Professional Documents

Culture Documents

40863-001 Calc - Inline Heater PDF

Uploaded by

omar equihuaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40863-001 Calc - Inline Heater PDF

Uploaded by

omar equihuaCopyright:

Available Formats

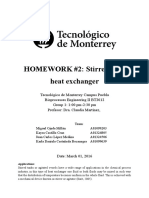

Title: Date : 17-03-15

Sinus Jevi Electric Heating

ELECTRIC IN-LINE HEATER

Aambeeld 19, 1671 NT Rev. no : 40.863-001

THERMAL CALCULATION

Medemblik, The Netherlands Project : GNU Gas Natural

Tel. +31 (0)227 549100

RESULTS Item : 115kW Ex- Immersion

Prepared by : Dennis Lauwers CASE : Normal Operation Sheet : 1 of 4

PROCESS PARAMETERS PROPERTIES FLUID note

Medium to be heated [-] Natural Gas Spec. gravity [kg/m3] 16,99

Fluid [-] Vapour Spec.Heat (P=const) Cp [J/kgK] 2340

Skin temp. allow. / calc. [C] TBA / 97 Thermal conductivity [W/mK] 3,50E-02

Pressure drop allow. / calc. [Bar] 0,5 / 0,2232 Dynamic viscosity [PaS] 1,08E-05

Heat flux allow. / calc. W/cm 2 7,5 / 6,87 Note: properties at avarage temperature Tav = (Tin + Tout) = 11 C

INLET CONDITIONS OUTLET CONDITIONS

Tin [C] 1,00 Tout [C] 21,12

Mass flow [kg/h] 7645,00 Flow [m3/h] 449,97

Pressure [Barg] 20,00 Pressure [Barg] 19,777

Pressure drop P = 0,2232 Bar Vout = 15,91 m/s

Cooling distance

H= 150 Heated length = 1750 Dimensions [mm]

100 DIMENSION ARE PRELIMINARY 100 Bundle Dia 180

93 93 Baffle Dia 190

Elm.Dia 12,7

first baffle last baffle

55 Elm.pitch vert. 26

Number of baffles: 9 (Segmental type) 200 Elm.pitch hor. 26

No. of rows 8

baffle pitch Baffle opening 349 Elm. Config. Triangular

370 183 24% from cross section surface area.

29% from baffle diameter.

Ex-equipment : N/A

Temp. [C]

T1 (<450C) H=250 mm

T2 (<300C) H=200 mm Element temp. Tskin Tskin= 97 full load+fouling

T3 (<200C) H=150 mm Tskin= 85 reduced load+fouling

T4 (<135C) H=100 mm Tskin= 91 full load

T5 (<100C) H=75 mm 86 Tskin= 79 reduced load Note 1

T6 (<85C) H=50 mm 75

Note : Tamb = 50C max. 79 Tout= 24 full load

69 Natural Gas temp.

L1, L2, L3

Tout= 21 reduced load

thyristor

4-20 mA signal

Tin = 1 Reduced load due to thyristor

control P= 99,98 kW

0 Heated length [m] 1,75 Full load without thyristor

Note 1 : calculated temperature values are only valid when control P = 115 kW

115 kW the heater is operating with full (100%) thyristor power controller.

ELECTRIC DATA HEATTRANSFER DATA (Tubular elements)

Total power installed [kW] 115,00 Note 7 Total heattransfer area AVO [m2] 1,68

Supply Voltage (3 Ph) [V] 400 (L1,L2,L3) Heattransfer coefficient bundle k [W/m2K] 887,54 Note 4

Frequence [Hz] 50 TLN TLN [C] 77,32

Max. load current [Amp] 166,0 Heat flux [w/cm2] 6,87

Number of U-pins [-] 12 Note 2 With fouling:

Voltage per element [Volt] 400 Note 3 Fouling factor Rf [m2K/W] 0,00010

Power per element [Watt] 9583 Heattransfercoeff. with fouling kf [W/m2K] 815,19 Note 4,5

Current per element [Amp] 23,96 TLN , with fouling [C] 84,19

Heated length [mm] 3500

Note 6 Heat flux [w/cm2] 6,87

Note 2 : number of elements : 12 connected + 3 spares, installed but not connected.

Calculations according VDI Wrme Atlas,

Note 3 : elements are delta connected. (fnfe Auflage - 1988) :

Note 4 : general heat transfer : Q = k . AVO . TLN = 115000 Watt (full load condition) Bltter Gg 1 - Gg 6

Bltter Gd 1 - Gd 5 for heat transfer calc

Note 5 : per defenition : 1/kf = 1/k + Rf (TEMA approach)

Bltter Ll 1 - Ll 10 for pressure drop calc

Note 6 : streched length of U-pin heating element. Bltter Oc 6 - Oc 23 for fouling (TEMA)

Note 7 : design margin on installed power : 15,0 %

PRESSURE DROP OVER THE HEATER

1 = 373,07 + 2 = 8606 + 3 = 178,59 + 4 = 13157,50

Total pressure drop P1 + P2 + P3 + P4 2

= 22315 N/m = 0,22315 Bar = 2231,53 mmWg

Filename: Heater design

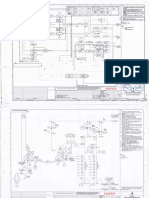

Title:

Sinus Jevi Electric Heating BV

Date : 17-03-15

aambeeld 19, 1671 NT SPECIFICATION/DATASHEET Rev. no : 40.863-001

Medemblik, The Netherlands ELECTRIC HEATER Project : GNU Gas Natural

Tel. +31 (0)227 549100 ITEM : 115KW EX- IMMERSION Item : 115kW Ex- Immersion

Prepared by : Dennis Lauwers Sheet : 2 of 4

PROCESS DESIGN CONDITIONS

Number req. 1 - Nozzle velocity (calc.) 15,9 (in outlet) m/s

Service Natural Gas - Dynamic head in nozzle 4303 kg/m.s2

Fluid Vapour - Skin temp. (allow.) TBA C

Flow rate 7645,0 kg/hr Skin temp. reduced / full load 79 / 91 (clean) C

Flow rate (process conditions) 450,0 m3/hr Fouling factor 0,0001 m2K/W

Pressure drop (allow) 0,5 Bar SITE CONDITIONS

Pressure drop (calc.) 0,223153 Bar Maximum wind velocity 44 m/s

Watt density (allow.) 7,5 W/cm2 Minimum air temperature -10 C

Watt density (calc.) 6,87 W/cm2 Blast loads (if applicable) 0,5 Barg

INLET CONDITIONS PROPERTIES FLUID

Temperature C 1,0 Ti Properties of the medium at avarage

To

Pressure Barg 20,00 temperature & working pressure :

Liquid flow kg/hr N/A T AV = (Ti + To) =0 C

Vapour flow kg/hr 7645 PW = 20,0 Barg

OUTLET CONDITIONS Description Symbol Unit Value

Temperature C 21,1 Spec. gravity [kg/m3] 16,99

Pressure Barg 19,78 Spec.Heat (P=const) Cp [J/kgK] 2340

Liquid flow kg/hr N/A Thermal conductivity [W/mK] 3,50E-02

Vapour flow kg/hr 7645 Dynamic viscosity [PaS] 1,08E-05

ELECTRIC HEATING DESIGN REQUIREMENTS

Area classification Zone 1 & 2 Guaranteed thermal eff. % 100%

Temp. Class T3 (<200C) Ambient air temp. Tamb -40C < Tamb < 50C

Ex certification heater (D8800) Ex II 2G Ex 'de' [ia] IIC Design electrical output kW 115,0 1 x 115,0 kW

Ingress Protection IP66 Number of stages 1 0 x 0,0 kW

POWER SUPPLY

Voltage Volt 400 Rated Power (heater) kW 115,0

Number of phases - 3 Rated Power (panel) kW 115,0

Frequency Hz 50 Earthing PE

Wiring elements - Delta Neutral available No

OVERALL DIMENSIONS REMARKS / NOTES

Instrument Box N6 N1 N2 DIMENSIONS ARE PRELIMINARY 1) Pressure-temperature ratings

not applicable C B Heated length : A SKETCH NOT TO SCALE ! of connection flanges acc.

Insulation ASME B16.5 - 1996 & 1998

N3 N4 thickness : M orientation

(D8800) nozzles 2) To avoid damage to the

0 insulation cover of the heater

during transport, we advise

F OD 270 90 H to insulate after installation

and hook-up on site.

180 E 3) Type connection flanges :

Heater flange raised face (RF),smooth finish.

G N5 4) Increased safety enclosure,

Overall length : L N type D8800, max. allowable

Fixed Slide ambient temperature (Tamb)

Dimensions in millimeters [mm] -40C < Tamb < 50C.

A B C OD E F G H L M N

1750 263 150 219,1 400 approx 500 approx. 300 610 2672 0 120

NOZZLE DATA WEIGHT CONTROL DATA

Mark Qty Type Size Rating lbs Orient. Service G = 2966 N (Mass = 302 kg)

N1 1 WNF 4 300 0 Inlet

9,81 m/s2

N2 1 WNF 4 300 0 Outlet

COG COG

N3 N/A WNF N/A N/A 0 N/A 610

N4 N/A WNF N/A N/A 0 N/A 400 G [N] G [N]

N5 1 WNF 2 300 180 Drain 1130 500

N6 1 WNF 8" 300 # Centre-line Heater 2672

INSTRUMENTATION

Over-temperature protection (High-High) Number : 1 , type : TC,type K Clamped to element tube surface(s)

Temperature control fluid Number : , type : N/A, by clients DCS, 4-20 mA analog

Over-temperature vessel wall Number : , type : N/A

Over-temperature protection Fluid Number : , type : N/A

Separate instrument junction box Y/N N

Title: Date : 17-03-15

Sinus Jevi Electric Heating

Aambeeld 19, 1671 NT SPECIFICATION/DATASHEET Rev. no : 40.863-001

Medemblik, The Netherlands MECHANICAL Project : GNU Gas Natural

Tel. +31 (0)227 549100 ITEM : 115KW EX- IMMERSION Item : 115kW Ex- Immersion

Prepared by : Dennis Lauwers Sheet : 3 of 4

MECHANICAL DATA / PED97/23/EC DATA

Description Units Ps = 30 Barg , V= 62,6 l , Ps.V= 1878 Bar.l

Design code (-) ASME VIII div 1 PED 97/23/EC : applicable

Design temperature, upper/lower [Ts] C 50 0 Equipment type : Vessel(s)

Design pressure, internal [Ps] Barg 30 Fluid group : Group 1 Gas

Corrosion allowance, pressure parts mm 1,6

Test pressure, hydrostatic Barg To Code Category : IV CHART 1

Miscellaneous Module : H1

INSPECTION REQUIREMENTS

Inspection To Code

Inspection authority Lloyds Register, if applicable.

Stress relieving N/A

PWHT N/A

Radiography Spot 10%

Other non-destructive testing Dye penetrant on tube sheet

Chemical analysis N/A

Material certificate(s) EN10204 3.1, non-pressure parts 2.2

MATERIAL SPECIFICATION

Shell ASTM A106 Gr. B

Spacer tubes / distance tubes AISI 316

Head ASTM A234 WPB

Reinforcing rings or pads ASTM A234 WPB

Saddles ASTM A516 Gr. 60

Jacket N/A

Flanges (DIN) N/A

Nozzles (line pipe) ASTM A106 Gr. B

Flanges (ANSI) ASTM A105N Tubesheet design as per appendix 41

Welding fittings ASTM A106 Gr. B

Terminal enclosure AISI 316(L)

Baffles AISI 316(L)

Sliding rods (internal) if applicable AISI 316(L)

Stud bolts (external) ASTM A193 B7, zinc plated

Nuts (external) ASTM A194 2H, zinc plated

Gasket CAMM Profile (SS + Graph.)

Insulation N/A

insulation cover N/A

Element tube AISI 316

Bite couplings or compression fittings N/A

Miscellaneous

WEIGHTS & SHIPPING DIMENSIONS

Erected weight [Kg] 302 (vessel : 184 kg , heater bundle : 118 kg )

Total weight operating [Kg] 303 (vessel : 184 kg , bundle : 118 kg, medium : 1,1 kg )

Total weight full off water (@ 20C) [Kg] 365

Shipping weight (incl. wooden case) [Kg] 449 (Heater : 302 kg , wooden case : 147 kg )

Shipping dimensions wooden case [cm] 64 x 85 x 282 (W x H x L)

Shipping Volume wooden case [m3] 1,55

ELECTRIC HEATING ELEMENT

Type Mineral Insulated, U-pin, see figure 2 below

Number of elements (U-pins), if applicable 12 connected + 3 spare(s), installed but not connected.

Number of elements (cartridge), if applicable N/A connected+ N/A spare(s), installed but not connected.

Tubular U-pin element diameter, da [mm] 12,7

Pocket diameter OD x ID, if applicable [mm] N/A X N/A Note: only with cartridge elements

Power per element [Watt] 9583 1 pocket tube

2

OD

Voltage per element (wired in delta) [volt] 400

ID

S1

Heat flux (watt density) [W/cm2] 6,87

Dimension connection pin, if applicable M6 Cartridge heating elem. da

FINISHING

Preparation Degreasing & shotblasting ISO-Sa2, profile 40 - 70 m

Coating system / or finishing Sinus-Jevi standard 3-layer coating system:

1 layer : Sigmacover 280 50 m

2 layer : Sigmacover 256 125-150 m

3 layer : Sigmadur 520 (HB finish) 60-75 m (RAL 7032)

Filename : Heater design

You might also like

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeDocument3 pagesThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaNo ratings yet

- Indirect Fired HeaterDocument2 pagesIndirect Fired HeaterJoshua CollierNo ratings yet

- Different Between Nm3Document11 pagesDifferent Between Nm3Iskandar Zulkarnain HasibuanNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocument44 pagesNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNo ratings yet

- Mean Metal Temperature CalculationDocument28 pagesMean Metal Temperature CalculationAvijit DasguptaNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- Gas-Liquid Vertical Separator PDFDocument2 pagesGas-Liquid Vertical Separator PDFRathish RagooNo ratings yet

- 761-V-103 (Vessel With Demister), PDFDocument1 page761-V-103 (Vessel With Demister), PDFAlvin SmithNo ratings yet

- Routine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsDocument3 pagesRoutine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsMohamed Sayed AbdoNo ratings yet

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Data Sheet - Gas-Gas Heat ExchangerDocument1 pageData Sheet - Gas-Gas Heat ExchangerPrabhakarNo ratings yet

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsDocument1 pageDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Pressure Vessel Cone Design ToolDocument1 pagePressure Vessel Cone Design ToolPramod KumarNo ratings yet

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDocument2 pagesACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Liquid Valve CV CalcDocument4 pagesLiquid Valve CV Calcamit_kt1973No ratings yet

- Stirred Tank Heat ExchangerDocument4 pagesStirred Tank Heat ExchangerMiguel OjedaNo ratings yet

- Pressure DropDocument19 pagesPressure DropGigis Kintan MyarthalunaNo ratings yet

- Firetube Heaters: FIG. 8-31 Convection HeaterDocument7 pagesFiretube Heaters: FIG. 8-31 Convection Heatery149487No ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- 00000-Jds-003 (Level Trans DS) Rev 0Document4 pages00000-Jds-003 (Level Trans DS) Rev 0sithulibraNo ratings yet

- BDVDocument3 pagesBDVJason ThomasNo ratings yet

- High Pressure Steam Let Down Station Data SheetDocument5 pagesHigh Pressure Steam Let Down Station Data SheetSabeeh AhmedNo ratings yet

- X Steam Tables (English Units)Document8 pagesX Steam Tables (English Units)Troy ThennisNo ratings yet

- Jet Mixing CalculationDocument3 pagesJet Mixing CalculationRachel FloresNo ratings yet

- Flare Stack Calculation Sheet by Erwin ADocument8 pagesFlare Stack Calculation Sheet by Erwin AaltruismNo ratings yet

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pages3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNo ratings yet

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainNo ratings yet

- Design criteria for determining temperature and pressureDocument19 pagesDesign criteria for determining temperature and pressureKorcan ÜnalNo ratings yet

- M07 PDFDocument48 pagesM07 PDFAdrian GuzmanNo ratings yet

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocument77 pagesAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- Comparative Study of Flare Modeling MethodologiesDocument15 pagesComparative Study of Flare Modeling MethodologiesLorena DávilaNo ratings yet

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNo ratings yet

- HeaterData SheetDocument1 pageHeaterData Sheethappale2002No ratings yet

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDocument8 pages503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14No ratings yet

- Thermosyphon Reboiler Hydraulics: ResultDocument5 pagesThermosyphon Reboiler Hydraulics: ResultVaishnavi RaghavNo ratings yet

- Two Phase Flow RegimeDocument8 pagesTwo Phase Flow RegimecitramuaraNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaNo ratings yet

- Htri Datasheet & Application Note - Datasheet ArchiveDocument4 pagesHtri Datasheet & Application Note - Datasheet ArchiveShantanuNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Heat Exchangers Explained: KSI/... Series OverviewDocument4 pagesHeat Exchangers Explained: KSI/... Series OverviewJohn F Diaz HNo ratings yet

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNo ratings yet

- US Units Heat Exchanger Specification SheetDocument1 pageUS Units Heat Exchanger Specification SheetDwi PutraNo ratings yet

- PSVDocument8 pagesPSVMohamed Sayed AbdoNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocument13 pagesProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (1)

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Heat Loss Insulated PipeDocument5 pagesHeat Loss Insulated Pipe22238.spoNo ratings yet

- Tabla de Bridas y Esparragos PDFDocument1 pageTabla de Bridas y Esparragos PDFmateu50% (2)

- Asme B31.8Document14 pagesAsme B31.8omar equihua100% (1)

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- Drawing Type 1 14 Od 1 Tanques EkcDocument1 pageDrawing Type 1 14 Od 1 Tanques Ekcomar equihuaNo ratings yet

- GFC Coalescing Filter Element CutsheetDocument1 pageGFC Coalescing Filter Element Cutsheetomar equihuaNo ratings yet

- Calculo de Valvulas de RetencionDocument26 pagesCalculo de Valvulas de Retencionmfruge7No ratings yet

- Volumen de Gas A 10 Kg.Document1 pageVolumen de Gas A 10 Kg.omar equihuaNo ratings yet

- Cap 3 Nube-Electronica PDFDocument7 pagesCap 3 Nube-Electronica PDFomar equihuaNo ratings yet

- Xartu - 1 Computador de Flujo Data SheetDocument2 pagesXartu - 1 Computador de Flujo Data Sheetomar equihuaNo ratings yet

- Catalogue Galileo Virtual Pipeline PDFDocument2 pagesCatalogue Galileo Virtual Pipeline PDFomar equihuaNo ratings yet

- A Torque, Tension and Stress Corrosion Evaluation of High Strength A286 Bolts PDFDocument28 pagesA Torque, Tension and Stress Corrosion Evaluation of High Strength A286 Bolts PDFBrad PhillipsNo ratings yet

- Chris DeArmitt PHD ThesisDocument160 pagesChris DeArmitt PHD Thesisalinbu2007No ratings yet

- HSChemistry StudyGuideDocument49 pagesHSChemistry StudyGuidetoshiroelric07No ratings yet

- GUIDELINES FOR PREPARATION OF OIL SPILL RESPONSE CONTINGENCY PLAN OISD - GUIDELINES-200 Amended Edition October 2002 - OISD-GDN-200Document36 pagesGUIDELINES FOR PREPARATION OF OIL SPILL RESPONSE CONTINGENCY PLAN OISD - GUIDELINES-200 Amended Edition October 2002 - OISD-GDN-200Vaishnavi JayakumarNo ratings yet

- Pyruvate and Hydroxycitrate:carnitine May Synergize To Promote Reverse Electron Transport in Hepatocyte Mitochondria, Effectively Uncoupling' The Oxidation of Fatty AcidsDocument10 pagesPyruvate and Hydroxycitrate:carnitine May Synergize To Promote Reverse Electron Transport in Hepatocyte Mitochondria, Effectively Uncoupling' The Oxidation of Fatty AcidsmreadesNo ratings yet

- CALC PID ReferenceDocument121 pagesCALC PID ReferenceJohn CebNo ratings yet

- Choline Chloride in Clay and Shale Stabilizer-619Document4 pagesCholine Chloride in Clay and Shale Stabilizer-619Lê Công100% (1)

- York Yvaa IomDocument144 pagesYork Yvaa Iomtm_20100% (1)

- Advances in Modern Refractory CastableDocument12 pagesAdvances in Modern Refractory CastableBagas Prasetyawan Adi Nugroho100% (1)

- Engine Oil Volatility Noack Evaporation MethodDocument5 pagesEngine Oil Volatility Noack Evaporation MethodAvinash Gamit100% (1)

- Astec Hot Mix Mag Vol19 No1Document48 pagesAstec Hot Mix Mag Vol19 No1Osman VielmaNo ratings yet

- Kalibrasi Mesin DialDocument78 pagesKalibrasi Mesin DialMrQmonkNo ratings yet

- Sikaflex 256Document2 pagesSikaflex 256aboali8686No ratings yet

- Separations and Reactors Design Project Production of Allyl ChlorideDocument8 pagesSeparations and Reactors Design Project Production of Allyl ChloridefathiNo ratings yet

- Evidence and Processes of EvolutionDocument14 pagesEvidence and Processes of EvolutionMiralen EndozoNo ratings yet

- Difference Between Nm3 Vs Sm3Document1 pageDifference Between Nm3 Vs Sm3Arun kumarNo ratings yet

- TiO2 (RC 635)Document1 pageTiO2 (RC 635)medo.k016No ratings yet

- Capacitor PosterDocument1 pageCapacitor PosterMajorNo ratings yet

- GAMSAT TopicsDocument7 pagesGAMSAT TopicsSewon KimNo ratings yet

- 20) Complexometric TitrationDocument47 pages20) Complexometric TitrationCzarina Angelli AnastacioNo ratings yet

- x40602 - Concrete Technology PDFDocument12 pagesx40602 - Concrete Technology PDFJay PatelNo ratings yet

- Fractional Distillation: Experiment #5Document14 pagesFractional Distillation: Experiment #5jamesNo ratings yet

- Physics of Aqueous Phase Evolution in Plutonic EnvironmentsDocument11 pagesPhysics of Aqueous Phase Evolution in Plutonic Environmentsjunior.geologia100% (1)

- Salkowski Test ConclusionDocument3 pagesSalkowski Test Conclusionclint xavier odangoNo ratings yet

- Microencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinDocument10 pagesMicroencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinErman ÇutukNo ratings yet

- Daily Lesson PlanDocument8 pagesDaily Lesson PlanTamie P. Galindo100% (1)

- What is Ozone? Explaining its Role in Protecting Earth from UV RadiationDocument1 pageWhat is Ozone? Explaining its Role in Protecting Earth from UV RadiationTenveer BhuttaNo ratings yet

- Application & Analysis of Banana Stem Fibre Use As Construction MaterialDocument12 pagesApplication & Analysis of Banana Stem Fibre Use As Construction MaterialEditor IJTSRDNo ratings yet

- Dr. Fixit Modern Tile Adhesive: DescriptionDocument3 pagesDr. Fixit Modern Tile Adhesive: DescriptionkiranNo ratings yet

- M Scan BrochureDocument8 pagesM Scan BrochureM-ScanNo ratings yet