Professional Documents

Culture Documents

Daily Activities Report 5-11-2017

Uploaded by

pstechnical_43312697Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Activities Report 5-11-2017

Uploaded by

pstechnical_43312697Copyright:

Available Formats

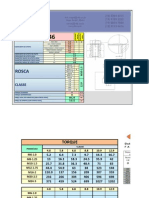

Daily Activity Report

BLCP Outage 2017 Unit#1 Shutdown Project

Date of Daily Activty Report : 5/11/2017

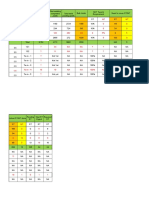

08:00-09:00 09:00-10:00 10:00-11:00 11:00-12:00 13:00-14:00 14:00-15:00 15:00-16:00 16:00-17:00 17:00-18:00 18:00-19:00 19:00-20:00

Weather Report S S S S S S S S S S S

Remarks: Sunny : S Clouded : C Rainy :R Heavy Rains : HR

Item Last day Item Today Item Next day

Piping Activity

1 Machine beveling support TA MHPS stub tube 1 Fit up & weld stub tube 4 joint. 1 Continues fit up & weld stub tube 4 joint.

2 Continues Tube Instaiiation fit up and weld (RHS top) 10 joint 2 Continues Tube Instaiiation fit up and weld (RHS top) 8 joint 2 Continues Tube Instaiiation fit up and weld (RHS top) 8 joint

3 Continues cut on RH tubes inside of boiler (RHS top) 3 Continues cut on RH tubes inside of boiler (RHS top) 30 joint 3 Continues cut on RH tubes inside of boiler (RHS top) 30 joint

4 Continues cut on RH tubes inside of boiler (LHS top) 4 Continues cut on RH tubes inside of boiler (LHS top) Finish today 4 Continues cut on RH tubes inside of boiler (Front left top)

5 Continues tube RH fit up & weld inside boiler (LHS top) 10 joint 5 Continues tube RH fit up & weld inside boiler (LHS top) 8 joint 5 Continues tube RH fit up & weld inside boiler (LHS top) 8 joint

6 Preparation spare part tube laydown area & Stock tube (for fit up Tube RH LHS top) 6 Preparation spare part tube laydown area & Stock tube (for fit up Tube RH LHS top) 6 Continues spare part tube laydown area & Stock tube (for fit up Tube RH LHS top)

7 Machine beveling tube RHS/LHS top. 7 Continues machine beveling tube RHS/LHS top. 7 Continues machine beveling tube RHS/LHS top.

Item Position Day Night Today Piping Activity Photo

MANPOWER

1 Site Engineer 1 0 1

2 QA Engineer 1 1 2

3 Safety 1 2 3

4 QA,QC Superviser 1 1 2

5 Superviser 7 2 9

6 Admin Staff 0 0 0

7 Welder 17 3 20

8 Fitter A,B 32 9 41

9 Electricain 1 2 3

10 Fire Watch 5 2 7

11 Store/General 4 0 4

12 Rigger 6 0 6

76 22 98

Piping Activity Photo

Total (Man-Day)

The TJEL manpower combine foe SPC Sub-Contact

Note : Progress Erection

No. Description Fit up Weld RT

1 RHS top (145 joints) 11 15 11 15 11

2 LHS top (145 joints) 7 14 7 14 7

3 Front side (297 joints) 0 0 0

Total 18 29 18 29 18

Note : Progress Cut tube

No. Description Joint Cut Balance

1 RHS top 145 93 52

2 LHS top 145 145 0

3 Front side 297 4 293

Total 587 242 345

Project repair rate up to date = 3/29 = 10%

Defect Porosity

You might also like

- Bosch Me7.4.5 1033Document2 pagesBosch Me7.4.5 1033Rafael FávaroNo ratings yet

- Pipeline Daily Construction ReportDocument2 pagesPipeline Daily Construction ReportKatie Benson83% (6)

- Keyway Sizing ChartDocument1 pageKeyway Sizing Chartpstechnical_43312697No ratings yet

- Underwater Welding Code: D3.6M:2017 An American National StandardDocument14 pagesUnderwater Welding Code: D3.6M:2017 An American National StandardSatendra kumar33% (3)

- Iso 15618-2-2001Document30 pagesIso 15618-2-2001abdulkadir aliNo ratings yet

- WPS, PQR, WPQ (Si007)Document5 pagesWPS, PQR, WPQ (Si007)Suresh RathodNo ratings yet

- Daily Activities Report 6-11-2017Document1 pageDaily Activities Report 6-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 12-11-2017Document1 pageDaily Activities Report 12-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 16-11-2017Document1 pageDaily Activities Report 16-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 15-11-2017Document1 pageDaily Activities Report 15-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 13-11-2017Document1 pageDaily Activities Report 13-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 30,10,17Document1 pageDaily Activities Report 30,10,17pstechnical_43312697No ratings yet

- TJELDaily Activities Report 25,10,17Document1 pageTJELDaily Activities Report 25,10,17pstechnical_43312697No ratings yet

- Mom Day 32Document65 pagesMom Day 32NSB-2018 PGDMNo ratings yet

- Daily 04-10 April 2021Document23 pagesDaily 04-10 April 2021b4503kyNo ratings yet

- Daily Report: 03 YG 00400 9-May-2017 Tuesday DPR-342Document7 pagesDaily Report: 03 YG 00400 9-May-2017 Tuesday DPR-342mcgNo ratings yet

- Rekap Man PowerDocument15 pagesRekap Man PowerYeti Nur HayatiNo ratings yet

- Daily 2-8mei 2021Document24 pagesDaily 2-8mei 2021b4503kyNo ratings yet

- Mom Day 33Document65 pagesMom Day 33NSB-2018 PGDMNo ratings yet

- Daily Report: 03 YG 00400 24-Jun-2017 Saturday DPR-388Document4 pagesDaily Report: 03 YG 00400 24-Jun-2017 Saturday DPR-388mcgNo ratings yet

- Daily Report: 730 03 YG 00400 30-Jul-2017 Sunday DPR-424Document4 pagesDaily Report: 730 03 YG 00400 30-Jul-2017 Sunday DPR-424Yati ChanNo ratings yet

- WP7c Daily ReportDocument3 pagesWP7c Daily ReportAndriNo ratings yet

- Daily Report: 03 YG 00400 20-Jun-2017 Tuesday DPR-384Document4 pagesDaily Report: 03 YG 00400 20-Jun-2017 Tuesday DPR-384mcgNo ratings yet

- Daily Report: M Tower Project (4 Basement + 26 Storey Steel Office Building)Document5 pagesDaily Report: M Tower Project (4 Basement + 26 Storey Steel Office Building)phyo7799No ratings yet

- Daily Report January 2018Document31 pagesDaily Report January 2018Mohd FadliNo ratings yet

- TJEL Daily Activities Report 23,10,17Document1 pageTJEL Daily Activities Report 23,10,17pstechnical_43312697No ratings yet

- Manhours Report PT KPEDocument8 pagesManhours Report PT KPENoven YudhaNo ratings yet

- Laporan Harian 088Document2 pagesLaporan Harian 088muhamad habibiNo ratings yet

- PP1 - NGLB 331P1 R 0001Document9 pagesPP1 - NGLB 331P1 R 0001Raden Maurin SimanjuntakNo ratings yet

- Project Name: Hlaine Tet Hotel Project Location: Kyaike WineDocument2 pagesProject Name: Hlaine Tet Hotel Project Location: Kyaike WineYati ChanNo ratings yet

- Daily Activities Report December 8Document8 pagesDaily Activities Report December 8Andrie BuenavistaNo ratings yet

- Field Daily Activity Report: Unit Today Qty SUM %Document5 pagesField Daily Activity Report: Unit Today Qty SUM %Helmi PermadiNo ratings yet

- Daily 9Document6 pagesDaily 9Yati ChanNo ratings yet

- Project Name: Hlaine Tet Hotel Project Location: Kyaike WineDocument2 pagesProject Name: Hlaine Tet Hotel Project Location: Kyaike WineYati ChanNo ratings yet

- Daily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographDocument1 pageDaily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographRicardo NapitupuluNo ratings yet

- GSL Par DPR 00097Document11 pagesGSL Par DPR 00097Ahmad SaeedNo ratings yet

- Daily Report: 653 03 YG 00400 14-May-2017 Sunday DPR-347Document8 pagesDaily Report: 653 03 YG 00400 14-May-2017 Sunday DPR-347mcgNo ratings yet

- Daily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Document3 pagesDaily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Manoranjan sharmaNo ratings yet

- Daily Report 27 Februari 2024Document2 pagesDaily Report 27 Februari 2024stefanustobing0907No ratings yet

- Daily Activities Report December 7Document7 pagesDaily Activities Report December 7Andrie BuenavistaNo ratings yet

- SRC & NDT Coverage BalaDocument11 pagesSRC & NDT Coverage BalaGomathyselviNo ratings yet

- Daily Report - W41Document14 pagesDaily Report - W41deludelNo ratings yet

- Laporan Harian "Konstruksi" Gresem Pipeline ProjectDocument10 pagesLaporan Harian "Konstruksi" Gresem Pipeline ProjectrudiawanNo ratings yet

- Daily Report Project Indofermex 71Document1 pageDaily Report Project Indofermex 71David GoldensonNo ratings yet

- Daily Report: 03 YG 00400 30-Aug-2017 Wednesday DPR-455Document4 pagesDaily Report: 03 YG 00400 30-Aug-2017 Wednesday DPR-455Yati ChanNo ratings yet

- Page 1 of 7Document6 pagesPage 1 of 7Andrie BuenavistaNo ratings yet

- ABH Pipeline ScheduleDocument13 pagesABH Pipeline ScheduleGovind Jha100% (1)

- MRM - 38 MRM PresentationJan'14Document25 pagesMRM - 38 MRM PresentationJan'14Jennifer FrenchNo ratings yet

- Auxiliary Mechanical: SectionDocument17 pagesAuxiliary Mechanical: SectionRavi Kiran MNo ratings yet

- Format Dialy Report HK-IBB Oktober 2022Document76 pagesFormat Dialy Report HK-IBB Oktober 2022Dimas agungNo ratings yet

- Daily 6-12 Juni 2021Document23 pagesDaily 6-12 Juni 2021b4503kyNo ratings yet

- Daily Progress Welding Joint Report Wharf Boat Landing Upper StructureDocument2 pagesDaily Progress Welding Joint Report Wharf Boat Landing Upper StructureAditya Hadi SNo ratings yet

- Daily Report, Selasa 21 Januari 2020 PDFDocument2 pagesDaily Report, Selasa 21 Januari 2020 PDFAndika AndikaNo ratings yet

- Daily Report 26 Februari 2024Document2 pagesDaily Report 26 Februari 2024stefanustobing0907No ratings yet

- Project Name: Hlaine Tet Hotel Project Location: Kyaike WineDocument2 pagesProject Name: Hlaine Tet Hotel Project Location: Kyaike WineYati ChanNo ratings yet

- QHM 2017-18Document16 pagesQHM 2017-18Ravi Kiran MNo ratings yet

- Equipment List HVACRDocument5 pagesEquipment List HVACRwork4zoroNo ratings yet

- Weekly Report For SM MOM #111 of RWEP: 1.1 Personnel On Project Management Office (PMO)Document13 pagesWeekly Report For SM MOM #111 of RWEP: 1.1 Personnel On Project Management Office (PMO)Welday GebremichaelNo ratings yet

- Daily Work Schedule ReportDocument1 pageDaily Work Schedule Reportahmedrehaan100% (2)

- U4 OH RT ReportDocument209 pagesU4 OH RT ReportLokesh KandyNo ratings yet

- Daily Report 21 Februari 2024Document2 pagesDaily Report 21 Februari 2024stefanustobing0907No ratings yet

- Daily Report 23 Februari 2024Document2 pagesDaily Report 23 Februari 2024stefanustobing0907No ratings yet

- Primary Reheater ReplacementDocument12 pagesPrimary Reheater Replacementpstechnical_43312697No ratings yet

- Stud Welding Recorded U51Document1 pageStud Welding Recorded U51pstechnical_43312697No ratings yet

- แบบโต๊ะตัดDocument32 pagesแบบโต๊ะตัดpstechnical_43312697No ratings yet

- Weld Geometry Defect Influence On BoilerDocument10 pagesWeld Geometry Defect Influence On Boilerpstechnical_43312697No ratings yet

- Bar Chart PDFDocument1 pageBar Chart PDFpstechnical_43312697No ratings yet

- Project Completion Report 7Document1 pageProject Completion Report 7pstechnical_43312697No ratings yet

- Daily Activities Report 9-11-2017Document1 pageDaily Activities Report 9-11-2017pstechnical_43312697No ratings yet

- Stud Welding Recorded U51Document1 pageStud Welding Recorded U51pstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 9-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 9-11-2017pstechnical_43312697No ratings yet

- S-Curve BLCP 7-11-2017Document1 pageS-Curve BLCP 7-11-2017pstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 9-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 9-11-2017pstechnical_43312697No ratings yet

- Temper BeadDocument1 pageTemper Beadpstechnical_43312697No ratings yet

- 1ryRH Update22Oct2017Document3 pages1ryRH Update22Oct2017pstechnical_43312697No ratings yet

- TJELDaily Activities Report 25,10,17 PDFDocument1 pageTJELDaily Activities Report 25,10,17 PDFpstechnical_43312697No ratings yet

- S-Curve RHDocument1 pageS-Curve RHpstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 12-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 12-11-2017pstechnical_43312697No ratings yet

- BLCP Outage Work Schedule & Progress Rev.2 13-11-2017Document1 pageBLCP Outage Work Schedule & Progress Rev.2 13-11-2017pstechnical_43312697No ratings yet

- Daily Activities Report 8-11-2017Document1 pageDaily Activities Report 8-11-2017pstechnical_43312697No ratings yet

- TJELDaily Activities Report 25,10,17Document1 pageTJELDaily Activities Report 25,10,17pstechnical_43312697No ratings yet

- Daily Activities Report 5-11-2017 PDFDocument1 pageDaily Activities Report 5-11-2017 PDFpstechnical_43312697No ratings yet

- Fish BondDocument1 pageFish Bondpstechnical_43312697No ratings yet

- Mirror Welding 1Document1 pageMirror Welding 1pstechnical_43312697No ratings yet

- Bar ChartDocument1 pageBar Chartpstechnical_43312697No ratings yet

- BLCP S CurveDocument1 pageBLCP S Curvepstechnical_43312697No ratings yet

- Cep-Phkt-M-Qc-006 WPS Prosedure WPS Awsd1.1Document9 pagesCep-Phkt-M-Qc-006 WPS Prosedure WPS Awsd1.1Ferdie OSNo ratings yet

- NO Name Position: List Manpower Piping Pt. Bumi Liputan PusakaDocument4 pagesNO Name Position: List Manpower Piping Pt. Bumi Liputan PusakaSofyan Nur AminNo ratings yet

- TEST RING For AES HEDocument6 pagesTEST RING For AES HEAdrian StoicescuNo ratings yet

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingDocument1 pageWelder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingReza100% (1)

- Permanent Mechanical Joints - Welding: Wending, Soldering, and BrazingDocument9 pagesPermanent Mechanical Joints - Welding: Wending, Soldering, and BrazingAaron PadreNo ratings yet

- Pozzolanic Cements : Franco MassazzaDocument30 pagesPozzolanic Cements : Franco MassazzaLaura Borges CostaNo ratings yet

- T35770 - Lubrificação Da Torre DM16 GL240MDocument1 pageT35770 - Lubrificação Da Torre DM16 GL240MMarcoNo ratings yet

- WPS, PQR & WQT According To ASME Section IX - 2019Document50 pagesWPS, PQR & WQT According To ASME Section IX - 2019Anon YmousNo ratings yet

- Amp rj45Document3 pagesAmp rj45HendriJuniantoNo ratings yet

- MIG Welding: Lab Report ME-223 Advance Workshop PracticeDocument2 pagesMIG Welding: Lab Report ME-223 Advance Workshop PracticeMomina ShakeelNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAli RazaNo ratings yet

- Gearbox Clutch Driveshaft Steering PDFDocument190 pagesGearbox Clutch Driveshaft Steering PDFluisxxx1100% (1)

- Aws C 5.4 Stud Welding PracticesDocument7 pagesAws C 5.4 Stud Welding PracticesJose Aciano Hernandez0% (1)

- Contoh WPS: Pengelasan Austenitik Stainless Steel Tipe 304: Dr. Ir. Winaarto, M.SCDocument14 pagesContoh WPS: Pengelasan Austenitik Stainless Steel Tipe 304: Dr. Ir. Winaarto, M.SCDessy Ayu Lestari100% (3)

- Tapping and Drilling ChartDocument3 pagesTapping and Drilling ChartChris HeydenrychNo ratings yet

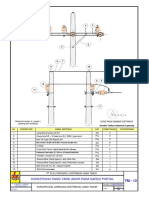

- Konstruksi Tiang Tarik Akhir Pada Gardu Portal: Konstruksi Jaringan Distribusi Jawa TimurDocument3 pagesKonstruksi Tiang Tarik Akhir Pada Gardu Portal: Konstruksi Jaringan Distribusi Jawa TimurrenggaNo ratings yet

- adaptadorDUS4101 PDFDocument3 pagesadaptadorDUS4101 PDFJCARLOS COLQUENo ratings yet

- Calculo de Torque X Forca AxialDocument4 pagesCalculo de Torque X Forca Axialmajonas77No ratings yet

- DW-55LSR: 4G 2G 2F 3G UphillDocument1 pageDW-55LSR: 4G 2G 2F 3G Uphillamit singhNo ratings yet

- PJU H 9mtr Tunggal PDFDocument1 pagePJU H 9mtr Tunggal PDFbgan29No ratings yet

- Selection of Filler Metal For WeldingDocument21 pagesSelection of Filler Metal For WeldingRegu vlogsNo ratings yet

- Juk LH-3128-7 3128Document48 pagesJuk LH-3128-7 3128RHoska100% (1)

- 1 Foundation of Boiler 24.10.2016-ModelDocument1 page1 Foundation of Boiler 24.10.2016-Model1449900% (1)

- HighDocument2 pagesHighVICTOR PEREZNo ratings yet

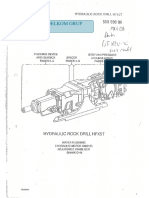

- Delkom Grup: Hydraulic Rock Drill H F X 5 TDocument20 pagesDelkom Grup: Hydraulic Rock Drill H F X 5 TStgo Turco100% (1)