Professional Documents

Culture Documents

17-0329-01 Domo Duraforce XSL 40M 16 Naturafill Domoflex-Q+QPRO PDF

Uploaded by

Juan Maria HormigoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

17-0329-01 Domo Duraforce XSL 40M 16 Naturafill Domoflex-Q+QPRO PDF

Uploaded by

Juan Maria HormigoCopyright:

Available Formats

FIFA Quality Programme for Football Turf

FIFA

LABORATORY

TEST REPORT

Manual 2015

Product name DOMO Duraforce XSL 40M/16/Naturafill/Domoflex

Product type (Field/Lines) Field

FIFA Licensee Domo Sports Grass

FIFA accredited Test Institute Ghent University (ERCAT)

Laboratory Test report number 17-0329-01

Date of test 10.03.2017

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

1 Introduction / Process Overview 3

2 Test Object, Participants 4

2.1 Test numbers

2.2 Test Object, Product name, Identification codes

2.3 Parties involved, Addresses (turf manufacturer, test institute, certifying body)

3 Test Conclusion, Product Approval 4

4 Product Information / Specifications 5

4.1 Overview a typical product composition

4.2 Artificial turf

4.3 Performance infill

4.4 Stabilising infill

4.5 Shockpad / elastic layer (where applicable)

4.6 Maintenance requirements

5 Detailed Laboratory Test Results 10

5.1 Overview ball and player to surface interactions

5.2 Product identification

5.3 Ball / surface interaction

5.4 Player / surface interaction

5.5 Environmental resistance (artificial, light, water)

5.6 Miscellaneous

5.7 Explanatory graphs / pictures

5.7.1 DSC (Differential Scanning Colorimetry) scans of pile yarn

5.7.2 a) Performance infill particle grading curve

5.7.2.b) Stabilising infill particle grading curve

5.7.3 TGA of performance infill

5.7.4 Unbound sub-base Composition

5.7.5 Simulated wear, photos before / after

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 2 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

1 Introduction / The Process of certification

In order to be certified, football turf fields must reach the performance and quality criteria established to be as close as

possible to playing characteristics of natural grass. To this end, each field must undergo four steps as outlined below:

a thorough composition and resilience test of the product in the laboratory (step 1)

the installation of the product as declared, applying the outlined procedures (step 2)

a test of the final installation for the relevant characteristics of the field as a whole system (step 3)

if successful, certification FIFA QUALITY or FIFA QUALITY PRO field (step 4)

After expiration of the certificate, the field can be retested (step 3/4)

Fig. 1.2 Approval process steps and the related documents / parties

Legend:

This process is part of the FIFA Quality Programme for Football Turf in order to

replicate the playing qualities of good quality natural grass,

create a playing environment that does not increase the risk of injury to players

achieve adequate durability (providing it is properly maintained)

For more details on FIFA Quality Programme for Football Turf see www.fifa.com/quality.

This document covers the complete step 1, FIFA LABORATORY TESTS REPORT. Consider:

Tests are performed on a representative sample of the manufacturers sample delivered to the FIFA accredited test

institutes

The test report is only valid if reproduced in its entirety

The results are only valid for the complete Football Turf (related product) as stated in 2.1

The related product is eligible for undergoing a field test on a final installation.

IMPORTANT:

To reach FIFA QUALITY PRO (or QUALITY) field certification, as next steps

the installation has to comply with the related Product Declaration / Method Statement (step 2)

a successfully passed subsequent FIELD TEST (step 3/4)

This FIFA LABORATORY TEST REPORT may only be used in relationship to Football Turf fields that are going to be submitted for

certification under the FIFA Quality Programme of Football Turf. Any other use of this report is a violation of the reports copy

right which is held by FIFA and breaches the terms of the FIFA Quality Programme of Football Turf licensing agreement.

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 3 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

2 Test Object, Participants

2.1 Test Numbers

Report Laboratory Test report number 17-0329-01

Identification Test Institute Project number 17-0329-01

2.2 Test Objects

Product Name DOMO Duraforce XSL 40M/16/Naturafill/Domoflex

Product Identification code

T920.400.T24.LTO

Name DOMO Duraforce XSL 40M/16

of the synthetic turf system

Performance infill Naturafill

Stabilising infill Silica sand

Shock-pad or elastic layer Domoflex

(if applicable)

Sub-base composition Rigid engineered Base

2.3 Participants, Addresses

Applicant

FIFA preferred producer Name Domo Sports Grass

Licensee

Address Domo Sports Grass

Contact Phone +3237804554 email Philippe.dierkens@slgroup.be

Name Ghent University (ERCAT)

Ghent University (ERCAT), ZWIJNAARDE

Address

FIFA accredited ercat@ugent.be

Contact Phone +3292645735 email

Test Institute

3 Test Conclusion, Product Approval

The presented Football Turf surface satisfies the FIFA LABORATORY TEST requirements of

FIFA QUALITY Passed passed or failed

FIFA QUALITY PRO Passed passed or failed

IMPORTANT: A successfully passed test of the final installation (FIFA FIELD TEST)

is mandatory to obtain FIFA QUALITY / QUALITY PRO Certification!

Name Stijn Rambour

Report Position Head of artificial turf

originated

by Date 04.04.2017

Name Prof Dr Paul Kiekens

Report Position Director

approved

by Date 04.04.2017

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 4 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

4 Product Information / Specifications

4.1 Overview a typical product composition

The basic structure and composition of artificial turf varies. To reach the goal of defined quality and specific functional

performances, a set of the relevant parameters for the products / materials used was defined.

Materials / products typically used are as follows:

Fig. 1.3 Products / materials used to build up artificial turf

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 5 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

4 Product Information / Specifications

4.2 Artificial turf (1/2)

Manufacturer Sports and Leisure Group

Tuft pattern straight

Standard

Pile yarns Yarn A Yarn B Yarn C

Test

Method

Yarn Manufacturer Domo Domo

Product name, code Duraforce XSL Duraforce XSL

Pile yarn profile See details below See details below See details below

Pile thickness

360 360

[m]

1 6003 6025

Pile colour

2

[RAL]

Pile width [mm] 1.0 1.0

No of tufts/m 2 10080 10080

ISO1773

Pile length [mm] 40 40

ISO 2549

Pile weight [g/m ] 2 710 710

ISO 8543

Pile yarn PE

PE

characterization

Pile yarn dtex 6750 6750

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 6 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

4 Product Information / Specifications

4.2 Artificial turf (2/2)

Product name / code D1

Primary

backing

Manufacturer Carpet backing

Product name / code /

Re- enforcement scrim

Manufacturer /

Product name / code 5/75

Secondary Manufacturer Eurocompound

backing

Dry application rate [g/m2] 1000

Minimum tuft

30

withdrawal force [N]

Carpet

Carpet mass

2675

per unit area [g/m2]

Method of jointing

Adhesive brand name AW glue

Adhesive manufacturer DOMO

Bonded joints

Application rate [g/lm] 300

Jointing film brand name LB145

Jointing film manufacturer DOMO

Tread brand name/product code /

Stitched seams

Tread manufacturer /

Stitch rate [stitch per lm] /

4.3 Performance infill

Specifications Standard

Test

Product name / code Naturafill Method

Manufacturer DOMO

Material type cork

Material grading 1-2.0

Particle shape irregular prEN 14955

Particle size range 1-2.0 EN 933-Part 1

Bulk density [g/cm3] 0.12 EN 1097-3

Application rate [kg/m2] 2.5

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 7 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

4 Product Information / Specifications

4.4 Stabilising infill

Specifications Standard

Test

Product name / code DOMO sand 0408 Method

Manufacturer DOMO

Material type silica sand

Material grading 0.4-1.0

Particle shape 80% round prEN 14955

Particle size [range] 0.4-1.0 EN 933-Part 1

Bulk density [g/cm3] 1.58 EN 1097-3

Application rate [kg/m2] 10

4.5 Shockpad / elastic layer*

Standard

Specifications Test

Product name / code Domoflex Method

Manufacturer DOMO

Type prefabricated

Composition** cross-linked PE

Bulk density [g/cm3] /

Thickness 11mm EN 1979

Shock absorption [%] 40 FIFA 4a

Deformation 4 FIFA 5a

Tensile strength [N] 0.15

Mass per unit area

[kg/m2] 0.5

* if part of system supplied

** type, rubber granule grading, binder content, etc

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 8 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

4 Product Information / Specification

4.6 Maintenance requirements (recommendations)

Equipment / material Remarks

Purpose - the power unit that pulls the maintenance tools over the

Tractor Unit

field

A maintenance attachment that re-distributes the infill and brings

Brush

the fibres into a more upright position

Drag

Mat

A maintenance tool used to re-distribute infill

A testing device used to assess the speed of a football over the

Ball roll ramp

surface

Is used to record all the maintenance activities that take place on the

Maintenance logbook

Football Turf Surface

Top up infill materials

to top up penalty spot and corner areas

For further maintenance requirements, please consult the

manufacturers recommendations for your specific system

FIFA Licensees comments / hints

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 9 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Laboratory Test Results

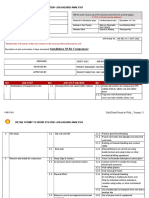

5.1 Overview ball and player to surface interactions

How is the field to play? By means of the following 8 parameters, this question can be answered very well.

Furthermore, some values allow conclusions regarding maintenance in order to keep the field in top shape.

Parameter Comments / hints Parameter Comments / hints

1- Vertical 5- Shock

ball rebound absorption Shock absorbency is an indication

of how hard the field feels to the

player. A value that is too low

indicates a hard field and cause

Th higher the value the

The damage to players joints too soft

higher the ball will rebound. and the surface is energy sapping

The ball should not bounce

Th resulting in increases in fatigue

too high or too low.

to and over-use injuries.

Ball / surface interaction Player / surface interaction

2- Angled Angled ball rebound is a

ball rebound combination of the hardness 6- Deformation

of the field and the

resistance from the fibres to

the ball and thus a high

th A surface that deforms too

reading can come from a much will result in

hard surface, or a low grip overstretching of ligaments

surface or a combination of

su particularly the around the

both ankle.

Ball / surface interaction Player / surface interaction

3- Ball roll

Th higher the value the

The

fa

faster the ball will run over

the surface. The ball should

th

not be too fast or too slow.

Ball / surface interaction

4- Rotational

resistance Th simulates the players

This

ability to alter direction, too

high a value and stress can

occur across knee ligaments,

too low and the player will

to

not be able to grip the

surface and may slip causing

su

ligament damage.

Player / surface interaction

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 10 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.2 Product identification

Property Test result

Carpet mass per unit area [g/m2] 2417

Tufts per unit area [m2] 10503

Pile length above backing [mm] 42

Artificial Turf Pile weight [g/m2] 1379

Water permeability of carpet [mm/h] >2000

Free pile height 16

Yarn cross section and thickness See Annex

Particle size range 0.8-2

Particle shape A2

Bulk density [g/cm3] 0.12

Performance infill

Infill depth 24

% organic

Thermographic

analysis

% inorganic

Particle size range 0.315-0.8

Stabilising infill Particle shape C2

Bulk density [g/cm3] 1.53

Shock absorption [%] 38

Shockpad /

elastic layer Deformation 7.1

(if part of system supplied)

Thickness 10.1

5.3 Ball / surface interaction

FIFA Approval P = passed

requirements F = failed

QUAL- PRO

Property Condition Test Results QUALITY PRO ITY

Dry 0.83 Passed Passed

Initial,

0.6 1m

un-aged 0.6-0.85

Wet 0.82 Passed Passed

Vertical m

ball rebound

After 3020 cycles 0.85 Passed

simulated

wear 6020 cycles 0.97 0.6 1m Passed

Dry 53 Passed Passed

Angled

45 80% 45 80%

ball rebound

Wet 70 Passed Passed

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 11 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

Initial, 5.8 Passed Passed

Dry

un-aged

After Dry 5.5 4 10m Passed

simulated

Reduced Ball wear

6.1 4 8m Passed

roll 3020 cycles Wet

After Dry 6.0 Passed

simulated

4 12m

wear

6.4 Passed

6020 cycles Wet

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 12 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.4 Player / surface interaction

FIFA Approval P = passed

requirements F = failed

Test QUALITY QUAL-

Property Condition QUALITY PRO

Results PRO ITY

Dry 68 Passed Passed

Initial,

57 68%

Un-aged 68 62 68% Passed Passed

Wet

3020 66 Passed

After cycles

Shock

simulated

absorption

wear 6020 63 Passed

cycles

68 57 68% Passed Passed

50C

62 68%

5C(1) 68 Passed Passed

Dry 9.8 Passed Passed

Initial 6 11mm

Wet 9.8 Passed Passed

6 10mm

Deformation 3020 9.6 Passed

After cycles

simulated

wear 6020 9.2 6 11mm Passed

cycles

Dry 38 Passed Passed

Initial 2748Nm

Wet 38 Passed Passed

3243Nm

Rotational

resistance 3020 40 Passed

After cycles

simulated

wear 6020 42 2748Nm Passed

cycles

Skin / surface 0.35 0.35

Dry 0.68 Passed Passed

friction 0.75 0.75

Skin abrasion Dry 16 + 30 % + 30 % Passed Passed

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 13 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.5 Environmental impact (artificial, light, water)

FIFA Requirements

P= passed F= failed

Property Aspect Condition Test result P/F

1 4-5 Passed

Colour change 2 4-5 > Grey scale 3 Passed

3

Pile yarns

1 After artificial -4 Passed

weathering

Yarn tensile

strength 2 1 Change < 50% Passed

Colour change > Grey scale 3

Polymeric infill

Visual change in

No change

composition

Complete

Water permeability N/A 941 >180 mm/h Passed

system

Un-aged

Stitched joints Strength > 1000N/100mm

Water aged

Un-aged 155 Passed

Bonded joints Strength > 75N/100mm

Water aged 154 Passed

Un-aged 40 Passed

Carpet tuft Withdrawal force > 30N

Water aged 30 Passed

Heat category 1-2

Information

Splash Splash characteristic >1.5% Information

5.6 Miscellaneous

Shockpad

Tensile strength Un-aged 0.21 > 0.15 MPa Passed

Elastic layer

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 14 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.1 DSC (Differential Scanning Colorimetry) scans of pile yarn

5.7.2 Performance infill particle grading curve / Stabilising infill particle grading curve

5.7.3 TGA (Thermo Gravimetric Analysis) of performance infill

5.7.4 Composition of unbound sub-base (if tested as part of system) Sub-base particle grading curve

5.7.5 Simulated wear, photos before / after

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 15 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.1 DSC Differential Scanning Colorimetry scans of pile yarn

Comments:

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 16 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.2 a) Performance infill particle grading curve

5.7.2 b) Stabilising infill particle grading curve

Comments:

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 17 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.3 TGA of performance infill

Comments:

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 18 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.4 Sub base (if tested as part of system)

Composition

Particle size range

Particle shape

Thickness

Compaction & test method

Sub-base particle grading curve

Comments:

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 19 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.5 Simulated wear (photos before / after wear) Page: 1

Before wear After wear

3005 c

6005c

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 20 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.5 Simulated wear (photos before / after wear) Page: 2

Before wear After wear

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 21 / 22

FIFA Quality Programme for Football Turf

Football Turf Laboratory Test Report

5 Detailed Test Results

5.7 Explanatory graphs / pictures

5.7.5 Yarn characteristics

Cross-section Yarn 1 Side A Yarn 1 Side B Yarn 1

Cross-section Yarn 2 Side A Yarn 2 Side B Yarn 2

Cross-section Yarn 3 Side A Yarn 3 Side B Yarn 3

Details of dimension measurements

circular thickness: FG: 357m, OG: 377m ; depth/max thickness: FG: 366m OG: 380m; width: FG: 1.1mm OG: 1.1mm

Manual 2015 REPORT No. 17-0329-01 Date: 10.03.2017 22 / 22

You might also like

- Dye and PryDocument11 pagesDye and PryeliasNo ratings yet

- Masterthesis Life CycleDocument83 pagesMasterthesis Life Cycleirfan FENERCİOĞLUNo ratings yet

- USGA 2017 LetterDocument1 pageUSGA 2017 Lettercmcdowell1827100% (1)

- Product Listing SchemeDocument14 pagesProduct Listing Schemeyunying21No ratings yet

- Technical Specification: Iso/Ts 17892-5Document11 pagesTechnical Specification: Iso/Ts 17892-5Khlif NadaNo ratings yet

- Methodology Tapping Methodology of WaterlineDocument15 pagesMethodology Tapping Methodology of WaterlineBryNo ratings yet

- Carta Alir PDFDocument5 pagesCarta Alir PDFMdnor RahimNo ratings yet

- Work Sample Report September 2022Document28 pagesWork Sample Report September 2022api-641490923No ratings yet

- Manufacturing Process FundamentalsDocument4 pagesManufacturing Process Fundamentalsmurare973No ratings yet

- TEST - 60MM FIFA2 BEKA DUOFILAMENT-310mDocument20 pagesTEST - 60MM FIFA2 BEKA DUOFILAMENT-310mitNo ratings yet

- Cert. Conformitate PROOFOT CLUB 50mmDocument19 pagesCert. Conformitate PROOFOT CLUB 50mmAnNe MaRieNo ratings yet

- TigerTurf - Championship 50 - FIFA - Lab Report - GreenDocument27 pagesTigerTurf - Championship 50 - FIFA - Lab Report - GreenPrince AndersonNo ratings yet

- FQP Handbook of Requirements v26Document32 pagesFQP Handbook of Requirements v26Waldo SchaefferNo ratings yet

- FQP Handbook of Requirements 2015 v31 W Cover PDFDocument31 pagesFQP Handbook of Requirements 2015 v31 W Cover PDFRain RobinNo ratings yet

- IRFU Artificial GrassDocument23 pagesIRFU Artificial Grasshoe3852No ratings yet

- XWR FIFA Test ReportDocument27 pagesXWR FIFA Test Reportsoufyane babaNo ratings yet

- Spray Foam KnowledgeDocument23 pagesSpray Foam KnowledgeRaheel AsgharNo ratings yet

- Bz/iso5794 1 2005 PDFDocument36 pagesBz/iso5794 1 2005 PDFJuan Carlos PosadaNo ratings yet

- Satra 80634 14c Mat Kws OutsoleDocument10 pagesSatra 80634 14c Mat Kws OutsoleFangfang YeohNo ratings yet

- Iso Astm 52904 2019 PDFDocument9 pagesIso Astm 52904 2019 PDFFantasticNo ratings yet

- ALLEN COOPER Safety FootwearDocument9 pagesALLEN COOPER Safety Footwearzakk jillNo ratings yet

- Lancer Safety FootwearDocument9 pagesLancer Safety Footwearzakk jillNo ratings yet

- A0271 Best Practice Manual GORE Technology (FTW) 29.01.2014Document19 pagesA0271 Best Practice Manual GORE Technology (FTW) 29.01.2014thanh2501No ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- FTR Kal2 2017 03607, Black F.terryDocument4 pagesFTR Kal2 2017 03607, Black F.terrySaifur RahmanNo ratings yet

- Fifa Quality Programme For Football Turf PDFDocument28 pagesFifa Quality Programme For Football Turf PDFsoortaNo ratings yet

- INSTA SBC EN 13589-2 Sep 2009Document17 pagesINSTA SBC EN 13589-2 Sep 2009Kipodim100% (1)

- 04 Alastair CoxDocument41 pages04 Alastair CoxcosineNo ratings yet

- 376884574-IOS-MAT-0003 (Dich)Document39 pages376884574-IOS-MAT-0003 (Dich)tranngocvuongNo ratings yet

- Tencate Ms Pro Product LeafletDocument2 pagesTencate Ms Pro Product Leafletamee101296No ratings yet

- MahadevDocument36 pagesMahadevquality fluconNo ratings yet

- Ford WSS-M8P25-CDocument5 pagesFord WSS-M8P25-CPablo AnguianoNo ratings yet

- MUTU-4105MEPA (2-0) Request For The Scope of CertificationDocument6 pagesMUTU-4105MEPA (2-0) Request For The Scope of CertificationParag SarodeNo ratings yet

- B3. Brahimi - 2014 - Qualification of ASTM F1136 Non-Chrome GEOMET 321 For Use With ASTM A490 High-Strength Structural BoltsDocument47 pagesB3. Brahimi - 2014 - Qualification of ASTM F1136 Non-Chrome GEOMET 321 For Use With ASTM A490 High-Strength Structural BoltsGavin BiggsNo ratings yet

- 392-2020-00314301 - VOC'S Emission - PERLIFOC HPDocument20 pages392-2020-00314301 - VOC'S Emission - PERLIFOC HPJaime Mena CamargoNo ratings yet

- MDDSDoc 8865 1.2Document9 pagesMDDSDoc 8865 1.2dragonvu72No ratings yet

- Test Certificate: Constructive SolutionsDocument1 pageTest Certificate: Constructive SolutionsBala KrishnanNo ratings yet

- Quality Concept: Step by Step To A FIFA Recommended Football Turf FieldDocument4 pagesQuality Concept: Step by Step To A FIFA Recommended Football Turf FieldmalkovristoNo ratings yet

- Ios Mat 0003Document39 pagesIos Mat 0003druliac100% (1)

- Powder CoatDocument10 pagesPowder CoatsouravNo ratings yet

- Chemical and Construction Input Industry Development Institute /C.C.I.I.D.IDocument6 pagesChemical and Construction Input Industry Development Institute /C.C.I.I.D.IEyob HaylemariamNo ratings yet

- TigerTurf Sports Product Brochure 2011Document24 pagesTigerTurf Sports Product Brochure 2011safinditNo ratings yet

- Jotafix Pu Topcoat PDFDocument2 pagesJotafix Pu Topcoat PDFcahyo hutomoNo ratings yet

- Chemical and Construction Input Industry Development Institute /C.C.I.I.D.IDocument5 pagesChemical and Construction Input Industry Development Institute /C.C.I.I.D.IEyob HaylemariamNo ratings yet

- Geosynthetics Certificate 07 Geoter F Pet October 2021Document5 pagesGeosynthetics Certificate 07 Geoter F Pet October 2021no pain no gainNo ratings yet

- Fluorten Products ListDocument8 pagesFluorten Products ListMax SalogniNo ratings yet

- Bber Compounding Technology-FinalDocument61 pagesBber Compounding Technology-Finalbodekiz90% (59)

- Venn AirDocument24 pagesVenn AirpepeNo ratings yet

- FireFre-88 Data SheetDocument4 pagesFireFre-88 Data SheetMojamethNo ratings yet

- Fifa Football Quality PDFDocument19 pagesFifa Football Quality PDFved100% (1)

- Draft Specification of IS 13893Document8 pagesDraft Specification of IS 13893Ved SharmaNo ratings yet

- Ma-Handbook 20210624 Clean-Version en enDocument31 pagesMa-Handbook 20210624 Clean-Version en enBrian MulengaNo ratings yet

- TD Bio-Flex F 1814 enDocument2 pagesTD Bio-Flex F 1814 enShruti SinghNo ratings yet

- Footwear Specify Materials Used in Footwear Soles: Level: 4 Credit: 6 Planned Review Date: November Sub-Field: PurposeDocument4 pagesFootwear Specify Materials Used in Footwear Soles: Level: 4 Credit: 6 Planned Review Date: November Sub-Field: PurposeManmohan KumarNo ratings yet

- Surface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteDocument5 pagesSurface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteClyde CoopperNo ratings yet

- Inoflon 610Document2 pagesInoflon 610Kishor JadhavNo ratings yet

- ISO 248 - Rubber, Raw - Determination of Volatile Matter Content (6-15-2005)Document14 pagesISO 248 - Rubber, Raw - Determination of Volatile Matter Content (6-15-2005)axeldanyNo ratings yet

- Flex - ULDocument8 pagesFlex - ULFareethAbdullahNo ratings yet

- Iso 00005-4-2009-1Document22 pagesIso 00005-4-2009-1pavanNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Mar For Paint System 5 C-PIP-REP-000-38156Document9 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Mar For Paint System 5 C-PIP-REP-000-38156ahmedNo ratings yet

- Group One (General Geology)Document20 pagesGroup One (General Geology)thea4bermejoNo ratings yet

- 05rotary Shaft Seals PDFDocument13 pages05rotary Shaft Seals PDFKhanh Pham DangNo ratings yet

- Mastertop 1205Document3 pagesMastertop 1205Haresh BhavnaniNo ratings yet

- Assessment of Valve FailuresDocument57 pagesAssessment of Valve FailuresSergioUlises100% (1)

- HDPE Vs Phenolic Vs SCRC Comparison Sell Sheet 2020Document6 pagesHDPE Vs Phenolic Vs SCRC Comparison Sell Sheet 2020heshamNo ratings yet

- RRS Full NotesDocument164 pagesRRS Full NotesAzhar KhanNo ratings yet

- Operation of A Centrifugal Oil PurifersDocument11 pagesOperation of A Centrifugal Oil PurifersIonescu GeorgeNo ratings yet

- Linear Guideway DoctorDocument1 pageLinear Guideway DoctorKai ZingNo ratings yet

- Durco IsoDocument28 pagesDurco Isomartin.rubenNo ratings yet

- A. Alan Blind: Buchanan, NY 10511Document104 pagesA. Alan Blind: Buchanan, NY 10511Agustin A.No ratings yet

- 71 PutilovaDocument8 pages71 Putilova1xlaleNo ratings yet

- Bota HazmatDocument2 pagesBota HazmatGuadalupe LechugaNo ratings yet

- 2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFDocument28 pages2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFVelibor Karanović100% (1)

- Hatch Covers Practical GuideDocument53 pagesHatch Covers Practical Guidemaneesh100% (3)

- Cast MaterialsDocument20 pagesCast MaterialsLoru GomezNo ratings yet

- Review of Wear Mechanisms in Hip Implants Paper 1 GeneralDocument9 pagesReview of Wear Mechanisms in Hip Implants Paper 1 GeneralCesar EscobarNo ratings yet

- JHA - Installation of Air CompressorDocument4 pagesJHA - Installation of Air CompressorFikri HidayatNo ratings yet

- 1 Product CatalogDocument100 pages1 Product CatalogFraz AhmadNo ratings yet

- 2021 CatalogueDocument27 pages2021 CatalogueGMAR ComercializadoraNo ratings yet

- Heat Exchanger 3Document53 pagesHeat Exchanger 3ravi00098No ratings yet

- UK Risk Focus - Hatch Covers WEBDocument24 pagesUK Risk Focus - Hatch Covers WEBniknik73No ratings yet

- Mechanical SealsDocument54 pagesMechanical Sealsajitkk79100% (2)

- Maine Industrial Tire v. T.Y Cushion TireDocument28 pagesMaine Industrial Tire v. T.Y Cushion TirePriorSmartNo ratings yet

- Selecting Target ISO Cleanliness CodesDocument4 pagesSelecting Target ISO Cleanliness CodesluaguNo ratings yet

- Klüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain BearingsDocument4 pagesKlüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain Bearingsphucdc095041No ratings yet

- AstmDocument4 pagesAstmHilal kan uyarNo ratings yet

- LGP - Processo ManualDocument29 pagesLGP - Processo ManualAnonymous mq0U43UsPNo ratings yet

- Plates-and-Sheets-CHATHAM STEEL PDFDocument15 pagesPlates-and-Sheets-CHATHAM STEEL PDFnanangNo ratings yet

- Short Notes On Kiln RefractoryDocument4 pagesShort Notes On Kiln RefractoryVijay BhanNo ratings yet

- Exp. 8: Pin On Disk Test: BITS PilaniDocument17 pagesExp. 8: Pin On Disk Test: BITS Pilaniakash chNo ratings yet