cell. Consider the octet unit cell in Fig. 1 and assume it is being built

in a SL machine vertically upward. For each layer in the SL build process, the unit cell is sliced by a plane. For the

vertical struts, the intersection of the plane and the strut is a circle. For slanted struts, the intersection is an ellipse,

while for horizontal struts, the intersection is a rectangle. Each case can be handled readily.

The cases for vertical and slanted struts are shown in Fig. 5. The notation is as follows: r = strut radius, W0 = laser

beam radius, = strut angle, rl = major axis of ellipse (with minor axis = r), and p = (px, py) = center of intersected

circle or ellipse. The specific parameters in the cases were determined empirically and give reasonable results for

typical SL resins and laser scanning speeds. For example, case a) rl 1.4 W0 or 1.6 W0 or other multiple of W0 could

have been selected and the laser irradiation time can be determined easily. However, long irradiation times can cause

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

590

cured struts to become too thick, while short irradiation times may not enable the layer to adhere to the previous one.

The multiple 1.5 times W0 is a reasonable compromise value. For horizontal struts, cases b), c), and d) apply.

Using the standard SL exposure model from Jacobs [6], the irradiation time for points and scan speeds for lines can be

computed easily. For reasonably long scan vectors (more than ~3 times the laser beam diameter), the exposure

received at a point (y, z) in the vat by a scan along the x axis is given by

2 PL 2 y 2

E ( x, y , z ) = e W02

e z D p

(1)

W0 Vs

where PL = laser power [mW], Vs = scan speed [mm/s], and Dp = depth of penetration [mm] (taken to be a constant

measure of a resins sensitivity to laser energy). SL resins are assumed to be cured (form a solid) when they receive

exposure that is equal to or greater than a certain amount, called the resins critical exposure, Ec [mJ/mm2]. For a

layer thickness of l = 0.1 mm, it is typical to cure the resin to a depth of 0.15 mm, or 1.5 times the layer thickness.

This cure depth reaches a maximum along a scans centerline (when y = 0). Eqn. 1 can be rearranged to solve for Vs

as follows in order to compute the scan velocity to give a cure depth of 1.5 times the layer thickness:

1.5l

2 PL Dp

(2)

Vs = e

W0 Ec

W0

W0

rl -xm xm

Scan is just a point 1 scan vector from x = -xm to x = xm. xm = rl - W0

Case a) rl 1.5 W0 Case b) r 2 W0

Scan 3 r

r

-xm ym

xm

W0

Scan 1

-ym

Scan 2

3 scan vectors: Scan 1 is same as case b),

Scan 2 is at y = -ym, Scan 3 is at y = ym.

xm = rl 1 ym2 x 2 W0 ym = rl - 0.8 W0

Case c) r 3 W0 Case d) otherwise

Fig. 5: Scan pattern cases for sliced struts.

Substituting reasonable values for a SLA-250/50 machine (PL = 30 mW, W0 = 0.125 mm, Ec = 0.12 mJ/mm2, l =

0.1mm, Dp = 0.1524 mm) yields a scan speed of about 600 mm/s. At this speed, the width of a cured scan line is

0.172 mm for the numbers in this example, or about 2/3 of the laser beam diameter. The cure model presented

briefly here has been implemented into a MEL for lattice unit cells fabricated using SL. By adjusting scan speeds, it is

possible to fine-tune a process plan such that lattice struts have appropriate sizes, which has been formulated as a

parameter estimation problem and solved using nonlinear least-squares methods [12].

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

591

3.4 Process Planning

Process planning is denoted by the mapping 1 : S P. Using the notation in Fig. 3, process planning consists of

two parts, one dealing with geometry decomposition (1 : SG PG) and the other for assigning values to process

variables (1 : SM PM) to process the material appropriately. The specifics of the geometric decomposition and

process modeling were covered in Section 3.3. In this section, we will briefly present the process planning formulation.

Parameter estimation, or inverse design, methods can be applied to AM process planning to enable plans to be

designed that meet design requirements on shape, surface finish, tolerances, and potentially other properties such as

stiffness. Inverse design methods were developed in the heat transfer area [9]. A typical application of inverse design

methods is to layout heater elements in a furnace, where heater positions are to be adjusted to achieve a desired

temperature distribution. Parameter estimation methods for SL will be used to achieve a desired surface finish. The

surfaces of a part fabricated in SL are defined by where the resin reaches a high enough crosslink density to remain

solid, which is related to the exposure received from the laser [6]. The challenge is to determine appropriate exposure

levels for each laser scan as it draws part cross sections such that part surfaces are precisely positioned and shaped.

The inverse design problem for SL process planning can be stated as: find exposure values along each scan vector to

minimize the deviation of exposure across part surfaces from the desired constant Ec value. A general mathematical

problem formulation is shown in Fig. 6 [12]. The constraint models the height of the part at a point P on its surface,

which has to be equal to the summation of the layer thicknesses at point P and the thickness of the Compensation

Zone at point P. The objective function to be minimized models the deviation of exposure at a set of grid points (on

the parts down-facing surfaces) from the critical exposure, Ec.

Since there are many more scan vectors than measurement points mj, least-squares solution techniques are

appropriate. We can take advantage of the MEL model by utilizing MEL parameterizations to sample each MEL and

to compute exposure values. The least-squares fitting problem can be formulated as follows. The squared error term

is the square of the objective function from Fig. 6,

denoted by D (Eqn. 3). This error term is to be Given: Geometry of the part g(x,y,z)

minimized, so the derivative of D, with respect to Material properties: energy absorption, ,

the vector of variables U, involves the Jacobian of critical exposure, E c.

the system. Since J is nonlinear, an iterative Find: LTi, OCip, CZp

solution technique must be used to solve for the Satisfy:

n

unknowns, which are the scanning velocities and

some scan vector positions. Both Gauss-Newton

Constraints: hp =

i =1

LTi + CZ p

and Levenburg-Marquardt methods [10] are

frequently used to solve such problems. In our Bounds: on variables

i

work, we use Matlabs non-linear least-squares n LTm + CZ p

( LTi + OCip )

solver, lsqnonlin, which selects from Gauss- Minimize: e e m=1

1 for all grid

Newton and Levenburg-Marquardt algorithms to i =1

solve problems. points P

Fig. 6: Math formulation of general process planning problem.

4. EXAMPLE

As an example, a cover plate for an aerospace

structure will be redesigned to use lattice structure to stiffen it.

The cover plate is shown in Fig. 7. It is approximately

300x350 mm in size and 3 mm thick. The thickness will be

increased to 9 mm to accommodate the lattice structure, while

the skin thickness will be decreased to 1.5 mm. A typical

design-manufacture scenario will be presented that includes

the decomposition of the cover plate geometry into cells, the

synthesis of the resulting cellular structure to achieve a desired

stiffness with minimum weight, and the decomposition of the

synthesized geometry into manufacturing operations using

MELs. The central region of the plate, inside of the bolt hole

pattern, is offset by the desired thickness of the lattice

structure. This central region is then decomposed into lattice

cells by mapping one layer of octet truss cells into the region.

A nominal size of 8x8x8 mm is chosen for the cells, which

Fig. 7: Cover plate example part.

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

592

results in 14,960 struts.

To achieve the objectives of a target stiffness (modeled by a target deflection) and minimum weight, a shape

optimization problem is solved. Lattice strut diameters are the design variables. Rather than allowing each of the strut

diameters to be a variable, we adopt the strategy of grouping struts into clusters based on an initial structural analysis.

Ten clusters were used, corresponding to 10 design variables for optimization, since in our experience good results are

often achieved. Diameter variables can vary between 0.2 and 1.2 mm, corresponding to the minimum

manufacturable strut size on the lower end. A reasonably large strut size is chosen for the maximum of the range; if

the strut diameters become larger, the cells start to lose porosity. The loading condition for size optimization is an area

load in the plate center of 0.064 N/mm2 applied to a 60x60 mm area.

Size optimization is performed in ANSYS. Input files are automatically generated for ANSYS from the cellular model.

The first-order gradient optimization method is used. Results are shown in Tab. 1. The number of optimization

iterations, maximum stress, maximum deflection of the cover plate, and part volume are reported, along with the

values of the diameter variables. This problem was not sensitive to the number of clusters used. Convergence of the

cluster diameters was smooth, with the lower stress clusters becoming thicker, some mid-level clusters fluctuating up or

down, as shown in Tab. 1. The final cover plate design is shown in Fig. 8. Note that various strut diameters can be

seen in the zoomed view.

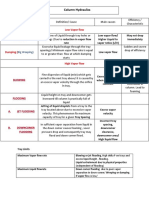

Diameters Initial [mm] Final [mm] Initial [N/mm2] Final [N/mm2]

D1 0.2 0.2 Max. Stress -278.15 57.33

D2 0.4 0.6

D3 0.6 0.79 Volume Initial [mm3] Final [mm3]

D4 0.6 0.73 8008 20,314

D5 0.8 0.84

D6 0.8 0.73

D7 1.0 0.88

D8 1.0 1.04

D9 1.2 1.2

D10 1.2 1.2

Tab. 1: Lattice optimization results.

The next step in the DFAM process is process planning to

ensure manufacturability. Each unit cell of the lattice

structure is represented by a lattice MEL from Section 3.3.

Recall that the relative orientation of each strut to the build

direction dictates how it will be decomposed into

manufacturing operations, which, in the case of SL or SLS

are laser scans. Each strut is modeled as a MEL to

facilitate process planning and process simulation. The

strut design from Fig. 9 is decomposed into MELs and

process planning is performed. Of the many struts in the Fig. 8: Cover plate with optimized lattice structure

design, we will illustrate the process planning of only two (shown on only half of the plate).

of them. First, a low stress strut near the lower left-hand corner of the lattice will be examined; second a strut with a

very high stress will be planned so that its lower surface is as smooth as possible to avoid stress concentrations.

The first strut is 0.2 mm in diameter and is bounded by nodes at (0,-146, 0.0745) and (4, -146, 0.274). The strut has

the smallest allowable diameter since it was in the lowest stress category. Assume that the part will be built on a SLA-

250/50 machine with a laser beam radius of W0 = 0.125 mm. This situation corresponds to a Case (a) MEL, since rl

1.5 W0. The strut is at an angle of only 1.389 degrees with respect to the horizontal. It crosses only a few layers.

Following the process plan method of Case a, the process plan consists of a total of 12 vector scans on only 4 layers.

The SLA-250/50 has a top scan speed of about 1500 mm/sec, so is limited in its capability to fabricate thin struts. A

layer thickness of 0.1 mm was used. Fig. 9 shows this part and its process plan. The scan vectors are shown as thin

black lines terminated with circles; they are also labeled. The desired strut profile is shown using dotted red lines,

while the resulting as-manufactured strut profile is shown as the thick blue lines.

After process planning, the scan speeds for the 12 scan vectors were computed as follows: V1 = 1000 mm/s, V2 =

1034 mm/s, V3 = 682 mm/s, and V4 through V12 were all the maximum speed, 1500 mm/s. As is evident, only the

first three scans were at speeds other than the lasers top speed. Only in the vicinity of the left side of the strut are the

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

593

thicknesses such that slower speeds are needed. Otherwise, the laser scans at its top speed, which is not fast enough

to fabricate the thin strut sections desired. The as-manufactured shape differs significantly from the desired strut

shape, but this is to be expected given the machines limitations. However, the strut is very thin and only lightly

loaded, so small manufacturing errors such as this are insignificant.

For the sake of illustration, the presentation here focused on the body of the strut, not the nodes at its end-points.

Three to eight struts are incident at nodes, so the process planning of the nodes is more complicated.

0.5

12

0.4 10 11

Y [mm]

0.3 5 6 7 8 9

0.2 1 2 3 4

0.1

0

0 1 2 3 4 5 6 7 8 9 10

X [mm]

Fig. 9: Process plan for flat strut.

The second strut to be investigated as a highly loaded strut near the center of the part; its coordinates were (200, 0,

37.44) and (200, -6.33, 33.38). It is 7.52 mm long, 1.2 mm in diameter, and at an angle of 32.68 degrees to the

horizontal. Since it is highly loaded, it was in category 10 and had the largest allowable diameter.

Process planning was based on a Case (d) MEL, with a default scan pattern. In this case, only scans in the transverse

direction (X coordinate direction) were used. Fig. 10 shows the process plan, where each * denotes a laser scan.

The layers are clearly evident. The blue lines and asterisks denote part geometry, while the red circles indicate points

along the geometry where laser exposure was measured. The pink rectangle at the bottom indicates support structure

(added automatically by the process planning tool, but not actually built for individual struts). The parameter

estimation method described in Section 3.4 was used for process planning. After planning, the strut manufacturing

plan was simulated and resulted in the strut profile shown in Fig. 11. Note that the bottom profile is much smoother

than the top surface and indicates the capability of our process planning method. The profile of the strut top is defined

by the layers used in the SL process (0.1 mm layer thickness).

6

5

5 4.5

4

4

3.5

3 3

Z [mm]

Z [mm]

2.5

2 2

1.5

1

1

0 0.5

0

-1

0 1 2 3 4 5 6 7

Y [mm] 1 2 3 4 5 6

Y [mm]

Fig. 10: Process plan for high stress strut. Fig. 11: Profile of as-manufactured strut.

5. CONCLUSIONS

Two advances are reported in this paper. First, a new Design for Additive Manufacturing (DFAM) method was

presented that supports part and specification modeling, process planning, and manufacturing simulations. Second,

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

594

Manufacturable ELements (MELs) were proposed as an intermediate representation for supporting the manufacturing

related aspects of the method. Specific conclusions from this work include:

Cellular material types provide one method for providing mesostructure within a part for achieving improved

stiffness, strength, or other functional requirements, as compared to monolithic materials.

Non-manifold modeling provides a useful abstraction for representing some cellular mesostructures so that

full 3D solid modeling is not necessary when thousands of shape elements are present in a design.

Manufacturing ELements (MELs) enable process planning within discrete regions of a part and also enable

process simulation. MELs represent one approach to achieving shape-specific process planning, rather than

a reliance on general purpose process planning methods, typical of the AM industry at present.

Design for Additive Manufacturing should be concerned with the exploration of expanded design spaces,

rather than the focus on constraints imposed by the manufacturing processes, as is typical of DFM methods.

6. ACKNOWLEDGEMENTS

We gratefully acknowledge the U.S. National Science Foundation, through grants IIS-0120663 and DMI-0522382,

and the support of the Georgia Tech Rapid Prototyping and Manufacturing Institute member companies, particularly

Pratt & Whitney, for sponsoring this work.

7. REFERENCES

[1] Ashby, M. F.; Evans, A.; Fleck, N. A.; Gibson, L. J.; Hutchinson, J. W.; and Wadley, H. N. G.: Metal Foams: A

Design Guide, Butterworth-Heinemann, Woburn, MA, 2000.

[2] Deshpande, V. S.; Fleck, N. A.; Ashby M. F.: Effective Properties of the Octet-Truss Lattice Material, Journal of

the Mechanics and Physics of Solids, 49(8), 2001, 1747-1769.

[3] Ensz, M.; Storti, D.; Ganter, M.: Implicit Methods for Geometry Creation, International Journal of

Computational Geometry Applications, 8(5,6), 1998, 50936.

[4] Gibson, L. J.; Ashby, M. F.: Cellular Solids: Structure and Properties, Cambridge University Press, Cambridge,

UK, 1997.

[5] Gursoz, E. L.; Choi, Y.; Prinz, F. B.: Vertex-based Representations of Non-manifold Boundaries, Geometric

Modeling for Product Engineering, IFIP WG5.2, Rensselaerville, NY, M. J. Wozny, J. U. Turner, and K. Preiss,

(eds.), North-Holland, Amsterdam, 1988, 107-130.

[6] Jacobs, P. F.: Rapid Prototyping & Manufacturing, Fundamentals of Stereolithography, SME, Dearborn, MI,

1992.

[7] Johnston, S. R.; Reed, M.; Wang, H.; Rosen, D. W.: Analysis of Mesostructure Unit Cells Comprised of Octet-

truss Structures, Solid Freeform Fabrication Symposium, Austin, TX, Aug. 14-16, 2006, 421-432.

[8] Olson, G. B., Computational Design of Hierarchically Structured Materials, Science, 277(5330), 1997, 1237-

1242.

[9] zisik, M. N.; Orlande, H. R. B.: Inverse Heat Transfer, Taylor & Francis, New York, 2000.

[10] Press, W. H.; Teukolsky, S. A.; Vettering, W. T.; Flannery, B. P.: Numerical Recipes in C, Chapter 15, 2nd

Edition, Cambridge University Press, Cambridge, UK, 1992.

[11] Rosen, D. W.; Atwood, C.; Beaman, J.; Bourell, D.; Bergman, T.; Hollister, S.: Results of WTEC

Additive/Subtractive Manufacturing Study of European Research, Proc. SME Rapid Prototyping &

Manufacturing Conference, paper # TP04PUB211, Dearborn, MI, May 10-13, 2004. Also, see:

http://wtec.org/additive/welcome.htm for the complete report.

[12] Sager, B.; Rosen, D. W.: Use of Parameter Estimation For Stereolithography Surface Finish Improvement, Proc.

Solid Freeform Fabrication Symposium, Austin, TX, Aug. 1-3, 2005.

[13] Shapiro, V.; Tsukanov, I.: Meshfree Simulation of Deforming Domains, Computer-Aided Design, 31(7), 1999,

459-471.

[14] Wang, H.; Chen, Y.; Rosen, D. W.: A Hybrid Geometric Modeling Method for Large Scale Conformal Cellular

Structures, Proc. ASME Computers and Information in Engineering Conference, paper DETC2005-85366,

Long Beach, CA, Sept 24-28, 2005.

[15] Wang, H.; Rosen, D. W.: Parametric Modeling Method for Truss Structures, ASME Computers and Information

in Engineering Conference, paper DETC2002/CIE-34495, Montreal, Sept. 29-Oct 2, 2002.

[16] Wang, A.-J.; McDowell, D. L.: Optimization of a metal honeycomb sandwich beam-bar subjected to torsion and

bending, International Journal of Solids and Structures, 40(9), 2003, 2085-2099.

Computer-Aided Design & Applications, Vol. 4, No. 5, 2007, pp 585-594

You might also like

- Rohini 15111698981Document12 pagesRohini 15111698981Kishore ImmanvelNo ratings yet

- Computational Materials Engineering: Achieving High Accuracy and Efficiency in Metals Processing SimulationsFrom EverandComputational Materials Engineering: Achieving High Accuracy and Efficiency in Metals Processing SimulationsNo ratings yet

- Design and Development of Cellular Structures For Additive ManufacturingDocument10 pagesDesign and Development of Cellular Structures For Additive ManufacturingSeçkin KoçNo ratings yet

- Integrated Design of Multiscale, Multifunctional Materials and ProductsFrom EverandIntegrated Design of Multiscale, Multifunctional Materials and ProductsNo ratings yet

- Comparing Synthesis Methods for Cellular StructuresDocument15 pagesComparing Synthesis Methods for Cellular StructuresJoyNo ratings yet

- 1 s2.0 S026412752030633X Main PDFDocument14 pages1 s2.0 S026412752030633X Main PDFParsaNo ratings yet

- Modelling and Characterization of A Porosity Graded Lattice Structure For Additively Manufactured BiomaterialsDocument20 pagesModelling and Characterization of A Porosity Graded Lattice Structure For Additively Manufactured BiomaterialsRob GNNo ratings yet

- Review de EjemploDocument15 pagesReview de EjemploBladimir charcaNo ratings yet

- Review of Multiple Material Additive Manufacturing TechnologiesDownloaded by Politecnico di Milano Bibl at 01:08 22 October 2015Liquid binders are selectively deposited to join powdermaterialsDocument33 pagesReview of Multiple Material Additive Manufacturing TechnologiesDownloaded by Politecnico di Milano Bibl at 01:08 22 October 2015Liquid binders are selectively deposited to join powdermaterialsFabioNo ratings yet

- Dms2015 Crolla SmarternodesDocument7 pagesDms2015 Crolla SmarternodesRohit GadekarNo ratings yet

- Object-Oriented Technology and Computing Systems Re-EngineeringFrom EverandObject-Oriented Technology and Computing Systems Re-EngineeringNo ratings yet

- A Short Review On 3D Printing Methods, Process Parameters and MaterialsDocument8 pagesA Short Review On 3D Printing Methods, Process Parameters and MaterialsfarishaNo ratings yet

- Additive Manufacturing: Ajit Panesar, Meisam Abdi, Duncan Hickman, Ian AshcroftDocument14 pagesAdditive Manufacturing: Ajit Panesar, Meisam Abdi, Duncan Hickman, Ian AshcroftrahulNo ratings yet

- A New Approach To The Design and Optimisation of Support Structures in Additive ManufacturingDocument9 pagesA New Approach To The Design and Optimisation of Support Structures in Additive Manufacturingnewkid2202No ratings yet

- Design, Printing Optimization, and Material Testing of A 3d-Printed Nasal Osteotomy Task TrainerDocument6 pagesDesign, Printing Optimization, and Material Testing of A 3d-Printed Nasal Osteotomy Task Trainerlabakoum badr-eddineNo ratings yet

- Neural NetworkDocument14 pagesNeural NetworkSimachew addisuNo ratings yet

- ArticleDocument6 pagesArticleArturo Alberto Ramos VelazquezNo ratings yet

- Literature Review On Additive ManufacturingDocument5 pagesLiterature Review On Additive Manufacturingc5m8rk4d100% (1)

- 1-s2.0-S0079642521001420-mainDocument43 pages1-s2.0-S0079642521001420-mainOğuzhan DündarNo ratings yet

- FIBERSIM Software Streamlines Composite DesignDocument9 pagesFIBERSIM Software Streamlines Composite DesignTakis PlimirasNo ratings yet

- What Are Principles For Design For Additive Manufacturing?: January 2014Document7 pagesWhat Are Principles For Design For Additive Manufacturing?: January 2014raicogonzalezNo ratings yet

- Experimental Investigation of Effects of Build Parameters On Flexural Properties in Fused Deposition Modelling PartsDocument15 pagesExperimental Investigation of Effects of Build Parameters On Flexural Properties in Fused Deposition Modelling PartsAnonymous 5AmJ13mLkNo ratings yet

- Computer-Aided Design: Dawei Li, Wenhe Liao, Ning Dai, Guoying Dong, Yunlong Tang, Yi Min XieDocument13 pagesComputer-Aided Design: Dawei Li, Wenhe Liao, Ning Dai, Guoying Dong, Yunlong Tang, Yi Min XieMoad BouzidaNo ratings yet

- Design of General Lattice Structures For LightweigDocument15 pagesDesign of General Lattice Structures For LightweigJaime Valente Morales BazalduaNo ratings yet

- Applications of Additive Manufacturing (3D Printing) : A ReviewDocument7 pagesApplications of Additive Manufacturing (3D Printing) : A ReviewReinaldi Luthfi AmirNo ratings yet

- 1-s2.0-S2212827122001159-main (1)Document6 pages1-s2.0-S2212827122001159-main (1)SUBHASHISH SAHOONo ratings yet

- PD - 1 - Literature ReviewDocument19 pagesPD - 1 - Literature ReviewMuhammad Wasif AnwarNo ratings yet

- PHD Thesis On Building MaintenanceDocument8 pagesPHD Thesis On Building Maintenancetunwpmzcf100% (2)

- The Roles and Applications of Additive Manufacturing in The Aerospace and Automobile SectorDocument6 pagesThe Roles and Applications of Additive Manufacturing in The Aerospace and Automobile SectorThilak gowdaNo ratings yet

- Materials 15 01838 v2Document11 pagesMaterials 15 01838 v2Seçkin KoçNo ratings yet

- Additive ManufacturingDocument26 pagesAdditive ManufacturingSonia rajpuroitNo ratings yet

- 5.a Further Analysis On Ti6Al4V Lattice Structures ManufacturedDocument10 pages5.a Further Analysis On Ti6Al4V Lattice Structures ManufacturedNishar Alam Khan 19MCD0042No ratings yet

- Computer-Aided Design and ApplicationsDocument11 pagesComputer-Aided Design and ApplicationsGunaseelanMurugesanNo ratings yet

- Kucewicz Et. Al., 2019Document10 pagesKucewicz Et. Al., 2019siyu chenNo ratings yet

- Applsci 12 02296Document27 pagesApplsci 12 02296mirza_munir_baig995No ratings yet

- DfamDocument37 pagesDfamapi-425243636No ratings yet

- Applsci 13 13218Document17 pagesApplsci 13 13218bareya.eztuNo ratings yet

- Uflib ThesisDocument7 pagesUflib Thesisafibaubdfmaebo100% (2)

- 01 - Machine Learning For Predicting Fracture Strain in Sheet Metal-Metals - 2022Document13 pages01 - Machine Learning For Predicting Fracture Strain in Sheet Metal-Metals - 2022Ali KhalfallahNo ratings yet

- Applied SciencesDocument17 pagesApplied Sciences18-29 SAKETH REDDY MECH III-ANo ratings yet

- Robotics and Computer-Integrated ManufacturingDocument11 pagesRobotics and Computer-Integrated ManufacturingFashiar RahmanNo ratings yet

- ABSTRACT This Study Aims to Contribute to the Promising Field of AlkaliDocument27 pagesABSTRACT This Study Aims to Contribute to the Promising Field of Alkalifranco cortez fernandezNo ratings yet

- DREAM3D A Digital Representation Environment For T PDFDocument17 pagesDREAM3D A Digital Representation Environment For T PDFVeerabhadra VeeramustiNo ratings yet

- VOLCOA Predictive Model For 3D Printed MicroarchitectureDocument14 pagesVOLCOA Predictive Model For 3D Printed MicroarchitectureRaimon Mir Al BesNo ratings yet

- 3D Concrete Printing Technology: Construction and Building ApplicationsFrom Everand3D Concrete Printing Technology: Construction and Building ApplicationsNo ratings yet

- Industrial Particle Flow Modeling Using DiscreteDocument46 pagesIndustrial Particle Flow Modeling Using Discrete1720296200No ratings yet

- Materials Today: Proceedings: Gagan Bansal, Desh Bandhu Singh, Harpreet Singh Virk, Abhinav Devrani, Abhishek BhandariDocument5 pagesMaterials Today: Proceedings: Gagan Bansal, Desh Bandhu Singh, Harpreet Singh Virk, Abhinav Devrani, Abhishek BhandariJavier Ricardo Sánchez CastilloNo ratings yet

- Sciencedirect: Finite Element Analysis and Validation of Cellular StructuresDocument6 pagesSciencedirect: Finite Element Analysis and Validation of Cellular Structuresirfan nuryantaNo ratings yet

- Experimental and Analytical Investigation of The Bending Behaviour of 3d-Printedbio-Based Sandwich Structures Composites With Auxetic Core Under Cyclic Fatigue TestsDocument23 pagesExperimental and Analytical Investigation of The Bending Behaviour of 3d-Printedbio-Based Sandwich Structures Composites With Auxetic Core Under Cyclic Fatigue Testssameterkan5864No ratings yet

- Ismail 1992Document14 pagesIsmail 1992Deep AhireNo ratings yet

- Microfabrication and Precision Engineering: Research and DevelopmentFrom EverandMicrofabrication and Precision Engineering: Research and DevelopmentNo ratings yet

- Design and 3D Printing of Scaffolds and Tissues 2015 EngineeringDocument8 pagesDesign and 3D Printing of Scaffolds and Tissues 2015 EngineeringSambit Kumar GhoshNo ratings yet

- Additive Designand Manufacturingof Jet Engine Parts Additive Designand Manufacturingof Jet Engine PartsDocument6 pagesAdditive Designand Manufacturingof Jet Engine Parts Additive Designand Manufacturingof Jet Engine Partsguilherme lacerdaNo ratings yet

- Astm D4218 PDFDocument3 pagesAstm D4218 PDFthlpapNo ratings yet

- MOM I Fundamentals of Stress & StrainDocument10 pagesMOM I Fundamentals of Stress & StrainNithin KannanNo ratings yet

- Artemis Trail - Troodos Mountain - CyprusDocument2 pagesArtemis Trail - Troodos Mountain - CyprusthlpapNo ratings yet

- The ORGONE ENERGY ACCUMULATOR in Treating Cancer in MiceDocument8 pagesThe ORGONE ENERGY ACCUMULATOR in Treating Cancer in MiceCambiador de MundoNo ratings yet

- Awakening To The Dream B. ALAN WALLACEDocument6 pagesAwakening To The Dream B. ALAN WALLACEnidavanNo ratings yet

- A Method To Generate Lattice Structure For Additive ManufacturingDocument5 pagesA Method To Generate Lattice Structure For Additive ManufacturingthlpapNo ratings yet

- The Reich-Einstein Experiment PDFDocument42 pagesThe Reich-Einstein Experiment PDFthlpapNo ratings yet

- FL Bioline DriplineDocument4 pagesFL Bioline DriplinethlpapNo ratings yet

- Fluid Dynamics in MicrochannelsDocument36 pagesFluid Dynamics in Microchannelsthlpap100% (1)

- E 0 B 49528 e 65 A 7 CC 93 FDocument4 pagesE 0 B 49528 e 65 A 7 CC 93 FthlpapNo ratings yet

- Us5028366 PDFDocument7 pagesUs5028366 PDFEdgarNo ratings yet

- Simultaneous Use of Liquid and Solid Foaming Agents by A Nonconventional Technique To Obtain A High-Strength Glass Foam With Fine PorosityDocument7 pagesSimultaneous Use of Liquid and Solid Foaming Agents by A Nonconventional Technique To Obtain A High-Strength Glass Foam With Fine PorosityMarius DragoescuNo ratings yet

- Expandafoam TDSDocument2 pagesExpandafoam TDSkhraieric16No ratings yet

- Floor Coating Additives Guide for Epoxy, Polyurethane and PMMA SystemsDocument21 pagesFloor Coating Additives Guide for Epoxy, Polyurethane and PMMA SystemsRatih AriyaniNo ratings yet

- 2018 Review Papar of Foam Mat Drying Friuit and Vegetable Develop PowderDocument4 pages2018 Review Papar of Foam Mat Drying Friuit and Vegetable Develop PowderDimas DwisardiNo ratings yet

- 1981 Catalytic Combustion Hydrogen2 OptimalDesign PDFDocument8 pages1981 Catalytic Combustion Hydrogen2 OptimalDesign PDFAlex CoțNo ratings yet

- SKB 3i Case Prices - 3D CasesDocument1 pageSKB 3i Case Prices - 3D Cases3D_FlightcaseNo ratings yet

- Design Guide - TraysDocument15 pagesDesign Guide - TraysMohamad FaifNo ratings yet

- Addis Ababa Science and Technology University: Department of Food EngineeringDocument15 pagesAddis Ababa Science and Technology University: Department of Food EngineeringmikialeNo ratings yet

- Priya Seminar ReportDocument19 pagesPriya Seminar ReportVinay Bagade50% (4)

- Aspirated Vs Non AspiratedDocument1 pageAspirated Vs Non AspiratedRoger AklNo ratings yet

- Car Detailing GuideDocument76 pagesCar Detailing GuideZohirNo ratings yet

- Mafra Maniac RangeDocument14 pagesMafra Maniac RangeYamin AhamedNo ratings yet

- Saes B 018Document15 pagesSaes B 018Li PengNo ratings yet

- Mil PRF 46194aDocument10 pagesMil PRF 46194aliuyx866No ratings yet

- Cosmetics Lab - Group 1 - Report 2Document10 pagesCosmetics Lab - Group 1 - Report 2Lê PhúcNo ratings yet

- Home & Decor Singapore - June 2013Document312 pagesHome & Decor Singapore - June 2013royorama0% (2)

- Ground ImprovementDocument96 pagesGround ImprovementGuilhermeslongo100% (1)

- Antifoam Solutions Brochure Indd PDFDocument12 pagesAntifoam Solutions Brochure Indd PDFRomán M Martín del CNo ratings yet

- Food Structure, Rheology, and TextureDocument5 pagesFood Structure, Rheology, and TextureDaniela Rojas MantillaNo ratings yet

- Modeling The Prediction of Compressive Strength For Cement andDocument12 pagesModeling The Prediction of Compressive Strength For Cement andAnil Kumar Sharma100% (1)

- SKUM Bladder Tank MTB Vertical - FDS14306 0214 LRDocument2 pagesSKUM Bladder Tank MTB Vertical - FDS14306 0214 LRLupiNo ratings yet

- Insulation Design GuideDocument38 pagesInsulation Design GuideGunawan Suryana100% (1)

- Cell Filled PavementDocument11 pagesCell Filled PavementAparna PANo ratings yet

- NFPA 11 - Annual Test Recommend For FoamDocument1 pageNFPA 11 - Annual Test Recommend For FoamReinhard SimbolonNo ratings yet

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word DocumentEngineering ProNo ratings yet

- Bw111a Engineroom and Pumproom Fixed SystemDocument6 pagesBw111a Engineroom and Pumproom Fixed SystemMihaela CimpeanuNo ratings yet

- Lesson 2 Introduction To UBDDocument64 pagesLesson 2 Introduction To UBDHeris SitompulNo ratings yet

- SiliFoam TechnicalBulletin PolytekDocument1 pageSiliFoam TechnicalBulletin PolytekIvan MarijanovićNo ratings yet