Professional Documents

Culture Documents

LSTX) 'Rlrhl3Ltslr: Manufacturer Data

Uploaded by

uripssOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LSTX) 'Rlrhl3Ltslr: Manufacturer Data

Uploaded by

uripssCopyright:

Available Formats

lstx)'rlrHl3ltslr "

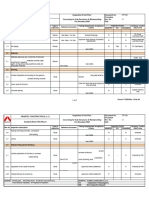

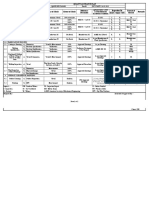

MANUFACTURER DATA RECORD

CHAPTER:

DOCUMENT TITLE :

QUALIW PLAN

CUSTOMER:

TOTAL E&P INDONESIE

EQUIPMENT TAG :

cEcF - oo1

ITEM NAME :

CENTAUR ENGINE CONTAINER FLAT END TYPE

l..rol )l)'I' It ll l3 I lS E *

)roject CENTAUR ENGINE CONTAINER tem Name CENTAUR CONTAINER PTI Job No

Jser TOTAL E&P INDONESIE FLAT END TYPE W.O No.

levision :0

Quality Plan )aoe Page 1 ot 1

No. Manufacturing Activity Description of CIC Activity Retbrence ReporU lnsoection Partv

llarlifl.lla PTI TOTAL

I Enqineerino & Drocedure

1 Delivery Drawing Review of the Drawing Drawing X R

2 Procedure Qualifl cation

2.1 Welding Procedure Specification Review of the Welding Procedure ASME o x R

2.2 Welder Certificate ?evier,v of the Welder Certificate ASME o X R

2.3 Painting Procedure leview of the Painting Procedure lso 8501 o X R

2.4 \ion Destructive Test ?eview of the NDT Procedure ASME o x R

'Magnetic particle examination)

I Psrchasino

( Raw material and component )

1 Requisition lor Purchasing Review of the Material Requisition Sheet (MRS) x

2 Receiving inspection material

2.1 Plate material Material inspection as per requirement of the

curtomer specification and/or material specificatlon

a. Visual examination of the surface material and X R

identification/ marking.

b. Dimensional check and thickness . o X R

c. Review of the certificate material test report. o x R

2.2 3olt and nut Material inspoction as per requirement of the

customer specification and/or material specification

a. Visual examination of the surface material and x R

identifi cation/ marking.

b. Dimensional check X R

c. Review of the certificate material test report. 0 X R

ilt lnspectloh durinq fabrication

1.1 Marking a, Visual check of material identification.

a. Certificale malarial

o X R

b. Cuting lay{ut

b. Dimensional check before cutting. c. Fab. Drawing o x R

d- Fab ToleEncs

y'isual check of cutting surface :. Fab. Drawing X

1.2. 3utting

1.3 Bending Visual check of bending surface d. Fab Tolorance X

y1/elding a. Check WPS and welder certificate

x

1.4.

b. Check the condition of welding electrode x

c. Visual check of weld to make sure that no defect o X R

after weld.

e. Dimensional and visual check after welding, o X R

1.5. Drilling Dimensional and visual check after drilling o x R

1.6 NDT(Non Destructive Test) a. Visual examination o X R

b. NDT will be performed on lifting point sel o x R

5 lnspec'tion Releas

5.1. Overall dimensional Dimensional inspection

r. Fab. Tderan6 o x R

,. Fab. Drawing

Visual check Visual inspection a. Fab. Drawing o X R

b. Fab Tolsrance

5.2 Final lnspection {cceptance of Conformity Is per customer o X R

'6quirsment

Remarke :

X r Preparationllnspectlon R: Review o: Reportrequtred

f A^riltffi

PT.IHDOTURSNE

You might also like

- CRC-CIV-ITP-000004-02 ITP For Rock Bolt InstallationDocument9 pagesCRC-CIV-ITP-000004-02 ITP For Rock Bolt Installationshahzad100% (2)

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- Qap ReactorDocument6 pagesQap ReactorPARMAR MUKESHNo ratings yet

- Inspection and Test Plan For Steel StructureDocument1 pageInspection and Test Plan For Steel Structureeva maniceNo ratings yet

- 18.9 ITP SUB BASE Rev01Document2 pages18.9 ITP SUB BASE Rev01YEHIA100% (1)

- Std. QAP of Expension Joints (March 16)Document6 pagesStd. QAP of Expension Joints (March 16)ghaghra bridgeNo ratings yet

- Customer PT. PLN (Persero) Inspection and Test Plan for CFSPP PROJECT UNIT 3&4 2X200 MW Civil & Mechanical WorksDocument4 pagesCustomer PT. PLN (Persero) Inspection and Test Plan for CFSPP PROJECT UNIT 3&4 2X200 MW Civil & Mechanical WorksTari HandayaniNo ratings yet

- Inspection Testing Plan (ITP)Document1 pageInspection Testing Plan (ITP)Kdown 99100% (1)

- Mar HM 18.06.22Document302 pagesMar HM 18.06.22özgen bölükNo ratings yet

- SR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignDocument1 pageSR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignAlpine ProjectsNo ratings yet

- M/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSDocument1 pageM/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSStructures ProductionNo ratings yet

- Inspection & Test Plan For Nozzle Replacement On VS ShellDocument1 pageInspection & Test Plan For Nozzle Replacement On VS ShellQC Taner 453100% (2)

- Pressure Vessel ITP Rev 0Document10 pagesPressure Vessel ITP Rev 0SLC HosurNo ratings yet

- Part 1 Inspection PlanDocument5 pagesPart 1 Inspection PlanRaja Sang MontiNo ratings yet

- Inspection Test PlanDocument2 pagesInspection Test PlanBalaji Guru90% (10)

- Inspection & Test PlanDocument1 pageInspection & Test PlanDanielNo ratings yet

- TS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIDocument3 pagesTS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIict petrexNo ratings yet

- Dokumen - Tips 3itp-ElectricalDocument28 pagesDokumen - Tips 3itp-ElectricalKyle WadsworthNo ratings yet

- QUALITY ASSURANCE PROTOCOLDocument2 pagesQUALITY ASSURANCE PROTOCOLShah Newaz KabirNo ratings yet

- Inspection and Test PlanDocument2 pagesInspection and Test PlanAbdullahNo ratings yet

- FQP 2Document25 pagesFQP 2Kuldeep ChakerwartiNo ratings yet

- ENMAS EPC Quality Assurance Plan for Piping ComponentDocument2 pagesENMAS EPC Quality Assurance Plan for Piping ComponentPavul RajNo ratings yet

- Attachment No.3-2. QIP - Shunt ReactorDocument2 pagesAttachment No.3-2. QIP - Shunt ReactorEdciel EbuenNo ratings yet

- Offshore Soil Investigation: Inspection & Test Plan Archirodon Petrojet ConsortiumDocument1 pageOffshore Soil Investigation: Inspection & Test Plan Archirodon Petrojet ConsortiumBelal hassanNo ratings yet

- Standard QA Plan (Elastomeric Bearings)Document8 pagesStandard QA Plan (Elastomeric Bearings)ghaghra bridgeNo ratings yet

- NS2-DH01-P0ZEN-740009 - ITP For Crane & Hoist Installation - REV.DDocument12 pagesNS2-DH01-P0ZEN-740009 - ITP For Crane & Hoist Installation - REV.DAnh VàngNo ratings yet

- Pre Salvage Inspection Report SummaryDocument1 pagePre Salvage Inspection Report SummaryM Ferry AnwarNo ratings yet

- LI BB Sensitivity & Satability Test Report Rev NEW FORMDocument5 pagesLI BB Sensitivity & Satability Test Report Rev NEW FORMRK KNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Bsibv-Itp-07-2 Pe Itp For 3lpe Coating Dpe Rev. 0Document10 pagesBsibv-Itp-07-2 Pe Itp For 3lpe Coating Dpe Rev. 0AMALENDU PAULNo ratings yet

- L&T QAPDocument2 pagesL&T QAPsriram.5230No ratings yet

- Itp For Fabn. & Erection of Structural WorksDocument4 pagesItp For Fabn. & Erection of Structural Workscrm 2No ratings yet

- Suria Engineering Dossier for GF-304CR StructureDocument35 pagesSuria Engineering Dossier for GF-304CR Structuresuria qaqcNo ratings yet

- Flsmidth Private Limited: Delivery ScheduleDocument3 pagesFlsmidth Private Limited: Delivery ScheduleNakeeran KrishnarajNo ratings yet

- Project and Location: 65 MW Noor Laayoune Solar PV Project at LaayouneDocument1 pageProject and Location: 65 MW Noor Laayoune Solar PV Project at LaayouneOussama BourimNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- 03 V-3125-001-A-702 (Site Inspection and Test Plan) ITP - 0Document4 pages03 V-3125-001-A-702 (Site Inspection and Test Plan) ITP - 0AlfaNo ratings yet

- Tank Inspection Data ReportDocument11 pagesTank Inspection Data ReportWahyudi MetrizaNo ratings yet

- Saadiyat Itp Concreting For Sub-Structure Boundary Wall InfrastructureDocument5 pagesSaadiyat Itp Concreting For Sub-Structure Boundary Wall InfrastructuresoorajNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Quality Assurance Plan for Metallic Expansion Joint ManufacturingDocument1 pageQuality Assurance Plan for Metallic Expansion Joint Manufacturingdemas100% (1)

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- Quality Assurance PlanDocument8 pagesQuality Assurance Plankamlesh vaishnavNo ratings yet

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- Field Inspection &test PlanDocument4 pagesField Inspection &test PlanSofda ImelaNo ratings yet

- FQP Field Quality Plan or ItpDocument30 pagesFQP Field Quality Plan or Itp9893203028No ratings yet

- UT ProcedureDocument15 pagesUT ProcedurejamelNo ratings yet

- Itp For Construction of Precast FoundationDocument7 pagesItp For Construction of Precast FoundationKhyle Laurenz Duro100% (1)

- Quality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Document13 pagesQuality Control in Fabricaton 1 Quality Assurance Plan 2 Inspection Report 3 NDT Report 4Varun MalhotraNo ratings yet

- 5 ITP Block WorkDocument2 pages5 ITP Block Workahmsami91No ratings yet

- ITP For Steel Structure1Document3 pagesITP For Steel Structure1吴兴泊No ratings yet

- BSIBV-ITP-07-2 PP ITP For 3LPP Coating DPE Rev. 0Document10 pagesBSIBV-ITP-07-2 PP ITP For 3LPP Coating DPE Rev. 0AMALENDU PAULNo ratings yet

- QAP-KGN-CIAL-001, Rev00Document2 pagesQAP-KGN-CIAL-001, Rev00iftekhar ahmedNo ratings yet

- IRT - CWC Coating Anode InstallationDocument3 pagesIRT - CWC Coating Anode InstallationPrafulla PatilNo ratings yet

- ITP List For Electrical Works (Chimney)Document16 pagesITP List For Electrical Works (Chimney)Ivan BabicNo ratings yet

- Field Inspection Plan for Concrete & Gabion WorksDocument4 pagesField Inspection Plan for Concrete & Gabion WorksSofda ImelaNo ratings yet

- Inspection and testing plan for concrete slab rectificationDocument7 pagesInspection and testing plan for concrete slab rectificationrayNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- 351 02003 00 Auto Manual ModuleDocument7 pages351 02003 00 Auto Manual ModuleuripssNo ratings yet

- Zinc Alloy Hull Anodes Specifications and DimensionsDocument2 pagesZinc Alloy Hull Anodes Specifications and DimensionsAnup NadkarniNo ratings yet

- SF-2200H Operating ManualDocument36 pagesSF-2200H Operating ManualuripssNo ratings yet

- Instruction of Plasma Cutting Machine UpgradeDocument2 pagesInstruction of Plasma Cutting Machine UpgradeuripssNo ratings yet

- ManualDocument3 pagesManualuripssNo ratings yet

- INFO winPCNC Optimierung PC Engl PDFDocument6 pagesINFO winPCNC Optimierung PC Engl PDFuripssNo ratings yet

- Winpc-Nc Controller: Null Modem CableDocument1 pageWinpc-Nc Controller: Null Modem CableuripssNo ratings yet

- PB SM082700 01Document1 pagePB SM082700 01uripssNo ratings yet

- Magentic Screw Conv PDFDocument2 pagesMagentic Screw Conv PDFuripssNo ratings yet

- Starcam Manual PDFDocument144 pagesStarcam Manual PDFuripssNo ratings yet

- 20170628100334852Document45 pages20170628100334852uripssNo ratings yet

- 1015PRO ManualDocument35 pages1015PRO ManualuripssNo ratings yet

- CNCDocument2 pagesCNCuripssNo ratings yet

- CNC Cutting ControllerDocument31 pagesCNC Cutting Controlleruripss100% (1)

- WiringDocument1 pageWiringuripssNo ratings yet

- LSS Linear Screw SlidesDocument1 pageLSS Linear Screw SlidesuripssNo ratings yet

- Desalter Trouble Shooting Guide: Baker PetroliteDocument2 pagesDesalter Trouble Shooting Guide: Baker PetroliteuripssNo ratings yet

- Planos Router CNCDocument53 pagesPlanos Router CNCMiguel JaquetNo ratings yet

- Caustic Soda Information ResourcesDocument2 pagesCaustic Soda Information ResourcesuripssNo ratings yet

- Calculating Starch Adhesive Solids PDFDocument4 pagesCalculating Starch Adhesive Solids PDFuripssNo ratings yet

- GlueDocument7 pagesGlueuripssNo ratings yet

- Hand Book of Adhesives With Their FormulaesDocument4 pagesHand Book of Adhesives With Their FormulaesVijay Gupta50% (16)

- Avoiding Noise ProblemsDocument2 pagesAvoiding Noise ProblemsUrip S. SetyadjiNo ratings yet

- Wood Adhesive From Crosslinked Poly Viny PDFDocument5 pagesWood Adhesive From Crosslinked Poly Viny PDFuripssNo ratings yet

- Vapour Lock N°2Document2 pagesVapour Lock N°2Urip S. SetyadjiNo ratings yet

- Maintain Your Vessel With a Dripless Shaft SealDocument14 pagesMaintain Your Vessel With a Dripless Shaft SealuripssNo ratings yet

- Water-Based Adhesive FormulationDocument6 pagesWater-Based Adhesive FormulationuripssNo ratings yet

- N70779Document6 pagesN70779uripssNo ratings yet

- PVC Bike RackDocument59 pagesPVC Bike RackuripssNo ratings yet

- 8116 PDFDocument1 page8116 PDFuripssNo ratings yet

- Vaithilingam QC Mech, ResumeDocument7 pagesVaithilingam QC Mech, ResumeharikumarNo ratings yet

- PLDYDocument48 pagesPLDYDavid CordovaNo ratings yet

- Trans Bridge Construction Inspection Manual Inspection Check SheetsDocument155 pagesTrans Bridge Construction Inspection Manual Inspection Check SheetsAnurag KumarNo ratings yet

- Iso 6183-2022Document76 pagesIso 6183-2022pendex40No ratings yet

- Sec614 - FormworkDocument9 pagesSec614 - FormworkAmr Adel HameedNo ratings yet

- CementingTools NS 1 A4 WatermarkedDocument7 pagesCementingTools NS 1 A4 Watermarkedislam atifNo ratings yet

- Handbook To BC1 2012Document53 pagesHandbook To BC1 2012undf2567% (3)

- Services Design ChecklistDocument5 pagesServices Design ChecklistIshan RanganathNo ratings yet

- CNC Machinist (1-Mpnth 2 Month OJT)Document12 pagesCNC Machinist (1-Mpnth 2 Month OJT)iqbalNo ratings yet

- 07.3.1.1 SSPC - Ab 1 - 2015 PDFDocument7 pages07.3.1.1 SSPC - Ab 1 - 2015 PDFandaechNo ratings yet

- Inspection of Corrosion under InsulationDocument10 pagesInspection of Corrosion under InsulationBIPIN BALANNo ratings yet

- MSIL Training On VSA Check SheetDocument145 pagesMSIL Training On VSA Check Sheetsumit_saraf_550% (16)

- Accident Prevention On Board Ship at Sea and in PortDocument207 pagesAccident Prevention On Board Ship at Sea and in PortElchinovNo ratings yet

- 09 Weekly Safety AssessmentDocument5 pages09 Weekly Safety AssessmentMohammed MinhajNo ratings yet

- Site Inspection ProceduresDocument101 pagesSite Inspection Procedureshrdsby100% (1)

- PIP RFEG1000 Guidelines For Use of Refractory PracticesDocument5 pagesPIP RFEG1000 Guidelines For Use of Refractory PracticesNicolasMontoreRosNo ratings yet

- Module 1 Introduction To Metrology PDFDocument10 pagesModule 1 Introduction To Metrology PDFhegdemachaNo ratings yet

- Cvi & GviDocument28 pagesCvi & GviAditi WadekarNo ratings yet

- BuildingnCODE NTDocument89 pagesBuildingnCODE NTAnil PyakurelNo ratings yet

- GLOBALG.A.P. Risk Assessment On Social Practice (Grasp)Document26 pagesGLOBALG.A.P. Risk Assessment On Social Practice (Grasp)KANINTA YUDHANo ratings yet

- Ductile IronDocument159 pagesDuctile IronPrabhakar KattulaNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- 欧州の舶用品認証制度に関する調査Document332 pages欧州の舶用品認証制度に関する調査Sairy TabNo ratings yet

- AS NZS 2885.3-2001 Pipelines - Gas and Liquid Petroleum - Operat PDFDocument75 pagesAS NZS 2885.3-2001 Pipelines - Gas and Liquid Petroleum - Operat PDFUniversal LaboratoryNo ratings yet

- Iec 61400 22 PDF FreeDocument59 pagesIec 61400 22 PDF FreeCliffordWellnerNo ratings yet

- Manufacturing Systems Analysis (MF-630) : Course Instructor Dr. Kashif IshfaqDocument38 pagesManufacturing Systems Analysis (MF-630) : Course Instructor Dr. Kashif Ishfaqshahid saeedNo ratings yet

- Job Description ElectronicsDocument2 pagesJob Description ElectronicssaravanakumarpalaniNo ratings yet

- Anand CV 2022arDocument6 pagesAnand CV 2022arsanbsahaNo ratings yet

- Jishu Hozen Audit Sheet CountermeasuresDocument7 pagesJishu Hozen Audit Sheet CountermeasuresharshavardhanNo ratings yet

- Building Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangDocument11 pagesBuilding Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangNrsyfqah SuleimanNo ratings yet