Professional Documents

Culture Documents

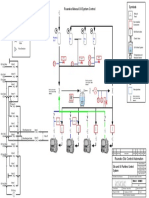

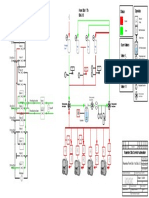

Roanoke Separated Oil Process

Uploaded by

David Adrián EsparzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roanoke Separated Oil Process

Uploaded by

David Adrián EsparzaCopyright:

Available Formats

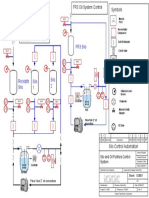

Separated Oil Process for Shipment Process Steps Symbols

1.- Prepare clean or new totes. (Use Only

Silo System Silo System totes with this characteristics). Ball Electrovalve

2.- Install the pivot into the totes cap.

Oil Purifier System

3.- Print the job identification for the oil and

put it into the totes.(The id must have Job

Number, Quantity of Oil, Type of Oil and the

tote number) MMT Temperature and

310

Moisture Sensor

4.- Apply 2 pounds of vacuum in the totes. MMT310

5.- Select in the HMI the job you want to use Flowmeter

QA S

H2 MMT to get the oil.

SCA 310

Manual Quality

6.- The system automatically will determine Sampler

how many oil gallons are destined to the

Controller tank and to the tote or totes. H2 H2 Scan

SCA

7.- Connect the Feed Valve from the

Enervac to the Drain Valve in the tank to

Enervac start filling the tank..

Status

8.- After the system reaches to the tank limit,

it will stop and will close the Feed Valve so

you can change it to the Drain Valve in the Close

next tote to fill it. This step will repeat for

each container tote.

Open

9.- Once the Tank and the totes are full with

the loaded oil, seal the totes and are ready

to ship. Unused

1 2 1 1 1 1 1

No Date Class Rev Description DWN VER CHKD SUB APP

Roanoke Oil Process

Drawn:D.Esparz

Design:D.Esparz

Poka-Yoke 2 oil connections

Roanoke Shipment Oil Process Checked: D.Rico

SilSilo Date: 02/09/2017

Submitted: David Esparza Approved for release: David Rico

Sheet: S-0001

Of 1

Classification: Reviewer: David Rico Date: 02/09/2017

Project ID: 12555 Drawing no: V36-901 Rev. 0

Pivot installation. Refer to Step 2 Tote Virginia Transformer Corporation

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Suntec Fuel Oil PumpDocument2 pagesSuntec Fuel Oil PumpkmthongNo ratings yet

- Npcs Afouad 8kpm GtcaDocument16 pagesNpcs Afouad 8kpm GtcaOmar KhaledNo ratings yet

- Guide Installation - Jauge Tankalert-ECO-OILDocument2 pagesGuide Installation - Jauge Tankalert-ECO-OILtestNo ratings yet

- Flowmaster Reservoir Level Sensor and Overflow Prevention SystemDocument4 pagesFlowmaster Reservoir Level Sensor and Overflow Prevention SystemВиталий КозловскийNo ratings yet

- VT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & CirculatorsDocument4 pagesVT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & Circulatorshamdi gshNo ratings yet

- Oil Purification Plants VOP 100 LT/H - 20 000 LT/HDocument6 pagesOil Purification Plants VOP 100 LT/H - 20 000 LT/Hjunaidi.036No ratings yet

- Engine Wiring Diagram Form: ECM 96-Pin E1 ConnectorDocument2 pagesEngine Wiring Diagram Form: ECM 96-Pin E1 Connectorjuan carlos rojas cadena100% (3)

- 6.2.1b 8000 Hours Maintenance - Comp MetricDocument17 pages6.2.1b 8000 Hours Maintenance - Comp MetricOmar KhaledNo ratings yet

- Work Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveDocument13 pagesWork Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveTareq MollaNo ratings yet

- Operations GearboxDocument96 pagesOperations GearboxjohnNo ratings yet

- The New Generation of Roto Drum Oil Skimmer 1995Document3 pagesThe New Generation of Roto Drum Oil Skimmer 1995arondaniel ocampoNo ratings yet

- RT-91 Pressure Retaining Valve in Servo Oil Return PipingDocument6 pagesRT-91 Pressure Retaining Valve in Servo Oil Return PipingcataNo ratings yet

- Fluid Power Design Data SheetDocument2 pagesFluid Power Design Data SheetohbabyohbabyNo ratings yet

- SB6B - Procedimiento de Limpieza Motor QuemadoDocument2 pagesSB6B - Procedimiento de Limpieza Motor Quemadoarmando jesus cedeño0% (1)

- Steam Turbine GovernorDocument25 pagesSteam Turbine GovernorGanesh Dasara100% (2)

- Series & Parallel Pump Lab ReportDocument10 pagesSeries & Parallel Pump Lab ReportNurye NigusNo ratings yet

- Hotpoint 44856891 11337128ENDocument12 pagesHotpoint 44856891 11337128ENFreccsNo ratings yet

- Solids-Retaining Centrifugal Separators: ApplicationDocument4 pagesSolids-Retaining Centrifugal Separators: ApplicationninatenaNo ratings yet

- Basics of Governing System: Drawings Are Not As Per ActualDocument25 pagesBasics of Governing System: Drawings Are Not As Per ActualAhemad100% (1)

- Steam Turbine GovernorDocument25 pagesSteam Turbine GovernorAshish Kumar MehtoNo ratings yet

- RTA-58 - Cleaning of Scavenging Air Cooler During Operation and at StandstillDocument7 pagesRTA-58 - Cleaning of Scavenging Air Cooler During Operation and at Standstilldhilip87No ratings yet

- Detect Component Wear with Oil AnalysisDocument46 pagesDetect Component Wear with Oil AnalysisSonofwill Auger OdagledNo ratings yet

- KOWADocument111 pagesKOWAgilar herliana putraNo ratings yet

- RTA-55 Exhaust Valve Seat and Exhaust Valve SpindleDocument10 pagesRTA-55 Exhaust Valve Seat and Exhaust Valve SpindleCatalin CataNo ratings yet

- RTA-34 Fuel Injection System Modifications and MaintenanceDocument12 pagesRTA-34 Fuel Injection System Modifications and MaintenanceCatalin CataNo ratings yet

- Service Manual: Marvel-Schebler Products DivDocument22 pagesService Manual: Marvel-Schebler Products DivKate PurnellNo ratings yet

- VPOWER Genset Operations, Service and Maintenance ManualDocument23 pagesVPOWER Genset Operations, Service and Maintenance ManualMahesh Mirajkar100% (1)

- 9-4130 - Loose Stepper MotorDocument2 pages9-4130 - Loose Stepper MotorarasNo ratings yet

- Televar Fuel LevelDocument16 pagesTelevar Fuel LevelVecherko GeorgiyNo ratings yet

- Tech Data Sheet 6700Document1 pageTech Data Sheet 6700Shubhankar MenonNo ratings yet

- 36e77619b0019 078Document550 pages36e77619b0019 078Omer Ghassan Abdulkareem Hassan AlsultanNo ratings yet

- Installation Instructions: LO-NOX™ Line Burners Page 5800-S-1Document6 pagesInstallation Instructions: LO-NOX™ Line Burners Page 5800-S-1Nicolás Becker CastellaroNo ratings yet

- QuickTrip ELECTRO-HYDRAULIC TRIP BLOCK ASSEMBLY FOR INDUSTRIAL STEAM TURBINESDocument1 pageQuickTrip ELECTRO-HYDRAULIC TRIP BLOCK ASSEMBLY FOR INDUSTRIAL STEAM TURBINESsunny vermaNo ratings yet

- RTA-19 - Oil Supply Monitoring For Geislinger Torsional Vibration DamperDocument5 pagesRTA-19 - Oil Supply Monitoring For Geislinger Torsional Vibration Damperdhilip87No ratings yet

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- Animated Governing System PresentationDocument24 pagesAnimated Governing System PresentationVijay Pal100% (1)

- Preventive Maintenance: 5.1 Regular ChecksDocument2 pagesPreventive Maintenance: 5.1 Regular Checksnitin9860No ratings yet

- SU - System Description - 1999Document18 pagesSU - System Description - 1999Centrifugal SeparatorNo ratings yet

- Upgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLDocument4 pagesUpgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLKushtrim MalaNo ratings yet

- Eries: For Marine ApplicationDocument20 pagesEries: For Marine ApplicationHector Ernesto Cordero AmaroNo ratings yet

- RTA-51 Deflagration in Engine Scavenge System and Exhaust ManifoldDocument8 pagesRTA-51 Deflagration in Engine Scavenge System and Exhaust ManifoldCatalin CataNo ratings yet

- Separation System, SA: Cleaning System For Fuel and Lubricating OilsDocument4 pagesSeparation System, SA: Cleaning System For Fuel and Lubricating Oilsganda irvan100% (1)

- CH 4 Drive Ability & EmissionsDocument44 pagesCH 4 Drive Ability & EmissionsjustcheerfulNo ratings yet

- Filling Up Hermetically Sealed TransformerDocument7 pagesFilling Up Hermetically Sealed TransformerDist Tx100% (3)

- Carburetor InformationDocument21 pagesCarburetor InformationPam WojciechowskiNo ratings yet

- Suntec TA3 Pump SpecificationDocument2 pagesSuntec TA3 Pump Specificationsayda MaowiaNo ratings yet

- Team Turbine GovernorDocument25 pagesTeam Turbine GovernorGanesh Dasara100% (1)

- Oil Pump Type T GEAR SIZES 2-3-4-5Document2 pagesOil Pump Type T GEAR SIZES 2-3-4-5Eden Ben100% (1)

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- Strength Tests: Semi-Automatic Cement Compression & Flexural MachinesDocument3 pagesStrength Tests: Semi-Automatic Cement Compression & Flexural MachinesADS ADSNo ratings yet

- Automatic Cement Compression & Flexure Testing MachinesDocument3 pagesAutomatic Cement Compression & Flexure Testing MachinesADS ADSNo ratings yet

- Fuel System Overview: 6-Point Testing to Reduce Catalytic Fines DamageDocument2 pagesFuel System Overview: 6-Point Testing to Reduce Catalytic Fines DamageJevgenij ChupinNo ratings yet

- Separator Purifier TrainingDocument39 pagesSeparator Purifier TrainingDesron SamuelNo ratings yet

- A Sample Preventative Maintenance Schedule PDFDocument2 pagesA Sample Preventative Maintenance Schedule PDFreda100% (1)

- Fleck 5800 LXT & SXT Downflow/Upflow: Service ManualDocument26 pagesFleck 5800 LXT & SXT Downflow/Upflow: Service ManualJean-Paul IstaceNo ratings yet

- Rtts Circulating Valves: SectionDocument40 pagesRtts Circulating Valves: Sectionwee zooNo ratings yet

- Documents, Manuals, Service Bulletins and ScreensaversDocument49 pagesDocuments, Manuals, Service Bulletins and ScreensaversAntoineNo ratings yet

- Centro-Matic Automated Lubrication Systems: SimplicityDocument53 pagesCentro-Matic Automated Lubrication Systems: Simplicityahmat ramadaniNo ratings yet

- Test1 PDFDocument1 pageTest1 PDFDavid Adrián EsparzaNo ratings yet

- Enervac Hydraulic DiagramsDocument6 pagesEnervac Hydraulic DiagramsDavid Adrián EsparzaNo ratings yet

- Roanoke Enervac AutomationDocument11 pagesRoanoke Enervac AutomationDavid Adrián EsparzaNo ratings yet

- Roanoke Silo System NewDocument1 pageRoanoke Silo System NewDavid Adrián EsparzaNo ratings yet

- Enervac User ManualDocument13 pagesEnervac User ManualDavid Adrián EsparzaNo ratings yet

- Planner Lost BodiesDocument2 pagesPlanner Lost BodiesDavid Adrián EsparzaNo ratings yet

- Roanoke Transformer RecycleDocument1 pageRoanoke Transformer RecycleDavid Adrián EsparzaNo ratings yet

- Hydraulic Diagram: Roanoke Enervac AutomationDocument3 pagesHydraulic Diagram: Roanoke Enervac AutomationDavid Adrián EsparzaNo ratings yet

- FR3 Silo Automation Symbols ManualDocument1 pageFR3 Silo Automation Symbols ManualDavid Adrián EsparzaNo ratings yet

- Roanoke Silo 1 To Silo 2-3Document1 pageRoanoke Silo 1 To Silo 2-3David Adrián EsparzaNo ratings yet

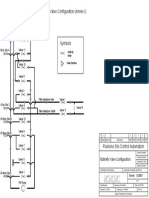

- Valve Configuration (Annex I) : Receipts Silo 1 Silo 4 Silo 3 Silo 2Document11 pagesValve Configuration (Annex I) : Receipts Silo 1 Silo 4 Silo 3 Silo 2David Adrián EsparzaNo ratings yet

- Roanoke Transformer To Silo 4Document1 pageRoanoke Transformer To Silo 4David Adrián EsparzaNo ratings yet

- Lost BodiesDocument1 pageLost BodiesDavid Adrián EsparzaNo ratings yet

- Chapter1 Dream DemonDocument10 pagesChapter1 Dream DemonDavid Adrián EsparzaNo ratings yet

- Roanoke Enervac AutomationDocument11 pagesRoanoke Enervac AutomationDavid Adrián EsparzaNo ratings yet

- Silo Control SystemsDocument1 pageSilo Control SystemsDavid Adrián EsparzaNo ratings yet

- Oil Process Tank-Tote and Tote-Tank Status SymbolsDocument1 pageOil Process Tank-Tote and Tote-Tank Status SymbolsDavid Adrián EsparzaNo ratings yet

- Annex IDocument1 pageAnnex IDavid Adrián EsparzaNo ratings yet

- NE NEMA Vs UL 012314 PDFDocument1 pageNE NEMA Vs UL 012314 PDFdesc82No ratings yet

- WtA - Glass Walkers Tribebook (Revised)Document106 pagesWtA - Glass Walkers Tribebook (Revised)api-27489897100% (17)

- Abelha (Ing)Document10 pagesAbelha (Ing)Lucia Silva100% (2)

- Drill and MarchingDocument34 pagesDrill and Marchingsharonmangundu036No ratings yet

- 1893 Dardistan in 1866, 1886 and 1893 by Leitner SDocument288 pages1893 Dardistan in 1866, 1886 and 1893 by Leitner SBilal Afridi100% (1)

- A+ Guide To Hardware, 4eDocument62 pagesA+ Guide To Hardware, 4eepriyaa100% (4)

- Kite FestivalDocument2 pagesKite FestivalSameer KhatriNo ratings yet

- Joke StructureDocument2 pagesJoke StructureMarcel Antonio100% (1)

- The Odyssey EssayDocument5 pagesThe Odyssey Essayapi-320308976No ratings yet

- Pimsleur Spanish IDocument21 pagesPimsleur Spanish INevenly Fae86% (7)

- Dynamics projectile motion problemsDocument2 pagesDynamics projectile motion problemsVon A. Damirez0% (1)

- Faq On Ivr 3d SecureDocument2 pagesFaq On Ivr 3d SecureRio PopoffNo ratings yet

- Saturn's RingDocument2 pagesSaturn's RingRobin GunawanNo ratings yet

- Drum Circle Clinic HandoutDocument4 pagesDrum Circle Clinic Handoutfinaldrumgod100% (1)

- Submitted To: Sir Hassan Submitted By: Syeda Mahwish Sajid (THM Evening 29)Document15 pagesSubmitted To: Sir Hassan Submitted By: Syeda Mahwish Sajid (THM Evening 29)Maniya GillaniNo ratings yet

- CHIP Malaysia FebDocument132 pagesCHIP Malaysia FebJohn100% (1)

- Simpleterms BTP PricingModel PDFDocument34 pagesSimpleterms BTP PricingModel PDFpreetigopalNo ratings yet

- Empowerment Technologies Contextualized Online Search and Research Skills / Developing Ict Content For Specific PurposesDocument3 pagesEmpowerment Technologies Contextualized Online Search and Research Skills / Developing Ict Content For Specific PurposesHannah MajadoNo ratings yet

- Mapeh 3 (St. Rose) : Health: I Can Be A Wise ConsumerDocument23 pagesMapeh 3 (St. Rose) : Health: I Can Be A Wise ConsumerSarvia GacosNo ratings yet

- Grittapas Weekly Report 23 29 Oct 08Document3 pagesGrittapas Weekly Report 23 29 Oct 08Grittapas100% (1)

- What Is Contemporary Literature? (10) : Personal Point of ViewDocument5 pagesWhat Is Contemporary Literature? (10) : Personal Point of ViewJeremie F. AlejandroNo ratings yet

- Your Electronic Ticket ReceiptDocument2 pagesYour Electronic Ticket Receiptpioabiraad60No ratings yet

- Pearson Teaching Activities Jamboree A PDFDocument99 pagesPearson Teaching Activities Jamboree A PDFbestatemanNo ratings yet

- Gerunds N Participles WorksheetDocument1 pageGerunds N Participles WorksheetUzma MushtaqNo ratings yet

- Jordan Vs LebronDocument6 pagesJordan Vs Lebronapi-719540801No ratings yet

- HCIP Datacom Advanced RS H12 831 - V1.0 ENUDocument123 pagesHCIP Datacom Advanced RS H12 831 - V1.0 ENUguido.martini100% (2)

- ReligionDocument2 pagesReligionasfasfNo ratings yet

- Jurassic Park Soundtrack Suite For Concert BandDocument23 pagesJurassic Park Soundtrack Suite For Concert BandRogério Abaurre100% (1)

- Carlcare QC Guide of Device Test Tools 20180921 PDFDocument20 pagesCarlcare QC Guide of Device Test Tools 20180921 PDFAnonymous bNf6FtewLPNo ratings yet

- PMK PricingDocument27 pagesPMK PricingLe Thi To Uyen (K16 HCM)No ratings yet

- SHTF 50Document6 pagesSHTF 50Tonyf6188No ratings yet

- I Wandered Lonely As A CloudDocument12 pagesI Wandered Lonely As A CloudDinesh SoniNo ratings yet