Professional Documents

Culture Documents

Brake Linings: Making Friction Parts Even Better Then They Ever Were

Uploaded by

Edgar Fernando GordilloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brake Linings: Making Friction Parts Even Better Then They Ever Were

Uploaded by

Edgar Fernando GordilloCopyright:

Available Formats

Brake Linings

Making friction parts

even better then they ever were.

DRIE-D has a large stock of high quality pressed and woven friction material in sheet

and roll form and of finished brake blocks and shoes for most common industrial and

maritime brake and clutch brands. In our modern workshop all work regarding brake li-

nings, including riveting and vulcanisation, is being carried out. DRIE-D is the central

point customers turn to with problems regarding brake systems such as early wear,

squeaking brakes, glazing linings, replacement of asbestos friction materials and so on.

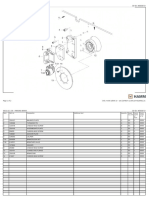

Friction Bands 300 T Winch Disc Brake Pads Pusnes winch Lay Barge Amcon Winch Blocks

G Brake lining 9850 G Brake lining 6813 G Brake lining 9850

G Asbestos free (as all DRIE-D products) G Asbestos free G Drilled and countersunk to pattern

G Replacing asbestos based linings G Allows very high temperatures G Replacing asbestos containing blocks

G Turn key job including coating, without fading G Longer living than the original asbestos

refurbishment of the joints, realignment G Replacement of linings and blocks

of the steel, etcetera refurbishment of damaged steel G Supplied in 3 weeks including bolts and

G Fast throughput backings nuts

G High and constant friction values G Non-aggressive for the brake discs G First asbestos free material to work well

G Very good fading resistance G Rivetted on backings G Smooth action, no fading, no noise,

no dust

DRIE-D AMERICAS

25 Elgin St.

Grimsby, ON Canada telephone: +1 905 309 9558 e-mail: americas@drie-d.com

L3M 4G7 fax: +1 905 309 4901 www.drie-d.com

You might also like

- Family Handyman Do-It-Yourself Basics Volume 2From EverandFamily Handyman Do-It-Yourself Basics Volume 2Family HandymanRating: 5 out of 5 stars5/5 (2)

- Glass Industry: Product GuideDocument8 pagesGlass Industry: Product GuideJames PowellNo ratings yet

- GeoGrip EDocument4 pagesGeoGrip EBaggerkingNo ratings yet

- RAVON BrochureDocument20 pagesRAVON Brochure9868257807No ratings yet

- Remalox HD 35 Optimum Impact and Wear ProtectionDocument2 pagesRemalox HD 35 Optimum Impact and Wear ProtectionCamilo MesaRNo ratings yet

- Seamless Rubber Tubing Brochure 2021V1Document11 pagesSeamless Rubber Tubing Brochure 2021V1Salih HasNo ratings yet

- Bearing Pad - 2007Document4 pagesBearing Pad - 2007Kumar JbsNo ratings yet

- Pistons Pistons: Genuine DEUTZDocument2 pagesPistons Pistons: Genuine DEUTZLoki RosadaNo ratings yet

- Building Profiles CatalogueDocument52 pagesBuilding Profiles CatalogueKumar AnandNo ratings yet

- Brochure HDPEDocument4 pagesBrochure HDPEAhmad MuchroniNo ratings yet

- Worldwide Unique Solution: FPT Seal A60Document2 pagesWorldwide Unique Solution: FPT Seal A60Gannavarapu KrishnaNo ratings yet

- Rubber: TracksDocument6 pagesRubber: TracksNasr PooyaNo ratings yet

- Kalzip StructuralDocument44 pagesKalzip StructuralZoranNo ratings yet

- RMI - Molded Rubber Products BrochureDocument25 pagesRMI - Molded Rubber Products BrochureJayson MariNo ratings yet

- General Catalog en GrindingDocument10 pagesGeneral Catalog en GrindingkarthikNo ratings yet

- MITCODocument28 pagesMITCOMaynor RuizNo ratings yet

- Rubber Roofing in CalgaryDocument3 pagesRubber Roofing in CalgaryMarium FatimaNo ratings yet

- Stergator PicioareDocument24 pagesStergator PicioareMihai PașcalăuNo ratings yet

- PROSPECT TENSA® GRIP CH enDocument4 pagesPROSPECT TENSA® GRIP CH ensab_veer2913No ratings yet

- WayTong CatalogDocument8 pagesWayTong Cataloghoff tengNo ratings yet

- R C-Laminates Pub Tds Prod C-Laminates v4.102020 Eu enDocument7 pagesR C-Laminates Pub Tds Prod C-Laminates v4.102020 Eu enabdo abjNo ratings yet

- Scaffold Catalogue GH 2013 CatalogDocument32 pagesScaffold Catalogue GH 2013 Cataloglwin_oo2435100% (1)

- Roofing ShinglesDocument10 pagesRoofing Shinglescertainteed 98No ratings yet

- Sikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveDocument4 pagesSikadur - 31 (IN) : 2-Part Thixotropic Epoxy AdhesiveJoeNo ratings yet

- Dramix Industrial Floors - BrochureDocument12 pagesDramix Industrial Floors - Brochurehareesh13hNo ratings yet

- Verdú GeneralDocument36 pagesVerdú GeneralMiguel Belda DiezNo ratings yet

- Aluminium Plastic Composite PanelDocument9 pagesAluminium Plastic Composite PanelFrankie ChanNo ratings yet

- 1-6 ST Nomenclature-FeaturesDocument25 pages1-6 ST Nomenclature-FeaturesMahmoud NassarNo ratings yet

- 1 Fastening Catalogue 2013 Hi ResDocument30 pages1 Fastening Catalogue 2013 Hi ResMujjo Sahb100% (1)

- MatsDocument1 pageMatsEmelia JugdavNo ratings yet

- Maxtrong Port Tire and Ind TireDocument34 pagesMaxtrong Port Tire and Ind TirevozefjadavNo ratings yet

- 106000Document36 pages106000ThaisailerNo ratings yet

- The Technical Truth About Belt Tensioners: Plastic vs. Steel Tensioner Pulleys - How Important Is Performance?Document1 pageThe Technical Truth About Belt Tensioners: Plastic vs. Steel Tensioner Pulleys - How Important Is Performance?ricks_4No ratings yet

- TWS CON Sell Sheet BrawlerHDskidsteer A4 EN LR102019 1Document2 pagesTWS CON Sell Sheet BrawlerHDskidsteer A4 EN LR102019 1Fabricio Roldan ErazoNo ratings yet

- DX DU: Self-Lubricating BearingsDocument33 pagesDX DU: Self-Lubricating Bearingsguruchims100% (1)

- T SectionDocument29 pagesT Sectionsinglagourav1806No ratings yet

- Texter CatalogueDocument12 pagesTexter Cataloguevasiferesti837No ratings yet

- 2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationDocument11 pages2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationJoseph BookerNo ratings yet

- Textar BRO BrakeDisc ENG WEBDocument8 pagesTextar BRO BrakeDisc ENG WEBhoussem houssemNo ratings yet

- WRS Brochure PDFDocument8 pagesWRS Brochure PDFlutfi_ismailNo ratings yet

- NSW Roofing Walling Rainwater and Structural Products BrochureDocument8 pagesNSW Roofing Walling Rainwater and Structural Products BrochurebarouniamineNo ratings yet

- 9791 Abrasion Lining and Conveyor Accessories PDFDocument8 pages9791 Abrasion Lining and Conveyor Accessories PDFStephenNo ratings yet

- Isolator SubmittalDocument70 pagesIsolator SubmittalrameshNo ratings yet

- Rema Tip Top Unigrip CR L 215Document2 pagesRema Tip Top Unigrip CR L 215dedison_rNo ratings yet

- 290923-Data Sheet Hi-Grid MGDocument8 pages290923-Data Sheet Hi-Grid MGTeknik produksi wikonNo ratings yet

- How A Tire Is MadeDocument6 pagesHow A Tire Is MadeanushamohanNo ratings yet

- Floating FendersDocument42 pagesFloating FendersATQ100% (1)

- Roofing ShinglesDocument10 pagesRoofing Shinglescertainteed 98No ratings yet

- Roofing ShinglesDocument10 pagesRoofing Shinglescertainteed 98No ratings yet

- Roofing ShinglesDocument10 pagesRoofing Shinglescertainteed 98No ratings yet

- TDS - Sika Grout 100 (G) Ed.2Document3 pagesTDS - Sika Grout 100 (G) Ed.2Himanshu ThakurNo ratings yet

- Permaban Wave FAQs Issue 6 131119Document4 pagesPermaban Wave FAQs Issue 6 131119Inteligencia MercadoNo ratings yet

- Hira WalravenDocument219 pagesHira WalravennunnaraoNo ratings yet

- Masking Ring Use: Materials Standard ProductDocument1 pageMasking Ring Use: Materials Standard ProductEnrico ManfrinatoNo ratings yet

- Berco BMU 424GBDocument20 pagesBerco BMU 424GBEdgar Alves100% (3)

- Multotec Rubber Screening Brochure PDFDocument6 pagesMultotec Rubber Screening Brochure PDFNilton Inca TitoNo ratings yet

- 298 Fms Extremultus Rotary Belt enDocument2 pages298 Fms Extremultus Rotary Belt enBhavesh ShiyaniNo ratings yet

- FRP Moulded Gratings CumigrateDocument3 pagesFRP Moulded Gratings CumigrateshankarklNo ratings yet

- USG Fiber Rock Interior PanelsDocument3 pagesUSG Fiber Rock Interior PanelsAngelo Carlo MalabananNo ratings yet

- Instalacion PolicarbonatoDocument4 pagesInstalacion Policarbonatobproano3992No ratings yet

- DAF LF45 LF55 CF65 CF75 CF85 XF95 Trucks Fault Codes DTC PDFDocument273 pagesDAF LF45 LF55 CF65 CF75 CF85 XF95 Trucks Fault Codes DTC PDFDahmani67% (3)

- Modern Automotive TechnologyDocument97 pagesModern Automotive TechnologyMarew GetieNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual PBDocument8 pages2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerNo ratings yet

- Brake System FundamentalsDocument31 pagesBrake System FundamentalsmdkhayumNo ratings yet

- DRUM AND LINING BRAKE 18 JanuariDocument15 pagesDRUM AND LINING BRAKE 18 Januarialbert svensenNo ratings yet

- Seminar On Braking System:-: Submitted byDocument17 pagesSeminar On Braking System:-: Submitted byGagan KumarNo ratings yet

- Brake SystemDocument186 pagesBrake SystemIancu Gabriel100% (1)

- BrakesDocument69 pagesBrakesdon krtekNo ratings yet

- Workshop Manual Transporter 2016 10-29Document109 pagesWorkshop Manual Transporter 2016 10-29samueleNo ratings yet

- Instructions For The Removal and Fitment of Wheel CylindersDocument1 pageInstructions For The Removal and Fitment of Wheel CylindersRachel Du PreezNo ratings yet

- Brake SystemDocument15 pagesBrake SystemPaúl TorresNo ratings yet

- Brakes System ActivitiesDocument13 pagesBrakes System ActivitiesCedric Vlog & GamesNo ratings yet

- European Braking Systems Product Catalogue Edition #2Document2 pagesEuropean Braking Systems Product Catalogue Edition #2FilipposNo ratings yet

- 0737090039d Macroblade 84 W Component ChartDocument1 page0737090039d Macroblade 84 W Component ChartELIZABETH GRACE ROJAS MIRANDANo ratings yet

- BrakesDocument7 pagesBrakesMilion dugumaNo ratings yet

- Audi - 80 - Wiring Diagram - 1991 - 1991Document5 pagesAudi - 80 - Wiring Diagram - 1991 - 1991alejandroNo ratings yet

- Catalogo FischerDocument162 pagesCatalogo FischerMarcos Gregorio da SilvaNo ratings yet

- TEKTRODocument12 pagesTEKTRODavid ARNo ratings yet

- 08.53.02 - 00 - Parking BrakeDocument2 pages08.53.02 - 00 - Parking BrakeIrving Jesus MartinezNo ratings yet

- Disc Brake Owner's Manual: Fig.C-1 Fig.C-4 Fig.C-3 Fig.C-2Document1 pageDisc Brake Owner's Manual: Fig.C-1 Fig.C-4 Fig.C-3 Fig.C-2Pablo AllosiaNo ratings yet

- Project Report On Hydraulic Disc BrakesDocument55 pagesProject Report On Hydraulic Disc BrakesNithinReddy78% (40)

- VW Golf 6 Brake System EngDocument139 pagesVW Golf 6 Brake System EngStevan KovacNo ratings yet

- Buga Caliper-And-RepairDocument92 pagesBuga Caliper-And-RepairАндрей КравчукNo ratings yet

- SCTR Performa LHBDocument4 pagesSCTR Performa LHBTechnical CellNo ratings yet

- Brake Work Sheet 1Document2 pagesBrake Work Sheet 1VimleshNo ratings yet

- JBK-031 TO 033 B (GIANT) : Atx V-Brake / 3510 QtyDocument44 pagesJBK-031 TO 033 B (GIANT) : Atx V-Brake / 3510 QtyAngeli CorderoNo ratings yet

- Ðåãóëèðîâêà Ñòîÿíî÷íîãî Òîðìîçà Íà 211Document2 pagesÐåãóëèðîâêà Ñòîÿíî÷íîãî Òîðìîçà Íà 211Javod DovajNo ratings yet

- Air Brake System 2Document19 pagesAir Brake System 2Ibrahim Faqaih100% (6)

- Hydraulic BrakeDocument7 pagesHydraulic BrakeA. A. SherpedoNo ratings yet

- Brakes and TyresDocument30 pagesBrakes and TyresYogesh SainiNo ratings yet