Professional Documents

Culture Documents

Overview of Geomembrane History in The Mining Industry

Uploaded by

Randall KnuckeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overview of Geomembrane History in The Mining Industry

Uploaded by

Randall KnuckeyCopyright:

Available Formats

Overview of geomembrane history in the mining industry

Breitenbach, A. J.

Vector Engineering, Golden, Colorado, USA

ajbreitenbach@hotmail.com

Smith, M. E., P.E.

Vector Engineering, Lima, PER

smith@vectoreng.com

Keywords: Heap leach, tailings, mining, geomembrane, liner

ABSTRACT: Geomembrane liners have been used significantly in the mining industry since about 1970 for

lining solution and evaporation ponds, tailings impoundments and heap leach pads. The most extensive use

of the geomembrane liners has been, and remains, in the construction of evaporation ponds, starting in the

early 1970s, and heap leach pads starting in the late 1970s. Tailings impoundments have historically been

mostly soil lined, but increasing in their use of geomembrane liners in recent times. This paper will present

an overview of the geomembrane liner history in the mining industry from the 1970's to present day. The

historic state of practice will be discussed, in addition to the major engineering concerns and the emerging

issues in heap leaching.

1 INTRODUCTION 2 35-YEARS OF HISTORY

Mining uses geomembrane liners principally for three

areas: evaporation (or solar) ponds for recovery of 2.1 Clay, geomembrane and composite liners

salts, heap leaching of mineral-bearing rock, and

The first large-scale use of geomembranes in mining

disposal of mill tailings (rock that has had most of the

was probably solar ponds for either Tenneco Minerals

mineral value removed). Evaporation ponds and heap

in Utah, USA, or Sociedada Qumica y Minera de

leaching are the largest applications of geomembranes

Chile S.A. (SQM) in Northern Chile. Tenneco

in mining, and heap leaching is the most complex.

installed 230 hectares (ha) in 1970, and SQMs first

Given the size and complexity, heap leaching will be

installations were at about the same time and size.

the focus of this paper, but other areas will also be

Prior to this, mining applications consisted mostly of

discussed. A good introduction to heap leaching is

small chemical ponds.

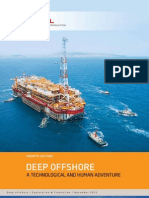

given by Thiel & Smith (2004). A large Andean

The first heap leach projects were copper dump

valley fill heap leach project is shown in Photo 1.

leach facilities and used only natural containment.

With gold and silver heap leaching starting in

Montana and Nevada, USA, in the late 1970s,

cyanide was introduced to heap leach technology and

natural containment was no longer viable politically, if

not technically. Most of the first gold and silver

operations, constructed in 1974 to 1983 in Nevada,

used low permeability soil liners only, though be 1983

geomembrane liners were becoming more common.

No modern large-scale leach pads use soil-only liners.

Large scale copper heap leaching began in Chile in

1980 with the Lo Aquirre project. By the early 1990s

Photo 1: Andean Heap Leach Facility (150 ha ultimate area)

Chile had about 10 major copper heap leach

operations; now there are dozens and the vast majority

of such facilities now use geomembranes. SQM first

started heap leaching nitrate ores in northern Chile in

1985, choosing polyvinyl chloride (PVC) liners for

high multi-axial elongation properties due to the

presence of up to 30% soluble salts in the foundation 2.2 Double geomembrane liners

soils. These salts allow even a small defect to grow

Process ponds started using double liners in the 1980s

progressively into a major failure if the liner cannot

in Nevada, but double liner use on large applications,

accommodate the resulting differential settlement.

such as leach pads, is still not common. Mining has

The now-infamous Summitville gold project in

resisted double geomembrane technology for a variety

Colorado, USA, which was ultimately classified as a

of reasons, ranging from higher cost to decreased

Superfund site, was originally designed in 1984 using

stability, but primarily due to the success of the single

PVC for the valley fill leach pad liner, but that was

and composite liner systems. By 1995 there were only

changed in construction to high density polyethylene

six double lined leach pads with some of the larger

(HDPE) in 1985. This was one of the first large scale

ones including: Amax Golds El Guanaco project

HDPE applications in gold mining.

(Chile), Heclas La Cholla project (Mexico) and

Very low density polyethylene (VLDPE) was first

Piedmonts Mother Load project (Nevada, USA).

used for small applications in the mid 1980s and for

Now there are several, primarily gold valley leach

larger lined tailings impoundments like the Ridgeway

operations, which impound water within the heap and

gold tailings dam (South Carolina, USA, 1986). The

thus can develop significant hydraulic heads over the

first large embankment dam with a geomembrane core

liner, in one case of up to 40 m. The best known

seepage barrier used VLDPE (the TS Ranch, Nevada)

being the Pierina (Photo 1) mine in Per, the Veladero

in 1989. Another large scale mining application was a

mine in Argentina, and the Cripple Creek mine in

solar pond for a potassium solution mining facility in

Colorado, USA, all of which use double liner systems

northwestern Argentina, where 12 ha were installed in

below the maximum water level. Ore depth over the

1992. Unfortunately, the high ultra violet exposure

liner system ranges from 125 to 160 m for these

resulted in serious deterioration of the liner and

projects.

abandonment of the pond in about one year. VLDPE

Part of the resistance to double liners has been cost.

made a much bigger entry into the leach pad industry

Conventional leach pads in Chile cost US $5 to

by the early 1990s where the materials relatively

$11/m2 (Smith, 2002). Adding a secondary

high multi-axial elongation and good frictional

geomembrane and leak collection and recovery system

resistance provided design benefits. Its use in heap

(LCRS) would add 30 to 100% to the installed cost.

leaching continued to grow until it was discontinued

However, constructability is also an important factor.

in 1994. Within about 2 years, however, various

For example, the largest leach pads in Chile can

formulations of linear low density polyethylene

exceed 150 ha. The time to construct is frequently

(LLDPE) began to take over as a preferred liner for

limited by qualified installer capacity, especially

leach pads due to improved elongation and frictional

limited in the developing world. Internal stability is

resistance in comparison to HDPE.

another key factor. Valley fill leach pads are

The first major composite geomembrane lined leach

commonly constructed on steep slopes. For

pad was the Zortman-Landusky valley fill gold project

impounding valley fills, double geomembrane liners

in Montana, first constructed in 1979 and expanded

are common (with composite bottom liners) below the

several times over the next dozen years and ultimately

maximum water level. Above that level composite

with 150 m of ore over the liner. Zortman-Landusky

liners are the standard. Slopes can exceed 0.75

used PVC, which was the geomembrane in common

horizontal to 1 vertical. Leach ore is stacked

use for leach pads until about 1985, when HDPE

intentionally in a very loose state to improve solution

liners started to dominate the industry. Now the

distribution and percolation; this results in very large

worlds largest composite lined leach pad is at

settlement potential upon wetting and with progressive

Newmonts Yanacocha gold complex in North-central

stacking (Breitenbach, 2004). Therefore, along the

Per. Most valley fill leach pads now use composite

steep slopes the potential for settling ore to drag the

liners above the maximum water storage level and

liner is significant. Using a double geomembrane liner

double geomembrane liners below that level.

would increase this risk. While this can be managed in

Single geomembrane liners are still the most

design, it nevertheless presents another strong rational

common liners for copper leach pads with composite

to guide projects towards composite liners.

liners more common for gold and silver leach pads.

There is also the social issue. When applying the

Copper run-of-mine dumps are generally unlined

principals of sustainable development, as is now

though this technology is also converting to

required by lenders and investors for most multi-

geomembranes. HDPE and LLDPE liners at 1.5 to 2.0

national projects, a broader perspective is required.

mm in thickness and PVC liners at 0.75 to 1.0 mm

For a large-scale copper mine in the Atacama Desert,

thickness are the most common types and thicknesses

where groundwater may be deeper than 300 m, is

of liners currently used in the mining industry.

often saline and rarely has local users, the cost to

upgrade an average leach pad to a double by virtue of being associated with mineralized ground,

geomembrane would typically cost US $5 to $10 are in high seismic zones. For example, central Chile

million. That same money could fund - in perpetuity was the site of the largest earthquake ever recorded in

the local elementary school. 1960 where a magnitude 9.5 event devastated the

country. Over the past 35 years typical heap depths

2.3 On/off leach pads have increased from about 15 m to over 100 m, and

now projects with 160 to 230 m of ore are being

When dynamic heap leach technology entered the

considered (Breitenbach & Thiel, 2005, Thiel &

industry, first with gold and now including copper,

Smith, 2004). Increasing heap heights are not just a

most on/off leach pads were constructed of asphaltic

matter of economics. Some sites simply do not have

concrete (AC) for structural support during loading

sufficient acceptable ground to economically allow

and unloading. Various approaches were used to

lower heaps. The general trend, with drivers ranging

create a low permeability barrier, ranging from simply

from closure and reclamation costs to minimizing

using a high bitumen content AC (e.g., the Bluebird

diversion of agricultural land and encouraging

copper mine, Arizona, USA, 1967 and the Borealis

sustainable development, is to reduce the amount of

gold mine, Nevada, 1982) to more creative solutions

land impacted by mining. A higher heap means fewer

including plain or rubberized bitumen layered between

hectares of disturbance.

lifts of AC (e.g., the Gilt Edge mine, South Dakota,

1986). Overall, this approach was not very successful

3.2 Pipe deformation & concentration of loads

and the industry has switched to geomembrane liners

with aggressive protective layers with the first large- Dual wall corrugated perforated polyethylene pipes

scale application probably being the Cerro Colorado are the standard design for leach pad drainage systems

copper mine in Chile (1991). The standard design is at the base of the ore. With the extreme depths of

now 1.5 to 2.0 mm thick HDPE or LLDPE with 1 to 2 modern heaps, pipe deformations often approach the

meters of gravel cover. collapse point for the pipes, which can be up to 30%.

Predicting pipe behavior at extreme loads is the

2.4 Rain coats & interlift liners subject of on-going research in laboratories and the

field (Smith et al, 2005). An important corollary issue

Temporary covers, often called rain coats, have been

is the increase in stress on the geomembrane near the

used on heap leach pads primarily in the Philippines,

deforming pipe. It is logical that the pressure here

Central America and Per since about 1988, where

would increase, since the arching affect of the flexible

high rainfall dilutes operating solutions and surplus

pipe causes the vertical load on the pipe to decrease

water can trigger the need for significant water

and force equilibrium requires a compensating

treatment costs. The rain coats generally include PVC

increase elsewhere. Load cells in one set of large scale

liners (typically 0.75 mm) for a temporary cover until

tests, and subsequent finite element analyses, found

the next dry season, and thicker HDPE liners (.75 to

that this over-pressurization reaches a peak value of

1.5 mm) for more permanent or reusable applications.

about 125% of the average vertical stress at a distance

Interlift liners have been used in more than a dozen

of one pipe diameter away from the pipe (Leduc &

copper mine leach pads since 1993, mainly in South

Smith 2004). Thus a more robust liner system maybe

America to reduce acid consumption in leach solutions

be required than would otherwise be indicated.

for copper oxide heaps. The interlift liners, most

commonly PVC (.45 to .75 mm) or LDPE (.75 to 1.0

3.3 Temperature affects

mm) can have some allowable leakage with the

underlying leach pad base liner as the environmental Most copper leach operations are using bio-chemical

barrier. One case study indicated that typical leakage processes to recover copper from sulfide ores. The

rates through thin interlift liners is 1 to 3% of the leach biological reactions are exothermic and operating

solution volume. temperatures at the base of a large sulfide heap are

estimated to reach up to 50C. High temperatures

soften thermoplastics which can weaken drainage

3 EMERGING ISSUES IN HEAP LEACHING pipes and soften geomembranes. Research for a major

operation in Chile produced high load pipe deflection

data that suggests that pipe deflection is not

3.1 High loads significantly affected by temperatures of up to 60C

(Smith et al 2005). However, geomembrane softening

Heap leaching presents a combination of extreme base

resulted in a significant increase in deformations under

pressures and high moisture conditions not present in

laboratory conditions, as shown in Photos 2 and 3

any other containment application. Often these sites,

(neither sample was punctured). Samples of the same commonly using geoelectric leak location surveys

geomembrane were tested for 48 hours under identical with 500 to 1,000 ha per year being surveyed.

conditions to simulated ore depths of 100 m, with only Informal data suggests that the typical frequency of

the test temperature varied. defects found in these surveys, after conventional

construction quality assurance, are 1 to 8 per ha.

CONCLUSIONS FROM 35 YEARS

The mining industry is using geomembrane liners

more frequently in recent times for solar ponds, heap

leach pads and tailings impoundments. Annual

installation rates probably exceed 2,000 ha of base

liner systems with additional geomembrane areas used

for rain coats and interlift liners (in some cases these

additional areas are significant). HDPE and LLDPE

dominates the leach pad industry (with LLDPE

increasing in market share annually) with 1.5mm to

2.0mm the most common thicknesses. PVC still

dominates in the solar pond business, with 0.75 to 1.0

Photo 2: 1.5mm HDPE tested for puncture at 21C. mm thicknesses most common; this seems to be

changing with HDPE becoming more common.

Emerging issues in heap leaching include: the extreme

loads (soon to exceed 200 m of ore depth) applied to

the geomembrane and drainage pipes; slope stability

and earthquake response; zones of overstress on the

geomembrane near drainage pipes under high loads;

temperature effects especially with respect to

geomembrane puncturing; and increasing use of

geoelectric surveys.

REFERENCES

Breitenbach, A.J. (1997), Overview study of several

geomembrane liner failures under high fill load conditions.

Proc. Geosynthetics 97, Long Beach, California, USA, v. 2,

pp. 1045 - 1062.

Photo 3: 1.5mm HDPE tested for puncture at 60C Breitenbach, A. J. (2004), Improvement in slope stability

performance of lined heap leach pads from operation to

3.4 Geoelectric leak location surveys closure. Geotechnical Fabrics Report, v. 22, no. 1, pp. 18 -

25.

Considering the value of the metals and reagents in Breitenbach, A. J. & Thiel, R. S. (2005), A tale of two

leach solution, Theil et al (2005) has shown that conditions: heap leach pad versus landfill liner strengths.

geoelectric surveys make sense from a strict economic Proc. GRI-19, Las Vegas, Nevada, USA, Dec.

viewpoint without regard to the reduction in Leduc, M. and Smith, M. E. (2004), Solution collection pipes &

overstressing of geomembrane liners. Mining Record, Sep.

environmental, political and social risk. Nevertheless, Smith, M. E. (2002), Copper dump leaching. Mining

the mining industry has been reluctant to embrace magazine, July.

geoelectric leak survey technology, although that may Smith, M. E., Beck, A. Thiel, R. & Metzler, P. (2005),

be changing in recent times. One of the first Designing for vertical pipe deflection under high loads.

applications of this technology to mining was a valley Proc. GRI meeting, Las Vegas, Nevada, USA, Dec.

Thiel, R. S., Beck, A. & Smith, M. E. (2005), The value of

fill heap leach operation in Nevada in 1995, where geoelectrick leak detection services for the mining industry.

placement of the overliner system was believed to Proc. Geofrontiers, Feb.

have damaged the geomembrane. The technology is Thiel, R. S. & Smith, M. E. (2003), State of the practice review

now becoming more commonly used in Chile, and the of heap leach pad design issues. Proc. GRI-18, Las Vegas,

first applications in Per and Argentina were at valley Nevada, USA, vol. 22, pp. 555 - 568, Dec.

fill operations in 2005. Solar ponds in Chile are now

To be presented at and published in the proceedings of

the 8th bi-annual meeting of the International

Geosynthetics Society (8IGS), Japan, September

2006.

You might also like

- Leach Pad GeomembraneDocument4 pagesLeach Pad GeomembraneAlcides Cordova MateoNo ratings yet

- Overview of Geomembrane History in The Mining IndustryDocument5 pagesOverview of Geomembrane History in The Mining IndustryvmachmarNo ratings yet

- Submarine Tailings Disposal ToolkitDocument16 pagesSubmarine Tailings Disposal Toolkit2012nibiruNo ratings yet

- Kwong2019 Article ComparisonOfEnvironmentalImpacDocument10 pagesKwong2019 Article ComparisonOfEnvironmentalImpacRizka Hari RakhmahNo ratings yet

- Silo - Tips - Keywords Leach Nickel Geomembrane Laterite Failure Containment History Mining Mineral ProcessingDocument7 pagesSilo - Tips - Keywords Leach Nickel Geomembrane Laterite Failure Containment History Mining Mineral ProcessingSebas MoraNo ratings yet

- Leach S X Ew Production Oof CopperDocument10 pagesLeach S X Ew Production Oof CopperJeromeNo ratings yet

- Topic 2: Mining: Metals, Minerals, Mining and (Some Of) Its ProblemsDocument45 pagesTopic 2: Mining: Metals, Minerals, Mining and (Some Of) Its ProblemsLFNo ratings yet

- Art State Vector Heap Leaching - GRI Dec 2003 R2Document17 pagesArt State Vector Heap Leaching - GRI Dec 2003 R2Jorge ZafraNo ratings yet

- RTR Canada OptionDocument16 pagesRTR Canada OptionPeteNo ratings yet

- Technical Considerations For TBM Tunneling For Mining ProjectsDocument8 pagesTechnical Considerations For TBM Tunneling For Mining ProjectsJibaNo ratings yet

- Korte 2000Document5 pagesKorte 2000Javier R. AmayaNo ratings yet

- Challenges of ultra-deep oil and gas drillingDocument12 pagesChallenges of ultra-deep oil and gas drillingRoger GuevaraNo ratings yet

- SMe Mining engineering handbook covers dry fill placementDocument1 pageSMe Mining engineering handbook covers dry fill placementYeimsNo ratings yet

- 13 MINING GROUTING A Rational Approach New OrleansDocument12 pages13 MINING GROUTING A Rational Approach New OrleansHari Prasad PidikitiNo ratings yet

- Thickened Tailings Disposal at Musselwhite MineDocument12 pagesThickened Tailings Disposal at Musselwhite MineΙωάννης ΖαφειράτοςNo ratings yet

- SPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsDocument9 pagesSPE Estimating Fracture Gradient in Gulf of Mexico Deepwater, Shallow, Massive Salt SectionsTHiago LOpesNo ratings yet

- The Challenger Gold MineDocument10 pagesThe Challenger Gold MinegeolukeNo ratings yet

- WATER PROBLEMS ASSOCIATED With Undersea LWDocument20 pagesWATER PROBLEMS ASSOCIATED With Undersea LWkatta_sridharNo ratings yet

- The Evolution of Paste For Backfill: D Stone Minefill Services, Inc., USADocument8 pagesThe Evolution of Paste For Backfill: D Stone Minefill Services, Inc., USABakang MolefeNo ratings yet

- 1984 SME Block Caving PaperDocument6 pages1984 SME Block Caving PaperAndy TrippNo ratings yet

- Development of The Argo MineDocument7 pagesDevelopment of The Argo MineCraig ThomasNo ratings yet

- 083 Pioneering Mass Caving at El TenienteDocument8 pages083 Pioneering Mass Caving at El TenienteKenny CasillaNo ratings yet

- Total Deep Offshore (Brochure)Document12 pagesTotal Deep Offshore (Brochure)dhruvarora0% (1)

- A History of Shotcrete Use at Vale Inco J Larsen, D Thibodeau & J HutterDocument8 pagesA History of Shotcrete Use at Vale Inco J Larsen, D Thibodeau & J HutterwjzabalaNo ratings yet

- Coal Mining Methods, Their Advantages and DisadvantagesDocument33 pagesCoal Mining Methods, Their Advantages and DisadvantagesChristian TewodrosNo ratings yet

- Potential Problems in Copper Dump LeachingDocument10 pagesPotential Problems in Copper Dump LeachingLuis Lemus MondacaNo ratings yet

- Thomson TypeS PDFDocument12 pagesThomson TypeS PDFibrahimNo ratings yet

- Recent Minefill Developments in AustraliaDocument7 pagesRecent Minefill Developments in Australiaalvaroaac4No ratings yet

- Industrial Uses of Volcanic MaterialsDocument17 pagesIndustrial Uses of Volcanic MaterialsClinthill Padilla100% (1)

- Backfilling Depleted Open Pit MinesDocument7 pagesBackfilling Depleted Open Pit MinesScott DownsNo ratings yet

- Peterson R Et Al Adaptive Risk Management and Lessons LearnedDocument12 pagesPeterson R Et Al Adaptive Risk Management and Lessons LearnedConstanza GomezNo ratings yet

- Materials' Stewardship Beyond The Pale: 8 Sme Mining Engineering HandbookDocument1 pageMaterials' Stewardship Beyond The Pale: 8 Sme Mining Engineering HandbookYeimsNo ratings yet

- Underground Mine Backfilling Using Paste and Hydraulic FillsDocument7 pagesUnderground Mine Backfilling Using Paste and Hydraulic FillsVanco AdziskiNo ratings yet

- UG Design and Support - 083238Document53 pagesUG Design and Support - 083238Quinton Dean ChingokaNo ratings yet

- Mines in AregentinaDocument6 pagesMines in AregentinaMANUELA MARIA ROMERO VICTORICANo ratings yet

- (Day 2017) Challenges and Shortcomings in Geotechnical Engineering Practice in The Context of A Developing CountryDocument25 pages(Day 2017) Challenges and Shortcomings in Geotechnical Engineering Practice in The Context of A Developing CountryHarrison StamoudisNo ratings yet

- J. Electrochem. Soc.-1952-Loonam-295C-8CDocument4 pagesJ. Electrochem. Soc.-1952-Loonam-295C-8CGeovanny JaenzNo ratings yet

- 2000 Mudd MoundSpringsOfTheGreatArtesianDocument14 pages2000 Mudd MoundSpringsOfTheGreatArtesianmcardenasga3No ratings yet

- pp55-69 +Wardrop+DR +Just+add+water+-+the+Askaka+story+Document15 pagespp55-69 +Wardrop+DR +Just+add+water+-+the+Askaka+story+Vale Espinel BurgosNo ratings yet

- Codelco 30 AñosDocument6 pagesCodelco 30 AñoskinsaeyaNo ratings yet

- Wheal Jane Mine Water Active Treatment Plant - Design, Construction and OperationDocument8 pagesWheal Jane Mine Water Active Treatment Plant - Design, Construction and OperationGeoffrey NyamagodoNo ratings yet

- Growing Risks of Colossal Tailings DamsDocument8 pagesGrowing Risks of Colossal Tailings DamsFernando GomesNo ratings yet

- 1999 - Mudd & Ali - Social and Ecological Impact of Water Extraction For A Copper-Uranium MineDocument21 pages1999 - Mudd & Ali - Social and Ecological Impact of Water Extraction For A Copper-Uranium Minemcardenasga3No ratings yet

- Minerals 13 00486Document13 pagesMinerals 13 00486Martín José Valenzuela DíazNo ratings yet

- Dicaperl Perlite Mine, Near Socorro, Socorro County, NMDocument6 pagesDicaperl Perlite Mine, Near Socorro, Socorro County, NMminingnovaNo ratings yet

- TheWorldofMining FlyerDocument8 pagesTheWorldofMining FlyerBwalya BwalyaNo ratings yet

- Contexto Minero en Chile y El MundoDocument13 pagesContexto Minero en Chile y El MundonarayaniIoNo ratings yet

- Engineering Encyclopedia: Oil Industry OverviewDocument8 pagesEngineering Encyclopedia: Oil Industry OverviewCobra_007No ratings yet

- MassMin 2016 Super CavesDocument8 pagesMassMin 2016 Super CaveskinsaeyaNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Mohammadhossein Sadeghiamirshahidi, Stanley J. VittonDocument9 pagesJournal of Rock Mechanics and Geotechnical Engineering: Mohammadhossein Sadeghiamirshahidi, Stanley J. VittonTewodirosNo ratings yet

- Topic 2: Mining: Metals, Minerals, Mining and (Some Of) Its ProblemsDocument45 pagesTopic 2: Mining: Metals, Minerals, Mining and (Some Of) Its Problemsفردوس سليمانNo ratings yet

- Ago 19 PDFDocument11 pagesAgo 19 PDFDanay ChNo ratings yet

- The Abiotic Theory of HydrocarbonDocument11 pagesThe Abiotic Theory of Hydrocarbonzaroia100% (1)

- CVD Diamond Coating - FinalDocument23 pagesCVD Diamond Coating - FinalSanjeeb SinhaNo ratings yet

- Stones DevelopmentDocument52 pagesStones Developmenttajman90No ratings yet

- Future of Mechanical Excavation in Underground Mining: JacklingDocument11 pagesFuture of Mechanical Excavation in Underground Mining: JacklingLuisSaavedraFloresNo ratings yet

- Lightweight Concrete Made From Natural (P Manufactured Vesicular AggregatesDocument17 pagesLightweight Concrete Made From Natural (P Manufactured Vesicular AggregatesAnvi GandhiNo ratings yet

- The Strength, Fracture and Workability of Coal: A Monograph on Basic Work on Coal Winning Carried Out by the Mining Research Establishment, National Coal BoardFrom EverandThe Strength, Fracture and Workability of Coal: A Monograph on Basic Work on Coal Winning Carried Out by the Mining Research Establishment, National Coal BoardNo ratings yet

- Impact of Social Media in Tourism MarketingDocument16 pagesImpact of Social Media in Tourism MarketingvidhyabalajiNo ratings yet

- Affine CipherDocument3 pagesAffine CipheramitpandaNo ratings yet

- Standard:: SS2H1 The Student Will Read About and Describe The Lives of Historical Figures in Georgia HistoryDocument4 pagesStandard:: SS2H1 The Student Will Read About and Describe The Lives of Historical Figures in Georgia Historyjeffmiller1977No ratings yet

- Vocabulary and grammar practice for future technologyDocument4 pagesVocabulary and grammar practice for future technologyRosa MartinezNo ratings yet

- LLRP PROTOCOLDocument19 pagesLLRP PROTOCOLRafo ValverdeNo ratings yet

- Manage Faisalabad WasteDocument2 pagesManage Faisalabad WasteUsama SanaullahNo ratings yet

- INGLESDocument20 pagesINGLESNikollay PeñaNo ratings yet

- Audit of Organizational Communication NetworksDocument17 pagesAudit of Organizational Communication NetworksLissette ObleaNo ratings yet

- Citizen Journalism Practice in Nigeria: Trends, Concerns, and BelievabilityDocument30 pagesCitizen Journalism Practice in Nigeria: Trends, Concerns, and BelievabilityJonathan Bishop100% (3)

- Loads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 WindDocument58 pagesLoads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 Windwaheedopple3998No ratings yet

- Standard Calibration Procedure Thermocouple Doc. No. Call/SCP/024 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Thermocouple Doc. No. Call/SCP/024 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- Syllabus in Study and Thinking SkillsDocument5 pagesSyllabus in Study and Thinking SkillsEnrique Magalay0% (1)

- Training Program On: Personality Development Program and Workplace SkillsDocument3 pagesTraining Program On: Personality Development Program and Workplace SkillsVikram SinghNo ratings yet

- Material Safety Data Sheet: Section I - Chemical Product and Company IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - Chemical Product and Company IdentificationMu ClasNo ratings yet

- MATHMATICAL Physics Book Career EndaevourDocument293 pagesMATHMATICAL Physics Book Career EndaevourSwashy Yadav100% (1)

- SPM Literature in English Tips + AdviseDocument2 pagesSPM Literature in English Tips + AdviseJessica NgNo ratings yet

- Learning OrganizationDocument104 pagesLearning Organizationanandita28100% (2)

- SQL Server DBA Daily ChecklistDocument4 pagesSQL Server DBA Daily ChecklistLolaca DelocaNo ratings yet

- 373 07 2Document143 pages373 07 2fpttmmNo ratings yet

- U.S. Copyright Renewals, 1962 January - June by U.S. Copyright OfficeDocument471 pagesU.S. Copyright Renewals, 1962 January - June by U.S. Copyright OfficeGutenberg.orgNo ratings yet

- Sony Kdl-42w654a rb1g PDFDocument100 pagesSony Kdl-42w654a rb1g PDFMihaela CaciumarciucNo ratings yet

- Introduction To Literary TheoryDocument3 pagesIntroduction To Literary TheoryAnil Pinto100% (4)

- Receiving of Packaging Material SOPDocument4 pagesReceiving of Packaging Material SOPanoushia alviNo ratings yet

- SWR SRB Product SheetDocument2 pagesSWR SRB Product SheetCarlo AguiluzNo ratings yet

- SampleAdmissionTestBBA MBADocument4 pagesSampleAdmissionTestBBA MBAm_tariq_hnNo ratings yet

- Jesd51 13Document14 pagesJesd51 13truva_kissNo ratings yet

- Construction Vibrations and Their Impact On Vibration-Sensitive FacilitiesDocument10 pagesConstruction Vibrations and Their Impact On Vibration-Sensitive FacilitiesKwan Hau LeeNo ratings yet

- SEM GuideDocument98 pagesSEM GuideMustaque AliNo ratings yet

- Variable frequency drives for electric submersible pumpsDocument34 pagesVariable frequency drives for electric submersible pumpshermit44535No ratings yet

- Forensic psychology: false confessions exposedDocument19 pagesForensic psychology: false confessions exposedBoNo ratings yet