Professional Documents

Culture Documents

Planetary Gear Box Failure

Uploaded by

tsrinivasan5083Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planetary Gear Box Failure

Uploaded by

tsrinivasan5083Copyright:

Available Formats

13 TS TIDINGS

FEED BACK NO. 2

Project: Kakatiya TPS

Problem: Problem faced in the planetary gear box of pulveriser

1. Introduction

BHEL Kakatiya TPS Stage-I 1x500MW project reported on 12-07-2010

suspected thrust pad bearing damage of Planetary Gearbox installed in Mill-B. Mill

was running smoothly from the date of "No Load Trial Run" in March 2010 as shown in

Annexure I, clocking about 300 hours load run. The damaged Gearbox was replaced

with spare gearbox and mill was put back into operation. Later, the Gearbox was sent

to BHEL/Hyderabad works for carrying out inspection and necessary repairs, test run

and dispatch back to site.

2. Receipt & Inspection

Preliminary inspection was carried out and the report is as follows:

* All external pipe lines damaged. To be replaced.

* Ball valves for bottom drain missing

* RTD Guards damaged.

* Table heavily rusted.

The Gearbox was further opened for internal inspection on 22.10.2010 and the

observations made are as follows:

. a) The thrust pad bearing was found damaged (total babbit material is worn out).

This was in conformance to what was reported by site. b) The table lower surface

visually looked OK.

The thrust pad bearing was replaced with new set. The Table lower surface was

re-ground and assembled. The Gearbox was made ready for test run. However,

during assembly and checking, excess play on the pinion was observed and bearing

damage of the bevel-helical stage of gears was suspected. Hence, the Planetary

Gearbox was again dismantled to check/inspect all the internals thoroughly.

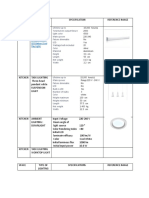

The following major damages were noticed further to the Gearbox components:

Bevel Pinion shaft teeth are broken. The inner side bearing of Pinion shaft

damaged and rollers found lying on the bevel gear. From the extent of damages

TECHNICAL SERVICES / PSSR

14 TS TIDINGS

noticed it is suspected that broken bearing parts have come between the Bevel-

helical gear set and damaged the Pinion shaft teeth.

The photo taken on the damaged parts is as shown in Annexure - II.

3. Failure mode - analysis

From the extent of damage occurred, it is concluded that severe shock/ thrust

loads have been transmitted to the Gearbox internals, due to hard to grind foreign

materials entering the mill along with coal, like stones, steel parts etc. Site had

also informed that during such foreign materials entry into mill very severe

vibrations were noticed in the mill. The heavy thrust loads not only resulted in

damages to the thrust pad bearings, but also lead to the Bevel pinion shaft inner

side bearing and the shaft teeth.

The failure mode of the bevel pinion shaft inner bearing was analysed in detail.

The experts of bearing suppliers (other than the original supplier of the failed

bearing) were consulted as well as damaged bearing parts were sent to BHEL

Corporate R&D for study purpose too. The reports conclude the following:

(i) The heavy shock/thrust loads that came up on the mill, has resulted in the

bevel gear exerting an abnormal axial movement to the bevel pinion shaft.

(ii) The axial movement of bevel pinion shaft has heavily loaded DE side of the

Non- Drive End bearing, which would have caused a) possible lubrication failure, b)

the solid cast brass cage was now driven by the DE side rollers where as the NDE

side rollers started slowing down, which tried to skew the cage and eventually led

to its failure.

(iii) Once the cage is broken, the rollers became free and escaped through the

assembly slot on the cone and into the bevel helical gear set damaging the bevel

shaft teeth.

(iv) On analysing the further damages that occurred to the bearing assembly

parts, it confirms the mode of failure explained above, whereby it can be

concluded that the bearing failure is not the prime suspect.

.The pictorial representation of the above is given in Annexure-III.

4. Repair procedure - test run

The list of activities to be done and components identified to be replaced

TECHNICAL SERVICES / PSSR

15 TS TIDINGS

for making the gearbox good is given in the Annexure-IV.

On 01-01-2011 the Gearbox assembly was completed and released for test run.

The test run of the Gearbox was carried out 02-01-2011 & 03-01-2011 and

concluded successfully. The test results are attached to this report as Annexure-

V.

A brief description of the Planetary Gearbox is given as Annexure-VI. The

repaired gearbox is declared fit and run worthy and cleared for dispatch to

Kakatiya site on 04-01-2011.

5.Conclusion

Entry of foreign materials like steels, stones, wooden blocks and larger size coal is

to be avoided for better availability and smooth functioning of pulveriser. Customer

may be advised to supply the recommended size coal and without foreign materials.

Annexure I

Following are the brief history details of Mill-B and its Planetary

Gearbox till the Failure date:12-07-2010:

1) No Load Trial Run was carried out on 23.03.10 and Ring-Roll gap setting

carried out.

2) Mill Has run for 300 Hours at various intermittent stages - 238 Hours in the

month of July'10 itself.

3) Failure of the PGB on 12/07/10 Parameters are as below

Mill Motor Current 108.5 Amps

Thrust bearing Temp 80.0 deg cent

Oil Temperature (Tank) 40.0 deg cent

The Oil inside the tank was found to be black in colour with frequent chocking of

filters.

4) There has been few incidences of foreign material entry like stones, wooden

logs etc. During this period Gear Box has got disturbed and realignment

had to be carried out. Considering the situation locking arrangement of the

Mill Gear Box was done for all the mills.

TECHNICAL SERVICES / PSSR

16 TS TIDINGS

5) During the Erection & Pre-commissioning period following activities were carried

out:

The Pipe lines after erection were acid cleaned as per the Erection manual &

Technical Services, Chennai guide lines.

The lube oil flushing were carried out as per the recommended procedure.

The Oil flushing was declared completed after ensuring the oil filters are clean for

24 hours.

6) The parameters of Lube oil system for the Mill-B before the failure date is as

follows:

, - Flow is maintained at the maximum of 150 LPM and minimum of 120 LPM.

- Lube oil temperature in the tank is around 36 to 38 deg.C.

- Lube oil temperature after the cooler is at 33 to 35 Deg.C.

- Lube oil pressure is maintained at 2.9 Kg/ Sq.Cm to 3.7 Kg/ Sq.Cm.

- No leakage of Hot air is observed from the seals to Gearbox thrust pad

bearing.

- During frequent filter cleaning, site observed silver coloured material

from the filters.

- Due to frequent chocking of the filters of Mill-B, site replaced these filters,

one from Mill-D and another from Mill-G. Then also this chocking of filter is

observed was observed to be happening frequently.

7) The vibrations of the Mill-B during No Load trial run are as follows:

SI. Motor Drive Motor Non-Drive Gearbox bearing drive

Pick Up

No End end end

Location D V

D V D V

1. Horizontal 8 2.3 13 4.8 6 2.7 .

2. Vertical 7 2.6 8 4.3 2 2.0

3. Axial 5 2.4 6 2.9 9 1.4

D - Displacement in microns; V - Velocity in mm/ sec.

TECHNICAL SERVICES / PSSR

17 TS TIDINGS

Annexure II

Gearbox as received from Kakatiya TPS

Gearbox as received from Kakatiya TPS

TECHNICAL SERVICES / PSSR

18 TS TIDINGS

Thrust Pad bearing -Babbit- material washed out PGB

Bevel pinion shaft damage - PGB Kakatiya TPS

TECHNICAL SERVICES / PSSR

19 TS TIDINGS

Bevel pinion shaft DE Side bearing - PGB Kakatiya TPS

TECHNICAL SERVICES / PSSR

20 TS TIDINGS

Bevel pinion shaft inner bearing damaged parts - PGB Kakatiya TPS

Bevel pinion shaft inner bearing damaged parts - PGB Kakatiya TPS

TECHNICAL SERVICES / PSSR

21 TS TIDINGS

Bevel pinion shaft, inner bearing broken pieces lying at the bottom of housing- PGB ,

Kakatiya TPS

Bevel pinion shaft damage - PGB Kakatiya TPS

TECHNICAL SERVICES / PSSR

22 TS TIDINGS

Bevel pinion shaft, damaged - PGB Kakatiya TPS

Annexure-III

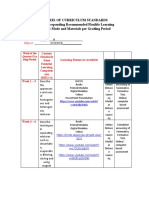

The sequence of Events leading to the bevel pinion shaft NDE side bearing failure-

1.There was a shock load / Over load on the drive.

2.Due to which, the spiral bevel has exerted a force in the direction.

TECHNICAL SERVICES / PSSR

23 TS TIDINGS

3. This Loaded the bearing (NDE side)

a. Due to this loading, the rollers on the DE end of the bearing were overloaded

which caused Possible Lubrication failure to the bearing.

b. The cage is made of solid cast.

c. The bearing cage (brass) was now driven by the DE end rollers and the NDE

end were slowing down, which tried to skew the cage and eventually lead to

its failure.

TECHNICAL SERVICES / PSSR

24 TS TIDINGS

d. The Rollers now free, a few escaped through the assembly slot on the cone

e. This further damaged the cage and the rollers, now unguided, skewed

inside and completely damaged the bearing.

f. This is-obvious from Heavier scoring on the NDE portion of the cup and

Blackening of the Outer diameter and face of the cup.

TECHNICAL SERVICES / PSSR

25 TS TIDINGS

TECHNICAL SERVICES / PSSR

You might also like

- Analysis of Process Fan Failure & Bearing Housing Case - StudyDocument16 pagesAnalysis of Process Fan Failure & Bearing Housing Case - Studytylerdurdane100% (1)

- Analysis of Bearing ClearancesDocument8 pagesAnalysis of Bearing Clearancesbwelz100% (1)

- Bearing Power PointDocument57 pagesBearing Power Pointkesai100% (1)

- Springs: Types of Springs & Applications - Spring Materials - CharacteristicsDocument15 pagesSprings: Types of Springs & Applications - Spring Materials - CharacteristicsSeanRiniFernando100% (1)

- Bearing Damage and CorrectiveDocument4 pagesBearing Damage and Correctivem2110100% (1)

- Abrasive ProcessesDocument63 pagesAbrasive ProcessesmohdhmNo ratings yet

- Bearing BasicsDocument69 pagesBearing BasicsHashem Mohamed HashemNo ratings yet

- Presentation GearDocument18 pagesPresentation Gearsou.bera100% (1)

- Shutdown Job at Rawmill Line-A (22!6!2016)Document2 pagesShutdown Job at Rawmill Line-A (22!6!2016)salman saleemNo ratings yet

- Bearing Defects FinalDocument47 pagesBearing Defects FinalAllen Dato100% (1)

- UNIT.1: Maintenance, Maintenance Planning, & Maintenance Activity For Machine ToolsDocument51 pagesUNIT.1: Maintenance, Maintenance Planning, & Maintenance Activity For Machine Toolsjulakanti1No ratings yet

- How To Determine End-Play in Thrust Bearings - Turbomachinery BlogDocument5 pagesHow To Determine End-Play in Thrust Bearings - Turbomachinery Blogjbalagee100% (1)

- Overhaul Procedure For Coal MillDocument5 pagesOverhaul Procedure For Coal MillJenal Tampubolon100% (1)

- Fits and TolerancesDocument26 pagesFits and TolerancesPrithviraj Daga100% (3)

- Bearing PreloadDocument3 pagesBearing PreloadASHOKNo ratings yet

- Kiln Stop Due To ID Fan VibrationDocument1 pageKiln Stop Due To ID Fan VibrationSafrin SangiaNo ratings yet

- Air Blaster System CabDocument8 pagesAir Blaster System CabkINGNo ratings yet

- PDAP A Guide For ManagersDocument15 pagesPDAP A Guide For ManagersPriyanka JaiswalNo ratings yet

- Machinery Alignment: Prepared by WADocument23 pagesMachinery Alignment: Prepared by WAmersiumNo ratings yet

- PreloadDocument3 pagesPreloadvenky364No ratings yet

- Cardan Shaft AlignmentDocument26 pagesCardan Shaft AlignmentconstantinNo ratings yet

- Fan Bearing Selection Fe 1200Document4 pagesFan Bearing Selection Fe 1200phineasphineNo ratings yet

- Screw Conveyor O&M ManualDocument20 pagesScrew Conveyor O&M Manualjay b100% (1)

- Bhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429Document51 pagesBhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429PreethamBAsaravalliMohanNo ratings yet

- Bearing NotesDocument6 pagesBearing NotesabhivpcoeNo ratings yet

- Technical Information: Radial Play (Internal Clearance) in Ball BearingsDocument4 pagesTechnical Information: Radial Play (Internal Clearance) in Ball BearingsAbdul JunaediNo ratings yet

- Lubrication and Bearing Module.Document64 pagesLubrication and Bearing Module.Anthony MayNo ratings yet

- Gitrh Gear VibrationsDocument5 pagesGitrh Gear Vibrationsgullipalli srinivasa raoNo ratings yet

- Bearings: Classification and Selection of BearingsDocument8 pagesBearings: Classification and Selection of BearingsMohamed Sadek100% (1)

- Fatigue Failure NewDocument21 pagesFatigue Failure NewAshwani DinkarNo ratings yet

- Case Study On Bearing FailureDocument33 pagesCase Study On Bearing FailureAyush JAin100% (1)

- Bearing Failure Analysis-V2Document9 pagesBearing Failure Analysis-V2Anonymous omGSHUEQNo ratings yet

- MLOG GX CMXA75 v4 0 322985a0 UM-ENDocument311 pagesMLOG GX CMXA75 v4 0 322985a0 UM-ENjamiekuangNo ratings yet

- Vib Screen - Vib Analysis PDFDocument16 pagesVib Screen - Vib Analysis PDFAngka SubaronNo ratings yet

- Integrating Vibration and Oil Analysis For Machine Condition MonitoringDocument10 pagesIntegrating Vibration and Oil Analysis For Machine Condition MonitoringAnda WahyudiNo ratings yet

- Gear Ring Radial AlignmentDocument2 pagesGear Ring Radial AlignmentJavier GutierrezNo ratings yet

- Bearing Life CycleDocument2 pagesBearing Life CyclemoerkerkNo ratings yet

- Belt and Chain VcetDocument56 pagesBelt and Chain VcetgowthamkuttiNo ratings yet

- Internal Bearing CleardssanceDocument3 pagesInternal Bearing Cleardssancejicki09No ratings yet

- PM WNCC - Sep. 2019 OM Monthly ReportDocument6 pagesPM WNCC - Sep. 2019 OM Monthly ReportMahmoud HanafyNo ratings yet

- Balancing of Rotating El McsDocument59 pagesBalancing of Rotating El McsDeep SYNo ratings yet

- Bowed Rotor Straightening WebVersion Dec 29 2010Document2 pagesBowed Rotor Straightening WebVersion Dec 29 2010elrajilNo ratings yet

- Foundation Selection ProcessDocument38 pagesFoundation Selection ProcessGabriel Alexis Malagon Carvajal100% (1)

- Girth Gear RunoutDocument1 pageGirth Gear RunoutvinodsnNo ratings yet

- ARLA Rotor Dynamics Seminar 1Document3 pagesARLA Rotor Dynamics Seminar 1cwfh779No ratings yet

- Alignment Shaft Thermal GrowthDocument6 pagesAlignment Shaft Thermal Growthmmcsw6624No ratings yet

- Failure Mode and Effect Analysis of Journal BearingDocument7 pagesFailure Mode and Effect Analysis of Journal BearingMuhammad Kurniawan100% (1)

- BeltDocument58 pagesBeltWilson Lim100% (1)

- Limits, Tolerances and FitsDocument30 pagesLimits, Tolerances and FitsSilentxpireNo ratings yet

- Presentation FatigueDocument22 pagesPresentation FatigueRavi Kiran MeesalaNo ratings yet

- Planned Maintenance Technique: DowntimeDocument43 pagesPlanned Maintenance Technique: DowntimeMurat TerziNo ratings yet

- Basic Rolling Bearing TechnologyDocument75 pagesBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- Bhel PresentationDocument31 pagesBhel PresentationSamuel Bhukya100% (1)

- Technical Report - 013.13 (Framehead Bearing With High Vibration Levels)Document6 pagesTechnical Report - 013.13 (Framehead Bearing With High Vibration Levels)Elvis Carneiro100% (1)

- Maintenance Instructions For UIC Type RUBBER VESTIBULE of BG Main Line CoachesDocument26 pagesMaintenance Instructions For UIC Type RUBBER VESTIBULE of BG Main Line CoachesOmeNo ratings yet

- CPECC-NB-EnG-2020-001 Design Disclosure To NB On Precast Piling of Spherical TanksDocument5 pagesCPECC-NB-EnG-2020-001 Design Disclosure To NB On Precast Piling of Spherical TanksNashaat DhyaaNo ratings yet

- Training Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine ServicesDocument42 pagesTraining Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine Serviceskp pkNo ratings yet

- 011-Repl of Kiln Shell Under TyreDocument32 pages011-Repl of Kiln Shell Under Tyremkpq100% (3)

- Abrasion of The Shaft Supporting The Cam Shaft Drive Chain UnitDocument3 pagesAbrasion of The Shaft Supporting The Cam Shaft Drive Chain UnitRani NoumanNo ratings yet

- Ethanol Distillation Plant DesignDocument9 pagesEthanol Distillation Plant Designtsrinivasan5083No ratings yet

- DIIPA Lecture-5 Thy Y P Y D E FE 07042020Document2 pagesDIIPA Lecture-5 Thy Y P Y D E FE 07042020VISHNU P SRIVASTAVA100% (1)

- Rectifier Design For Fuel Ethanol PlantsDocument7 pagesRectifier Design For Fuel Ethanol PlantsenjoygurujiNo ratings yet

- Distillation PDFDocument20 pagesDistillation PDFKiril AckovskiNo ratings yet

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083No ratings yet

- 2013 Fermentation CalculationsDocument1 page2013 Fermentation Calculationsskipperz_10No ratings yet

- Biorefinery Concept Design & EvaluationDocument185 pagesBiorefinery Concept Design & Evaluationtsrinivasan5083100% (1)

- chymney-Hadek-Karrena CR-24-2Document8 pageschymney-Hadek-Karrena CR-24-2dnageshm4n244No ratings yet

- 2G BioEthanol-Civil Works Tender-BridgeRoof-BPCL-TCEDocument85 pages2G BioEthanol-Civil Works Tender-BridgeRoof-BPCL-TCEtsrinivasan5083No ratings yet

- Distillery Spent Wash OTL Application ImpactDocument6 pagesDistillery Spent Wash OTL Application Impacttsrinivasan5083No ratings yet

- 2G BioEthanol-Civil and Structural Works Spec-BPCL-TCEDocument415 pages2G BioEthanol-Civil and Structural Works Spec-BPCL-TCEtsrinivasan5083No ratings yet

- Biorefinery Concept Design & EvaluationDocument185 pagesBiorefinery Concept Design & Evaluationtsrinivasan5083100% (1)

- Civil-Indian Standards-Revised-2021Document1 pageCivil-Indian Standards-Revised-2021tsrinivasan5083No ratings yet

- Bus BarDocument70 pagesBus BarTirthankar ChandraNo ratings yet

- Sodium Carboxymethyl Cellulose InformationDocument8 pagesSodium Carboxymethyl Cellulose Informationtsrinivasan5083No ratings yet

- TNPCB & You-2020 GuideDocument327 pagesTNPCB & You-2020 Guidetsrinivasan5083100% (1)

- IEEE C37.122 IEEE Standard For Gas-Insulated SubstationsDocument85 pagesIEEE C37.122 IEEE Standard For Gas-Insulated SubstationsEmily Bullock100% (7)

- whr08 enDocument357 pageswhr08 enzaheeruddin_mohdNo ratings yet

- Sugar Plant Buyers Guide 2019Document60 pagesSugar Plant Buyers Guide 2019tsrinivasan5083No ratings yet

- Solar PV PP 8 MW Tender Hubballi Airport PDFDocument189 pagesSolar PV PP 8 MW Tender Hubballi Airport PDFtsrinivasan5083No ratings yet

- Solar Pump Installation-MNRE Office Memorandum-22.06.20 PDFDocument3 pagesSolar Pump Installation-MNRE Office Memorandum-22.06.20 PDFtsrinivasan5083No ratings yet

- DPR Ethanol Plant 20klpd LaturDocument124 pagesDPR Ethanol Plant 20klpd Laturtsrinivasan5083100% (9)

- Me303-4 1 1Document2 pagesMe303-4 1 1Tanesh SelvarajuNo ratings yet

- Power Plant DesignDocument12 pagesPower Plant DesignMarvin BayanayNo ratings yet

- Power Plant Construction During Covid Lockdown May 2020Document18 pagesPower Plant Construction During Covid Lockdown May 2020tsrinivasan5083No ratings yet

- 2020 Transmission Charges CERC Order May 2020Document46 pages2020 Transmission Charges CERC Order May 2020tsrinivasan5083No ratings yet

- ISO 10437 2003 (E) - Character PDFDocument11 pagesISO 10437 2003 (E) - Character PDFtsrinivasan5083No ratings yet

- NEMA Enclosure Types 11-05-2Document9 pagesNEMA Enclosure Types 11-05-2Duron SaavedraNo ratings yet

- 2020 Indian Electricity Act 2020Document35 pages2020 Indian Electricity Act 2020tsrinivasan5083No ratings yet

- 2020 Indian Electricity Act 2020Document35 pages2020 Indian Electricity Act 2020tsrinivasan5083No ratings yet

- Foundation Engineering Shot NotesDocument21 pagesFoundation Engineering Shot NotesSejal VermaNo ratings yet

- NBN Co Network Design RulesDocument50 pagesNBN Co Network Design Rulesmisr1972No ratings yet

- CS412, Fall 2010, Assignment 1: SolutionDocument8 pagesCS412, Fall 2010, Assignment 1: SolutionpeacekentNo ratings yet

- Chapter 9 PondsDocument65 pagesChapter 9 Pondssheil.cogayNo ratings yet

- Backhoe Loaders: 820 860 SX 860 Elite 970 Elite 880 SX 880 Elite 980 EliteDocument4 pagesBackhoe Loaders: 820 860 SX 860 Elite 970 Elite 880 SX 880 Elite 980 EliteJuan Carranza LeonNo ratings yet

- Mekaniko On The Go: An Online Mechanic Mobile Application: A System Analysis and Design ProjectDocument8 pagesMekaniko On The Go: An Online Mechanic Mobile Application: A System Analysis and Design ProjectMarco MagdaelNo ratings yet

- Pal LeDocument10 pagesPal LemoebiuszeroNo ratings yet

- Rohit Bebarta CVDocument1 pageRohit Bebarta CVRohit BebartaNo ratings yet

- Evaporador Alfa Laval PDFDocument26 pagesEvaporador Alfa Laval PDFcarlos342asd100% (2)

- FU2185011009 Description PICO With Bayonet Connector ENDocument10 pagesFU2185011009 Description PICO With Bayonet Connector ENDonny Wierya pratamaNo ratings yet

- STA505Document10 pagesSTA505kizonzNo ratings yet

- The Cunard Building, LiverpoolDocument2 pagesThe Cunard Building, LiverpoolIbrahim FawwazNo ratings yet

- The VI Editor PDFDocument7 pagesThe VI Editor PDFPurandhar TataraoNo ratings yet

- Std-Insp-0002 (Incoming Material Inspection Procedure)Document3 pagesStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNo ratings yet

- Risk Assesment-Rebar Loading & UnloadingDocument1 pageRisk Assesment-Rebar Loading & Unloadingmainraj rajNo ratings yet

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Manual V100-V30-70 ENGDocument38 pagesManual V100-V30-70 ENGAzeddine LANo ratings yet

- Chapter 11Document38 pagesChapter 11Ismail HussainNo ratings yet

- Usage of D6T-44L - 8L - 1A Thermal SensorDocument23 pagesUsage of D6T-44L - 8L - 1A Thermal SensorEduardo ggNo ratings yet

- Philips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Document4 pagesPhilips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Shrutie PatilNo ratings yet

- Sika MonoTop 615 PDS (CE)Document6 pagesSika MonoTop 615 PDS (CE)Virah Sammy ChandraNo ratings yet

- Welding PDFDocument6 pagesWelding PDFNavneet ChaubeyNo ratings yet

- Matrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodDocument2 pagesMatrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodNora HerreraNo ratings yet

- Sample Letters To DEPDocument7 pagesSample Letters To DEPSJLibraryNo ratings yet

- Paccar PX 8 Spec SheetDocument6 pagesPaccar PX 8 Spec SheetCarlos Alberto Gutierrez Lopez0% (1)

- Building Completion Certificate: Certificate Number Plot Number Initial Issue DateDocument2 pagesBuilding Completion Certificate: Certificate Number Plot Number Initial Issue DateAbrar AbbasiNo ratings yet

- Ditch Excavation Procedure - C01Document8 pagesDitch Excavation Procedure - C01Toreson OfuafoNo ratings yet

- Guide To Single Point Moorings Old PDFDocument456 pagesGuide To Single Point Moorings Old PDFsarifin100% (1)

- Best Available Techniques (BAT) For Pulp and PaperDocument900 pagesBest Available Techniques (BAT) For Pulp and PaperHuy NguyenNo ratings yet

- Datasheet Dc-m9204 & Di-M9204 Manual Call PointDocument4 pagesDatasheet Dc-m9204 & Di-M9204 Manual Call PointHajji MehdiNo ratings yet