Professional Documents

Culture Documents

Quality Plan for Steel Structure Manufacturing

Uploaded by

Pageduesca RouelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Plan for Steel Structure Manufacturing

Uploaded by

Pageduesca RouelCopyright:

Available Formats

DOC. NO.

: PEB-QP-J0B-

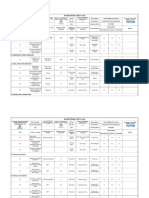

QUALITY PLAN REV. : 1

PAGE : Page 1 of 23

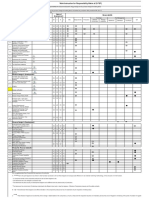

CONTENTS

1 - SCOPE

2 - APPLICATION

3 - INTRODUCTION OF THE WORK

4 - MANAGEMENT COMMITMENT

5 - ORGANIZATION

6 COMMUNICATION

7 ENGINEERING AND DESIGN

8 - DRAWING AND DOCUMENT CONTROL

9 PURCHASING

10 MANUFACTURING PROCESS

11 - SPECIAL PROCESSES

12 PRODUCT IDENTIFICATION AND TRACEABILITY

13 MARKING AND CUTTING PROCESS

14 BULD UP MEMBER AND FITTING PROCESS

15 WELDING PROCESS

16 FINISHING PROCESS

17 BLASTING PAINTING PROCESS

18 INSPECTION AND TESTING

19 CONTROL OF NONCONFORMING PRODUCT

20 CORRECTIVE AND PREVENTIVE ACTION

21-STORAGE, PACKING, AND DELIVERY

22 -QUALITY RECORDS

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 2 of 23

0. REVISION STATUS

Rev Description of Change Effective Date

No

0 Initial release

1 Additional processes and Organizational chart 20.08.08

Prepared by: Cc to: Approved by:

QUALITY DEPT. CUST. SERV. DEPT DIRECTOR

Department

Name Mark Nofuente Nanda Kumar Adib Kouteili

Date 23rd of Oct. 08 23rd of Oct. 08 23rd of Oct. 08

Signature

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 3 of 23

1. SCOPE

This quality plan describes the manufacturing details of pre-engineering

structures and the quality control requirements where all the respective

departments of PEB Steel Buildings Co., Ltd. need to demonstrate their ability to

consistently provide the service that meet customers and applicable regulatory

requirements.

2- APPLICATION

This quality plan is intended to be applicable to all the respective departments of

the manufacturing process of the PEB Steel Buildings Co., Ltd.

3- INTRODUCTION OF THE WORK

CUSTOMER :

NAME OF PROJECT :

JOB SITE LOCATION :

DESCRIPTION OF ITEMS:

WORK VOLUME:

PERIOD OF MANUFACTURING:

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 4 of 23

4. MANAGEMENT COMMITMENT

The management of PEB Steel Buildings Co. Ltd. has fully committed to

meeting all the specified requirements on time with high degree of quality.

The manufacturing and quality system requirement described in this

quality plan is based on PEB STEEL and international standards, design

and technical specification, and other contractual requirements.

All our employees are responsible for comply with this quality plan and for

the quality of work carried out on the manufacturing process of structures,

services and performance.

Operation Director, Mr. Adib Kouteili is responsible and has the authority

to organize, maintain and administer this quality plan and to ensure its

effective implementation.

Further all other key staff of our factory is given the responsibility and

authority to identify any problem and implement solutions to those

problems and to control the product quality at all stages of manufacturing.

This includes preventing dispatch defective, nonconforming and

unsatisfactory products to customer until satisfactory corrective action has

been taken.

Each process group is required to implement this quality plan in each area

of their responsibility.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 5 of 23

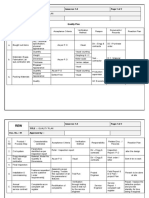

5. ORGANIZATION

ENGINEERING MANAGER SUPERVISORS

QC SUPERVISOR &

QUALITY DEPT. HEAD INSPECTORS

SHIPPING /PURCHASING

SUPERVISOR &

LOGICSTIC & PURCHASING FOREMAN

MANAGER

CUSTOMER SERVICE

CUSTOMER SERVICE ENGINEER/SUPERVISOR

DIRECTOR

MANAGER

Mr. ADIB KOUTEILI

ACCOUNTANT

CHIEF ACCOUTANT

ADMIN & HR H.R.ASSISTANT

PLANT MANAGER PRODUCTION/PLANNING

ENGINEERING/SUPERVIS

MR. NABIL KHALAF OR

SITE ENGINEERS / EREC.

PROJ. MGMT. MANAGER COOR.

IT SUPERVISOR IT TECHNICIANS

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 6 of 23

6- COMMUNICATION

6.1 Management has ensured that the appropriate communication process by

defining interrelations between the departments within the organization by

means of documented internal communication instructions. It shall ensure the

effective communications take place regarding the effectiveness of the

quality control and manufacturing system.

6.2 All the communication shall be addressed to:

Mr.Adib Kouteili

Director

Ho Chi Minh City Office

Unit 701, 7th Floor, City Plaza,

60A Truong Son St.,

Tan Binh Dist, HCMC

Tel: (84) 8 847 5475 / 997 5975

Fax: (84) 8 847 6476 / 9975157

Vung Tau City Office

PEB Steel Buildings Co., Ltd.

Dong Xuyen Industrial zone, Ward 10, Vung Tau city Viet Nam

Tel: (84) 64 613 124 / 613126

Fax: (84) 64 613 125

Mobile: (84) 903 353 335

E-mail: adib@pebsteel.com.vn

7- ENGINEERING AND DESIGN

7.1 PEB design department shall take the responsibility of the following related to:

a. Design development

b. Identifying and documenting any statutory and regulatory requirements

c. Review of the selection of design input requirements

d. Resolving incomplete, ambiguous or conflicting requirements

e. Documenting the design output

f. Design calculations

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 7 of 23

g. Design analysis

h. Design reviews

i. Design verification

j. Design validation

7.2 Acceptance criteria and identifying any crucial design requirements for the main

frame and other structures shall be the responsibility of customer.

7.3 Any design modification required by design department or customer during the

manufacturing process, a written instruction shall need to be issued through

PEBs Customer Service Department so that the modification can be embodied

in the final product.

8. DRAWING AND DOCUMENT CONTROL

8.1 Planning Engineer shall establish and maintain a project document list showing

the latest revision status of the documents and it shall be readily available to

preclude the use of invalid/superseded documents.

8.2 Any superseded document retained for reference by the user and it shall be

communicated to the Planning Engineer. Planning Engineer shall identify those

documented to clearly differentiate from current version of documents by means

of stamp SUPERSEDED and RETAINED BY USER.

8.3 All the engineering documents which include PEB design, drawing and detailed

engineering drawings, connection details, engineering specifications and product

drawing or shop drawings shall be reviewed, controlled, managed, maintained,

issued revised and recalled by the Panning Engineer.

8.4 Design drawing list shall be based on drawing number and showing the status of

revision and date of receipt from the PEBs Customer service department. The

Engineer in-charge shall ensure that all the information provided in the design

drawings is very clear, complete and legible.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 8 of 23

8.5 If any unclear, portion of the design drawing shall be clouded and marked as

HOLD in design drawing. No engineering work shall be carried out on

HOLD until it is released by PEBs design dept. with appropriate information.

8.6 Upon receipt of revised design drawing from PEBs design dept. the Planning

Engineer shall update the drawing list for new revision and he will ensure that

the revised portions have been clouded clearly, having the revision mark in a

triangle at every place of revision.

8.7 The new revised information shall be compared with existing drawing to identify

the changes or modification. If any discrepancy or conflict is found, it shall be

reported to PEBs design dept. immediately.

8.8 Upon receipt of new revision, the existing drawing shall be SUPERSEDED

and the new revision drawings shall be distributed to all the processes area

concerned and the old revision drawing shall be withdrawn from all the process

concern.

8.9 If any design revision received after issue of shop drawing to the production

process, the Planning Engineer shall communicate this information to the

production process and request them to hold the production process of such

items.

9. PURCHASING OF MATERIAL, CONSUMABLES AND PAINTING

MATERIAL

9.1 Purchasing department of PEB shall ensure all the materials, welding consumables

and paint material purchased from approved manufacturer/supplier to confirm the

specified requirements of design drawing and international standards.

9.2 All of the steel materials shall be procured for the main frame structure by PEB

STEEL purchasing department and delivered to the factory at Vung Tau city.

Purchasing department in-charge in Factory will coordinate with Head office to

procure other consumables such as: Welding electrode & Wire, Paint and thinner,

Tools, Safety devices and accessories etc.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 9 of 23

9.3 Purchase order/Sales contracts shall be described and defined clearly the material

to be purchased. All the purchasing information shall be defined and documented

in the purchase order/sales contract.

9.4 Prior to order being placed to any supplier or manufacturer, purchasing

department Head shall ensure the adequacy of the specified purchase requirement

by communicating with the supplier or manufacturer.

9.5 Prior to release purchase order/sales contract to the supplier, the purchasing

Documents shall be verified by the end user in the company who made the

Requests and it shall be reviewed by the Planning.

9.6 All the materials, consumables and paints from the supplier or manufacturer

shall be verified and inspected to ensure that the materials meet specified

purchase requirements. All the verifications and inspection activities shall be in

accordance with the company in-coming material receiving inspection and test

procedure.

10. MANUFACTURING PROCESS

The company has identified various processes that involve in the manufacturing

of mainframe structures:

Marking / cutting

Build up of members

Fitting / assembly

Final Welding

Secondary and Sundry Parts

Sheeting, Panel and Trims

Surface Treatment and Painting

Buyouts

Loading /Delivery

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 10 of 23

11. SPECIAL PROCESSES

The following processes are considered as special processes where conformity of

product is totally depend upon the capability of personnel, equipment and

facilities used and where the resulting output cant be fully verified by

subsequent inspection and testing and where the deficiencies become apparent

only after the product is used:

Welding

Surface treatment and painting

NDT

12. PRODUCT IDENTIFICATION AND TRACEABILITY

12.1. Identification of parts shall be followed in accordance with PEB STEEL design

and shop detail drawings.

12.2 Planning and Production Manager in consultation with other concern

departments shall establish the identification of each item based on design and

contract requirement.

12.3 Upon completion of marking and prior to start cutting every parts, the

identification number of the particular parts shall be written by means of

crayons/paint in accordance with drawing and part list.

12.4 Prior to start blasting of items, blasting team shall prepare the metal tags with

hard punched identification number of the particular items and hang on the

product by mean of steel wire to avoid missing of the tags during blasting.

12.5 Identification of completed product and logo of company shall be stenciled by

paint on the surface of connecting parts so that it will not appear on the final l

structure.

13. MARKING AND CUTTING PROCESS

13.1 Prior to marking, bend or deformation of the material shall be corrected by

mechanical method or heat-cooling methods. On the heat-cooling method, the

heating temperature should be less than 4500C

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 11 of 23

13.2 Prior to start marking, cutting plan showing allotment of the component on the

ordered materials shall be made to minimize the losses and surpluses.

13.3 Application to the center punch in the marking shall be minimized except for

those areas where marking can be completely erased afterwards by means of

drilling, coping or welding.

13.4 As much as possible, original heat number which is stamped by mill must be

retained and marking should be avoided on the identification numbers. Only on

un-avoidable circumstances, the original plate heat numbers shall be transferred

by means of hard punch at unusable corner of the material.

13.5 The cutting face of each member shall be perpendicular to the axis line unless

otherwise specified on the drawing.

13.6 Cut face shall be free from remarkable uneven notch or slag attachment. In case

of occurrence of notch, such part shall be welded and finished to flatness by

means of grinder.

14. BULD UP MEMBER AND FITTING PROCESS

14.1 Fitter shall inspect the items visually for any surface damages, bends and

deformation. If so, it shall be properly corrected in accordance with shop detail

drawings.

14.2 It is the responsibility of fitter/QC Supervisor to verify the size, thickness, hole

details, hole diameter, spacing and number of holes. The contact surfaces of the

components shall be free of burrs and foreign materials that would prevent solid

seating of the part.

14.3 All the edge preparation and site assembly profile on both main members and

components shall be carried out prior to start fitting and in accordance with shop

drawing.

14.4 Assembly work shall be carried out with suitable tools and equipment, such as

surface plate, positioners, jacks, lever blocks, chain blocks and strong backs.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 12 of 23

14.5 All full penetration weld joints of fitting shall have minimum root gap of 3mm

and the edge preparation strictly in accordance with shop drawing.

14.6 The fitter performing the tack welding shall be qualified for the process in

accordance with the applicable welding procedure specification.

14.7 Electrode for tack welding shall be in accordance with the specification and as

per the approved welding procedure.

15. WELDING PROCESS

15.1 All the welding process shall be in accordance with the approved welding

procedure specification (WPS) and procedure qualification record (PQR).

15.2 All the welders to be engaged in this work should have approved welder

performance qualification test certificates.

15.3 Prior to the welding, all welding joint surfaces shall be clean and dry condition.

Rust, paint, dust, grease or any other foreign particles shall be cleaned by

mechanically using wire brush or grinding.

15.4 When the pre-heat is required as per WPS, pre-heating temperature of the base

metal shall be of 100-1200C and shall be checked by temperature crayon.

15.5 Welding gaps or bevels must be accurately controlled over the entire joint during

welding operation.

15.6 Control prior to welding

15.6.1 Consumables such welding electrodes, flux etc. to be used shall be as per

standards. Deteriorated or spoiled consumables should not be used.

15.6.2 Welding equipment should be in satisfactory working condition and be able to

product right quality welds.

15.6.3 Weld testing equipment should be in good operating condition and be handled

by the well trained staff.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 13 of 23

15.7 Control during welding

15.7.1 The weld groove should be free from dirt, rust, oil, slag or any other foreign

particles which affect the quality of the weld.

15.7.2 Job edge preparation should be as per approved welding procedure

15.7.3 The fit-up, gap, orientation, welding position, method and sequence of

assembly all should be as per approved welding procedure.

15.7.4 Tack welds should be of adequate size, length and pitch.

15.7.5 Fittings, clamps, fixtures, etc. should not interfere with welding

15.7.6 Methods should be adopted to minimize distortion

15.7.7 Slag should be thoroughly removed from each pass in multi-pass arc welds and

spot welding electrodes should be dresses periodically.

15.8 Control after welding

15.8.1 Cleaning and visual inspection of welding includes: Final weld appearance,

final weld size, extent of welding, dimensional of accuracy, amount of

distortion, surface cracks, undercut, overlap, exposed porosity, unacceptable

weld profile, and roughness of the weld face.

15.8.2 Check the welding conformity to the drawings and specification.

16. FINISHING PROCESS

16.1 Welding slag and spatter must be cleaned properly and use wire brush or power

brush as post cleaning operation.

16.2 If any undercutting or porosity found during cleaning, mark the spot by means of

crayons and report to welding supervisor for repair and ensure the repair has

been done in accordance with the standard and acceptable level.

16.3 If any crater observed, note down the welder identification number which is

written near the welding and call the same welder for repair.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 14 of 23

16.4 All the bolt holes must be clean and trimming by means of grinder, round file

and reamer if in case necessary.

16.5 All the cutting edges must be grind smooth and all the sharp edges must be

radius and smooth.

16.6 All the gas notches must be rebuilt by (touch up) qualified welders and grind

smooth.

16.7 Any bend, deflection and deformation of member out of tolerance should be

corrected by means of heating and cooling methods.

17. BLASTING PAINTING PROCESS

17.1 Prior to start painting blasted surface shall be cleaned by dry compressed air and

ensure the surface is dust free.

17.2 The following area shall be covered by masking tape to avoid painting:

The parts to be metal to metal contact

Embedded steel in contact with concrete

The parts where field welding is to be applied

17.3 Each container of paint shall be clearly marked or labeled to show paint

identification date of manufacture, batch number, analysis of contents,

identification of all toxic substance and special instruction.

17.4 All ingredients in any container of paint shall be thoroughly mixed before use and

shall be agitated often enough during application to keep the paint uniform.

17.5 The type of thinner shall comply with paint manufacturers instructions. Correct

amount of thinner to be added to particular application when the use of thinner is

permissible, thinner shall be added slowly to paint during mixing process.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 15 of 23

17.6 The equipment used for painting application shall be suitable for the appropriate

purpose and coating system and shall be capable of properly atomizing the paint

to be applied.

17.7 All the paint pot shall be equipped with suitable pressure regulators and gauges.

17.8 Paint shall be applied in a uniform layer with overlapping at the edges of the

pattern. During application, the painting spray gun shall be held perpendicular to

the surface which will ensure that a wet layer of paint is deposited on the surface.

The trigger of the gun should be released at the end of each stroke.

17.9 The air caps, nozzles and needles shall be those recommended by the paint

manufacturers of material being sprayed and equipment being used.

17.10 Traps or separators shall be provided to remove oil and condensed water from air. The

traps or separators must be of adequate size and must be drained periodically during

operations.

17.11 The pressure on the material in the pot and of the air at the gun shall be adjusted

for optimum spraying effectiveness.

17.12 The pressure on the material in the pot shall be adjusted when necessary for

changes in elevation of the gun above the pot. The atomizing air pressure

At the gun shall be high enough to properly atomize the paint.

17.13 When spraying the spray gun should be held from 250 mm to 350 mm from the

surface and maintained perpendicular to the surface throughout the stroke. At the

end of each pass, the gun trigger should be released.

17.14 For airless application, the distance should be from each spray pass should

overlap the previous one by 50%, and where possible, a cross hatch technique

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 16 of 23

should be used. This requires a duplicate series of pass at 90o to the first to

ensure complete and uniform coverage.

17.15 Paint shall not be applied when the temperature of steel or the paint is below 4o C.

17.16 Paint shall not be in rain, wind, fog, mist or when the steel surface temperature is

less than 3o C above the dew point.

17.17 Paint shall not be applied when the relative humidity is above 80%. The

manufacturers instructions shall be followed regarding the acceptable humidity

range for the particular paint.

17.18 Paint thickness shall be in accordance with the customer requirements.

18. INSPECTION AND TESTING

18.1 Material receiving inspection

18.1.1 All the materials shall be inspected against the specified material specification

and the mill certificate.

18.1.2 Upon receipt of materials/products, storekeeper shall verify the quantity, number

of packing, type of materials, general appearance of materials and conformance

against the requisition order, purchase documents, packing list and delivery

order. He shall also make arrangements to request Q.C Inspector for receiving

inspection.

18.1.3 Q.C Inspector shall carry out the following visual inspection upon receipt

Of materials:

General appearance

Corrosion or pitting conditions

Conformance to the purchase order

Material identification (heat number) conformance to the Mill certificate.

18.1.4 All the welding consumables shall be in inspected before use.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 17 of 23

18.1.5 Material shall not be used for production until it has been inspected or verified as

conforming to specified requirements.

18.2 In-process inspection and testing

18.2.1 In-process inspection shall be carried out in all stages of process in order to verify

the conformance of the product against drawings and technical specification.

18.2.2 Product shall be hold until the required in process and test have been completed

and shall be released for next process, only after acceptance by QC inspector.

18.2.3 If any part or item found nonconformity during in-process inspection and test

shall be identified, segregated and hold until the items to be re-inspected and

accepted by QC inspector.

18.2.4 Marking and cutting process

a) The in- process inspection during marking and cutting process shall include:

Checking of full scale template

Verification of marking against the required dimension including any

cutting allowance

Verification of part number

Transfer of heat number, when necessary

Edge preparation in accordance to the drawing

b) In-process inspection during marking and cutting shall be carried out by the

marking/cutting group leader and the Q.C Supervisor / Engineer may

witness the transfer of heat number when necessary.

18.2.5 Fit up process

a) In process inspection during the fitting and assembly of the items

b) Any non-conformance observed during inspection, QC supervisor shall fix a

HOLD label and subsequently NCR to be raised.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 18 of 23

c) Appropriate corrective action shall be carried out within the period stated in

the NCR reports. Upon completion of satisfactory corrective action, the

same item shall be re-inspected again in accordance with the requirements.

d) If any items are not in conformance with the requirements after necessary

repair and re-inspection, QC Engineer shall fix REJECT label and

separate the item from the assembly line and further investigation to be

conducted for the failure.

18.2.6 Welding process

a) QC Engineer shall verify the following conditions for conformity to the

applicable specification, AWS D1.1 Edition 2008.

Review of the welding procedure specification (WPS)

Review of welding procedure qualification record (PQR)

Review of welders performance test records

Verification of the welders against their qualification badge number

Verification of joint preparation, dimensions against design drawing

and cleanliness

Alignment and fit up of the pieces being welded.

Welding process and consumables

Condition of welding equipment and power sources

Preheat temperature

Condition of tack welding

b) QC Engineer/welding Supervisor shall inspect the following aspect during

the welding process

Treatment of tack welding

Verification of corrective usage of electrodes and classification

Verification of welder identification number written near the weld joint

Inspection of quality of the root pass and the succeeding weld layers

Ensure the sequence of welding

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 19 of 23

Ensure the adequate cleaning of welding

Verify the root pass penetration prior to welding a second side and ensure the

back chipping/grinding in accordance with the welding procedure specification.

c) Any welding defect noticed by the QC Engineer who shall mark the

defective area and subsequently the welding supervisor shall take necessary

corrective action.

18.2.7 Non-destructive Inspection

As applicable for jobs

NDT inspection shall be carried out by subcontractor.

Any non-conformance found through NDT test reports and the defects shall be

identified by the paint/chalk and subsequently HOLD label shall be fixed to

the defective area and NCR to be raised for necessary corrective action.

18.2.8 Painting inspection

a) QC Engineer shall perform random inspection on the profile of the surface

preparation. Surface profile comparator shall be used to verify the surface

profile conformance.

b) The following shall be inspected upon completion of painting:

Required dry film thickness

Dryness of the paint

Completeness of coverage

Brush mark, run sags etc.

Adhesion of dry paint

Specified number of coats

Blisters, pores etc.

18.2.9 Final inspection and testing

a) The equipment shall not be dispatched or handed over to customer until all

the activities specified in this work plan/quality plan, inspection & test plan

including applicable records and documents have been satisfactorily

completed.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 20 of 23

b) The final inspection activities shall include:

Ensure all the previous inspection and tests have been performed

The as-built configuration is the same as the issued status of all parts, sub

assemblies, specified by the design standard.

All the documented non-conformities have been resolved and remedial

action taken and verified

All customers and Engineers concession if any, has been approved.

All the inspection and test records have been collected and complete the

final inspection records and documentation.

Any inspection and test result beyond the specified limit is either subject to

an approved concession, an approved specification change or re-inspection

which shows conformance with the requirements.

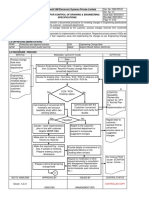

19. CONTROL OF NONCONFORMING PRODUCT

19.1 QC Engineer shall be responsible for review and disposition of non-conforming

report.

19.2 Al the non-conforming product shall be segregated from the routine process or

from the conforming items. If the parts or items are heavy and too big, a

HOLD label shall be fixed until the appropriate corrective action taken.

19.3 Any item or part number that has been repaired, reworked and modified shall be

re-inspected prior to it being released to further process or dispatch. Re-

inspection and test records shall indicate the original rejection, disposition and

the result of the re-inspection.

19.4 Upon completion of correction action, QC Engineer shall verify the effectiveness

of the corrective action and records in the non-conformance report. NCR shall be

closed once the corrective action is completed and satisfied.

19.5 QC Engineer shall ensure that product which does not conform to the specified

requirements is prevented from further processing or dispatch to the customer.

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 21 of 23

20. CORRECTIVE AND PREVENTIVE ACTION

20.1 The QC Engineer shall be responsible for the execution of proposed corrective

action for any customers complaint or comments and he is also responsible to

submit the appropriate corrective action reports to customers representative

when required.

20.2 Corrective action shall include the documenting/recording both cause and

proposed appropriate corrective action needed to eliminate the cause of non-

conformities.

20.3 The concerned action party shall report when the corrective action has been

completed and the QC Engineer shall verify it.

20.4 If QC Engineer determines the non-conformance is minor and the effect of non-

conformities does not affect the performance of the product, it shall be

recommended to use as it is without any corrective action.

20.5 In case of product non-conformity is considered as major the QC Engineer shall

recommend for repair the product to meet the requirements. In such case, the

repair method and acceptance criteria shall be documented in the non-

conformance report.

21. STORAGE, PACKING, PRESERVATION AND DELIVERY

21.1 Storage

21.1.1 Appropriate designated storage areas for raw materials and the equipment shall

be planned in advance in order to prevent damage or deterioration.

21.1.2 After painting, the product shall be kept in open yard on the stable steel skid

beams and there shall not be any deflection in the middle.

21.2. Preservation (protection)

21.2.1. Machined surfaces shall be coated with rust preventive grease

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 22 of 23

21.2.2. All threads of bolt and nuts including any exposed parts should be coated with

rust preventive grease or oil to prevent corrosion during storage.

21.3 Packing and marking

Marking and identification shall be done clearly on the equipment and other

packages and shall be in accordance with requirements, which is stated in

contract or technical specification.

21.4 Delivery

21.4.1 Products shall be delivered to the Project site based on schedule and instruction

to delivery from Customer Service Department (PEB STEEL).

21.4.2 Delivery/shipping documents as required shall be prepared by the Shipping

Manager, Reviewed by Factory Manager and submit to CSD for review and final

submission to customers/client.

22. QUALITY RECORDS

22.1 The following records shall be maintained to demonstrate to conformance of the

goods to the requirements:

Material Mill Certificate ( from the Manufacturer)

Appropriate Welding Procedure Specification (WPS)

Appropriate Procedure Qualification Record (PQR)

List of Qualified Welder Involved in Welding Process

Approved Welder Performance Qualification.

Incoming Material Inspection Report

In Process and Final Dimensional Inspection Report

Secondary Inspection Report

Final Welding Inspection Record

Appropriate NDT Inspection Report

PEB/ QC./Updated Quality plan

DOC. NO. : PEB-QP-J0B-

QUALITY PLAN REV. : 1

PAGE : Page 23 of 23

Surface Preparation Inspection Report

Painting Inspection Report

Appropriate Non-conformance Report

Pre Shipment Inspection Report

Final Release Inspection Report

22.2 All the quality records shall be stored in the place having the facilities that

provide a suitable environment to prevent damage or deterioration and to prevent

loss.

PEB/ QC./Updated Quality plan

You might also like

- Quality PlanDocument51 pagesQuality PlanAJAYAKUMAR CHANDRANPILLAINo ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- Quality Manual: Duty Party Document Ref. Quality RecordDocument1 pageQuality Manual: Duty Party Document Ref. Quality RecordShida ShidotNo ratings yet

- IAC Corrective Action ReportDocument2 pagesIAC Corrective Action Reportsvanand500No ratings yet

- Material TraceabilityDocument24 pagesMaterial TraceabilityStanley AlexNo ratings yet

- Material Traceability Procedure EMC-MTP-01Document9 pagesMaterial Traceability Procedure EMC-MTP-01Roshan Aravinth100% (2)

- Quality Monthly Report - NOV 2015Document15 pagesQuality Monthly Report - NOV 2015KumaravelNo ratings yet

- Control Calibrated EquipmentDocument11 pagesControl Calibrated Equipmentmoytabura96100% (1)

- Quality System Procedure Identification & TraceabilityDocument3 pagesQuality System Procedure Identification & TraceabilityMohammed ZubairNo ratings yet

- Inspection & Test Plan for SEPCOIII Electric Power Construction CorporationDocument3 pagesInspection & Test Plan for SEPCOIII Electric Power Construction Corporationtrey100% (4)

- Process Analysis: SL No Process Proces S Owner Input Output Methods Interfaces With Measure of Performance (MOP)Document12 pagesProcess Analysis: SL No Process Proces S Owner Input Output Methods Interfaces With Measure of Performance (MOP)DhinakaranNo ratings yet

- QC Process Chart Template for Supplied PartDocument4 pagesQC Process Chart Template for Supplied Partbarja subarjaNo ratings yet

- ISO - Control of Non-Conforming ProductsDocument5 pagesISO - Control of Non-Conforming ProductsAlmario SagunNo ratings yet

- Quality Manual - VVRDocument67 pagesQuality Manual - VVRRajamani100% (2)

- PLAN For Quality Assurance and ControlDocument39 pagesPLAN For Quality Assurance and ControlmutamanthecontractorNo ratings yet

- NCR Trend Analysis for Barzan Onshore ProjectDocument15 pagesNCR Trend Analysis for Barzan Onshore ProjectrmdarisaNo ratings yet

- Controlled Quality ManualDocument51 pagesControlled Quality ManualMoment BatureNo ratings yet

- Quality Manual: M. Barbisotti & Sons LTDDocument20 pagesQuality Manual: M. Barbisotti & Sons LTDengsam777100% (1)

- Automotive Quality Management System Identification and TraceabilityDocument6 pagesAutomotive Quality Management System Identification and Traceabilityom cncNo ratings yet

- IQA Audit PlanDocument1 pageIQA Audit PlanSachin RamdurgNo ratings yet

- QSV 2 Product Release Procedure EN 01 PDFDocument6 pagesQSV 2 Product Release Procedure EN 01 PDFprashanthNo ratings yet

- CONTRACT NO. TANK D101-1 REPAIR AND CLEANING QC PROCEDUREDocument6 pagesCONTRACT NO. TANK D101-1 REPAIR AND CLEANING QC PROCEDUREAndreas Schlager100% (3)

- Quality Manual: Observed Non ConformityDocument1 pageQuality Manual: Observed Non Conformitykhyle093009No ratings yet

- Materials Receipt and InspectionDocument6 pagesMaterials Receipt and InspectionMj AndresNo ratings yet

- Quality Requirements For Subcontractor: Project ProcedureDocument15 pagesQuality Requirements For Subcontractor: Project ProcedureDindo QuintanNo ratings yet

- Control 1000+ workers on large projectsDocument9 pagesControl 1000+ workers on large projectsAjaz MalikNo ratings yet

- Site Quality ManualDocument376 pagesSite Quality ManualsNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- APQP Flow Chart Sample 2 Rev ADocument9 pagesAPQP Flow Chart Sample 2 Rev ALuis AlejandroNo ratings yet

- Incoming Material ProcedureDocument2 pagesIncoming Material ProcedureTridib Dey100% (6)

- Inspection Procedure MaterialDocument1 pageInspection Procedure MaterialZharel AhmadNo ratings yet

- Quality PlanDocument2 pagesQuality PlanSekar Krish100% (1)

- Procedure For Control of Non-ConformanceDocument8 pagesProcedure For Control of Non-ConformanceraviNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- QM501FA - Nonconformance ReportDocument1 pageQM501FA - Nonconformance ReportRio Handoko100% (1)

- Kencana Infrastructure Quality Assurance ProcedureDocument22 pagesKencana Infrastructure Quality Assurance Procedurenaseema1100% (9)

- Quality Control PlanDocument6 pagesQuality Control PlanMaaz Mullanji100% (1)

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanNESTOR YUMULNo ratings yet

- Appendis3 IQA Incoming Material Inspection Flow ChartDocument1 pageAppendis3 IQA Incoming Material Inspection Flow ChartnguyencaohuygmailNo ratings yet

- Design Control Quality Assurance ProcedureDocument13 pagesDesign Control Quality Assurance ProcedurePrakash TiwariNo ratings yet

- Quality Plan AuditDocument5 pagesQuality Plan AuditRajan100% (1)

- Control Drawing & Engineering SpecificationsDocument1 pageControl Drawing & Engineering SpecificationssumanNo ratings yet

- Control PlanDocument4 pagesControl PlanRakesh PandeyNo ratings yet

- Material ControlDocument33 pagesMaterial ControlFerdie OS100% (1)

- Job Procedure For Inspection of Incoming Materials HRRLDocument6 pagesJob Procedure For Inspection of Incoming Materials HRRLmahesh naik100% (1)

- K101-QC-PL.001 - Quality Plan - Rev 0 PDFDocument85 pagesK101-QC-PL.001 - Quality Plan - Rev 0 PDFberthitasNo ratings yet

- Control of Records ProcedureDocument1 pageControl of Records ProcedureZharel AhmadNo ratings yet

- QMS PROCEDURE IDENTIFICATION & TRACEABILITYDocument3 pagesQMS PROCEDURE IDENTIFICATION & TRACEABILITYRainer-SlawetzkiNo ratings yet

- Project Quality Plan TemplateDocument15 pagesProject Quality Plan TemplateRavi ValiyaNo ratings yet

- Internal Audit Check Sheet Ok 2016Document11 pagesInternal Audit Check Sheet Ok 2016manttupandeyNo ratings yet

- Quality Walk Report FormatDocument14 pagesQuality Walk Report FormatAmar KolachinaNo ratings yet

- QC's SOPDocument11 pagesQC's SOPDavid SeeNo ratings yet

- Responsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsDocument4 pagesResponsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsAL BARAKAH GRAINS100% (1)

- Concession Request Form Project ChangesDocument1 pageConcession Request Form Project ChangesganeshNo ratings yet

- All Departments Monthly Meeting TemplateDocument34 pagesAll Departments Monthly Meeting TemplateSachin RamdurgNo ratings yet

- Material Handling and Preservation ProcedureDocument2 pagesMaterial Handling and Preservation ProcedureIman ZNo ratings yet

- Quality Audit Checklist On FabricatorDocument9 pagesQuality Audit Checklist On Fabricatorarinmerliana100% (1)

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- (QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Document9 pages(QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Gourav SainiNo ratings yet

- 01 Qulaity Control Plan - Asf QC QCP 001Document8 pages01 Qulaity Control Plan - Asf QC QCP 001Ahmad Nabil ElsharkawyNo ratings yet

- Banta Ylan Sang AnDocument136 pagesBanta Ylan Sang AnPageduesca RouelNo ratings yet

- Gen. Principles of TaxationDocument22 pagesGen. Principles of TaxationPageduesca RouelNo ratings yet

- Computation of Income TaxDocument10 pagesComputation of Income TaxPageduesca RouelNo ratings yet

- Project Execution ProcedureDocument4 pagesProject Execution Procedurecyno2167% (3)

- Typical Project Quality Plan & ITP CPCDocument14 pagesTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- Computation of Income TaxDocument10 pagesComputation of Income TaxPageduesca RouelNo ratings yet

- Excavation Checklist PDFDocument4 pagesExcavation Checklist PDFPageduesca RouelNo ratings yet

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDocument34 pages5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Project Exec & Quality PlanDocument7 pagesProject Exec & Quality PlanGurumoorthy Chandran100% (1)

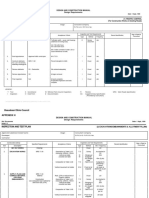

- PI - Template - 06A Water ITPDocument8 pagesPI - Template - 06A Water ITPPageduesca RouelNo ratings yet

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Project Quality PlanDocument43 pagesProject Quality PlanPageduesca RouelNo ratings yet

- Qatar Building Engineering Company Earthwork Inspection PlanDocument4 pagesQatar Building Engineering Company Earthwork Inspection PlanPageduesca RouelNo ratings yet

- Project Exec & Quality PlanDocument7 pagesProject Exec & Quality PlanGurumoorthy Chandran100% (1)

- Quality Management PlanDocument32 pagesQuality Management PlanPageduesca Rouel100% (1)

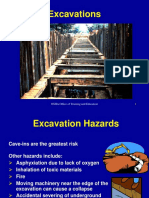

- Excavation SafetyDocument31 pagesExcavation SafetyPageduesca RouelNo ratings yet

- Typical Project Quality Plan & ITP CPCDocument14 pagesTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- Project Execution ProcedureDocument4 pagesProject Execution Procedurecyno2167% (3)

- Excavations 2Document31 pagesExcavations 2sumitdel9136No ratings yet

- Engineering Development/Quality Inspection Test Plan (ITPDocument13 pagesEngineering Development/Quality Inspection Test Plan (ITPPageduesca RouelNo ratings yet

- Appendix H: Design and Construction Manual Design RequirementsDocument17 pagesAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelNo ratings yet

- PI - Template - 06A Water ITPDocument8 pagesPI - Template - 06A Water ITPPageduesca RouelNo ratings yet

- Excavation Checklist PDFDocument4 pagesExcavation Checklist PDFPageduesca RouelNo ratings yet

- Excavation Safety: Texas Department of InsuranceDocument12 pagesExcavation Safety: Texas Department of InsurancePageduesca RouelNo ratings yet

- Engineering Development/Quality Inspection Test Plan (ITPDocument13 pagesEngineering Development/Quality Inspection Test Plan (ITPPageduesca RouelNo ratings yet

- Excavation SafetyDocument31 pagesExcavation SafetyPageduesca RouelNo ratings yet

- Floor Finish OptionsDocument69 pagesFloor Finish OptionsPageduesca RouelNo ratings yet

- Deep Excavation Techniques Deep Excavation Techniques: Presented byDocument31 pagesDeep Excavation Techniques Deep Excavation Techniques: Presented byRizwan Khurram100% (1)

- BIT CIVIL UNDERWATER CONCRETINGDocument21 pagesBIT CIVIL UNDERWATER CONCRETINGPageduesca Rouel100% (2)

- AR Gapura Angkasa 2018Document222 pagesAR Gapura Angkasa 2018Alexius SPNo ratings yet

- Condition Types Are Defined in General Using The Condition Class and in DetailDocument11 pagesCondition Types Are Defined in General Using The Condition Class and in DetailMonk DhariwalNo ratings yet

- CHED New Policies On Tuiton and Other School FeesDocument13 pagesCHED New Policies On Tuiton and Other School FeesBlogWatch100% (2)

- Tally 7.2Document38 pagesTally 7.2sarthakmohanty697395No ratings yet

- Accounting For Developers 101Document7 pagesAccounting For Developers 101farkasdanNo ratings yet

- Oe/Ee/Hps:: Instructions To Bidder FORDocument46 pagesOe/Ee/Hps:: Instructions To Bidder FORRabana KaryaNo ratings yet

- Sup SysadminDocument390 pagesSup SysadminSworna VidhyaNo ratings yet

- BD - 2013 Netrc 011 Bi 009Document144 pagesBD - 2013 Netrc 011 Bi 009Aryan LaudeNo ratings yet

- Oligopoly For MPADocument41 pagesOligopoly For MPAAshraf Uz ZamanNo ratings yet

- Sales Funnel Strategies PDFDocument41 pagesSales Funnel Strategies PDFgeyles100% (4)

- Essential Links for Marketing, Finance & TechDocument3 pagesEssential Links for Marketing, Finance & TechsouranilsenNo ratings yet

- Archon Umipig Resume 2018 CVDocument7 pagesArchon Umipig Resume 2018 CVMaria Archon Dela Cruz UmipigNo ratings yet

- Ghaziabad Development Authority Vs Balbir SinghDocument2 pagesGhaziabad Development Authority Vs Balbir SinghHimanshu KanaujiaNo ratings yet

- PAL Pilots Seek Reinstatement After Illegal Strike RulingDocument835 pagesPAL Pilots Seek Reinstatement After Illegal Strike RulingJohn Robert BautistaNo ratings yet

- G.O. 361-I&prDocument3 pagesG.O. 361-I&prBalu Mahendra SusarlaNo ratings yet

- Part B EnglsihDocument86 pagesPart B EnglsihLiyana AzmanNo ratings yet

- United States Court of Appeals Second Circuit.: Nos. 256-258. Docket 27146-27148Document16 pagesUnited States Court of Appeals Second Circuit.: Nos. 256-258. Docket 27146-27148Scribd Government DocsNo ratings yet

- Work Order: Department: Hapag-Lloyd Guatemala S.A. Phone: +0 Order To: Interlogic Service DistributionDocument2 pagesWork Order: Department: Hapag-Lloyd Guatemala S.A. Phone: +0 Order To: Interlogic Service DistributionAlex MarroquinNo ratings yet

- Chapter 12Document31 pagesChapter 12KookieNo ratings yet

- Brand Management - PPT (Part2)Document3 pagesBrand Management - PPT (Part2)muna siddiqueNo ratings yet

- 'Air Astana ' Airline Industry OrganisationDocument5 pages'Air Astana ' Airline Industry OrganisationФариза ЛекероваNo ratings yet

- Tribe of TradersDocument6 pagesTribe of TradersdatsnoNo ratings yet

- The Distribution Trap - Keeping Your Innovations From Becoming Commodities - SalesAndMarketingDocument2 pagesThe Distribution Trap - Keeping Your Innovations From Becoming Commodities - SalesAndMarketingsabhijit19No ratings yet

- Ahrend Sen 2012Document12 pagesAhrend Sen 2012sajid bhattiNo ratings yet

- Psa 210Document3 pagesPsa 210Medina PangilinanNo ratings yet

- "Brands Aren't Just Names On Packages!": Executive PerspectiveDocument5 pages"Brands Aren't Just Names On Packages!": Executive PerspectiveMeray George Wagih EbrahimNo ratings yet

- QA System KMC AS7Document76 pagesQA System KMC AS7Rayudu VVSNo ratings yet

- Saint GobainDocument85 pagesSaint Gobainkannankavin100% (2)

- Business LetterDocument6 pagesBusiness LetterGlory Mae OraaNo ratings yet

- Basma Rice Mills PVTDocument3 pagesBasma Rice Mills PVTAmna SaadatNo ratings yet