Professional Documents

Culture Documents

CSDX6413S-A1-12.25X14.25 PDF Report PDF

Uploaded by

Mohamed Mahmoud Rezk Dimo0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

CSDX6413S-A1-12.25X14.25_pdf_Report.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageCSDX6413S-A1-12.25X14.25 PDF Report PDF

Uploaded by

Mohamed Mahmoud Rezk DimoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

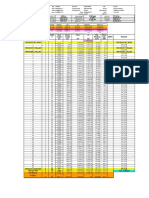

Design Specifications

Make up Length 2.44

(ft):

Shank Bore (ins): 2.750

Shank Diam (ins): 8.000

Connection std: Y

Connection Size 6.625

(ins):

Connection Type: Api Reg Pin

Make up Torque 47500

(ft-lbs):

Drift Diam (ins): 12 1/4"

Drill Diam (ins): 14 1/4"

Max Tool (ins): 9 6250"

Drift Diameter : 12 1/4"

Drill Diameter : 14 1/4"

CSDX6413S-A1 Pilot Dia (ins): 10 3/8"

Max Tool Size: 9 6250"

Pilot Gauge

Design Features of this Hole Opener Length (ins): 2.3250

100% TReX* cutters - Thermostable PDC cutters featuring a unique layer of thermostable PDCGeometry: Straight

that is 200% more heat tolerant and 400% more abrasion resistant than premium PDC. The

thermostable layer dramatically improves abrasion resistance by maintaining a sharp, Profile: Flat

slow-wearing, tough cutting edge. When a wearflat finally develops, the thermostable layer Reamer Gauge

wears more slowly than the multimodal polycrystalline diamond behind it, forming a sharp Length (ins): 2.850

lip that maintains ROP. This allows the bit to drill significantly further and faster than

Geometry: Straight

premium PDC cutter bits.

Profile: Flat

Stabilizing Cutters cutters which are specially designed and placed to produce a

beneficial increase in cutting force. These cutters are used to reduce the bit imbalance

or to provide cutting forces that centralize the bit thus improving bit stability. Blade Qty

Typically a bit will contain one stabilizing cutter per blade.

Pilot: 6

CSD* - Bicenter bits that have the capability to drill the cement and float equipment,

Reamer Full: 4

then drill a new hole section with a larger diameter than it passed through. These bits

reduce the number of bits used and trips required, saving significant time and money. The Reamer Half: 6

CSDs patented design features not only allow it to drill out the casing equipment but Body Materials

also demonstrate excellent directional control. The improved force balance (now comparable Pilot Body: Steel

to standard PDC drill bits) allows the CSD to slide effectively during steering operations

on PDM. Reamer Body: Steel

IMPORTANT NOTE : If a motor is run behind a bicentre bit ALWAYS ensure that there is no

part of the motor that will cause pass though problems - even when using "slick" motors.

The size of the "slick sleeve or lower stabiliser thread protector" and wear pads on the

bearing housing can cause problems. In some applications this bit is run

successfully beyond these parameters. Contact

your ReedHycalog Representative for recommended

operating parameters in your application.

ReedHycalog reserves the right to revise these

specifications, based on advances and

improvements in technology.

Cutting Structure Nozzles & Ports

Pilot Qty Location Dia(mm) Shape Pilot Qty Type Size

Primary 42 PILOT FACE 13 BULLET 5 AAK VARIABLE

Primary 5 PILOT FACE 13 STABILISING Reamer Qty Type Size

Primary 11 PILOT TRIMMERS 13 BULLET 6 AAK VARIABLE

Reamer Qty Location Dia(mm) Shape

Primary 39 REAMER FACE 13 BULLET

Primary 5 REAMER FACE 13 STABILISING

Primary 4 REAMER GAGE 13 BULLET

Primary 4 REAMER GAGE 13 CHAMFERED

Primary 4 REAMER TRIMMERS 13 BULLET

ref: 10011065 * Denotes a Copyright ReedHycalog

Trademark of ReedHycalog

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Tarifa WaterDocument1 pageTarifa WaterMohamed Mahmoud Rezk DimoNo ratings yet

- 8 1/2'' MX-30DXDH: Product SpecificationsDocument1 page8 1/2'' MX-30DXDH: Product SpecificationsMohamed Mahmoud Rezk DimoNo ratings yet

- 8-1/2" X 9-7/8" QDS42: IADC: S243 ER: 2108Document1 page8-1/2" X 9-7/8" QDS42: IADC: S243 ER: 2108Mohamed Mahmoud Rezk DimoNo ratings yet

- CSDX6413S-A1-12.25X14.25 PDF Report PDFDocument1 pageCSDX6413S-A1-12.25X14.25 PDF Report PDFMohamed Mahmoud Rezk DimoNo ratings yet

- PDCHC607 PDFDocument1 pagePDCHC607 PDFMohamed Mahmoud Rezk DimoNo ratings yet

- 4.25 Inch D71 PDFDocument2 pages4.25 Inch D71 PDFMohamed Mahmoud Rezk DimoNo ratings yet

- 105 QDS75Document1 page105 QDS75Mohamed Mahmoud Rezk DimoNo ratings yet

- 8 1/2" MX-20GDX: Product SpecificationsDocument1 page8 1/2" MX-20GDX: Product SpecificationsSamia IbrahimNo ratings yet

- Tiw Tally Marzouk-2Document2 pagesTiw Tally Marzouk-2Mohamed Mahmoud Rezk DimoNo ratings yet

- 9.625'' Seal NippleDocument1 page9.625'' Seal NippleMohamed Mahmoud Rezk DimoNo ratings yet

- Radial Flow Hydraulics: Additional Optional FeaturesDocument2 pagesRadial Flow Hydraulics: Additional Optional FeaturesMohamed Mahmoud Rezk DimoNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Mohamed Mahmoud Rezk DimoNo ratings yet

- Ali Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDDocument1 pageAli Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDMohamed Mahmoud Rezk DimoNo ratings yet

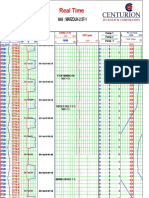

- Marzouk-2 St1 Realtime 4-2-2009Document14 pagesMarzouk-2 St1 Realtime 4-2-2009Mohamed Mahmoud Rezk DimoNo ratings yet

- Risk MatrixDocument1 pageRisk MatrixMohamed Mahmoud Rezk DimoNo ratings yet

- BP Hand Finger InjuryDocument18 pagesBP Hand Finger InjuryMohamed Mahmoud Rezk DimoNo ratings yet

- Safety Induction LogDocument2 pagesSafety Induction LogMohamed Mahmoud Rezk DimoNo ratings yet

- Marzouk-2 St1 Adt Log 01-02-09Document1 pageMarzouk-2 St1 Adt Log 01-02-09Mohamed Mahmoud Rezk DimoNo ratings yet

- 4-Confined Space EntryDocument10 pages4-Confined Space EntryMohamed Mahmoud Rezk DimoNo ratings yet

- EMPTY FlashDocument1 pageEMPTY FlashMohamed Mahmoud Rezk DimoNo ratings yet

- Job Haz AnalysisDocument10 pagesJob Haz AnalysisMohamed Mahmoud Rezk DimoNo ratings yet

- 5-Occupational Health & Environmental ControlDocument8 pages5-Occupational Health & Environmental ControlMohamed Mahmoud Rezk DimoNo ratings yet

- Food Safety Information Handbook - C. Roberts (Oryx, 2001) WWDocument331 pagesFood Safety Information Handbook - C. Roberts (Oryx, 2001) WWMohamed Mahmoud Rezk DimoNo ratings yet

- 9.625'' Inspection SheetDocument3 pages9.625'' Inspection SheetMohamed Mahmoud Rezk DimoNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Mohamed Mahmoud Rezk DimoNo ratings yet

- Abujabl 1 13 CSG CemcadeDocument7 pagesAbujabl 1 13 CSG CemcadeMohamed Mahmoud Rezk DimoNo ratings yet

- 9.625'' Seal NippleDocument1 page9.625'' Seal NippleMohamed Mahmoud Rezk DimoNo ratings yet

- Radial Flow Hydraulics: Additional Optional FeaturesDocument2 pagesRadial Flow Hydraulics: Additional Optional FeaturesMohamed Mahmoud Rezk DimoNo ratings yet

- 8 1/2" MX-20GDX: Product SpecificationsDocument1 page8 1/2" MX-20GDX: Product SpecificationsSamia IbrahimNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IGS-NT 4.3.1 New Features ListDocument33 pagesIGS-NT 4.3.1 New Features ListJo RoNo ratings yet

- Exhaust Header Length Calculation - OcmsDocument4 pagesExhaust Header Length Calculation - Ocmssayantan ghoshNo ratings yet

- Mobile BugDocument11 pagesMobile BugAnu JoNo ratings yet

- CAM SWITCH CS12-00404: Technical SpecificationsDocument2 pagesCAM SWITCH CS12-00404: Technical Specificationskristinacarranza100% (1)

- TLE7 IA AUTO M4 v2Document22 pagesTLE7 IA AUTO M4 v2Howell ConsueloNo ratings yet

- Garmin Wiring Diagrams - G3X - AllDocument15 pagesGarmin Wiring Diagrams - G3X - AllAviv SofferNo ratings yet

- Acer Travelmate 4150 Dunlin LA-2601 SchematicsDocument51 pagesAcer Travelmate 4150 Dunlin LA-2601 SchematicsDoru Razvan100% (1)

- SDC 634RF Instruction ManualDocument2 pagesSDC 634RF Instruction ManualJMAC SupplyNo ratings yet

- Index 2017 Electric Motor ControlDocument10 pagesIndex 2017 Electric Motor ControlCelso SimonatoNo ratings yet

- GX1000 B Quick Reference ManualDocument26 pagesGX1000 B Quick Reference ManualRafał KwaśnyNo ratings yet

- Effect - Short ChannelDocument17 pagesEffect - Short Channelmaheshwarivikas1982No ratings yet

- Everest EverestDocument24 pagesEverest Everestabhi24shekNo ratings yet

- Hc3500t Multimeter ManualDocument3 pagesHc3500t Multimeter Manualjmfcoto33% (3)

- Samsung AR12Document103 pagesSamsung AR12PauloNo ratings yet

- Introduction To Machinery Principles: Mochammad Ariyanto, ST, MTDocument31 pagesIntroduction To Machinery Principles: Mochammad Ariyanto, ST, MTutsmanheruNo ratings yet

- FBS Ii enDocument10 pagesFBS Ii enunsalNo ratings yet

- Orbit27999 Manual PDFDocument32 pagesOrbit27999 Manual PDFDanno NNo ratings yet

- ZF Axles Adn Transmissions ProductsDocument44 pagesZF Axles Adn Transmissions ProductsMarek WyszatyckiNo ratings yet

- Fex GuideDocument60 pagesFex Guidejambor_istvanNo ratings yet

- Project Circuit Analysis: Temperature Controlled DC FanDocument4 pagesProject Circuit Analysis: Temperature Controlled DC Fanaqib aliNo ratings yet

- Heat Tracing ManualDocument50 pagesHeat Tracing ManualYerlanNo ratings yet

- Eaton Electrical Catalog Vol.11Document186 pagesEaton Electrical Catalog Vol.11Clifton JamisonNo ratings yet

- Manual Ar LG Mod L8UC150BFA1Document7 pagesManual Ar LG Mod L8UC150BFA1Paulo LaraNo ratings yet

- Typesofmemory UpdatedDocument8 pagesTypesofmemory UpdatedErmin SehicNo ratings yet

- Guidebook of Circuits Featuring Voltage Reference Ics in Various ConfigurationsDocument32 pagesGuidebook of Circuits Featuring Voltage Reference Ics in Various ConfigurationsPatrick StivénNo ratings yet

- DICD Tutorial 5Document5 pagesDICD Tutorial 5Pavika Sharma100% (1)

- ERSA Microsoldering Irons: ERSA Minor ERSA Minityp ERSA Tip 260Document1 pageERSA Microsoldering Irons: ERSA Minor ERSA Minityp ERSA Tip 260Maria KokkinariNo ratings yet

- Panasonic+sa-Akx34ph Akx34pnDocument126 pagesPanasonic+sa-Akx34ph Akx34pnAndres Florentin Pizarro LazarteNo ratings yet

- Clutch LectureDocument15 pagesClutch LectureellyNo ratings yet

- Pressure Fryers: Project Quantity Item NoDocument2 pagesPressure Fryers: Project Quantity Item NoeliahNo ratings yet