Professional Documents

Culture Documents

Helmet Oct15

Uploaded by

AS VatsalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helmet Oct15

Uploaded by

AS VatsalCopyright:

Available Formats

HELMET

Environment Health Safety

EHS journal of L&T Construction

Volume - 5, Issue - 4 October - December 2015

We need more responsibility

and accountability to make

safety a culture

- S. N. Subrahmanyan

Contents From the EDITOR

Safety has to be a way of life 3 It will never happen to me! are the famous words of

Safety has to be a way of life

an infamous man: Edward John Smith, Captain of RMS

Titanic. History has shown us what a titanic blunder Safety Month inaugurated at HQ Campus

Making of a safe retail 6 that was but the learning for us from Capt. E J Smith

masterpiece is that everyone is always at risk and this kind of false

bravado just does not pay. Unfortunately, a lot of people

are very much like Capt. Smith, living in fools paradise

and believing that danger will always miss them: much

Staying right on the tracks 12 like in the Final Destination series of films in which

in terms of safety everyone keeps getting killed while the hero keeps

miraculously escaping. That is reel life; at construction

sites we are faced with real life and it is the endeavor

Making a powerful impact 18 of every safety in-charge to make a construction site

as boring as possible: meaning make it completely

incident free.

Safety comes in different 22 Safety is often described as the absence of danger

shapes and sizes which is possible by meticulous planning, religiously

following instructions, being ever aware of ones

surrounds and the people one is working with and

being always prepared for danger that could be lurking

A sound idea to deafen 26 round every corner. January is observed as Safety

the clamor Month at L&T and month-long events are planned to

make everyone aware of the importance and relevance

of safety in our lives. The reality is that safety cannot be

a month-long event; it has to a life-long commitment.

All projects that we have featured in this issue have

been very challenging from a safety perspective. The

Editor : Vinod Jacob Chacko dangers have been of various shapes and degrees.

Constructing one of the largest malls in the country

Associate Editor : Gopi Kannan. S calls for a different kind of safety orientation from

that required when laying rail tracks for the dedicated

Process Owners : M. Kamarajan freight corridor over 626 km next to a live railway

S

Malay Kumar Mahanta line on which a train whistles by every 20 minutes.

afety month January 2016 kicked off with an inaugural

Stephen Philip Storey Stringing transmission lines across miles of shifting

function on 4th January at HQ campus where the

sand dunes or marshy backwaters or laying some of

Ramachandran N presence of senior management underlined the Safety lapses are now being reviewed at the board level

the largest pipes laid in Asia thus far posed their own

K. S. Sudheesh Kumar set of tricky questions. The good news is that in all importance, relevance and commitment to EHS. and soon the respective project manager will be made

these cases, the safety teams were able to answer all the accountable and answerable in the event of incidents, was

Technical Associates : P. Nagarajan | Gabrial Fernandez

tricky questions and have been successful in making In his welcome address, Mr. M.V. Satish, Whole-Time Director Mr. S. N. Subrahmanyan's, Deputy Managing Director &

Sudarsan Rajendran & Senior Executive Vice President, Buildings, Minerals &

life extremely boring across all these sites. We share President, L&T, strong message in his keynote address. He also

Md Quaisar Imam with you how they made it happen. Metals, expressed that although the organization had secured highlighted that despite persistent efforts, incidents at sites

Sathyanarayana Seelamanthula 23 RoSPA, 22 British Safety Council, and 59 National Safety were still continuing that called for stringent measures to

Murali Krishnan In all sites, danger is present, tangible and up close Council awards, accidents still continued to occur at sites with

but there are times when one is unaware of exposure improve safety performance towards zero incidents.

Mathivanan Palaniappan plant and machinery and fall from heights being the major

to danger like when assaulted by noise beyond

S. Anantha Prasanna Venkatesh areas that needed focus. MVS urged the gathering to take a It is important to first think Global before aspiring to grow

acceptable levels. In this issue of Helmet, we speak

about the ills of noise pollution and remedies if you closer look at a safer way of implementing mechanization at to such levels, said SNS and urged the safety team to adhere

Editorial team : V. Ramesh Kumar to and implement global best practices for better results. He

care to listen to us! sites to reduce the frequency of such reportable accidents and

Ashwin Chand | Mayura. K advised the senior management of all ICs to demand safety made a special mention to reignite the fervor of the Suraksha

So we invite you to celebrate this Safety Month by excellence from their teams. Safety has to be a way of life at Jeet programme and to make the Safety Innovation School

Photography : V. S. Natanavelu | R. Vijay Kumar

reigniting that sense of safety in ourselves and live operational at the earliest. On a positive note, SNS appreciated

the projects, he summed up forcefully.

Design & layout : Global Print Design, Chennai incident free every day because one can never be too

careful!

2 HELMET, October - December 2015 HELMET, October - December 2015 3

Safety

of Honour

R o ll

Helmet congratulates the following sites for achieving

ten million and more LTI free safe man-hours

35 NISER Project, Bhubaneswar

September 2011 to December 2015

14 Riverview Phase 2 Project, Lucknow

March 2012 to December 2015

33 Prestige Bella Vista Project, Chennai

April 2012 to December 2015

14 C-17 IAF Hindan Project, Ghaziabad

August 2012 to December 2015

31 The Address Wadhwa Project, Mumbai

April 2010 to December 2015

13 HCL Ph III Project, Noida

January 2013 to December 2015

27 Delhi One Project

December 2011 to December 2015

13 Mall of India Project, Noida

September 2013 to December 2015

the Shell project team at Bangalore which had recently won

an extraordinary award from the Royal Dutch Shells overall 25 Cognizant Elcot IT Park Project,

Sholinganallur

13 ESIC Hospital Project, Coimbatore

March 2011 to December 2015

awards for HSE. Such best practices from such trendsetting

sites need to be shared across the organization for all to reap October 2012 to December 2015

the benefits fully, he finished strongly. 12 CMRL Depot Project, Koyambedu

Mr. M. Kamarajan, Head - Environment Health & Safety 25 ITC Sonar Hotel Project, Kolkata

August 2009 to December 2015

December 2010 to December 2015

(EHS), B&F IC, administered the safety pledge. In the month

long EHS initiative, L&T Constructions project sites across the 12 ESIC Hospital Project, Joka

globe will focus on innovative measures to instill and sustain a 18 Shell NTCB Project, Bengaluru

February 2014 to December 2015

November 2009 to December 2015

safe work culture. Based on a strong theme of ownership, this

years Safety message has been woven around every individual 12 UP Awas Vikas Basement Project,

willing, owning, consciously demonstrating and thereby 17 ESIC Hospital Project, Kollam

April 2010 to December 2015

Ghaziabad

August 2012 to December 2015

helping to build a positive EHS culture.

Several activities have been planned to increase awareness 16 Experion Windchants Project, Gurgaon

April 2014 to December 2015

12 Wonder Cement Line II Project,

Rajasthan

towards making EHS excellence a habit through training

programs and cultural events. Some projects also involve the June 2014 to December 2015

families of the workforce and sensitize them on safety at home 15 Godrej Garden City Ph-III Project,

apart from conducting health awareness camps. The safety Ahmedabad

July 2011 to December 2015

12 Omkar Bhoiwada Rehab Building

Project, Mumbai

audits conducted by the various sub-committees that get

formed during the safety month provide a clear insight on EHS June 2011 to December 2015

lapses if any and guide the project team on delivering results 15 Emami City Project, Kolkata

January 2013 to December 2015

by working on areas that need improvement.

15 DLF Capital Green Project, Moti Nagar

June 2014 to December 2015

4 HELMET, October - December 2015 HELMET, October - December 2015 5

BUILDINGS & FACTORIES

A closer look OSHAS standards. Team work played a

major role here.

With the prospect of a huge amount of

The EHSMS offers a systematic way

footfalls in the 1,70,000 sq. meter mall

to identify hazards and control risks

day in and day out, safety was one of

while assuring that the risk controls

the key criteria that had to be addressed

are effective. Like all management

when conceiving, designing and

systems, the EHS management system

executing the Mall of India. However,

also involves goal setting, planning, and

from an EHS perspective, a demanding

performance evaluation.

client like DLF expected only the highest

safety standards during execution which

was the challenge for the EHS team led Leading Indicators

by Kannan Subramanian.

Just as a pre-trip inspection can

We worked exactly based on the help prevent a vehicle from breaking

L&Ts Environment Health & Safety down during a road trip, the practice

Management Systems (EHSMS) and of planning ahead instead of waiting

its careful implementation resulted in for something bad to happen can

quantifiable and qualitative outcomes be applied to workplace safety in

that made even a giant like DLF and the form of leading indicators, says

expats like Du-Pont & Turner wonder Kannan. All measures were taken to

how an Indian construction company ensure that the project was completed

possessed a framework on par with incident free.

T

he Indian retail industry has

witnessed a dramatic change

in recent times. From just 3

Making of a safe retail in 2000, today there are a surfeit of

malls that have become shopping and

entertainment destinations for citizens

masterpiece

across social classes. The DLF Mall of

India, touted as one of the biggest in the

country, is all set to usher in a unique

mall experience for the people of Delhi

and its environs.

6 HELMET, October - December 2015 HELMET, October - December 2015 7

BUILDINGS & FACTORIES BUILDINGS & FACTORIES

workplace that could otherwise cause yy Temporary Electrical Distribution

incidents and injuries. System

yy Barricades for Excavation

The EHS team also conducted site

inspections, daily walk-downs, training yy The implementation level was

programmes along with regular EHS assessed on a monthly basis by the

meetings to monitor and provide team

current information about effective

performance, activities and processes Kaizen

of the EHS management system

The project team introduced the concept

implemented at site. The higher

of Kaizen for improving productivity

number of people trained, the safer the

which led to the creation of a culture of

work environment is going to be, says

improvement that was more a way of

Kannan. Caps for rebar

life than a policy.

Ensuring upward Sewage water treatment plant Engineering revisions

communication Based on L&Ts corporate EHS Policy-

MCWP (Mast Climbing Working

Instead of External scaffold

Platform)

Conserve natural resources, minimize

Upward communication was

waste generation & environment Material Hoist Instead of manual handling

encouraged among the workmen and a

emissions, a sewage treatment plant was

Dictaphone was effectively used for this Boom lift / Cradle Instead of Scaffolds External

installed at site to reduce the ground

purpose. Suggestions and near misses

water consumption and buying of raw Spider lift / Scissor Lift Instead of Scaffolds Internal

reported by the workmen were recorded

water.

regularly and this information helped Plaster machine Instead of Manual

the EHS team in ensuring Occupational Recycled water was used for internal Delay Start Mechanism Proactive control measures

Health and Safety. consumption such as landscape

work curing processes, toilets, dust Hydro jet water pumps Instead of acid wash

On spot appreciation sprinkling, gardening and permissible

Chemical earthing Alternation

to workmen for safe construction activities after quality

Anti-collision / Anemometer for tower

testing. Proactive control measures

behaviour cranes

In-house scaffolds

To further motivate workmen and

reinforce positive EHS behavior, a In line with the specification of the hired

reward system was introduced which scaffold, the site team made its own

was implemented in addition to the scaffolds of the same standard thereby

existing monthly reward system. The reducing the number of hired scaffolds.

EHS committee members during their Over 40 such scaffolds were made by

Safety improvement Safe-to-start work card walk downs rewarded the workmen for the site team during the peak periods of

slips A safe-to-start-work card system was

reinforcing safe behavior at work. August and September 2014.

implemented at site to ensure that the Implementation of Standard Twin Mast Climbing Working

All supervisors, engineers and managers

concerned supervisor or engineer looked Operating Procedure (SOP) Platform

were given safety improvement slips to

into any prevailing / possible hazards

report any unsafe act or unsafe condition yy Lift Shaft & Floor Opening The project introduced a Twin Mast

(what can go wrong) and indicated the

at site. This was seen as a positive Protection Climbing Working Platform for external

actual controls available at the work area

contribution to EHS management at site plaster work, which is safer and faster

(to prevent things from going wrong) in yy Working on Peripheral Platforms

and the employee was given positive than conventional methods. A multi-

the card. This helped in identifying and yy Builders Hoist Operations

scores while measuring his monthly functional hoist was used for carrying

eliminating or controlling risks at the

EHS performance. Street plays for a strong EHS message

8 HELMET, October - December 2015 HELMET, October - December 2015 9

BUILDINGS & FACTORIES

materials like sand bags, blocks, cement bags and other items

used for finishing with an additional guide railing provided for

Safety

of Honour

safety. R o ll

Finishes

Ceiling finishes were achieved using a Long Neck Ceiling

Grinder for the removal of enamel paint from the concrete Helmet congratulates the following sites for achieving

ceiling. The result was quick, easy, highly reliable and excellent.

two million and more LTI free safe man-hours

Completed incident free, the project has been recognized with

honours from the British Safety Council and National Safety

Council respectively. Its P&M has been awarded for top class

19 Kandla Mundra Road Project

April 2011 to December 2015

3 Mumbai Monorail

June 2013 to December 2015

operations and the project is LEED certified by Indian Green

Building Council.

15 Delhi Agra Road Project

October 2012 to December 2015

3 Vriddhachalam-Ariyalur Railway

Construction Project

December 2011 to December 2015

14 Samakhiali Gandhidham Road Project

October 2012 to December 2015 3 Hospet-Harlapur Railway

Construction Project

January 2013 to December 2015

7 Ganjbasoda Sanchi Railway

Construction Project

March 2010 to December 2015

2 Maithon Railway Siding Project

March 2010 to December 2015

Award for significant 6 Sambalpur Rourkela Road Project

July 2014 to December 2015 2 Rahuri Daund Railway

contribution to the Electrification Project

September 2010 to December 2015

EHS profession 5 10 MTPA Tata Steel Electrified Rail

Corridor Project

July 2009 to December 2015

2 Rajpura Railway Siding Project

April 2011 to December 2015

5 Chennai Metro Track works Project

February 2011 to December 2015 2 Bina-Ganjbasoda Railway

Construction Project

Mr. G. Madhava Kumar, Cluster EHS Manager, B&F IC Hyderabad Cluster, has won a prestigious award from D. L. Shah Trust

December 2012 to December 2015

and American Society of Safety Engineers (ASSE) for his significant contribution to the EHS profession in India. The award

was won amidst several such high quality submissions made by professionals from across the country. Mr. Madhava Kumar 5 KMDA Flyover Project

November 2012 to December 2015

received the award from Mr. Michael Belcher, President, ASSE, in the presence of Mr. Hari Taneja, Head, DL Shah Trust, and

other jury members at an event held at The Lalit Hotel, Mumbai, on October 15, 2015.

2 Wadi-Raichur Railway

Electrification Project

Committed to advancing the safety profession in India, the D. L. Shah Trust and American Society of Safety Engineers 4 Hyderabad Metro Track & OETS Project

January 2013 to December 2015

January 2012 to December 2015

announced the creation of an ongoing professional awards program. Consisting of three similar awards in the fields of

Occupational Safety and Health, Environmental Protection and Sustainability, the awards program recognizes excellence

and commitment to protecting people, property and the environment.

10 HELMET, October - December 2015 HELMET, October - December 2015 11

TRANSPORTATION INFRASTRUCTURE

Welding Machine located at the far end respective safety engineers to reach

of the depot detailing the world-class the Task Force Leaders (TFL) office

safety initiatives that he and his team where they are documented for further

have implemented. In my 25 years, I review. Monitoring is a challenge as

have handled engineers & workmen ours is a very linear project with about

of all nationalities and have realized 6000 workmen spread across 626 km.

that safety is a common area through Even the smallest error or oversight

which you can reach out to them to by the most insignificant person in the

make attitudinal change. At WDFC, we chain can prove to be the weakest link

are ensuring that the countrys largest that can put several lives in jeopardy.

railway job by a private player is right We must remain totally focused and

on track when it comes to safety, mobile, continually reinforcing the

pointing to the safety arrangements at safety messages to the many hundreds

the flash butt welding yard that ensure of construction sites on the project,

total protection to all operators. exclaims Nigel mopping the sweat

off his brow, standing in the morning

A global twist to the heat of the arid and windswept region.

Stopping by a stationary and unmanned

regional fare grading machine, Nigel peers inside and

pockets the keys that are in the ignition.

Across WDFC, it is mandatory for Unable to find the operator, he points to

workmen to assemble and take the safety a green sticker and explains that it is a

pledge followed by a brief tool box talk fitness certificate for the equipment to

at the beginning of every shift. Safety be deployed at the project. Going over

communication is key across the safety to the Plant & Machinery department,

function and within minutes, pictures Nigel approaches the in-charge to

of the event and safety observations investigate why the grader has been

are shared through WhatsApp by the left unmanned and gets granular on the

Working in close proximity to a live railway line

S

afety as a subject matter can be

interesting as a large group of

Staying right on the

workmen realize as they hang

onto every word from the towering figure

of Wirtz Nigel Cameron, Head EHS, who

is explaining its importance in everyday

tracks in terms of safety work life. With his discourse laced with

a bit of Hindi, this British safety expert

has been addressing them as part of the

tool box talk at the expansive Bhagega

depot. Ending his sharp briefing, Nigel

starts to walk over to the Flash Butt

12 HELMET, October - December 2015 HELMET, October - December 2015 13

TRANSPORTATION INFRASTRUCTURE TRANSPORTATION INFRASTRUCTURE

perils of leaving a construction machine We approach safety with an ownership perils of working at a railway project. We the potential of causing death or serious

unmanned while in close proximity to based concept because it is not merely often notice, much to our horror, that injuries are listed under Class 1 and

a live railway line. The driver is later the function of a single department but the existing track becomes a favorite highest thrust is given to this area. We

summoned and cautioned on this lapse a coordinated effort of all present at resting area for the workmen. With a first identify the hazards, evaluate risks,

before we proceed to the site office. the project sites. The entire project, he train plying once every 20 minutes, it is work on control measures, implement

elaborates, has been divided into four extremely risky to do so. Workmen are them diligently and follow up with

Putting systems on sections and the EHS department has categorically told never to venture into periodic reviews. Very often, we develop

further divided each of these sections the existing track area unnecessarily. an easy to follow 10 point safe work

track into 3 smaller sections of 50 km each We have even implemented punitive method which becomes sacrosanct for

Sitting in the cool comfort of the for greater focus. Fourteen such sections measures to dissuade them from the entire workforce. Workmen are also

site office, Nigel meets with his team located throughout the project make up breaking this rule, asserts Nigel and adds encouraged to report all incidents as

over various trackers and monitoring the complete EHS set-up including an that in certain stretches IP cameras have this prevents repeat occurrences and

systems that have been developed ambulance each to cater to emergencies. been set-up to monitor implementation. thereby save precious lives.

to ensure proper conduct of training

programs, audits and implementation

A colleague presents us a couple of

pocket-sized booklets in Hindi and

Class 1 focus On the pulse of a live

of EHS initiatives. In almost every

English that detail the EHS systems The team has classified the risks with issue

domain, the enormous data of monthly

and even provides key information on special emphasis on Class 1 risks that

achievement figures smartly fit onto a Topping the chart of Class 1 risks is

emergency response systems. Apart include working near live railway

simple A3 sheet. Our ultimate motto the task of having to work in close

from basic and mandatory safety lines, at heights, involving vehicles

is to achieve international safety proximity to a live railway track.

inductions, all the employees and & cranes, plant & equipment, use of

standards by meeting and exceeding Explicit permissions from the Indian

workmen are provided with this ready explosives, excavations and working

the clients and L&Ts EHS requirements. Railways are necessary to carry out

reckoner that educates them on the with electricity. All activities that have

any activity 3.5 m from the centre of

the track. This includes exercising Barricades at the flash butt welding area

speed regulations and, if necessary,

stoppage of services for a brief period.

We installed a fencing system to

demarcate the sensitive zones. All

vehicles and construction equipment

are strictly prohibited from entering

the fenced zone. For abundant safety,

we have a look-out and a flagman

whose only job is to alert the team on

train movements. According to the

EHS team, the biggest issue is that the

IR cables that should be buried 1.5 m

belowground are most often found

at much shallower depths, sometimes

even in uncharted territories. This

is why excavation is carried out

with immense caution and in case

of any infringement, the matter is

immediately escalated to the highest

level so as to avoid penal action which

could even mean imprisonment

because stoppage of train services falls

under the terrorists act.

14 HELMET, October - December 2015 HELMET, October - December 2015 15

TRANSPORTATION INFRASTRUCTURE

a special Back to School campaign that

promotes education by providing free

Safety

of Honour

study kits to underprivileged children. R o ll

A good rapport has been forged with

the many communities through such

initiatives to create a hassle-free work

environment. Additionally, the villages Helmet congratulates the following sites for achieving

have also been made aware to avoid

riding on the newly laid formation beds one million and more LTI free safe man-hours

which could affect project quality as

well as very risky for individuals.

The entire construction team has 4 BSNL-MOD NFS OFC PKG- E-BSNL 1 765/400 KV GIS Varanasi

been sensitized on safeguarding October 2014 December 2015 New EXT-PGCIL

the environment and apart from November 2013 to December 2015

regular monitoring of air quality and 3 400 kV Raipur - Jagadalpur

suppression of dust with sprinkler November 2013 to December 2015

trucks, the team is also careful to protect 1 Pkg C Jharkhand-PGCIL

December 2012 to December 2015

certain rare species of flora and fauna.

Safely shifting the head hardened rails

The WDFC project was chosen by NACO 2 400 kV Jammalamadugu to

Uravuakonda TL

Creating a rubric hot, the nights can get unbearably

cold. Added to this extreme climatic

(National Aids Control Organization) for

May 2015 to December 2015 1 R-APDRP Part-B Works - KSEB,

Kozhikode - Kerala

implementing an employer-led model

For the very first time in the history of condition is the danger of encountering of train the trainer program under March 2015 to October 2015

the Indian Railways, imported automatic poisonous reptiles while working in which the EHS personnel who were 1 400/220 kV Switchyard Package,

KAPP 3 & 4 - NPCIL

track laying machines and equipment the wilderness. Even the soil is very trained by the NACO team continually

have been pressed into service. Though soft and unpredictable especially in create awareness on HIV/Aids and other July 2011 to December 2015 1 800 kV Champa to Kurukshetra -

Pkg 6 - PGCIL

state-of-the-art and built incorporating the mountainous terrain making potential diseases among the workmen

May 2015 to December 2015

all safety parameters, some simple and

easy to understand safety guidelines

excavation and blasting tough safety

challenges. In some areas, we have

across the project sites.

1 2 X 600 MW STTP Athena

January 2012 to December 2015

have been prepared for the workforce to cross underground oil and gas A hands-on approach

operating these machines. While the pipelines with extreme caution, be it

flash butt welding machine warranted for controlled blasting or even simple Our focus is on living injury free each Correct answers

complete barricades and special eye hill cuts, describes Nigel. Two years of day and we are very particular that we yy Lack of protection against soil collapse

working in Rajasthan has conditioned do not hinder train operations on the and excavation area not barricaded

wear, the tamping, ballast regulation

the team, he feels, that is now competent existing track. Our monitoring and yy Exclusion zone not provided around

and new track construction machines excavation - Vehicle movement near

enough to handle even unprecedented management systems ensure that EHS

required sound operating knowledge edge of excavation

awareness is high and that we only

and seamless coordination among the floods and heavy monsoons. We are

not sure if we have tamed the wild or have to sustain it to get tangible results.

Spot the yy Safety beacon lights not installed

operators. The head hardened rail yard yy Water stagnation in excavation area

HAZARDS

got ourselves tamed in the process, but Our weekly audits, surprise checks and workmen engaged in pile head

was demarcated as out of bounds during

the consequence is that we are now well and stakeholder engagement have all chipping

the shifting of the 250 m long rails as

acclimatized, winks Nigel. created a high level of EHS performance yy Stock pile and construction material

there was the danger of unauthorized

WINNERS

and we have already crossed 15 million stored close to the edge of excavation

entry causing incidents. yy Gas cylinders placed near excavator

A conjoint operation incident free man hours. Safety starts

D. Sriram yy Excavator swing area not isolated

right at the design stage, believes

Taming an unforgiving Speaking on community welfare Nigel and should be managed through

Asst. Manager EHS, Buildings & Factories yy No safe access & egress into

excavation

terrain initiatives, the EHS team shares that proper planning and right through the Umang Chimalwar

Asst. Manager EHS, Heavy Civil Infrastructure yy Improper usage of PPE like helmets &

apart from periodic health awareness execution process. reflective jackets

Rajasthan can be quite unforgiving. camps and tree plantation drives, the Maulick Shah yy Improper housekeeping

While the days are swelteringly Manager, Ahmedabad Cluster, Buildings & Factories

project team has laid great emphasis on

16 HELMET, October - December 2015 HELMET, October - December 2015 17

POWER TRANSMISSION & DISTRIBUTION

a sandy zone with close to 5 km of the

alignment running through backwaters

Working out the

and 3 km of underground cabling methodology

along the shoreline. Working in such

The client was on the ball with a

challenging terrains called for a range of

specific quality and safety system and

on-field innovations to be implemented

timely audits for all activities hence it

to facilitate execution. Heres what

was imperative to develop a thorough

Christopher A Fontecha, Manager EHS,

method statement. To create a secure

had to say on how Team L&T achieved

work system, an internal safety plan

the milestones adhering to the highest

was formulated after approval from

safety standards.

the client which detailed the work

Double checking the procedures and schedules. Workmen

were trained on 5S implementation

two-way alignment through mock drills to prepare them

As the alignment was strategically to meet the specific work-in-progress

divided at Wasit and Abu Ali running audits conducted by the client, says

to 26.24 and 29.94 kms respectively, two Christopher. The team identified

EHS committees were formed to double most of the intense tasks such as

check the prerequisites, highlights excavation, preparing the access

Christopher. Further, each stretch routes, civil and mechanical works

functioned as an independent site and and stipulated sequential steps after

the execution teams were guided on making a thorough review of the work

the high risk activities through job process based on the on-site conditions.

safety analysis reports by the respective Vehicular routing was meticulously

committees. planned as the project involved the

movement of a large number of heavy

Defining the access equipment such as rigs and cranes on

zone sandy terrain and a Minimum Vehicle

Safety Management Programme was

As most of the alignment was across also put in place. Christopher adds, At

an arid terrain, it was imperative to some stretches of the alignment, the

chart a secure access route, begins road access was re-routed to balance

Christopher, and the EHS team worked the heavy traffic that hindered the

in tandem with the survey units to ground works.

predefine the route for execution by

T

he Power Transmission

avoiding some stretches that had a type

of soil called Sabhka known for its low

Backing up through

& Distribution IC of L&T

bearing strength and compressibility. certified P&M

Construction has added yet

Though the land related challenges

Making a powerful

another benchmark to its list of All major activities such as foundation

were approachable, the tough part was

illustrious projects by upgrading the works, installation of tower elements,

where the alignment cut across 5 km

existing power infrastructure system stringing, and underground cabling

of slushy backwaters. We raised an

for Saudi Aramco, the worlds largest were executed safely by deploying

impact

island to erect the towers in this stretch

crude oil exporter at its Abu Ali gas plant client certified Plant & Machinery

by dumping sand from an adjacent dry

to enable the facility meet its future (P&M). During tower works, the wind

bed in a phased manner. A total of 684

electrical demand load. The project factor had to be constantly monitored

piles across 155 locations were cast in

involved construction of a double and it was mandatory to suspend work

place after defining the safe zones for

circuit overhead transmission line in if the wind speed went above 32 km/hr,

the tower and gantry locations.

18 HELMET, October - December 2015 HELMET, October - December 2015 19

POWER TRANSMISSION & DISTRIBUTION

shares Christopher. The towers were

erected by deploying 250 t telescopic

Strategizing the cross controlled by the Royal Commission of

Jubail and Saudi Electricity Company.

Safety

cranes and the stringing works with overs A comprehensive safety document R o ll

of Honour

tensioners; pullers and man lifts were Execution of cross overs called for was evolved at site taking into

used for wire clipping and jumper some in-depth strategizing as the line consideration the requirements of the

installations. passed over a highway and substation external stake holders for executing the

works. Working inside the energized Helmet congratulates the following sites for achieving

substation required thorough vigilance

and the team secured the passage way four million and more LTI free safe man-hours

by installing goal posts and flags to mark

the sensitive zones. Further, a dedicated

person was assigned to monitor the

movement of the crane boom and

15 Storm Water Drainage Works - Jabalpur 4 Nalgonda UGD & WSS

ensure that it was well away from the

energized lines.

6 Hoshiarpur & Jalandhar Sewerage Scheme 4 GDWSS Hyderabad

Ensuring robust 5 Hogenikal Waater Suply Project PKG 5 3 UFW-D2B - Bangalore

support 5 Kamal Vihar Project Raipur 3 Garden Reach Water Supply Project

Considering the desert environment

and the possibility of strong winds while

working at heights, the project team

4 GIDC-DAHEJ Water Supply Project, 3 Ratangarh - Sujangarh Water Supply

25 & 50 MGD Project

availed the most appropriate PPEs such

as the latest model of safety harnesses

with provision for work positioning belt,

4 UGDS & WSIS - Nizamabad 3 Jawai Cluster Distribution Project

back rest and additional D rings in the

front for anchoring the rope grab device

4 Trans Varuna Sewerage Work - Varanasi

on to the vertical lifeline along with

suspension trauma prevention straps.

The erection and stringing gangs were

also provided with an emergency rescue

kit to quickly bring down those who

required medical attention.

Reinforcing the clients

trust

L&Ts role in putting together a major

part of the power system in a secure

manner was acknowledged by the client

as it facilitated the other EPC players

Spot the

HAZARDS

to seamlessly integrate the subsea and

underground works. For the safety team

there were lots of gains after the hard

work beams Christopher, We achieved

an overall Project Safety Index of 93%, If you have spotted the hazards, rush it to

clocked more than 8 lakh million safe ngfernandez@lntecc.com.

man hours and bagged two major

Tower erection in progress international safety accolades.

20 HELMET, October - December 2015 HELMET, October - December 2015 21

WATER SMART WORLD & COMMUNICATION

84 km, L&T has completed 90% of the spiral submerged arc welding process

works that will link 21 dams along the and later inspected for hydro and non-

stretch. Here are insights from Ganesh destructive quality tests. Close to 83801

Sadashiv Gadade, Sr. Engineer EHS on RMT of steel was bent to a dia of 3000

how the team achieved this milestone mm with each unit weighing close to

with a zero incident record within a 17 t and having a plate thickness of 17.5

stringent schedule of 24 months. mm.

Assessing from ground Customizing a safe

level channel way

As the alignment predominantly passed Mitigating the risks involved during

through farmlands it was important to excavation was crucial as 85% of the

assess the risk factors before we stepped pipeline passed through hard rock

in, highlights Ganesh. The first task was indicates Ganesh. We were the first

a line survey to review the type of land among all the EPC contractors to plan

ownership, ground elevation, soil profile the schedule for pipe laying in a safe

and the bottlenecks along the way such manner that involved establishing a

as major land and water body crossings. range of innovative material handling

The alignment passed through 2 major systems. To start off, the EHS team

rivers, national and state highways, hilly informed the locals about the hazards

terrain, railway crossing and a crude through megaphones and cordoned off

oil line, points out Ganesh, so it was the area. To make the system further

imperative to schedule the works with fool proof, the team deployed safety

as little disturbance as possible and accessories such as blasting mats to

complete the tasks in a secure manner minimize the risk of hazards. More

by signing off with a No Objection than 12,00,000 cu.m of hard rock was

Certificate from the various stake excavated by the team as per the SOPs

holders. The project team approached using licensed blasters after obtaining

the task in a phased manner by dividing permissions from the Collector and

the alignment into stretches and specific Mamlatdar. The above ground

teams were earmarked to achieve the clearances were equally important for

milestones. at many locations, power lines were

Orienting the crew on oil pipeline crossing passing along the ROU and the team had

to come up with on-site solutions such

Casting the conduits as height extension of the electric poles,

with precision

L

&Ts Industrial Water Supply BU is availing temporary shutdowns to meet

the safety requirements.

executing a slew of lift irrigation Measuring close to 10 feet, these were

Safety comes in different shapes

schemes across the country some of the biggest pipelines in Asia, About 2.5 km of the alignment passes

among which is the Saurashtra Narmada shares Ganesh about the sheer size of through a hilly terrain which called

Avtaran Irrigation (SAUNI) Yojana the fabricated conduits. Two of the for enhancing the trench depth up

and sizes; each as important scheme, the largest lift irrigation project

undertaken in India which envisions

filling up of 115 irrigation dams across

most reliable pipe manufacturers were

roped in to handle the requirements

to 22 m to mitigate the hydraulic

gradient. By deploying a pilot vehicle,

as the other

of the packages. As the manufacturing the team assessed the ROU and made

the eleven districts in 900 villages of process involved a huge amount of timely improvisations to facilitate the

Saurashtra from the surplus waters of quality welding, separate teams were transportation of pipelines from the

the Narmada river. Entrusted with two formed to inspect the works which was stockyard after winning the trust of the

key packages Link 3 and 4 running to carried out through a special helical locals and the government bodies.

22 HELMET, October - December 2015 HELMET, October - December 2015 23

WATER SMART WORLD & COMMUNICATION WATER SMART WORLD & COMMUNICATION

Going by the rulebook Permit to work Streamlining the piping mm wide weld pit inside the pipeline

trench that could accommodate a crew

The EHS team formulated a Being a long span project it was important laying process of 4. A special type of fall arrestor

comprehensive task list after taking to establish a system to monitor work The crux of this project was in getting system was introduced and by listing

updates from the survey and customized across sections and the project team the right kind of heavy lift equipment to out all procedures, the team ensured

SOPs for the different activities along implemented the Permit to Work handle the pipe laying. We approached that the task was safely completed

the alignment. Elaborating on the risk system which provided access to work this task in a phased manner by zoning with the clients approval. Close to 456

management done at site, Ganesh says, spots, minimized risks and assessed t of electrodes have been consumed

100 m as one stretch and allocated 8

Hazards identification was carried out the safe conditions at site. The 'Safe at site for the jointing works and post

pipes within that area and deployed a

involving experienced execution teams Execution Cards system was introduced welding works covered a range of

dozen 75 t cranes thereby guaranteeing

to track and focus on critical aspects of which added value to the existing safety assessments tests, stable backfilling

a safe working radius of 12 m to

safety during execution. To make the initiatives such as monthly safety walk and levelling."

facilitate the process. The EHS team

system more robust, workmen were downs, PEP talks and rewards schemes. also ensured on-site inspections and

oriented before every activity with a At times, it was necessary to illustrate load tests of the heavy equipment for

Crossing over

rewards scheme to motivate achievers.

As we were dealing with mega

through examples, asserts Ganesh. safe laying of pipes and implemented with care

When one of the agencies was found the task only through authorized

dimension pipelines, on the job training violating safety norms, the project team Crossing over the 24/7, 365-day live

operators.

was imparted through e-learning was quick to identify and terminate the 10 m crude oil pipe line was most

videos, emergency preparedness and services which sent a strong message Having put the pipes in line, a secure challenging and to mitigate the risks

mock drills to assimilate the actuals that we were serious about adhering to strategy for joint welding was evolved involved, the EHS team carried out

risks involved. a safe work culture at site. by creating a 500 mm deep and 1000 a detailed survey to assess the on-

site conditions by roping in officials

of Bharath Oman Refineries and

Leading the safety

finally concluded that the only way charge

forward was through push method

Working alongside multiple EPC

of excavation as blasting around the

contractors was an advantage according

site premises was prohibited. A skilled

to Ganesh. We were looked upon as the

crew was handpicked for executing

best and the onus was to lead by example

this task and the EHS team drew up a

and set benchmarks for others to follow.

detailed mock-up scheme to further

Team L&T drove this point down the

illustrate the actual hazards and the

line and ensured that in addition to the

precise procedures to be followed.

systems and procedures implemented

Ganesh concedes that the task was

there were also a range of on-site

laborious with the excavation through

environmental conscious initiatives

rock breakers and even manual at

such as segregating welding rod waste,

some critical areas. To further stabilize

finding value for it in the scrap market

the works, a MS casing pipe was

and using the money for workmen

installed during the pipe pushing and

welfare which largely motivated the

laying works. The project team was

team and made sure that the site clocked

able to complete this critical task

1 million incident free hours, he

within one and half months which

sums up with the satisfaction of a job

earned the appreciation of the client

well done.

and the BORL officials.

Joint welding

24 HELMET, October - December 2015 HELMET, October - December 2015 25

Maximum allowed exposure as per Indian

legislation

Total Time of Exposure

(continuous / or number of Sound pressure level

short-term exposures) per (in dBA)

day (in hours)

8 90

A sound idea to deafen the clamor 4 95

2 100

1 105

110

A

construction site is more often heard rather than yy Difficulty in catching certain sounds or getting confused 115

seen. Despite sophistication and mechanization of with similar sounding words

construction activities, construction sites continue

to be high risk sources for noise related ill health. Concrete

yy Ringing, whistling, buzzing or humming in the ears The mitigation move feedback to make suitable alterations to

perfect the programme.

Because they can be mass produced, are

economical and disposable, ear plugs

pumps, DG units, impacting tools, creaky hoists and blasting yy Depression and loss of sleep

The surest way to prevent occupational have become a popular choice in the

can all produce noise that is far beyond accepted levels. Of the more popular hearing protection construction industry. However, it is

deafness is to reduce noise at source

While the list of sources for noise creation in a construction devices are the ear plugs which are important to follow the manufacturers

through innovative engineering

site is pretty long, what is more worrying is that a pair of small foam based implements that are

Typical noise levels at construction sites methods. However, there are limitations instructions to get the right fit inside

equipment working in tandem can have a multiplier effect inserted to block the ear canal. Sold the ear for effective noise reduction.

to this approach. Not all equipment /

on noise levels and equipment of various trades operating as both disposable and reusable types, Usually it is advised to pull the ear

processes can be modified to produce

together in a busy construction site can exponentially DECIBEL - dB(A) EQUIPMENT there are custom molded versions also lobe upward and outward to straighten

lesser operating noise. For instance,

increase noise output. available in the market for a perfect the ear canal before inserting the plug

while a generator unit can be silenced

Pile driver fit. Ear muffs are other very popular using clean hands. Experts also insist

It is equally worrying that many people are not even aware Double protection 112 using special padding and muffling

recommended 110 Air arcing gouging hearing protection devices that are that ear plugs should be worn all the

of this serious threat that can impact both their physical and above 105 dB(A) 108 Impact wrench devices, a grinding tool cannot be,

made of sound-attenuating material time when in a noisy environment to

psychological wellbeing. A simple thumb-rule to know if 107 Bulldozer - no muffle owing to the nature of the process. But

102-104 Air grinder and soft ear cushions that fit around derive its full benefit. Intermittently

you are exposed to noise pollution is to observe if you can based on the risks involved, workmen

102 Crane - uninsulated cab the ear and come with hard outer cups.

Bulldozer - no cab can certainly use hearing protection to removing the plugs, even for a short

have a normal conversation while standing about 2 m away 101-103

These cups are held together by a head

97 Chipping concrete minimize the impact of noise reaching duration, can substantially reduce its

from another person. If you have to raise your voice to be 96 Circular saw and hammering band.

their ears. effectiveness.

heard even for a few minutes in a day, it means that you 96 Jack hammer

96 Quick-cut saw

are a victim of noise pollution! Experts opine that getting Based on the level of noise, comfort, and It is also necessary to frequently check

exposed to 80 decibels of noise over 8 hours can potentially

95

94

Masonry saw

Compactor - no cab

Listen to what the the desired noise reduction, a suitable the ear plugs / muffs for wear and tear,

harm an individual and noise above 115 decibels has to be Hearing protection

recommended

90

87

Crane - insulated cab

Loader/backhoe - insulated cab

experts have to say option can be chosen. Normally, if any, and replace the cushions in the

completely avoided. earplugs are meant for environments case of muffs. Some versions of ear

above 85 dB(A) 86 Grinder

85-90 Welding machine Considered the last line of defense, that remain noisy for long periods of plugs are washable to remove skin oil

Exposure to noise can cause both acute and chronic disorders 85 Bulldozer - insulated cab hearing protection devices help reduce time and it would be inconvenient to

Speaking voice and dirt which can cause infection.

including acoustic trauma or a gradually developing noise 60-70

exposure to noise that is beyond keep removing and reinserting them Periodic cleaning of hearing protectors

induced hearing loss which may result in the following 85 decibels. However, it should be often. For such intermittent exposure is mandatory to avoid infection and if

discomforts: chosen following a complete hearing to noise, ear muffs are more suitable.

Though there are regulations to control noise levels at damaged or dirtied beyond redemption,

industrial settings, these are hardly adhered to or diligently conservation program that begins with While ear plugs are personal, compact, it would be a sound idea to replace them

yy Normal conversation becomes difficult

implemented. professional noise assessment, selection convenient and easy to wear, ear muffs with new ones to deafen the clamor.

yy Trouble using the telephone or watching television with of the right hearing protectors based are large and do not fit easily over other

normal sound on the results and later followed up on PPEs such as helmets and goggles.

26 HELMET, October - December 2015 HELMET, October - December 2015 27

L&T-ites take to the roads to

create awareness on safety

ROAD SAFETY

TIME FOR

ACTION NOW!

The Ministry of Road Transport and Highways observed Road Safety Week between 10 and 16 January

2016. Project sites across L&T conducted rallies and demonstrations to infuse this years Road Safety

Week theme, "Road Safety Time for Action," among road users. At HQ Chennai, a Walkathon was

conducted from L&Ts Manapakkam Campus to the Porur junction on 10th of January 2016 in which

about 300 enthusiastic L&T-ites and their family members participated to increase the awareness on

road safety.

Edited by Mr. Vinod Jacob Chacko for L&T Construction from L&T Construction Headquarters, Manapakkam, Chennai - 600 089. The views

expressed in this magazine are not necessarily those of the Management. The contents of this magazine may not be reproduced without the

written permission of the Editor. Not for sale. Only for circulation among employees of L&T Construction.

You might also like

- I Z K:i K F Odk L K S Tuk: Akbsna (Mmrda)Document1 pageI Z K:i K F Odk L K S Tuk: Akbsna (Mmrda)AS VatsalNo ratings yet

- Nsunder W: AH R 5 R Llutıon Contr L Bo DDocument2 pagesNsunder W: AH R 5 R Llutıon Contr L Bo DAS VatsalNo ratings yet

- Case ListDocument4 pagesCase ListAS VatsalNo ratings yet

- ConsentDocument4 pagesConsentAS VatsalNo ratings yet

- Looking For Higher StandardsDocument16 pagesLooking For Higher StandardsAS VatsalNo ratings yet

- Fall ProtectorDocument20 pagesFall ProtectorAS VatsalNo ratings yet

- Air TronDocument12 pagesAir TronAS VatsalNo ratings yet

- Air TronDocument12 pagesAir TronAS VatsalNo ratings yet

- Coram: Hon'Ble Dr. Justice Jawad Rahim, Acting Chairperson Hon'Ble Mr. Justice S.P. Wangdi, Judicial Member Hon'Ble Dr. Nagin Nanda, Expert MemberDocument3 pagesCoram: Hon'Ble Dr. Justice Jawad Rahim, Acting Chairperson Hon'Ble Mr. Justice S.P. Wangdi, Judicial Member Hon'Ble Dr. Nagin Nanda, Expert MemberAS VatsalNo ratings yet

- 02 Why Safety2Document44 pages02 Why Safety2Kundan KumarNo ratings yet

- 2012 Green Plumbing Mechanical CodeDocument173 pages2012 Green Plumbing Mechanical CodeAS VatsalNo ratings yet

- Chemical Mixing Compatibility Chart: (To Assist With Safe Chemical Segregation)Document1 pageChemical Mixing Compatibility Chart: (To Assist With Safe Chemical Segregation)AS VatsalNo ratings yet

- Blackboard PPT TemplateDocument1 pageBlackboard PPT Templateejikieru03No ratings yet

- Maharashtra Industry Minutes Provide InsightsDocument36 pagesMaharashtra Industry Minutes Provide InsightsAS VatsalNo ratings yet

- Behavior SafetyDocument49 pagesBehavior SafetyMelanie100% (1)

- Type Description % Trigger ColourDocument19 pagesType Description % Trigger ColourAS VatsalNo ratings yet

- Waterfall Chart TemplateDocument3 pagesWaterfall Chart TemplateAS VatsalNo ratings yet

- Sarpa MitraDocument2 pagesSarpa MitraAS VatsalNo ratings yet

- Looking For Higher StandardsDocument16 pagesLooking For Higher StandardsAS VatsalNo ratings yet

- Visitor Policy 2012Document2 pagesVisitor Policy 2012AS VatsalNo ratings yet

- 08 - Water Efficient ProductsDocument5 pages08 - Water Efficient ProductsAS VatsalNo ratings yet

- PWM NewsletterDocument6 pagesPWM NewsletterAS VatsalNo ratings yet

- Helmet Oct14Document23 pagesHelmet Oct14AS VatsalNo ratings yet

- Helmet Mar15Document36 pagesHelmet Mar15AS VatsalNo ratings yet

- Helmet NewsDocument21 pagesHelmet NewsAS VatsalNo ratings yet

- Helmet NewsDocument21 pagesHelmet NewsAS VatsalNo ratings yet

- Helmet Jul15Document25 pagesHelmet Jul15AS VatsalNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Role of Physiotherapy in The Management of Functional Neurological Disorder in Children and AdolescentsDocument13 pagesThe Role of Physiotherapy in The Management of Functional Neurological Disorder in Children and AdolescentsLIZETH MUnOZ SOLARTENo ratings yet

- Principles in Trauma ManagementDocument34 pagesPrinciples in Trauma Managementvirz23No ratings yet

- FatigueDocument8 pagesFatigueSabeeh Ul HassanNo ratings yet

- NIOSH Hazardous DrugsDocument22 pagesNIOSH Hazardous DrugsjimstasonNo ratings yet

- Exploring the skills and qualities of effective counselingDocument12 pagesExploring the skills and qualities of effective counselingDinesh Cidoc100% (3)

- Ijoto2016 4817429Document6 pagesIjoto2016 4817429Devi Arnes SimanjuntakNo ratings yet

- ArdsDocument29 pagesArdsAmani KayedNo ratings yet

- Fibromyalgia Acupressure TherapyDocument3 pagesFibromyalgia Acupressure TherapyactoolNo ratings yet

- Hypoxia: Deficiency in Oxygen Delivery or Utilization at Tissue LevelDocument37 pagesHypoxia: Deficiency in Oxygen Delivery or Utilization at Tissue LevelandrenicholastobingNo ratings yet

- Cobb - Endoscopic Carpal Tunnel ReleaseDocument8 pagesCobb - Endoscopic Carpal Tunnel ReleaseJohnny WangNo ratings yet

- Implant Supported Overdenture: Presented By:-Dr. Anuja Gunjal 19/01/18Document93 pagesImplant Supported Overdenture: Presented By:-Dr. Anuja Gunjal 19/01/18Instrument SeparationNo ratings yet

- Free Nutrition Practice Test QuestionsDocument4 pagesFree Nutrition Practice Test QuestionsDalbir SinghNo ratings yet

- The Aetiology and Management of Atrophic RhinitisDocument11 pagesThe Aetiology and Management of Atrophic Rhinitisanoop_aiims1No ratings yet

- Integrated Management of Childhood Illnes1Document5 pagesIntegrated Management of Childhood Illnes1Ryan VocalanNo ratings yet

- Senthil Papers and BoardDocument4 pagesSenthil Papers and BoardRamakrishnan RajappanNo ratings yet

- Neurologic Music Therapy Improves Executive Function and Emotional Adjustment in Traumatic Brain Injury RehabilitationDocument11 pagesNeurologic Music Therapy Improves Executive Function and Emotional Adjustment in Traumatic Brain Injury RehabilitationTlaloc GonzalezNo ratings yet

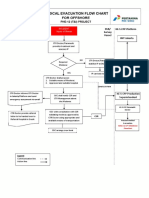

- 3-A4 - Medical Evacuation Flow Chart (Rev.0)Document1 page3-A4 - Medical Evacuation Flow Chart (Rev.0)SiskaNo ratings yet

- Psychiatric Nursing ProcessDocument24 pagesPsychiatric Nursing ProcessJoric MagusaraNo ratings yet

- MSDS of Soda AshDocument3 pagesMSDS of Soda AshAtif IqbalNo ratings yet

- The Addiction Casebook - Chap 04Document11 pagesThe Addiction Casebook - Chap 04Glaucia MarollaNo ratings yet

- Ankle Dislocations Health Conference 2010Document16 pagesAnkle Dislocations Health Conference 2010Aswan IsmailNo ratings yet

- AMC Recalls 2014Document99 pagesAMC Recalls 2014saleema1175% (4)

- Presentation 1Document17 pagesPresentation 1api-547492718No ratings yet

- The Power of Being Present in The Moment in Polyphonic DialoguesDocument46 pagesThe Power of Being Present in The Moment in Polyphonic DialoguesJoão Vitor Moreira MaiaNo ratings yet

- Neonatal Resuscitation Power PointDocument29 pagesNeonatal Resuscitation Power PointsameerarswNo ratings yet

- Article - Importance of Fruits, Nuts, and Vegetables in Human Nutrition and HealthDocument3 pagesArticle - Importance of Fruits, Nuts, and Vegetables in Human Nutrition and HealthAlena JosephNo ratings yet

- Stevia Global MarketDocument12 pagesStevia Global MarketPratibha Singh50% (2)

- Clopidogrel Plus Aspirin Versus Aspirn Alone For Acute Minor Ischaemic Stroke or High Risk TIA. BMJ Dec 2018Document10 pagesClopidogrel Plus Aspirin Versus Aspirn Alone For Acute Minor Ischaemic Stroke or High Risk TIA. BMJ Dec 2018oussama dieselNo ratings yet

- Chapter 10Document32 pagesChapter 10Anna MartinNo ratings yet

- Amen ADD QuestionnaireDocument3 pagesAmen ADD QuestionnaireReeshabhdev GauttamNo ratings yet