Professional Documents

Culture Documents

Detailed Gasification Chemistry

Uploaded by

Faris HamidiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detailed Gasification Chemistry

Uploaded by

Faris HamidiCopyright:

Available Formats

DETAILED GASIFICATION CHEMISTRY

The chemical reactions of gasification can progress to different extents depending on the

gasification conditions (like temperature and pressure) and the feedstock used. Combustion

reactions take place in a gasification process, but, in comparison with conventional

combustion which uses a stoichiometric excess of oxidant, gasification typically uses one-

fifth to one-third of the theoretical oxidant. This only partially oxidizes the carbon feedstock.

As a "partial oxidation" process, the major combustible products of gasification are carbon

monoxide (CO) and hydrogen, with only a minor portion of the carbon completely oxidized

to carbon dioxide (CO2). The heat produced by the partial oxidation provides most of the

energy required to drive the endothermic gasification reactions.

Within a gasification process, the major chemical reactions are those involving carbon, CO,

CO2, hydrogen (H2), water (steam) and methane (CH4), as follows:

The combustion reactions:

1. C + O2 CO (-111 MJ/kmol)

CO + O2

2. (-283 MJ/kmol)

CO2

3. H2 + O2 H2O (-242 MJ/kmol)

Other important gasification reactions include:

4. C + H2O CO + "the Water-Gas Reaction"

H2 (+131 MJ/kmol)

5. C + CO2 2CO "the Boudouard Reaction"

(+172 MJ/kmol)

6. C + 2H2 CH4 "the Methanation Reaction"

(-75 MJ/kmol)

With the above, the combustion reactions are essentially carried out to completion under

normal gasification operating conditions. And, under the condition of high carbon

conversion, the three heterogeneous reactions (reactions 4 to 6) can be reduced to two

homogeneous gas phase reactions of water-gas-shift and steam methane-reforming

(reactions 7 and 8 below), which collectively play a key role in determining the final

equilibrium synthesis gas (syngas) composition.

7. CO + H2O "Water-Gas-Shift Reaction"

CO2 + H2 (-41 MJ/kmol)

8. CH4 + H2O "Steam-Methane-Reforming Reaction"

CO2 + 3 H2 (+206 MJ/kmol)

In the low-oxygen, reducing environment of the gasifier, most of the feedstocks sulfur

coverts to hydrogen sulfide (H2S), with a small amount forming carbonyl sulfide (COS).

Nitrogen chemically bound in the feed generally converts to gaseous nitrogen (N2), with

some ammonia (NH3), and a small amount forming hydrogen cyanide (HCN). Chlorine is

primary converted to hydrogen chloride (HCl). In general, the quantities of sulfur, nitrogen,

and chloride in the fuel are sufficiently small that they have a negligible effect on the main

syngas components of H2 and CO. Trace elements associated with both organic and

inorganic components in the feed, such as mercury, arsenic and other heavy metals, appear

in the various ash and slag fractions, as well as in gaseous emissions, and need to

be removed from the syngas prior to further use.

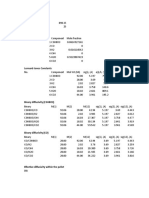

The table at right summarizes the

main transformations of solid fuel

constituents to gaseous species in both

gasification and combustion. This

shows clearly the marked differences

between gasification (resulting in

syngas) and combustion (resulting in

exhaust gas).

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Welding ProcessesDocument51 pagesWelding ProcessesAtul100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- UC3842 Inside SchematicsDocument17 pagesUC3842 Inside Schematicsp.c100% (1)

- Method Statement PlumbingDocument8 pagesMethod Statement Plumbingdstv200560% (5)

- Abb Price ListDocument340 pagesAbb Price ListyogeshNo ratings yet

- New Heat ExchangerDocument12 pagesNew Heat ExchangerMosaddekNo ratings yet

- MIF II Instruction ManualDocument245 pagesMIF II Instruction Manualmikaellasy100% (1)

- GP 43-47-Pipeline Commissioning and Handover To OperationsDocument20 pagesGP 43-47-Pipeline Commissioning and Handover To Operationsmengelito almonte0% (2)

- Simulation of Methanol Production From Synthesis Gas PDFDocument5 pagesSimulation of Methanol Production From Synthesis Gas PDFFaris HamidiNo ratings yet

- +rostrupnielsen1984 - (Catalytic Steam Reforming)Document117 pages+rostrupnielsen1984 - (Catalytic Steam Reforming)Faris Hamidi100% (1)

- Methanol plant process design and economic assessmentDocument66 pagesMethanol plant process design and economic assessmentFaris Hamidi100% (2)

- General Chemistry Course OutlineDocument3 pagesGeneral Chemistry Course OutlineShairuz Caesar Briones DugayNo ratings yet

- Gas Dispersion GDMR 1Document10 pagesGas Dispersion GDMR 1Faris HamidiNo ratings yet

- Shop Math Refresher: Part 2: Self StudyDocument27 pagesShop Math Refresher: Part 2: Self StudyFaris HamidiNo ratings yet

- BookReview - Faris Hamidi - Direktorat Infrastruktur Dan TeknologiDocument74 pagesBookReview - Faris Hamidi - Direktorat Infrastruktur Dan TeknologiFaris HamidiNo ratings yet

- CHERNIVAL2016Document14 pagesCHERNIVAL2016Faris HamidiNo ratings yet

- 1 s2.0 S1876610217302977 MainDocument10 pages1 s2.0 S1876610217302977 MainLe Nguyen Phuc ThienNo ratings yet

- Process Simulation of The Transport Gas If I ErDocument12 pagesProcess Simulation of The Transport Gas If I ErFaris HamidiNo ratings yet

- 1 s2.0 S1876610217302977 MainDocument10 pages1 s2.0 S1876610217302977 MainLe Nguyen Phuc ThienNo ratings yet

- Resume Untuk KinetikaDocument16 pagesResume Untuk KinetikaFaris HamidiNo ratings yet

- Desulfurization by Hot Zinc OxideDocument2 pagesDesulfurization by Hot Zinc OxideFaris HamidiNo ratings yet

- Peksen2009 (Conservation)Document12 pagesPeksen2009 (Conservation)Faris HamidiNo ratings yet

- Eksekusi 1Document858 pagesEksekusi 1Faris HamidiNo ratings yet

- Glycerol Pre-Reformer SpreadsheetDocument38 pagesGlycerol Pre-Reformer SpreadsheetFaris HamidiNo ratings yet

- Resume Untuk KinetikaDocument16 pagesResume Untuk KinetikaFaris HamidiNo ratings yet

- Peksen2009 (Conservation)Document12 pagesPeksen2009 (Conservation)Faris HamidiNo ratings yet

- Relation Between Catalyst Structure and Hds Reaction MechanismDocument2 pagesRelation Between Catalyst Structure and Hds Reaction MechanismFaris HamidiNo ratings yet

- Characterization&HDS Activity CoMo SupportedDocument27 pagesCharacterization&HDS Activity CoMo SupportedFaris HamidiNo ratings yet

- Who Materi Am IDocument2 pagesWho Materi Am IFaris HamidiNo ratings yet

- Albrecht - Autothermal Partial Oxidation SimulationDocument135 pagesAlbrecht - Autothermal Partial Oxidation SimulationFaris HamidiNo ratings yet

- Fugsi Kelarutan Vs Suhu Asam OksalatDocument1 pageFugsi Kelarutan Vs Suhu Asam OksalatFaris HamidiNo ratings yet

- Advances in HDS Catalytic DesignDocument152 pagesAdvances in HDS Catalytic DesignFaris HamidiNo ratings yet

- Exchange and Desulfurization of Thiophene Over Synthetic andDocument10 pagesExchange and Desulfurization of Thiophene Over Synthetic andFaris HamidiNo ratings yet

- H2S Removal With ZnO During Fuel Processing For PEMFC Applications PDFDocument1 pageH2S Removal With ZnO During Fuel Processing For PEMFC Applications PDFFaris HamidiNo ratings yet

- Oil-Eating Bacteria To Clean Up Oil Spills: SourceDocument5 pagesOil-Eating Bacteria To Clean Up Oil Spills: SourceFaris HamidiNo ratings yet

- R16B TechEEEIVYearRevisedSyllabusDocument52 pagesR16B TechEEEIVYearRevisedSyllabussundeep sNo ratings yet

- Digitizing Power Grids: Resetting The Way We Power The WorldDocument7 pagesDigitizing Power Grids: Resetting The Way We Power The WorldHitachi America, Ltd.No ratings yet

- StressDocument13 pagesStressLenielle AmatosaNo ratings yet

- 4TEC3F60B1000ADocument21 pages4TEC3F60B1000ABlackdragon86No ratings yet

- Tufftride - Qpq-Process: Technical InformationDocument19 pagesTufftride - Qpq-Process: Technical InformationmwasicNo ratings yet

- Tüvis: TÜVIS-Prüfgrundlagen: AD 2000 Code, Volume 1, Register A Replaces Page - VersionDocument2 pagesTüvis: TÜVIS-Prüfgrundlagen: AD 2000 Code, Volume 1, Register A Replaces Page - VersionGentelmanOnlyNo ratings yet

- NX 0614T - 1214T: 159-352 KW Chiller, Air Source For Outdoor InstallationDocument67 pagesNX 0614T - 1214T: 159-352 KW Chiller, Air Source For Outdoor Installationsantifer26No ratings yet

- Cost Analysis Proyek Tambang BatubaraDocument34 pagesCost Analysis Proyek Tambang BatubaraTIN'S KITCHENNo ratings yet

- Mechanics - EssayDocument5 pagesMechanics - EssayVic de BloisNo ratings yet

- Unit-44 Industrial Power,Electronics and storageDocument11 pagesUnit-44 Industrial Power,Electronics and storageChathura RanathungaNo ratings yet

- 7PG23 5B3 Complete Technical ManualDocument36 pages7PG23 5B3 Complete Technical ManualDan StreetNo ratings yet

- Triangular Wave Generator Using Op Amp - EEEGUIDEDocument6 pagesTriangular Wave Generator Using Op Amp - EEEGUIDEfauzan WaseemNo ratings yet

- December Electricity BillDocument1 pageDecember Electricity BillwakeupkenyansNo ratings yet

- Recloser COOPER POWER SYSTEMSDocument28 pagesRecloser COOPER POWER SYSTEMSValentina ArthurNo ratings yet

- D Regulators enDocument52 pagesD Regulators enmasakpNo ratings yet

- Current Issues in Environmental Management in Australia: What Do People Think?Document21 pagesCurrent Issues in Environmental Management in Australia: What Do People Think?Mahwestie PwarnasoekmaNo ratings yet

- Datasheet For OT FIT 40 220-240 1A0 CSDocument4 pagesDatasheet For OT FIT 40 220-240 1A0 CSpeter hansenNo ratings yet

- Thermal Physics KPN MurthyDocument151 pagesThermal Physics KPN MurthyRithish BarathNo ratings yet

- BRAZILIAN MIDRANGE COMBINE SCHEMATICDocument75 pagesBRAZILIAN MIDRANGE COMBINE SCHEMATICRenato AssisNo ratings yet

- Exercises On Design of Biogas PlantDocument2 pagesExercises On Design of Biogas Plantمحمود صالح محمود عليNo ratings yet

- 6th Sem Institution Electives_2023-24Document3 pages6th Sem Institution Electives_2023-24bhuvankumar3877No ratings yet

- Form 4 Measurements & Motion Practice QuestionsDocument72 pagesForm 4 Measurements & Motion Practice QuestionsSiti Arbaiyah AhmadNo ratings yet