Professional Documents

Culture Documents

MasterCell 10ME TDS

Uploaded by

علي عثمانCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MasterCell 10ME TDS

Uploaded by

علي عثمانCopyright:

Available Formats

RHEOCELL 10 ME

A liquid admixture for the production of lightweight concrete

DESCRIPTION these applications that the cavity is entirely filled

RHEOCELL 10 ME is a ready to use liquid with a material that will not settle or shrink.

foaming agent which is used to produce Through the heat of hydration of the cement, the

lightweight foam concrete for a variety of air enclosed in the air pores of the

insulation and construction applications. RHEOCELL 10ME is heated thereby causing

RHEOCELL 10 ME lightweight concrete has a the pores to expand. RHEOCELL 10 ME

very fine cellular structure and optimum lightweight foam concrete expands against the

workability for a given water cement ratio. This walls of the cavity through its own internal

combination offers lower materials weight per pressure without imposing any additional load on

unit volume, and therefore a lower deadload the wall.

imposed on the structure. Significant reductions When specifying densities a margin of

in heat conductivity will also be achieved. 50kg/m should be allowed for.

PRIMARY USES ADVANTAGES

As thermal insulation Self compacting.

Plastic density approx. 1000kg/m Simple placing by means of chutes, pipes or

RHEOCELL 10 ME lightweight foam concrete is pumps.

particularly suitable as a light, insulating, No additional transfer equipment.

levelling layer on roofs and floors. As it can be Pre-selected strength density values.

pumped easily, it offers significant advantages High placing performance.

over other lightweight building materials. Placing Extremely economical.

by pump can be achieved on sites where access

would otherwise be difficult, as with the repair PACKAGING

and maintenance of buildings.

Packaging

As encasement concrete RHEOCELL 10 ME is supplied in 1000 litre

Plastic density approx. 600kg/m

Pipes can be encased with RHEOCELL 10 ME

METHOD

lightweight foam concrete and held in place. At

some later stage should access be required to A mortar of specific composition is delivered to

these encased services, the foam concrete can the site in a truck mixer. Using the compact

easily be removed. If conventional concrete had foam generator, (which operates using a 2 bar

been used this would be difficult. water source) the required volume of foam is

produced in a short time.

As backfill concrete

Plastic density approx. 1350kg/m With a water pressure of 2 bar, each second,

RHEOCELL 10 ME lightweight foam concrete 11 litres of foam are produced: 660 litres of foam

can be placed directly from the truck mixer and per minute are produced.

requires no compaction, unlike granular fill 26 litres of water are consumed per minute.

materials, which need careful compaction. 1 litre of RHEOCELL 10 ME is needed per

minute.

RHEOCELL 10 ME lightweight foam concrete is

particularly suitable for filling old sewer pipes

and drains which have been taken out of

service. Also underground fuel storage tanks,

disused cellars or tunnels. It is important in

RHEOCELL 10 ME

The foam dosage can be regulated very simply SAFETY PRECAUTIONS

by adding the foam produced by the foam gun in RHEOCELL 10 ME is not a fire or health hazard.

a given time, to achieve a certain density.

Spillages should be washed down immediately

with cold water. For further information refer to

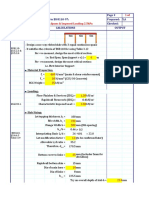

Density of required Foaming time for the Material Safety Data Sheet.

concrete in kg/m 1m foam concrete

800 58 seconds

NOTE

1000 52 seconds

1200 42 seconds Field service, where provided, does not

constitute supervisory responsibility. For

1350 39 seconds

additional information contact your local BASF

1600 29 seconds

representative.

BASF reserves the right to have the true cause

The foam, fed directly into the truck mixer with of any difficulty determined by accepted test

the mixer turning at maximum speed, is rapidly methods.

incorporated into the base mix to produce a

homogeneous foam concrete. Foaming is

enhanced at higher ambient temperatures. QUALITY AND CARE

Density can be checked using a standard 1 litre All products originating from BASFs Dubai, UAE

plastic density pot. Should the density be low facility are manufactured under a management

more foam can be added, too high and system independently certified to conform to the

additional mixing will displace a certain amount requirements of the quality, environmental and

of air. occupational health & safety standards ISO

9000, ISO 14001 and OHSAS 18001.

Typically for 6m of RHEOCELL 10 ME foamed

concrete, 3.6m of sand/cement slurry shall be = Registered trademark of the BASF-Group in many countries.

delivered from the readymix supplier. (BASF

can assist with mix designs). To this is added

2.4m of foam at the site.

STORAGE

RHEOCELL 10 ME may be stored for 6 months

in properly sealed original containers at a

temperature of at least +10C. Should the

temperature drop below 0C the product should

be carefully heated and mixed thoroughly before

use.

BASF_CC-UAE/Cast_10ME_05_08/v1/12_13

The technical information and application advice given in this BASF publication are based on the present state of

STATEMENT OF our best scientific and practical knowledge. As the information herein is of a general nature, no assumption can be

RESPONSIBILITY made as to a product's suitability for a particular use or application and no warranty as to its accuracy, reliability or

completeness either expressed or implied is given other than those required by law. The user is responsible for

checking the suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF either

NOTE orally or in writing may be followed, modified or rejected by the owner, engineer or contractor since they, and not

BASF, are responsible for carrying out procedures appropriate to a specific application.

BASF Construction Chemicals UAE LLC

P.O. Box 37127, Dubai, UAE

Tel: +971 4 8090800 Fax: +971 4 8851002

www.master-builders-solutions.basf.ae

You might also like

- Rheocell 10 ME: A Liquid Admixture For The Production of Lightweight ConcreteDocument2 pagesRheocell 10 ME: A Liquid Admixture For The Production of Lightweight ConcreteCivil SanamNo ratings yet

- TDS - MasterRheobuilld 1100Document2 pagesTDS - MasterRheobuilld 1100Taposh PaulNo ratings yet

- MasterRheobuild 2000 Hyperplasticizing AdmixtureDocument2 pagesMasterRheobuild 2000 Hyperplasticizing AdmixtureKonax Lihysd MandeNo ratings yet

- MasterRheobuild 1100 v1Document2 pagesMasterRheobuild 1100 v1Vivek GaurNo ratings yet

- TDS - Rheobuild 1100Document3 pagesTDS - Rheobuild 1100Alexi ALfred H. Tago100% (1)

- SpEC Confoam - CONCENTRATED FOAMING AGENT FOR CEMENT SYSTEMS - TDSDocument2 pagesSpEC Confoam - CONCENTRATED FOAMING AGENT FOR CEMENT SYSTEMS - TDSsales02No ratings yet

- Masterseal - 551Document2 pagesMasterseal - 551Sathish KumarNo ratings yet

- Foamix: F A L W CDocument2 pagesFoamix: F A L W CEng-Medrar AlkateryNo ratings yet

- Masterglenium Sky 8705Document2 pagesMasterglenium Sky 8705usenuyaNo ratings yet

- CEMENT ADMIXTURESDocument3 pagesCEMENT ADMIXTURESBadshah AkhilNo ratings yet

- Masterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)Document3 pagesMasterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)RajNo ratings yet

- MasterSeal - 551 v4Document2 pagesMasterSeal - 551 v4piyu114No ratings yet

- MasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGDocument3 pagesMasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGvahab_shaikNo ratings yet

- Masterflow 150 v1Document2 pagesMasterflow 150 v1vinayNo ratings yet

- Glenium Sky 777 v4Document2 pagesGlenium Sky 777 v4babu_ssrNo ratings yet

- BASF-MasterGlenium SKY 690 Jan - 17 enDocument2 pagesBASF-MasterGlenium SKY 690 Jan - 17 enJohn GiannakopoulosNo ratings yet

- TDS - Rheobuild sp1Document2 pagesTDS - Rheobuild sp1Alexi ALfred H. TagoNo ratings yet

- Fosroc Conplast SP2000: Constructive SolutionsDocument2 pagesFosroc Conplast SP2000: Constructive SolutionsVincent JavateNo ratings yet

- Duconmix RBS 100 Technical Data SheetDocument2 pagesDuconmix RBS 100 Technical Data SheetmasudNo ratings yet

- Delvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteDocument2 pagesDelvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteShoyeeb AhmedNo ratings yet

- High-performance superplasticizer for concreteDocument2 pagesHigh-performance superplasticizer for concreteMUHAMMAD ALFIN FERRY VERNANDANo ratings yet

- Foamed ConcreteDocument24 pagesFoamed ConcretewlidhaaaNo ratings yet

- Conplast X421ICDocument2 pagesConplast X421ICMahadeva PrasadNo ratings yet

- Duconmix RSP PCE 800 - High Early Strength, High Range Water Reducing/superplasticising, Admixture For Precast ConcreteDocument2 pagesDuconmix RSP PCE 800 - High Early Strength, High Range Water Reducing/superplasticising, Admixture For Precast ConcreteFounTech612No ratings yet

- Duconmix WS ES 860 RbsDocument3 pagesDuconmix WS ES 860 RbsmasudNo ratings yet

- Rheomac® 707Document4 pagesRheomac® 707M HAFEEZ RAJANo ratings yet

- Water ProofDocument3 pagesWater ProofMohamed KhanNo ratings yet

- Developments in Epoxy Modified CementsDocument12 pagesDevelopments in Epoxy Modified Cementsb4rfNo ratings yet

- Cico Plast Super C804Document2 pagesCico Plast Super C804ASRAR AHMED KHANNo ratings yet

- Alccofine 1108SR : Description Typical PropertiesDocument2 pagesAlccofine 1108SR : Description Typical Propertiesravi100% (1)

- Conplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionDocument3 pagesConplast CWP: High Performance Integral Crystalline Waterproofing For Concrete Uses DescriptionAditya KrisnandaNo ratings yet

- MasterPolyheed 8177 v3Document3 pagesMasterPolyheed 8177 v3Rajesh NairNo ratings yet

- Masterrheobuild 1126 v2Document2 pagesMasterrheobuild 1126 v2Shub KotiNo ratings yet

- Method Statement For RoofDocument22 pagesMethod Statement For Roofahmed samirNo ratings yet

- TDS - Rheobuild 850Document2 pagesTDS - Rheobuild 850nischal_babuNo ratings yet

- Conplast WP 421 PDFDocument2 pagesConplast WP 421 PDFharsoNo ratings yet

- Masterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteDocument2 pagesMasterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteweamNo ratings yet

- 1 Brushbond (M)Document3 pages1 Brushbond (M)marzuki0202No ratings yet

- Admix F1000Document2 pagesAdmix F1000mohab hakimNo ratings yet

- Rheomix 131: Page 1 of 2Document2 pagesRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- Foam Concrete: A Lightweight Building MaterialDocument36 pagesFoam Concrete: A Lightweight Building MaterialamitNo ratings yet

- Basf Masterpolyheed 8118 TdsDocument2 pagesBasf Masterpolyheed 8118 Tdsaji arafat100% (2)

- TDS of CHRYSO FOAMCRETE-E PDFDocument2 pagesTDS of CHRYSO FOAMCRETE-E PDFBijaya Raula0% (1)

- QQDocument2 pagesQQdana setiawanNo ratings yet

- Basf Masterseal 550 TdsDocument3 pagesBasf Masterseal 550 Tdsraza102No ratings yet

- Duconmix RSP 600Document2 pagesDuconmix RSP 600FounTech612No ratings yet

- Fosroc Data Sheet 350 DISDocument2 pagesFosroc Data Sheet 350 DISKUNAL SHAHNo ratings yet

- Data Sheet - F12 EN 2021.12.09Document4 pagesData Sheet - F12 EN 2021.12.09arthur chungNo ratings yet

- Adhere Mix-700: High Grade Super PlasticizerDocument2 pagesAdhere Mix-700: High Grade Super PlasticizerAbdur RazzaqNo ratings yet

- Masterroc® TCC 780 TdsDocument2 pagesMasterroc® TCC 780 TdsinvestmentmanifestNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- DIY Pex Pipe Plumbing: Step-By-Step Residential Pex Plumbing, Fittings and Tools Guide Book: Homeowner Plumbing Help, #7From EverandDIY Pex Pipe Plumbing: Step-By-Step Residential Pex Plumbing, Fittings and Tools Guide Book: Homeowner Plumbing Help, #7No ratings yet

- QasemDocument6 pagesQasemعلي عثمانNo ratings yet

- Fracture and Failure - Abaqus PDFDocument36 pagesFracture and Failure - Abaqus PDFdilrangiNo ratings yet

- Cover LetterDocument1 pageCover Letterعلي عثمانNo ratings yet

- Ansys Modeling of Flexural Behavior of RC Beam Strengthening by FRPDocument57 pagesAnsys Modeling of Flexural Behavior of RC Beam Strengthening by FRPKhaled Ahmad Ghrier100% (3)

- Civil Academy ProgramsDocument2 pagesCivil Academy Programsعلي عثمانNo ratings yet

- Faults Detection in Power Systems Using Artificial Neural Network PDFDocument7 pagesFaults Detection in Power Systems Using Artificial Neural Network PDFsuryaNo ratings yet

- Elimination of Arbitrary ConstantDocument3 pagesElimination of Arbitrary ConstantJomar Del BarrioNo ratings yet

- Partial Diffrential EquationDocument29 pagesPartial Diffrential Equationعلي عثمانNo ratings yet

- Lecture2 PDE 2016Document21 pagesLecture2 PDE 2016Akash MahalikNo ratings yet

- One-Way Ribbed Slab Design As Per BS8110Document5 pagesOne-Way Ribbed Slab Design As Per BS8110yusuf abdinasir100% (5)

- Lab 8 (Carwash) : Simulation and Modeling (CSCI 3010U)Document4 pagesLab 8 (Carwash) : Simulation and Modeling (CSCI 3010U)علي عثمانNo ratings yet

- Design of Prestressed Concrete" by Arthur H NilsonDocument1 pageDesign of Prestressed Concrete" by Arthur H Nilsonعلي عثمانNo ratings yet

- PlateTectonics ARADocument2 pagesPlateTectonics ARAعلي عثمانNo ratings yet

- Slab On GradeDocument4 pagesSlab On GradeLekins Sefiu YekiniNo ratings yet

- Slab On GradeDocument4 pagesSlab On GradeLekins Sefiu YekiniNo ratings yet

- Prestressed - Solved ExamplesDocument4 pagesPrestressed - Solved ExamplesSofya Sa91% (11)

- Microsoft Word Document جديد Document1 pageMicrosoft Word Document جديد علي عثمانNo ratings yet

- VHNGHCJNH: Fhcdesign of Prestressed Concrete" by Arthur H NilsonfnfhDocument1 pageVHNGHCJNH: Fhcdesign of Prestressed Concrete" by Arthur H Nilsonfnfhعلي عثمانNo ratings yet

- MasterCell 10ME TDSDocument2 pagesMasterCell 10ME TDSعلي عثمانNo ratings yet

- MasterCell 10ME TDSDocument2 pagesMasterCell 10ME TDSعلي عثمانNo ratings yet

- MasterCell 10ME TDSDocument2 pagesMasterCell 10ME TDSعلي عثمانNo ratings yet

- Introduction of IS2062 E250 Grade ADocument2 pagesIntroduction of IS2062 E250 Grade AnareshNo ratings yet

- Latent Heat of Phase ChangesDocument18 pagesLatent Heat of Phase ChangesHarsh TripathiNo ratings yet

- Jsa Jis H 8304Document30 pagesJsa Jis H 8304farhad100% (1)

- Thermodynamics-I: Fall 2019Document11 pagesThermodynamics-I: Fall 2019muhammad umairNo ratings yet

- Open Ended Structure LabDocument24 pagesOpen Ended Structure LabIzzatul Syahira Binti ZakariaNo ratings yet

- Installation of LintelsDocument3 pagesInstallation of LintelsJustine Noel De CastroNo ratings yet

- Bemil, Jared C. Bsce 2-A Plate No.1Document3 pagesBemil, Jared C. Bsce 2-A Plate No.1jaredNo ratings yet

- Lim Fire Research 03 2Document351 pagesLim Fire Research 03 2torNo ratings yet

- ASTM A276 Stainless Steel Round BarsDocument4 pagesASTM A276 Stainless Steel Round BarsRaaj SteelNo ratings yet

- Alistair Doig - Some Metallurgical Aspects of Shaped Charge LinersDocument3 pagesAlistair Doig - Some Metallurgical Aspects of Shaped Charge LinersGhoree23456No ratings yet

- f84835752 ERECTION PROGRESS REPORT FOR Gulf MallDocument5 pagesf84835752 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNo ratings yet

- Thesis On Structure DesignDocument6 pagesThesis On Structure DesignHarshit NagarNo ratings yet

- Downfeed SystemDocument12 pagesDownfeed SystemcharbelNo ratings yet

- Measuring Hardness Using Rockwell TestDocument27 pagesMeasuring Hardness Using Rockwell TestSaad AliKhanNo ratings yet

- Boq - Fencing EstimateDocument2 pagesBoq - Fencing EstimateAugustine Believe100% (3)

- Falk Gear Couplings, All Types Failure Analysis White PaperDocument7 pagesFalk Gear Couplings, All Types Failure Analysis White PaperNasir InceNo ratings yet

- Greenheck DGXDocument72 pagesGreenheck DGXBrad GNo ratings yet

- ORI Catalogue - Pipe and Fittings Table DataDocument63 pagesORI Catalogue - Pipe and Fittings Table DataMuhammad Aidil FitrahNo ratings yet

- Nonlinear Structural Analysis of A 2D Cut-And-Cover Tunnel Exposed To FireDocument6 pagesNonlinear Structural Analysis of A 2D Cut-And-Cover Tunnel Exposed To Firebalamurugan25011990No ratings yet

- Pompa MagnaDocument34 pagesPompa Magnasuysuy00No ratings yet

- Course:: Heating Ventilation & Air-Conditioning (ME 326)Document45 pagesCourse:: Heating Ventilation & Air-Conditioning (ME 326)Muhammad OsamaNo ratings yet

- A-1 - Perspective, Vicinity Map and Location MapDocument1 pageA-1 - Perspective, Vicinity Map and Location MapOJ MatiasNo ratings yet

- Case 1 REPORTDocument13 pagesCase 1 REPORTnorman1968No ratings yet

- Dissimilar WeldingDocument42 pagesDissimilar WeldingMan MNo ratings yet

- TWI Passivation Report July 2013Document7 pagesTWI Passivation Report July 2013sakshi patilNo ratings yet

- Bollard Catalog - SPDocument28 pagesBollard Catalog - SPrisiana_limuriaNo ratings yet

- Catalogo Chumaceras SKFDocument95 pagesCatalogo Chumaceras SKFmanuelzavala2012100% (1)

- Microstructures and Mechanical Properties of Cold Rolled Mg-8Li andDocument5 pagesMicrostructures and Mechanical Properties of Cold Rolled Mg-8Li andVidya me20d015No ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Apgenco (Mechanical) 2017-QpDocument16 pagesApgenco (Mechanical) 2017-QpSamresh GarnaikNo ratings yet