Professional Documents

Culture Documents

Lithium Bromide Absorption Refrigeration System

Uploaded by

S R Akhil KrishnanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lithium Bromide Absorption Refrigeration System

Uploaded by

S R Akhil KrishnanCopyright:

Available Formats

Lithium Bromide Absorption Refrigeration System

The lithium-bromide absorption refrigeration system uses a solution of lithium bromide

in water. In this system, the *water is being used as a refrigerant whereas lithium bromide, which

is a highly hydroscopic salt, as an absorbent. The lithium bromide solution has a strong affinity

for water vapour because of its very low vapour pressure. Since lithium bromide solution is

corrosive, therefore inhibitors should be added in order to protect the metal parts of the system

against corrosion. Lithium chromate is often uged as a corrosion inhibitor. This system is very

popular for air conditioning in which low refrigeration temperatures (not below 0 C)** are

required.

Fig. 3.4 shows a lithium bromide vapour absorption system. In this system. the absorber

and the evaporator are placed in one shell which operates at the same low pressure of the system.

The generator and condenser are placed in another shell which operates at the same high pressure

of the system. The principle of operation of this system is discussed below :

The water for air-conditioning coils or process requirements is chilled as it is pumped

through the chilled-water tubes in.the evaporator by giving up heat to the refrigerant water

sprayed over the tubes. Since the pressure inside the evaporator is maintained very low,

therefore, the refrigerant waterevaporates. The water vapours thus formed will be absorbed by

the strong lithium-bromide solution which is sprayed in the absorber. In absorbing the water

vapour, the lithium bromide solution helps in maintaining very low pressure (high vacuum)

needed in the evaporator, and the solution becomes weak. This weak solution is pumped by a

pump to the generator where it is heated up by using steam or hot water in the heating coils. A

portion of water is evaporated by the heat and the solution now becomes more strong. This

strong solution is passed through the heat exchanger and then sprayed in the absorber as

discussed above. The weak solution of lithium bromide from the absorber to the generator is also

passed through the heat exchanger. This weak solution gets heat from the strong solution in the

heat exchanger, thus reducing the quantity of steam required to heat the weak solution in the

generator.

Fig. 3.4. Lithium-Bromide absorption refrigeration system.

The refrigerant water vapours formed in the generator due to heating of solution are

passed to the condenser where they are cooled and condensed by the cooling water flowing

through the condenser water tubes. The cooling water for condensing is pumped from the

cooling water pond or tower. This cooling water first enters the absorber where it takes away the

heat of condensation and dilution. The condensate from the condenser is supplied to the

evaporator to compensate the water vapour formed in the evaporator. The pressure reducing

valve reduces the pressure of condensate from the condenser pressure to the evaporator pressure.

The cooled water from the evaporator is pumped and sprayed in the evaporator in order to cool

the water for air conditioning flowing through the chilled tubes. This completes the cycle.

You might also like

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- Safety Instructions Operating Instructions Owner's Manual and Installation InstructionsDocument138 pagesSafety Instructions Operating Instructions Owner's Manual and Installation InstructionsEmeka IkeNo ratings yet

- MECH3429Air Conditioning and Refrigeration Engineering3Document84 pagesMECH3429Air Conditioning and Refrigeration Engineering3Umair Khan MarwatNo ratings yet

- Types of compressors and their advantages and disadvantagesDocument4 pagesTypes of compressors and their advantages and disadvantagesAj Ax100% (1)

- Bosch Dishwasher SPS58M98EU Short User ManualDocument2 pagesBosch Dishwasher SPS58M98EU Short User ManualTerrmosTerrmosNo ratings yet

- About RefrigeratorDocument3 pagesAbout RefrigeratorRieza AldioNo ratings yet

- Refrigeration SystemDocument38 pagesRefrigeration SystemAdrian Derek IvashkoveNo ratings yet

- Introduction of REfrigeratorDocument45 pagesIntroduction of REfrigeratorSantosh Ojha100% (2)

- "Refrigeration Using LPG": Prof. Bhupendra PandeyDocument16 pages"Refrigeration Using LPG": Prof. Bhupendra PandeyAditya Mishra100% (1)

- New Inverter RefrigeratorDocument4 pagesNew Inverter RefrigeratormonikeshNo ratings yet

- Air Con Elements PDFDocument6 pagesAir Con Elements PDFJerico LlovidoNo ratings yet

- Kenmore 587.12333 DishwasherDocument36 pagesKenmore 587.12333 DishwasherdvageonNo ratings yet

- Comfort and Psychrometrics Chart ExplainedDocument15 pagesComfort and Psychrometrics Chart Explaineddavidfr2100% (1)

- Bootstrap Air Cooling System AerospaceDocument22 pagesBootstrap Air Cooling System AerospaceShambhavi LeolineLeveret100% (1)

- Air Conditioning Principles and ConceptsDocument64 pagesAir Conditioning Principles and ConceptsILYAS AHMED100% (1)

- Symbols Terms Refrig Air Con - English PDFDocument1 pageSymbols Terms Refrig Air Con - English PDFLuís AbreuNo ratings yet

- (B Purushothama) Humidification and Ventilation Ma (BookFi) 2Document456 pages(B Purushothama) Humidification and Ventilation Ma (BookFi) 2Debele Chemeda33% (3)

- Experiment No. 1 Name of Experiment - Study of Window Air ConditionerDocument65 pagesExperiment No. 1 Name of Experiment - Study of Window Air ConditionerMir Aqueel AliNo ratings yet

- Technological University (Maubin) Department of Mechanical Engineering Mini One Door RefrigeratorDocument13 pagesTechnological University (Maubin) Department of Mechanical Engineering Mini One Door RefrigeratorLin Yi100% (1)

- Washer Tech Data Sheet: Troubleshoot The Problem by Using Charts On The Pages 3-5. Quick CheckDocument16 pagesWasher Tech Data Sheet: Troubleshoot The Problem by Using Charts On The Pages 3-5. Quick CheckPedro ArceNo ratings yet

- Cascade Refrigeration System (Report)Document8 pagesCascade Refrigeration System (Report)THE PUBGTV100% (1)

- Adsorption RefrigerationDocument22 pagesAdsorption RefrigerationVijay Krishnan100% (1)

- Apparatus Dew PointDocument4 pagesApparatus Dew PointS DasNo ratings yet

- Thermodynamics II Refrigeration: Mohsin Mohd SiesDocument40 pagesThermodynamics II Refrigeration: Mohsin Mohd SiesSaadFerekhNo ratings yet

- Refrigeration in AutomobilesDocument11 pagesRefrigeration in Automobilesanswer1No ratings yet

- Chapter 11 - Refrigeration CyclesDocument25 pagesChapter 11 - Refrigeration CyclesPaul RodgersNo ratings yet

- Pub 120 Table 7 PDFDocument2 pagesPub 120 Table 7 PDFОливер АндовскиNo ratings yet

- Types of Air Conditioning UnitsDocument10 pagesTypes of Air Conditioning Unitssnowgalvez44No ratings yet

- Review of Adsorption Refrigeration Technologies PDFDocument5 pagesReview of Adsorption Refrigeration Technologies PDFVerma AbhiNo ratings yet

- Vapour AbsorptionDocument10 pagesVapour Absorptiongayakwad12_ramNo ratings yet

- Operating and Installation Instructions: Combined Fridge-Freezer With Biofresh CompartmentDocument18 pagesOperating and Installation Instructions: Combined Fridge-Freezer With Biofresh CompartmentBasilio DanziNo ratings yet

- IceDocument4 pagesIcemuzammilkhatibNo ratings yet

- Performance Analysis of Refrigerator Using Water Cooled CondenserDocument21 pagesPerformance Analysis of Refrigerator Using Water Cooled Condenserjaiminspatel127100% (1)

- Provision Cooling GuideDocument13 pagesProvision Cooling Guideedo100% (1)

- Ag 31-011 1215daDocument78 pagesAg 31-011 1215daSicologo CimeNo ratings yet

- Refrigeration System DiagramDocument7 pagesRefrigeration System DiagramNama Saya ZulNo ratings yet

- Refrigeration and Air ConditioningDocument7 pagesRefrigeration and Air ConditioningManjunatha EikilaNo ratings yet

- 16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairDocument22 pages16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairPRASAD326100% (4)

- Free Cooling Types and ControlsDocument2 pagesFree Cooling Types and ControlsHnin PwintNo ratings yet

- Exp Tank SizingDocument5 pagesExp Tank SizingChaos100% (1)

- Compressor Motor & ComponentsDocument22 pagesCompressor Motor & Componentsicarus_fallenNo ratings yet

- Mek General AnwarDocument98 pagesMek General AnwarRaktim Kumar SinghNo ratings yet

- Evaporative CoolingDocument2 pagesEvaporative CoolingSanjana SahajramaniNo ratings yet

- Refrigeration SystemsDocument100 pagesRefrigeration SystemsRay RavelNo ratings yet

- Tumble DryersDocument20 pagesTumble DryersGrover CondoriNo ratings yet

- Uscg - Steam MCQDocument308 pagesUscg - Steam MCQAnshu BhushanNo ratings yet

- How condensers work and their key factorsDocument44 pagesHow condensers work and their key factorspriya dharshiniNo ratings yet

- Baseline Audit Report: L G Sea FoodsDocument29 pagesBaseline Audit Report: L G Sea FoodsMAHESH CHAVANNo ratings yet

- Troubleshooting Refr SystemsDocument12 pagesTroubleshooting Refr SystemsDnyanesh BodreNo ratings yet

- RACDocument3 pagesRACneerajbhayal3456No ratings yet

- SDFFFFFDocument10 pagesSDFFFFFromy_singlaNo ratings yet

- Refregeration CycleDocument6 pagesRefregeration CycleFinito TheEndNo ratings yet

- Lithium Bromide Absorption Refrigeration SystemDocument15 pagesLithium Bromide Absorption Refrigeration SystemAmir AbbaszadehNo ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- A Presentation On Lithium Bromide Absorption Refrigeration SystemDocument15 pagesA Presentation On Lithium Bromide Absorption Refrigeration SystemAyub GNNo ratings yet

- Literature Review of Vapour Absorption Refrigeration SystemDocument7 pagesLiterature Review of Vapour Absorption Refrigeration SystemnqdpuhxgfNo ratings yet

- Thermal Engineering Unit 5Document23 pagesThermal Engineering Unit 5MohanCool100% (1)

- Vapour Absorption System: Basic Principles and ComponentsDocument11 pagesVapour Absorption System: Basic Principles and Componentssanjay vermaNo ratings yet

- Absorption Refrigeration Systems (Absorption Chillers)Document2 pagesAbsorption Refrigeration Systems (Absorption Chillers)machi_5No ratings yet

- 2 To Study VASDocument5 pages2 To Study VASAnand GujaratiNo ratings yet

- Module 3aDocument26 pagesModule 3aS R Akhil KrishnanNo ratings yet

- Expansion DevicesDocument14 pagesExpansion DevicesS R Akhil KrishnanNo ratings yet

- Jult M D3) N Ill: Steint)Document23 pagesJult M D3) N Ill: Steint)S R Akhil KrishnanNo ratings yet

- CFF M-5Document25 pagesCFF M-5S R Akhil KrishnanNo ratings yet

- EvaporatorDocument24 pagesEvaporatorS R Akhil KrishnanNo ratings yet

- TD Solved Ktunotes - inDocument266 pagesTD Solved Ktunotes - inS R Akhil KrishnanNo ratings yet

- Refrigeration System Components: - Vishakh GaneshDocument34 pagesRefrigeration System Components: - Vishakh GaneshS R Akhil KrishnanNo ratings yet

- Refrigerant leakage detection and charging methodsDocument22 pagesRefrigerant leakage detection and charging methodsS R Akhil KrishnanNo ratings yet

- Refrigerant leakage detection and charging methodsDocument22 pagesRefrigerant leakage detection and charging methodsS R Akhil KrishnanNo ratings yet

- Connecting Rod: Numericals From K Raghavendra Dme-2 Text Book Databook Referred: Design Data Book K MahadevanDocument14 pagesConnecting Rod: Numericals From K Raghavendra Dme-2 Text Book Databook Referred: Design Data Book K MahadevanS R Akhil KrishnanNo ratings yet

- ATD1Document83 pagesATD1S R Akhil KrishnanNo ratings yet

- CompressorDocument20 pagesCompressorS R Akhil KrishnanNo ratings yet

- Heat Transfer Full NotesDocument215 pagesHeat Transfer Full NotesjotaNo ratings yet

- Advanced ThermodynamicsDocument83 pagesAdvanced ThermodynamicsS R Akhil KrishnanNo ratings yet

- Pressure Distribution and Choking in Convergent Divergent NozzleDocument6 pagesPressure Distribution and Choking in Convergent Divergent NozzleS R Akhil KrishnanNo ratings yet

- B Tech 2430 Heat Mass Transfer 2008 SCH s6 May2011Document3 pagesB Tech 2430 Heat Mass Transfer 2008 SCH s6 May2011S R Akhil KrishnanNo ratings yet

- MLN 03Document10 pagesMLN 03raghavlambiNo ratings yet

- HMTDocument1 pageHMTS R Akhil KrishnanNo ratings yet

- MLN 04Document21 pagesMLN 04abhishek_mishra_51No ratings yet

- Material Science: Prof. Satish V. KailasDocument7 pagesMaterial Science: Prof. Satish V. Kailasanupam_kayalNo ratings yet

- CondensorDocument19 pagesCondensorS R Akhil KrishnanNo ratings yet

- Gating Special Notes SystemDocument38 pagesGating Special Notes SystemS R Akhil KrishnanNo ratings yet

- MLN 01 PDFDocument6 pagesMLN 01 PDFadityacareNo ratings yet

- MLN 02Document18 pagesMLN 02Anand K. MouryaNo ratings yet

- GI Objectives Set1Document2 pagesGI Objectives Set1S R Akhil KrishnanNo ratings yet

- Gas Dynamics and Jet PropulsionNovDec2014R2008 PDFDocument3 pagesGas Dynamics and Jet PropulsionNovDec2014R2008 PDFS R Akhil KrishnanNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Weldin G 2016Document100 pagesWeldin G 2016S R Akhil KrishnanNo ratings yet

- Module 1Document2 pagesModule 1S R Akhil KrishnanNo ratings yet

- Lesson Plan 160205 Jelly Snake PracticalDocument7 pagesLesson Plan 160205 Jelly Snake Practicalapi-309206763No ratings yet

- A. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Document12 pagesA. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Nur HaeniNo ratings yet

- 1st ClassDocument18 pages1st Classchitl.23bi14075No ratings yet

- Chapter 4Document19 pagesChapter 4EyadNo ratings yet

- Hall Design For SpeechDocument1 pageHall Design For SpeechSarovar SaroNo ratings yet

- Vijay Solvex PROJECT "Retention Strategy"Document110 pagesVijay Solvex PROJECT "Retention Strategy"Jayesh SinghNo ratings yet

- Communication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisDocument44 pagesCommunication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisTeacherlucy BorregoNo ratings yet

- Class 9 - Half Yearly Examination - 2023 - Portions and BlueprintDocument16 pagesClass 9 - Half Yearly Examination - 2023 - Portions and BlueprintSUBRAMANI MANOHARANNo ratings yet

- NotesTransl 108 (1985) Larsen, Who Is This GenerationDocument20 pagesNotesTransl 108 (1985) Larsen, Who Is This GenerationluzuNo ratings yet

- Thesis PromptsDocument7 pagesThesis Promptsauroratuckernewyork100% (2)

- Newly Constructed Masculinity' in Mahesh Dattani's Dance Like A ManDocument4 pagesNewly Constructed Masculinity' in Mahesh Dattani's Dance Like A ManIJELS Research JournalNo ratings yet

- Participatory Assessment of Ragay Gulf Resources and SocioeconomicsDocument167 pagesParticipatory Assessment of Ragay Gulf Resources and SocioeconomicsCres Dan Jr. BangoyNo ratings yet

- Health Benefits of Kidney BeansDocument17 pagesHealth Benefits of Kidney BeansShyneAneeshNo ratings yet

- M13 - Solution of TrianglesDocument5 pagesM13 - Solution of Triangles9703693564No ratings yet

- 2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsDocument15 pages2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsSamuel PintoNo ratings yet

- Analog Communication Interview Questions and AnswersDocument34 pagesAnalog Communication Interview Questions and AnswerssarveshNo ratings yet

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetDocument2 pagesWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhNo ratings yet

- BCMEDocument9 pagesBCMEVenkateshwaran VenkyNo ratings yet

- 1-2-Chemical Indicator of GeopolymerDocument4 pages1-2-Chemical Indicator of GeopolymerYazmin Alejandra Holguin CardonaNo ratings yet

- Xbox Accessories en ZH Ja Ko - CN Si TW HK JP KoDocument64 pagesXbox Accessories en ZH Ja Ko - CN Si TW HK JP KoM RyuNo ratings yet

- Armitage Tutorial for Cyber Attack ManagementDocument54 pagesArmitage Tutorial for Cyber Attack Managementworkmumbai3870No ratings yet

- The Seasons of Life by Jim RohnDocument111 pagesThe Seasons of Life by Jim RohnChristine Mwaura97% (29)

- Lim vs. CA DigestDocument2 pagesLim vs. CA Digestsamme1010100% (1)

- More Med Surg Practice QuestionsDocument14 pagesMore Med Surg Practice QuestionsmisscoombsNo ratings yet

- School readiness assessmentDocument10 pagesSchool readiness assessmentJave Gene De AquinoNo ratings yet

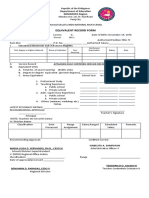

- Equivalent Record Form: Department of Education MIMAROPA RegionDocument1 pageEquivalent Record Form: Department of Education MIMAROPA RegionEnerita AllegoNo ratings yet

- Bread Machine Sunbeam 5891Document44 pagesBread Machine Sunbeam 5891Tyler KirklandNo ratings yet

- Quality of Good TeacherDocument5 pagesQuality of Good TeacherRandyNo ratings yet

- JNTUA Mechanical Engineering (R09) Syllabus BookDocument147 pagesJNTUA Mechanical Engineering (R09) Syllabus Bookslv_prasaad0% (1)

- Diwali - An Overview of The Festival of LightsDocument3 pagesDiwali - An Overview of The Festival of LightsSumeetNo ratings yet