Professional Documents

Culture Documents

Treatment of Wastewater Containing Dyes Used in The Syrian Textile Industry

Uploaded by

Dr. Arif HidayatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Treatment of Wastewater Containing Dyes Used in The Syrian Textile Industry

Uploaded by

Dr. Arif HidayatCopyright:

Available Formats

Journal of Chemical Technology and Biotechnology J Chem Technol Biotechnol 77:437443 (online: 2002)

DOI: 10.1002/jctb.537

Treatment of wastewater containing dyes used

in the Syrian textile industry

Saleh El-Kadri, Ousama Dabbit* and Hassan Kakhia

Chemistry Department, Science Faculty, Aleppo University, Aleppo, Syria

Abstract: Three types of wastewater, from commercial dyeings containing reactive, disperse and

direct dyes were treated using an organic coagulant at pH 5.5 as a rst step, with stirring for 5 min. The

second step was oxidation by Fenton's reagent (hydrogen peroxide and iron(II) sulfate) at pH 2.53 for

30 min. The pH of the solution was then raised to 7.58 where coagulation by iron hydroxide took place

over 20 min. Finally, sand ltration was performed. The percentage of color removal from treated

wastewater was more than 99.00% and the percentage decrease in COD was more than 96.00%.

# 2002 Society of Chemical Industry

Keywords: environment; pollution; wastewater; dyes; coagulant; COD

INTRODUCTION dyes.5 Organic polymers have therefore been devel-

The principal route by which dyes enter the environ- oped for color-removal treatments and, in general,

ment is via wastewater from batch processes in both they offer the same advantages with the production of

the dye-manufacturing and the dye-consuming indus- less sludge and signicantly improved color removal.6

tries. In 1978 it was estimated that of the 450 000 For the removal of color from dyehouse efuent, no

tonnes of dye produced worldwide, some 9000 tonnes such effective and simple inorganic option exists for

(2%) were discharged in aqueous efuents from many soluble dyes.10

manufacturing operations and 40 000 tonnes (9%) The treatment procedure described depends on an

from the coloration.2 organic coagulant marketed as Setax-wws (Setash),

Dyes are required to show a high degree of chemical which is also used as a xative for the direct dyeings.

and photolytic stability in order to full the fastness Any xing agent not absorbed by the ber enters the

requirements of both retailers and consumers. One dyehouse efuent.

consequence of this stability is that they are not readily

degraded under the aerobic conditions prevailing in

the biological treatment plant at a sewage treatment

works. So unless color is removed by physical or EXPERIMENTAL

chemical means, either at the dyehouse or in tertiary Three samples of real dye wastewater from com-

treatment, it may well pass to the receiving water.1,3 mercial dyeings in Aleppo were treated. Each type of

Dye wastewater forms a serious problem in Aleppo, wastewater contained pairs of reactive, disperse or

because about 250 dyehouses discharge to the direct dyes (see below).

environment at least 4 000 000 m3 of wastewater per

year, which may contain more than 5 tonnes of Materials

dyes. Hydropon-ERN (Sabo)

Many techniques have been used for treatment of This is a leveling and dispersing agent, which has the

dye wastewater, such as adsorption, biological treat- following chemical and physical properties:

ment, oxidation, coagulation and/or occulation, of

which coagulation is one of the most commonly used Chemical constitution: synergistic blend of anionic

techniques. Inorganic coagulants such as lime and and non-ionic agents

salts of iron, magnesium and aluminum have been Appearance at 20 C: dark brownish liquid

used over many years, but with changes in dyes and Ionic type: anionic

with the dye consents proposed by water authorities, Solubility: easily soluble in hot or cold water

these no longer give completely satisfactory treat- pH of 5% aqueous solution: about 7

ments.6 Not all dyes are effectively removed by in- Stability: stable to hard water, alkaline and acidic

organic coagulants; thus alum is unsatisfactory for the conditions and electrolytes in the amounts normally

removal of soluble dyes such as reactive and direct used in dyeing

* Correspondence to: Ousama Dabbit, Chemistry Department, Science Faculty, Aleppo University, Aleppo, Syria

(Received 27 September 2000; revised version received 8 September 2001; accepted 5 October 2001)

# 2002 Society of Chemical Industry. J Chem Technol Biotechnol 02682575/2002/$30.00 437

S El-Kadri, O Dabbit, H Kakhia

Dye name l max (nm) Constitution Number in CI Supplier

Reactive Yellow 81 (RY 81) 344 Youhoaw

Reactive Blue 21 (RB 21) 668 Setash

Disperse Yellow 82 (Dis Y 82) 460 Spectrom

Disperse Blue 60 (Dis B 60) 750 61104 Basf

Direct Yellow 11 (Dir Y 11) 412 40000 Goint-Stock

Disperse Yellow 56 (Dis Y 56) 328 Spectrom

Table 1. Commercial dyes used in this study

Setalan-BNH (Setash) Analysis

This is a detergent for washing-off reactive dyes, which The concentrations of all dye wastewaters were

has the following chemical and physical properties: obtained by measuring the absorbency with a Shi-

madzu Co type UV-240 spectrophotometer.

Chemical composition: condensation product of The COD of all samples were determined by the

etoksile dichromate reux method.13 Quantitative analysis for

Ionic character: non-ionic the ions studied was carried out using an HACH DR/3

Appearance: viscous yellow liquid spectrophotometer.

pH value: 6.08.0 (10% solution)

Solubility: soluble in water in all proportions Collection and composition of dye wastewater

All dye wastewaters were sampled as follows: a quan-

Setafix-wws (Setash) tity of the dye wastewater was taken from the dyeing

This is a xing agent for direct dyeings, and has the machine after the end of the dyeing process, and the

following chemical and physical properties: same quantity was taken from the washing-off water.

The reactive dye wastewater resulted from the dye-

Chemical composition: diciandiamide and formal- ing of 120 kg of cotton (on mass of ber) with 3.7%

dehyde condensation polymer Reactive Blue 21 and 0.6% Reactive Yellow 81 in

Ionic character: cationic 1200 dm3 deionized water. Auxiliaries present were

Appearance: colorless clear liquid 1.04 g dm 3 Hydropon-ERN, 104 g dm 3 sodium sul-

pH value: 4.56 (concentrated) fate and 20.8 g dm 3 sodium carbonate. The rst

Solubility: soluble in water in all proportions washing-off solution contained 3 g dm 3 Setalan-

BNH.

Commercial dyes The disperse dye wastewater resulted from the

The commercial dyes shown in Table 1 have the dyeing of 120 kg of polyester with 0.75% Disperse

following chemical structures.4 Blue 60 and 0.02% Disperse Yellow 82 in 1200 dm3

water.

Reactive Yellow 81 is a bifunctional monochloro-

triazine dye of the azo class.

Reactive Blue 21 is a venylsulfone dye of the

phthalocyanine class.

Disperse Yellow 82 is an azo dye.

Disperse Blue 60 has the structure shown in

Scheme 1.

Direct Yellow 11 is an azostilbene dye made by self

condensation of 4-netrotoluene-2-sulfonic acid (see

Scheme 2).

Disperse Yellow 56 has the structure shown in

Scheme 3.

Scheme 2

Scheme 1 Scheme 3

438 J Chem Technol Biotechnol 77:437443 (online: 2002)

Treatment of wastewater containing dyes

The disperse/direct dye wastewater resulted from

the dyeing of 120 kg of polyester/cotton with 0.06%

Disperse Yellow 56 and 0.06% Direct Yellow 11 in

1200 dm3 water.

We have used Disperse Yellow 56 with Direct

Yellow 11 because it is not common in Aleppo to use

direct dyes alone but generally they are used jointly

with disperse dyes for fabrics made of cotton and

Scheme 4

polyester.

Treatment procedure

The treatment was performed in two steps, viz co- anions and positive groups in the polymer result in co-

agulation followed by oxidation and inorganic coagu- precipitation, as shown in Scheme 5.6

lation.

Coagulation RESULTS AND DISCUSSION

The procedure for coagulation is carried out as Determination of effective amount of coagulant

follows: Figures 1, 2 and 3 show the effect of coagulant dosage

on the percentage of COD reduction and color

adjust the wastewater to pH 55.5

removal for reactive, disperse and the mixture of direct

add the coagulant Setax-wws to 100 cm3 of the

and disperse dyes, respectively. Table 2 illustrates the

pH-adjusted sample

percentage of COD reduction and color removal due

stir for 5 min then let the sample stand for 1 min

to the effective amount of coagulant for the dye waste-

nally, lter through a sand lter

waters studied. These results indicate that a signicant

amount of dye can be removed in the rst step of

Oxidation and inorganic coagulation treatment and the removal of dye increases with

Hydrogen peroxide and ferrous ions are usually more increases in the coagulant dose. The percentage

stable in a strong acid. But if hydrogen peroxide is reduction of COD increases as the coagulant dose

added to an aqueous system containing an organic increases up to the effective amount, where the COD

substrate and excess ferrous ions in a strong acid, a has a minimum value. When more than this amount is

complex redox reaction will occur. This reaction will used, the percentage reduction of COD reduces as

generate the vigorous hydroxyl radicals and ferric ions. residual coagulant remains in the treated water.

The hydroxyl radicals may be used to decolorize the Since the decolorization mechanism, in the rst step

dye wastes.15 Ferric ions may form ferric hydroxo of treatment, depends on the electrostatic attraction

complexes with hydroxide ions. These complexes have between the oppositely charged soluble dye and

a pronounced tendency to polymerize at pH 3.57.14 polymer molecules, so the coagulant dose depends

Thus coagulation would probably occur. The remain- on the chemical structure of the dye molecule,

ing decolorized dye molecules in wastewater can be especially on the negative groups. The coagulant dose

coagulated and precipitated.8 depends also on the presence of other compounds

The oxidation and inorganic coagulation has been such as Hydropon-ERN which is present in the

performed as follows: reactive dye wastewater. It is evident from the results

(Table 2) that this dye wastewater required the highest

reduce the pH of water from the rst step of treat-

dose of coagulant (700 mg dm 3). This is because of

ment to less than pH 3

the competitive reaction between the coagulant and

add the desired amounts of hydrogen peroxide and

Hydropon-ERN molecules with dye molecules. This

iron(II) sulfate (Fenton's Reagent)

explanation will be reinforced if we remember that the

stir for 30 min

Hydropon-ERN is a leveling and dispersing agent

increase the pH to 8, and stir for a further 20 min

which is frequently used as an auxiliary in the dyeing

stop the stirring and allow the sample to stand for

processes to prevent the accumulation of dye mol-

2 min

ecules. Thus it will oppose the coagulant role which

nally, lter through a sand lter

brings the dye molecules together. But the percentages

Mechanism of decolorization

The mechanism by which synthetic organic polymer

coagulants remove dissolved dyes depends on electro-

static attraction between the oppositely charged

soluble dye and polymer molecules.6 The coagulant

we used (setax-wws) has the structure shown in

Scheme 4.

Interaction between negative reactive or direct dye Scheme 5

J Chem Technol Biotechnol 77:437443 (online: 2002) 439

S El-Kadri, O Dabbit, H Kakhia

taining a mixture of disperse and direct dyes required

the lowest dose of coagulant (50 mg dm 3). This is for

two reasons; rstly this wastewater did not contain any

auxiliaries to interfere with the reaction of the coagu-

lant and dye molecules. Secondly it contained Direct

Yellow 11 which is strongly negatively charged (con-

tains 11 negative groups, as is clear from its chemical

structure), and this will result in easier electrostatic

attraction between the polymer molecules and the

Direct Yellow 11 molecules.

Determination of effective amount of ferrous sulfate

and hydrogen peroxide

The most effective amounts of FeSO4 and H2O2 were

determined for each sample of wastewater. Figures 4,

5 and 6 show the effects of varying the FeSO4 dosage at

a xed concentration of hydrogen peroxide on the

percentage of COD reduction. Table 3 illustrates the

percentage of COD reduction and color removal due

to the effective amounts of FeSO4 and H2O2 for the

dye wastewaters studied.

It is clear from these results that the percentage of

COD reduction increases as the FeSO4 dose increases,

Figure 1. Effect of coagulant dosage on the percentage of (a) COD

reduction and (b) color removal.

of dye removal were 93 and 95% for Reactive Yellow

81 and Reactive Blue 21, respectively. These high

values mean that the removal of dyes was not

signicantly affected in the presence of the leveling

and dispersing agent Hydropon-ERN. The low value

of the percentage of COD removal (56%, Table 2)

may be attributed to the non-ionic fraction of the

Hydropon-ERN (return to the Hydropon-ERN

chemical composition) because it most likely will not

be removed by the cationic polymer.

Electrostatic attraction also takes place between the

insoluble disperse dye, which is partially negatively

charged, and the positively charged coagulant mol-

ecules. Despite the fact that the disperse dye molecules

are not strongly charged, they do not require large

amounts of coagulant. The percentages of Disperse

Yellow 82 and Disperse Blue 60 remained were 99 and

97% (Table 2) respectively. It seems that this coagu-

lant is effective in removing the insoluble dyes (small

particles) in addition to its efciency in removing the

soluble dyes, as has been observed before. Figure 2. Effect of coagulant dosage on the percentage of (a) COD

It is clear from Table 2 that the wastewater con- reduction and (b) color removal.

440 J Chem Technol Biotechnol 77:437443 (online: 2002)

Treatment of wastewater containing dyes

Figure 4. Effect of FeSO4 dosage on the percentage of COD reduction in

the treatment of reactive dyes.

Figure 5. Effect of FeSO4 dosage on the percentage of COD reduction in

the treatment of disperse dyes.

Figure 3. Effect of coagulant dosage on the percentage of (a) COD Figure 6. Effect of FeSO4 dosage on the percentage of COD reduction in

reduction, and (b) and (c) color removal. the treatment of direct and disperse dyes.

Table 2. The percentage of COD reduction and color removal due to the effective amount of coagulant for the dye wastewaters studied

Reactive dyes Disperse dyes Direct and disperse dyes

3

Effective amount of coagulant (mg dm ) 700 200 50

COD removal (%) 56 92 85

Name of dye RY 81 RB 21 Dis Y 82 Dis B 60 Dir Y 11 Dis Y 56

Color removal (%) 93 95 99 97 94 99

J Chem Technol Biotechnol 77:437443 (online: 2002) 441

S El-Kadri, O Dabbit, H Kakhia

Table 3. The percentage of COD reduction and color removal due to the effective amounts of FeSO4 and H2O2 for the dye wastewaters

studied

Reactive dyes Disperse dyes Direct and disperse dyes

Effective amount of H2O2 (mg dm 3) 500 350 600

Effective amount of FeSO4 (mg dm 3) 1900 950 4000

COD removal (%) 97 98.5 94

Name of dye RY 81 RB 21 Dis Y 82 Dis B 60 Dir Y 11 Dis Y 56

Color removal (%) >99% >99% >99% >99% >99% >99%

treated sample will react with potassium dichromate

during the COD measurement, leading to a high value

of the COD of the sample. It is evident from Fig 7

that when large doses of FeSO4 (2000, 2700 and

3200 mg dm 3) are added, the percentage of COD

reduction will increase again to the value obtained

when the effective amount of hydrogen peroxide was

added (about 97%). This increase resulted from the

consumption of the excess hydrogen peroxide by

iron(II) being oxidized to iron (III). This may be

taken as evidence for the previous explanation.

Measurement of some physical and chemical

parameters of wastewater before and after treatment

Figure 7. Effect of FeSO4 dosage on the percentage of COD reduction in

the treatment of reactive dyes using 800mg dm 3 H2O2.

Some analyses were performed on the reactive and

disperse dye wastewater, before and after treatment, to

compare the quality of the treated wastewater with

some specications for treated wastewater (Table 4)

which is acceptable for release to the environment, as

up to an optimum amount where the COD has the determined by the Directory of Prevention of Public

minimum value. On the other hand, when more than Water Pollution of the Syrian irrigation ministry.11

the effective amount of FeSO4 is added, the percent- Table 5 shows analytical data for reactive and disperse

age of COD reduction will not increase signicantly. dye wastewaters before and after treatment.

This might it be attributed to the existence of The important result that can be noted from Table 5

chemicals that either resist the oxidation by Fenton's is that the organic coagulant used in the treatment has

Reagent and/or they are oxidized to products that are a high ability for removing iron ions, Total Dissolved

not capable of removal by coagulation with the iron Solids (TDS) and Total Suspended Solids (TSS). It is

complexes which are formed in the second step of clear from Table 5 that the decrease in the amount of

treatment. iron ions is about 95% when dyeing wastewater

It was found that when more than the effective resulting from reactive dyes is treaded. The decreases

amount of hydrogen peroxide is added (Fig 7), the in the amounts of TDS are about 78 and 82% when

percentage of COD reduction was less than 97% reactive and disperse dye wastewaters respectively are

(obtained when the effective amount of hydrogen treated and the decreases in the amounts TSS are

peroxide was added, Table 3). This result is similar to about 92 and 97% when dyeing wastewaters resulting

the conclusions of Kou8 and Perkins et al. 9 The reason from reactive and disperse dyes respectively are

is that the residual hydrogen peroxide remaining in the treated.

Table 4. Specifications of treated wastewater acceptable for release to the environment, as determined by the Directory of Prevention of Public Water Pollution of

the irrigation ministry11

Parameter

2

HPO4 CN S2 H2S NO3 TSS TDS

3

Draining place pH T ( C) mg dm COD%

Rivers, streams, lakes 69.5 35 40 0.1 1 10 80 2000 100150

Sewage 6.59.5 40

Agricultural lands 1 80 150

442 J Chem Technol Biotechnol 77:437443 (online: 2002)

Treatment of wastewater containing dyes

Reactive wastewater Disperse wastewater

Parameter Before treatment After treatment Before treatment After treatment

3

COD (mgO2 dm ) 805.9 24.3 1788.2 25.2

TDS (mg dm 3) 10 800 2600 8300 1770

TSS (mg dm 3) 125 10 325 10.7

NO3 (mg dm 3)

H2S (mg dm 3)

S2 (mg dm 3)

CN (mg dm 3)

HPO42 (mg dm 3)

Total Fe (mg dm 3) 6.6 0.1 0.4 0

Table 5. Analytical data for reactive and T ( C) 40 23 40 23

disperse dye wastewater before and after pH 7.74 7.72

treatment

CONCLUSION REFERENCES

The main point we want to make in this paper is the 1 Brian DW, The regulator's view, in Color in Dyehouse Efuent, Ed

possibility of using some organic pollutants present in by Peter C, 1st edn, SDC, UK. pp 2233 (1995).

2 Brown D and Labourer P, Chemosphere 12:397 (1983).

the wastewater of the nishing process as coagulants

3 Clark EA, Anliker. Rev Prog Coloration 14:84 (1984).

instead of inorganic coagulants to be used before

4 Color Index, 3rd, 4th and 9th edn (1992).

advanced treatment of dye wastewater. It was ob- 5 Developments in chemistry and technology of organic dyes.

served that, acceptable when compared with inorganic Critical Reports on Applied Chemistry, London Blackwell

coagulants such as aluminum salts results could be Scientic (1984).

obtained in some cases (disperse wastewater and the 6 Hazel GB, Industry evaluation of color reduction and removal

mixture of direct and disperse dye wastewaters) by the DEMOS Project, in Color in Dyehouse Efuent, Ed by Peter

using one of these organic pollutants (Setax-wws). It C, 1st edn, SDC, UK. pp 5973 (1995).

is clear from Table 2 that the COD reduction could 7 Hung, Gulin, Liang, Ping, Fen, Synthesis and application of

reach about 92%. Sheng12 obtained a COD reduction special polymer for dyeing wastewater treatment. Gongye

of about 72% by treating the dye wastewater using Shuichuli Zazhishe 19(6):2930 (1999) (in Chinese).

8 Kou WG, Decolorizing dye wastewater with Fenton's reagent.

aluminum salts while Hung et al 7 obtained a COD

Wat Res 26(7):881886 (1992).

reduction of about 80% by treating the dye wastewater

9 Perkins WS, Judkins JF and Perry WD, Renovation of dyebath

using 700800 mg dm 3 aluminum sulfate with a water by chlorination or ozonation. Part 1: reaction of dyes.

mixture of polyacrylamide, acrylic acid and ethelen- Textile of Chemical Color 12:182187 (1980).

diamine at a pH of 78 for 5 h. 10 Peter JH, Color removal from dyehouse efuent using synthetic

We have tested some more organics (without deter- organic coagulants, in Color in Dyehouse Efuent Ed by Peter C,

mining the effective amounts) used in the nishing 1st edn, SDC, UK. pp 171184 (1995).

process, such as the cationic xing agents Arix 40 11 Primary Syrian standard specifications of drained industrial waste-

(DANNA), which is an amino-amide condensate and water (1986).

Alcox FD (Allied Colloids), and cationic softeners 12 Sheng H, Treatment of Textile Wastewater by Chemical Methods for

such as Garipan soft (Dr Th. Bohme) which is a fatty Reuse, Elsevier Science Ltd 31(4): pp 868876 (1997).

13 Standard Methods for Examination of Water and Wastewater, 18th

acid amide derivative, Sabonina S3 (Sabo) which is a

edn, American Public Health Association, American Water

synergic blend of amide derivatives and waxes, and

Works Association and Water Environment Federation

Alcolube XJS (Allied Colloids). It was found that all (1992).

compounds in both groups could coagulate the three 14 Stumm W and Morgan JJ, Chemical aspects of coagulation. J Am

types of dye wastewaters studied. More investigations Wat Wks Ass, pp 971992 (1962).

are needed to detect the effective amounts. The 15 Walling C and Koto S, The oxidation of alcohols by Fenton's

anphotric, non-ionic and ionic xing agents and reagent: the effect of copper ion. J Am Chem Soc 93:42754281

softeners did not result in any coagulation. (1971).

J Chem Technol Biotechnol 77:437443 (online: 2002) 443

You might also like

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityFrom EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityNo ratings yet

- Alkalinity Hardness &chlorideDocument34 pagesAlkalinity Hardness &chloridelhkooNo ratings yet

- Potassium Permanganate As Oxidant in The Cod Test For Saline Water SamplesDocument11 pagesPotassium Permanganate As Oxidant in The Cod Test For Saline Water SampleskomodobutaNo ratings yet

- RV College PACT ReportDocument14 pagesRV College PACT ReportHarish GowdaNo ratings yet

- AlkalinityDocument3 pagesAlkalinityGajaNand MallickNo ratings yet

- Water Treatment Processes - Coagulation and Flocculation ExplainedDocument7 pagesWater Treatment Processes - Coagulation and Flocculation ExplainedDr-Manoj GargNo ratings yet

- Municipal wastewater treatment using rice husk and kikar charcoalDocument4 pagesMunicipal wastewater treatment using rice husk and kikar charcoalIbrar ZahidNo ratings yet

- Managing Food Industry Waste EffluentsDocument5 pagesManaging Food Industry Waste EffluentsAbiodun GbengaNo ratings yet

- Experiment 6 - EDTA Titration of The Hardness of WaterDocument2 pagesExperiment 6 - EDTA Titration of The Hardness of Waterfrogie90100% (1)

- SRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDDocument2 pagesSRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDpetros222No ratings yet

- Removal of Methylene Blue Using Moss Grass and AlgaeDocument37 pagesRemoval of Methylene Blue Using Moss Grass and Algaesamar_biotech100% (2)

- Jar Test Lab Report Level 2Document14 pagesJar Test Lab Report Level 2syaaa0% (1)

- Chemical Treatment ProcessesDocument152 pagesChemical Treatment ProcessesTeo Peng KeatNo ratings yet

- Levapor Carriers and Their Application For Wastewater TreatmentDocument29 pagesLevapor Carriers and Their Application For Wastewater TreatmentAmit Christian100% (1)

- DBDocument25 pagesDBAbhijit MondalNo ratings yet

- Advanced Wastewater TreatmentDocument16 pagesAdvanced Wastewater TreatmentvikkykambleNo ratings yet

- What is COD and how to measure itDocument4 pagesWhat is COD and how to measure itgurubakkiamjai100% (1)

- Slow Sand Filtration: A Proven Household Water Treatment OptionDocument2 pagesSlow Sand Filtration: A Proven Household Water Treatment OptionBernadette Tumacder MaganaNo ratings yet

- Landfill LeachateDocument7 pagesLandfill LeachateChristian Mihai GNo ratings yet

- Elution study results reveal water softener performance issuesDocument2 pagesElution study results reveal water softener performance issuesVương Đình NamNo ratings yet

- Lime Soda Ash SofteningDocument23 pagesLime Soda Ash SofteningNithi AnandNo ratings yet

- Co2 Degasifier To Adjust The PHDocument2 pagesCo2 Degasifier To Adjust The PHGhuna UcihaNo ratings yet

- Membrane Bioreactor (MBR) Technology PPT - FERA MEILASARI - 21080122420021Document14 pagesMembrane Bioreactor (MBR) Technology PPT - FERA MEILASARI - 21080122420021fera meilasariNo ratings yet

- Solution: Introduction To Solutions Group 5 Cornelia Espiritu Lumasag Mejorada OmbleroDocument12 pagesSolution: Introduction To Solutions Group 5 Cornelia Espiritu Lumasag Mejorada OmbleroGezem GigantoNo ratings yet

- Thermochemistry - Heat of Solution of Potassium NitrateDocument2 pagesThermochemistry - Heat of Solution of Potassium NitrateSri LikhithaNo ratings yet

- Treatment of Dairy Waste Water Using Low Cost AdsorbentsDocument2 pagesTreatment of Dairy Waste Water Using Low Cost AdsorbentsijsretNo ratings yet

- Environmental EngineeringDocument49 pagesEnvironmental EngineeringswathiprasadNo ratings yet

- Lec4 Water and Wastewater TreatmentDocument54 pagesLec4 Water and Wastewater TreatmentKent Harry CumpioNo ratings yet

- Turbidity Suspended SolidsDocument6 pagesTurbidity Suspended SolidsStrazdas100% (1)

- Chemical Water Treatment Process StepsDocument46 pagesChemical Water Treatment Process StepsNazar Abdul KareemNo ratings yet

- Advanced Oxidation ProcesssesDocument25 pagesAdvanced Oxidation ProcesssesDHANANJAY RAJNIKANTBHAI BODANo ratings yet

- Project Semester ReportDocument60 pagesProject Semester ReportPrabhjot Singh TinnaNo ratings yet

- 07 - Chapter 2 Adsorption Literature ReviewDocument59 pages07 - Chapter 2 Adsorption Literature ReviewMaheera MohamadNo ratings yet

- Wastewater Treatment Solutions - AqwiseDocument4 pagesWastewater Treatment Solutions - AqwiseIsrael ExporterNo ratings yet

- Introduction to Industrial WWTP: Key CharacteristicsDocument11 pagesIntroduction to Industrial WWTP: Key CharacteristicsSupatmono NAINo ratings yet

- 7 - Pre-Treatments To Reduce Fouling of Low Pressure Microfiltration (MF) Membranes PDFDocument10 pages7 - Pre-Treatments To Reduce Fouling of Low Pressure Microfiltration (MF) Membranes PDFRinaAprianiAapNo ratings yet

- Chapter-1: 1.1 Waste Water Treatment PlantDocument39 pagesChapter-1: 1.1 Waste Water Treatment PlantKalyan Reddy AnuguNo ratings yet

- DesignDocument3 pagesDesigntata_77No ratings yet

- Advanced Oxidation Processes and Their Application in PDFDocument21 pagesAdvanced Oxidation Processes and Their Application in PDFdiamond_101190No ratings yet

- Water Treatment PlantDocument14 pagesWater Treatment PlantTalha SheikhNo ratings yet

- dw-25 Hypochlorite WBDocument105 pagesdw-25 Hypochlorite WBSADHEDNo ratings yet

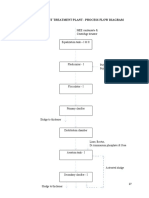

- Effluent Treatment Plant - Process Flow DiagramDocument45 pagesEffluent Treatment Plant - Process Flow DiagramAmarnath PNo ratings yet

- Coagulation For Wastewater Treatment A RDocument5 pagesCoagulation For Wastewater Treatment A RHenryPeña100% (1)

- Drinking Water Sludge Recovery Feb 2011Document2 pagesDrinking Water Sludge Recovery Feb 2011Fernando GarcíaNo ratings yet

- Calculation of Sludge Production From Aerobic ASP JanusDocument8 pagesCalculation of Sludge Production From Aerobic ASP Janusكرم عمرو100% (1)

- Biochemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD)Document35 pagesBiochemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD)wahyu hidayatNo ratings yet

- Measure Pollutant Level in Waste Water Using COD TestDocument10 pagesMeasure Pollutant Level in Waste Water Using COD TestAmirah SyakiraNo ratings yet

- Taste Masking by Ion Exchange Resin and Its New Applications A ReviewDocument16 pagesTaste Masking by Ion Exchange Resin and Its New Applications A ReviewNhonPhanThanhNo ratings yet

- RODocument10 pagesROShahrooz Leo QureshiNo ratings yet

- Sodium Silicate PDFDocument19 pagesSodium Silicate PDFnasirtaxila9094No ratings yet

- CH 9 - Attached Growth ProcessDocument30 pagesCH 9 - Attached Growth Processxuantra92100% (1)

- Treatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorDocument8 pagesTreatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorIna SitaNo ratings yet

- Ion Exchange 2Document26 pagesIon Exchange 2api-3737745100% (3)

- Lecture 3 - Coagulation and FlocculationDocument93 pagesLecture 3 - Coagulation and FlocculationChuah Chong YangNo ratings yet

- Determination of Lead in Drinking Water PW PointDocument18 pagesDetermination of Lead in Drinking Water PW PointAbhijith AjithNo ratings yet

- Stream Water Quality AnalysisDocument12 pagesStream Water Quality AnalysisRahul DekaNo ratings yet

- Anaerobic Baffled Reactor (ABR) - SSWM PDFDocument9 pagesAnaerobic Baffled Reactor (ABR) - SSWM PDFAnonymous gqtnY7iRk1No ratings yet

- 2010 SMR ClarifierDocument60 pages2010 SMR ClarifierRohan KakdeNo ratings yet

- Biosorption of Lead (II), Cadmium (II), Copper (II) and Nickel (II) by Anaerobic Granular BiomassDocument9 pagesBiosorption of Lead (II), Cadmium (II), Copper (II) and Nickel (II) by Anaerobic Granular BiomassDr. Arif HidayatNo ratings yet

- Adsorption of Reactive Black 5 From An Aqueous Solution - Equilibrium and Kinetic StudiesDocument10 pagesAdsorption of Reactive Black 5 From An Aqueous Solution - Equilibrium and Kinetic StudiesDr. Arif HidayatNo ratings yet

- Teks Lasporan Hasil Observasi KucingDocument1 pageTeks Lasporan Hasil Observasi KucingDr. Arif HidayatNo ratings yet

- An Efficient Synthesis of Warfarin Acetals On Montmorillonite Clay K-10 With MicrowavesDocument5 pagesAn Efficient Synthesis of Warfarin Acetals On Montmorillonite Clay K-10 With MicrowavesDr. Arif HidayatNo ratings yet

- Short Communication: of Afzelia AfricanaDocument2 pagesShort Communication: of Afzelia AfricanaDr. Arif HidayatNo ratings yet

- Ozonation of Cationic Red X-GRL in Aqueous Solution - Degradation and MechanismDocument11 pagesOzonation of Cationic Red X-GRL in Aqueous Solution - Degradation and MechanismDr. Arif HidayatNo ratings yet

- Effect of Wettability and Ageing Conditions On The Physical and Mechanical Properties of Uniaxially Oriented Jute-Roving-Reinforced Polyester CompositesDocument12 pagesEffect of Wettability and Ageing Conditions On The Physical and Mechanical Properties of Uniaxially Oriented Jute-Roving-Reinforced Polyester CompositesDr. Arif HidayatNo ratings yet

- Interfacial Evaluation of Modified Jute and Hemp FibersDocument14 pagesInterfacial Evaluation of Modified Jute and Hemp FibersDr. Arif HidayatNo ratings yet

- Decolourisation of The Textile Dye Astrazon Red FBL by Funalia Trogii PelletsDocument3 pagesDecolourisation of The Textile Dye Astrazon Red FBL by Funalia Trogii PelletsDr. Arif HidayatNo ratings yet

- Short Communication: Studies On S o M e Seeds and Seed OilsDocument3 pagesShort Communication: Studies On S o M e Seeds and Seed OilsDr. Arif HidayatNo ratings yet

- 5 Jurnal Hafi 40-48Document10 pages5 Jurnal Hafi 40-48Dr. Arif HidayatNo ratings yet

- BD 05 PDFDocument11 pagesBD 05 PDFDr. Arif HidayatNo ratings yet

- Extraction of Essential Oils From Jasmine Flower Using Solvent Extraction MethodDocument38 pagesExtraction of Essential Oils From Jasmine Flower Using Solvent Extraction MethodNguyen Bich Anh100% (4)

- Sludge Conditioning Characteristics of Copper Chemical Mechanical Polishing Wastewaters Treated by ElectrocoagulationDocument5 pagesSludge Conditioning Characteristics of Copper Chemical Mechanical Polishing Wastewaters Treated by ElectrocoagulationDr. Arif HidayatNo ratings yet

- Acceptance Letter Paper Id 9398Document3 pagesAcceptance Letter Paper Id 9398Dr. Arif HidayatNo ratings yet

- BA 302 Lesson 3Document26 pagesBA 302 Lesson 3ピザンメルビンNo ratings yet

- Pnas 1703856114Document5 pagesPnas 1703856114pi. capricorniNo ratings yet

- Th255, Th255c Axle Cat ServiceDocument280 pagesTh255, Th255c Axle Cat ServiceKevine KhaledNo ratings yet

- 9-Lesson 5 Direct and Indirect SpeechDocument8 pages9-Lesson 5 Direct and Indirect Speechlaiwelyn100% (4)

- Usage Instructions - Hengro PoolProtect 1 - 5Document3 pagesUsage Instructions - Hengro PoolProtect 1 - 5Brian VisserNo ratings yet

- Maths Note P1 and P3Document188 pagesMaths Note P1 and P3Afeefa SaadatNo ratings yet

- Documentation For UStarDocument26 pagesDocumentation For UStarthunder77No ratings yet

- CD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesDocument26 pagesCD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesMAC CONSULTORESNo ratings yet

- Individual Moving Range (I-MR) Charts ExplainedDocument18 pagesIndividual Moving Range (I-MR) Charts ExplainedRam Ramanathan0% (1)

- Alaris 8210 and 8220 SpO2 Module Service ManualDocument63 pagesAlaris 8210 and 8220 SpO2 Module Service ManualNaveen Kumar TiwaryNo ratings yet

- Electromagnetic Braking SystemDocument14 pagesElectromagnetic Braking SystemTanvi50% (2)

- SOP Questionnaire GREDocument4 pagesSOP Questionnaire GREYuvraj GuptaNo ratings yet

- Chapter 6 - 31-05-2023Document163 pagesChapter 6 - 31-05-2023Saumitra PandeyNo ratings yet

- Tutorial Sim MechanicsDocument840 pagesTutorial Sim MechanicsHernan Gonzalez100% (4)

- Packing, Transportation and Marketing of Ornamental FishesDocument16 pagesPacking, Transportation and Marketing of Ornamental Fishesraj kiranNo ratings yet

- 9.tools and Equipment 1Document13 pages9.tools and Equipment 1NKH Mega GasNo ratings yet

- ST326 - Irdap2021Document5 pagesST326 - Irdap2021NgaNovaNo ratings yet

- NACE CIP Part II - (6) Coatings For Industry - (Qs - As)Document23 pagesNACE CIP Part II - (6) Coatings For Industry - (Qs - As)Almagesto QuenayaNo ratings yet

- Board of Intermediate & Secondary Education, Lahore: Tahir Hussain JafriDocument2 pagesBoard of Intermediate & Secondary Education, Lahore: Tahir Hussain Jafridr_azharhayatNo ratings yet

- 2002 AriDocument53 pages2002 AriMbarouk Shaame MbaroukNo ratings yet

- Sewer CadDocument10 pagesSewer CadAlvaro Jesus Añazco YllpaNo ratings yet

- ECE Laws and Ethics NotesDocument29 pagesECE Laws and Ethics Notesmars100% (1)

- Information HandoutsDocument6 pagesInformation HandoutsPooja Marwadkar TupcheNo ratings yet

- Maytag MDG78PN SpecificationsDocument2 pagesMaytag MDG78PN Specificationsmairimsp2003No ratings yet

- Ancon Channel & Bolt FixingsDocument20 pagesAncon Channel & Bolt FixingsatiattiNo ratings yet

- 1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFDocument11 pages1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFBonnie JamesNo ratings yet

- Holacracy FinalDocument24 pagesHolacracy FinalShakil Reddy BhimavarapuNo ratings yet

- How To Approach To Case Study Type Questions and MCQsDocument4 pagesHow To Approach To Case Study Type Questions and MCQsKushang ShahNo ratings yet

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 pagesManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- ERC12864-12 DemoCode 4wire SPI 2Document18 pagesERC12864-12 DemoCode 4wire SPI 2DVTNo ratings yet