Professional Documents

Culture Documents

69 PDF

Uploaded by

Anonymous p8HJKJTaFaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

69 PDF

Uploaded by

Anonymous p8HJKJTaFaCopyright:

Available Formats

housing containing a spring and a stud with a steel pin.

This assembly is held onto the removable portion of the cowling or

access door with a metal grommet. The stud fits into a pressed steel receptacle which is riveted to the structure of the aircraft,

and a quarter of a turn locks the steel pin in a groove in the bottom of the receptacle.

Camloc fasteners are made in a variety of styles and designs. Included among the most commonly used are the 2600, 2700,

40S51, and 4002 series in the regular line, and the stressed panel fastener in the heavy duty line. The latter is used in stressed

panels which carry structural loads. A quarter turn (clockwise) of the stud locks the fastener. The fastener can be unlocked only

by turning the stud counter-clockwise

d. Airlock

An Airloc fastener consists of a steel stud and cross-pin in a removable cowling or door and a sheet spring-steel receptacle in the

stationary member. The studs are manufactured from steel and case hardened to prevent excessive wear. The stud hole is

reamed for a press fit of the cross pin. The total amount of material thickness to be secured with the Airloc fastener must be

known before the correct length of stud can be selected for installation. The total thickness of material that each stud will

satisfactorily lock together is stamped on the head of the stud in thousandths of an inch (0.040, 0.070, 0.190, and so forth).

Studs are manufactured in three head styles: flush, oval, and wing. The cross pin is manufactured from chrome-vanadium steel

and heat treated to provide maximum strength, wear, and holding power. It should never be used the second time; once

removed from the stud, replace it with a new pin.

Receptacles for Airloc fasteners are manufactured in two types: rigid and floating. Sizes are classified by number: No. 2, No. 5,

and No. 7. They are also classified by the center to center distance between the rivet holes of the receptacle: No. 2 is inch; No.

5 is 1 inch; and No. 7 is 1 38 inch. Receptacles are fabricated from high-carbon, heat-treated steel.

An upper wing assures ejection of the stud when unlocked and enables the cross pin to be held in a locked position between the

upper wing, cam, stop, and wing detent, regardless of the tension to which the receptacle is subjected.

To lock this type of fastener, the stud slips into the receptacle and is rotated a quarter of a turn. The pin drops into an

indentation in the receptacle spring and holds the fastener locked.

5.12.1 Outline the construction, applications, installation procedures and precautions relating to the following classifications of

cable:

a. Nonflexible

In areas where a linkage does not pass over any pulleys non-flexible cable can be used. It is available in either a 1 x 7 or 1 x 19

configuration. The 1 x 7 cable is made up of one strand comprised of seven individual wires, whereas the 1 x 19 consists of one

strand made up of 1 x 19 individual wires. Nonflexible cable is available in both galvanised carbon steel and stainless steel.

b. Flexible

Made up of seven strands of seven wires each is called 7 x 7 or flexible cable, and is available in 1/16 and 3/32 inch sizes in both

galvanised carbon steel and stainless steel.

You might also like

- NutsDocument49 pagesNutsIshant JaiswalNo ratings yet

- Stop LogsDocument7 pagesStop LogsDangol RupeshNo ratings yet

- MODULE 6.5 FastenersDocument12 pagesMODULE 6.5 FastenerssreeramNo ratings yet

- Sluice Gate ValveDocument15 pagesSluice Gate ValveRinia DurrsakeNo ratings yet

- Revised AnswersDocument40 pagesRevised AnswersNOOBplaysNo ratings yet

- Steel Wire RopesDocument23 pagesSteel Wire RopeskevinNo ratings yet

- Conduleta en TDocument6 pagesConduleta en TEd CalheNo ratings yet

- SCC Cat 991aDocument12 pagesSCC Cat 991aEddy JorgeNo ratings yet

- CUTOUT Fuse Holders: (Standard)Document9 pagesCUTOUT Fuse Holders: (Standard)MadyNo ratings yet

- Globe Valves: ORION S.p.A. Via Caboto, 8 - 34148 Trieste - Italy - Tel. +39 040813204 - Fax +39 040811203Document12 pagesGlobe Valves: ORION S.p.A. Via Caboto, 8 - 34148 Trieste - Italy - Tel. +39 040813204 - Fax +39 040811203Stanley PeterNo ratings yet

- WS Ii BoltsDocument115 pagesWS Ii BoltsRicha LalwaniNo ratings yet

- Anchoring of Monolithic Refractories - UkDocument9 pagesAnchoring of Monolithic Refractories - Ukantoniorossini100% (1)

- Expansion Joints BrochureDocument12 pagesExpansion Joints BrochureEzequiel Guillermo Trejo NavasNo ratings yet

- TNN January 2007Document16 pagesTNN January 2007Luis Aguero CantilloNo ratings yet

- Project Report On Wire RodDocument9 pagesProject Report On Wire RodEIRI Board of Consultants and Publishers100% (1)

- Parker Series 2A Air CylinderDocument36 pagesParker Series 2A Air Cylindersdey26No ratings yet

- Neral Capítulo.9 PDFDocument24 pagesNeral Capítulo.9 PDFtrinoNo ratings yet

- 130 Fluid LinesDocument4 pages130 Fluid LinesGuevarra, Gellie M.No ratings yet

- Hancock Type 4000 yDocument8 pagesHancock Type 4000 yGohilakrishnan ThiagarajanNo ratings yet

- Canales UNISTRUTDocument44 pagesCanales UNISTRUTMarkNo ratings yet

- ACO PitsDocument3 pagesACO PitsEver Piñon-SimonssonNo ratings yet

- Nut Bolt Installation PracticesDocument8 pagesNut Bolt Installation PracticesArjun SharmaNo ratings yet

- Steel BarsDocument8 pagesSteel BarsJerome Barra AbreaNo ratings yet

- Double Block Valves (Orion)Document8 pagesDouble Block Valves (Orion)marcoo8No ratings yet

- Anker Schroeder - Anchors For Marine StructuresDocument28 pagesAnker Schroeder - Anchors For Marine Structuresmark keijzersNo ratings yet

- Reskem Manwaybulletin PDFDocument2 pagesReskem Manwaybulletin PDFkinjalpatel12345No ratings yet

- Phoenix Mining Catalog 2009Document37 pagesPhoenix Mining Catalog 2009José VillegasNo ratings yet

- Dhofar Power Company Saog: Mott MacdonaldDocument1 pageDhofar Power Company Saog: Mott Macdonald54045114No ratings yet

- Technical Specification: Section - C1Document5 pagesTechnical Specification: Section - C1Anonymous EVFw59No ratings yet

- TST 04 Insulator Stringset OkeDocument6 pagesTST 04 Insulator Stringset Okerostyo tioNo ratings yet

- RivetDocument15 pagesRivetEllyYanaNo ratings yet

- Material Compliance Sheet ValvesDocument10 pagesMaterial Compliance Sheet ValvesindikumaNo ratings yet

- Flexible Steel Pipe Applications: Dana FraserDocument15 pagesFlexible Steel Pipe Applications: Dana FraseraishahNo ratings yet

- ProductCatalog Cyrus Shank PSVDocument95 pagesProductCatalog Cyrus Shank PSVmramos4191No ratings yet

- Adea Company BroucherDocument15 pagesAdea Company BroucherVelu SamyNo ratings yet

- L - 9 Ah - SSBLF I (6.5)Document7 pagesL - 9 Ah - SSBLF I (6.5)Arjun SharmaNo ratings yet

- RivetsDocument75 pagesRivetsPramod P Nair100% (1)

- 12492-Jones-Brochure-Wet Barrel Fire Hydrants-Web - 0Document6 pages12492-Jones-Brochure-Wet Barrel Fire Hydrants-Web - 0Mohsen ParpinchiNo ratings yet

- AVS28 ReelsDocument2 pagesAVS28 ReelsmahmoudglobaltechNo ratings yet

- Wind Socks3Document7 pagesWind Socks3Damodar BhatNo ratings yet

- ASWP Manual - Section 3 - Joints (10!6!12)Document12 pagesASWP Manual - Section 3 - Joints (10!6!12)shah1980No ratings yet

- Flange: Navigation SearchDocument21 pagesFlange: Navigation Searchfaizan_2008No ratings yet

- HARDWARE AsdfeDocument8 pagesHARDWARE AsdfeJuly TadeNo ratings yet

- Aircraft FastenerDocument91 pagesAircraft FastenerPrasanthNo ratings yet

- Instructions For Stow and Securing Steel CoilsDocument8 pagesInstructions For Stow and Securing Steel CoilsKhoai Sai GonNo ratings yet

- ACA Clamps&ConnectorsDocument4 pagesACA Clamps&ConnectorsvenkyeeeNo ratings yet

- Especificacion Tecnica Comp RadialDocument3 pagesEspecificacion Tecnica Comp RadialreviloNo ratings yet

- Slide GateDocument11 pagesSlide Gate陈淀No ratings yet

- SECTION 02822 Chain Link Fences and Gates Part 1 - GeneralDocument4 pagesSECTION 02822 Chain Link Fences and Gates Part 1 - GeneralEmad KhanNo ratings yet

- Pole Barn Metal DetailsDocument52 pagesPole Barn Metal DetailsKurt Stailey100% (1)

- Transmission Lines - PresentationDocument24 pagesTransmission Lines - PresentationMadanasekhar TadimarriNo ratings yet

- DefinitionDocument4 pagesDefinitiondaveadeNo ratings yet

- Guidelines For The Installation, Inspection, MaintenanceDocument23 pagesGuidelines For The Installation, Inspection, MaintenanceantiacidoNo ratings yet

- Manufacturing and Assembling of Stator and Rotor Inturbo GeneratorsDocument4 pagesManufacturing and Assembling of Stator and Rotor Inturbo GeneratorsAshfiya YazdaniNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Roofing: Chapter-IxDocument30 pagesRoofing: Chapter-IxRamsubbuNo ratings yet

- FRP Installation GuideDocument8 pagesFRP Installation GuideDouglas HillNo ratings yet

- Aircraft HardwareDocument36 pagesAircraft HardwareUmar HasanNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- A. Alpha: 25.12 Propeller Maintenance PracticesDocument1 pageA. Alpha: 25.12 Propeller Maintenance PracticesAnonymous p8HJKJTaFaNo ratings yet

- D. Cracks: 25.6 Mounting of PropellersDocument1 pageD. Cracks: 25.6 Mounting of PropellersAnonymous p8HJKJTaFaNo ratings yet

- 25 Turbine Engine Propellers: 25.1 Propeller TerminologyDocument1 page25 Turbine Engine Propellers: 25.1 Propeller TerminologyAnonymous p8HJKJTaFaNo ratings yet

- 25.9 Ice Protection: 25.9.1 Describe The Following Types of Propeller Ice Protection SystemsDocument1 page25.9 Ice Protection: 25.9.1 Describe The Following Types of Propeller Ice Protection SystemsAnonymous p8HJKJTaFaNo ratings yet

- 25.2 Propeller TheoryDocument1 page25.2 Propeller TheoryAnonymous p8HJKJTaFaNo ratings yet

- 16 MORE Crime Documentaries For 'Making A Murderer' ObsessivesDocument12 pages16 MORE Crime Documentaries For 'Making A Murderer' ObsessivesAnonymous p8HJKJTaFa100% (1)

- 25.4 Propeller ClassificationsDocument1 page25.4 Propeller ClassificationsAnonymous p8HJKJTaFaNo ratings yet

- 24 Auxiliary Power Units (Apus)Document1 page24 Auxiliary Power Units (Apus)Anonymous p8HJKJTaFaNo ratings yet

- 301Document1 page301Anonymous p8HJKJTaFaNo ratings yet

- 21.3 Engine Performance Interpretation: K. Over TorqueDocument1 page21.3 Engine Performance Interpretation: K. Over TorqueAnonymous p8HJKJTaFaNo ratings yet

- 23 Turbo-Prop & Turbo-Shaft EnginesDocument1 page23 Turbo-Prop & Turbo-Shaft EnginesAnonymous p8HJKJTaFaNo ratings yet

- 22 Inspection and Maintenance: 22.1 Cold-End InspectionsDocument1 page22 Inspection and Maintenance: 22.1 Cold-End InspectionsAnonymous p8HJKJTaFaNo ratings yet

- 22.3.4 Identify The Atmospheric Conditions in Which Engine Calibration and Trim Checks Should Be Undertaken. 22.3.5 Specify Reasons For Trimming An EngineDocument1 page22.3.4 Identify The Atmospheric Conditions in Which Engine Calibration and Trim Checks Should Be Undertaken. 22.3.5 Specify Reasons For Trimming An EngineAnonymous p8HJKJTaFaNo ratings yet

- 68 PDFDocument1 page68 PDFAnonymous p8HJKJTaFaNo ratings yet

- 62 PDFDocument1 page62 PDFAnonymous p8HJKJTaFaNo ratings yet

- 21 Engine Operation and Ground RunningDocument1 page21 Engine Operation and Ground RunningAnonymous p8HJKJTaFaNo ratings yet

- 66 PDFDocument1 page66 PDFAnonymous p8HJKJTaFaNo ratings yet

- 65 PDFDocument1 page65 PDFAnonymous p8HJKJTaFaNo ratings yet

- 5.4.6 Describe The Material Head Marking System For The Following Standard Aircraft BoltsDocument1 page5.4.6 Describe The Material Head Marking System For The Following Standard Aircraft BoltsAnonymous p8HJKJTaFaNo ratings yet

- 67 PDFDocument1 page67 PDFAnonymous p8HJKJTaFaNo ratings yet

- 64 PDFDocument1 page64 PDFAnonymous p8HJKJTaFaNo ratings yet

- 63 PDFDocument1 page63 PDFAnonymous p8HJKJTaFaNo ratings yet

- G. Special PurposeDocument1 pageG. Special PurposeAnonymous p8HJKJTaFaNo ratings yet

- 56 PDFDocument1 page56 PDFAnonymous p8HJKJTaFaNo ratings yet

- 51Document1 page51Anonymous p8HJKJTaFaNo ratings yet

- 50Document1 page50Anonymous p8HJKJTaFaNo ratings yet

- 52Document1 page52Anonymous p8HJKJTaFaNo ratings yet

- 53Document1 page53Anonymous p8HJKJTaFaNo ratings yet

- Welding Consumables For Cast SteelDocument4 pagesWelding Consumables For Cast Steelmehul20110% (1)

- G 962 1188 - BomDocument8 pagesG 962 1188 - BomDibyendu ChakrabortyNo ratings yet

- S 3 DPCFDocument20 pagesS 3 DPCFsure516vNo ratings yet

- 03 Monthly Progress Report May 2022 Rev 00Document38 pages03 Monthly Progress Report May 2022 Rev 00Raj KamatNo ratings yet

- Asme B18.12-2020Document113 pagesAsme B18.12-2020윤규섭0% (1)

- New COADocument15 pagesNew COAAhadNurParagNo ratings yet

- Adecco Salary Guide: SingaporeDocument21 pagesAdecco Salary Guide: SingaporeLina GanNo ratings yet

- Floor Tiling Installation GuideDocument37 pagesFloor Tiling Installation GuideGashi ArianitNo ratings yet

- Deep Drawing: Benefits and Industrial ApplicationsDocument3 pagesDeep Drawing: Benefits and Industrial ApplicationsChandru NatarajanNo ratings yet

- Silt TrapDocument5 pagesSilt TrapasyreenhaikalNo ratings yet

- Libya Private Sector Mapping - 2015 PDFDocument101 pagesLibya Private Sector Mapping - 2015 PDFmdshoppNo ratings yet

- Engine 250 10 006Document24 pagesEngine 250 10 006Devraj BaruahNo ratings yet

- Casagrand Grandio BrochureDocument53 pagesCasagrand Grandio BrochureJoshikha MNo ratings yet

- California Plumbing CodeDocument7 pagesCalifornia Plumbing CodeMOHAMMAD ASIFNo ratings yet

- PIDS Installation DetailsDocument1 pagePIDS Installation Detailsmohamed ghazyNo ratings yet

- FB 16-EDocument48 pagesFB 16-EserialamineNo ratings yet

- Filter Diaphragms PDFDocument13 pagesFilter Diaphragms PDFZlatko BiočićNo ratings yet

- Bridge Design Report - Final-SadaDocument294 pagesBridge Design Report - Final-SadaSadatcharaMoorthi NNo ratings yet

- Wet Abrasive Blasting System and MethodDocument13 pagesWet Abrasive Blasting System and MethodhainguyenbkvhvNo ratings yet

- Curriculum Vitae: Personal Information Sallam Q. ShurrabDocument3 pagesCurriculum Vitae: Personal Information Sallam Q. ShurrabSallam Q. ShurrabNo ratings yet

- Literature Study: by Kataru Lohith Krishna Reg No:RA1811201010070Document10 pagesLiterature Study: by Kataru Lohith Krishna Reg No:RA181120101007099 kingsNo ratings yet

- Piling: Information Provided Rules Definition Coverage Rules Supp MentDocument1 pagePiling: Information Provided Rules Definition Coverage Rules Supp MentVimalNo ratings yet

- Zinc-Coated Steel Strand For Messenger Support of Figure 8 CableDocument3 pagesZinc-Coated Steel Strand For Messenger Support of Figure 8 CableDarwin DarmawanNo ratings yet

- Project Two Storey Residence Subject BilDocument6 pagesProject Two Storey Residence Subject BilEdgar LavapiezNo ratings yet

- Fabric Expansion Joint: Catalogue Flytech Engineering SDN BHD 1/1/2011Document7 pagesFabric Expansion Joint: Catalogue Flytech Engineering SDN BHD 1/1/2011Sejadah MaryamNo ratings yet

- Furniture Materials and CharacteristicsDocument2 pagesFurniture Materials and CharacteristicsKathleen Anne CabreraNo ratings yet

- Dolebury End: Dolberrow, Churchill, BS25 5NSDocument4 pagesDolebury End: Dolberrow, Churchill, BS25 5NSFace sheNo ratings yet

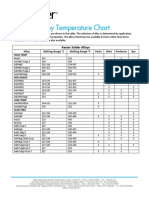

- Alloy Temperature ChartDocument2 pagesAlloy Temperature ChartDaymer AularNo ratings yet

- Brich HansenDocument5 pagesBrich HansenHUGINo ratings yet

- CHAPTER 2design Against Static LoadDocument33 pagesCHAPTER 2design Against Static LoadmanishtopsecretsNo ratings yet