Professional Documents

Culture Documents

Precommissioning Checks in Pyro - Kiln Feed Area

Uploaded by

Vijay BhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precommissioning Checks in Pyro - Kiln Feed Area

Uploaded by

Vijay BhanCopyright:

Available Formats

PRECOMMISSIONING CHECKS IN PYRO Kiln Feed Area.

The silo aeration pads are loose and/or not grouted to the silo floor.

The silo roof leaks. If it is not raining during the check out period, have the

silo closed up without any light inside and check for sunlight coming into silo.

It may also be necessary to form water pools around all silo roof equipment

such as nivo pilots, dust collectors, over / under vent ports, and inspection ports

to check for leaks.

Verify that the aeration pad canvases are installed properly without holes or

weld splatter.

All trash and construction debris must be removed from silo, air slides, feed

bins and dust collectors. Verify that the extraction points are clear. (For CF

silos, ensure the discharge orifice plates are installed in the proper locations.)

Check that the air slides are properly constructed. Check that the canvas is

tight, joints are sealed, and the bottom plenums extend to within 9 inches of

discharge points and turn boxes. Ensure that there are no holes or weld splatters

in canvas. Perforated plates should be installed at high impact areas, such as the

discharge of bucket elevators and at any point after a significant drop.

Check that the air slides are dry and that moisture cannot enter.

Check that the diverter gates are installed properly, particularly that the

mounting flanges bolt together flush so as not to tear rubber seals. Gates open

and close without rubbing and show the proper indication in the control room.

Verify that high level devices and nivo pilots are mounted in the proper place

and extend down to the proper level.

Make sure bins, mounted on load cells are mechanically free, so that all weight

is on the load cells, evenly distributed and load cells have been calibrated.

Check that all pneumatic and mechanical valves open and close fully and

indications in the control room are correct.

Check that plant air and plant cooling water are piped correctly; try to have air

pressure gauges and water flow meters located strategically for trouble

shooting.

Check that the mass flow meters are installed correctly with the proper

clearances and alignment.

Verify the rotary feeders have sufficient clearance.

Check that vent take off points have pressure-measuring ports below blast

gates, for balancing vent systems after start up.

Check that dust collector bags are mounted correctly with the jet pulse holes

positioned directly over the center of bags. Ensure jet pulse systems are

working and the timing sequence has been initially set.

You might also like

- Supertramp - Crisis What Crisis (Book)Document40 pagesSupertramp - Crisis What Crisis (Book)Josip Mešin82% (11)

- HighNote3 - Mediation T 2Document2 pagesHighNote3 - Mediation T 2MiKeLsNo ratings yet

- A TEC Leaflet HURRICLON PDFDocument2 pagesA TEC Leaflet HURRICLON PDFthanhNo ratings yet

- I Thank God-Maverick City Music-Move Your Heart.GDocument5 pagesI Thank God-Maverick City Music-Move Your Heart.Gemmapowell2007No ratings yet

- Annex List of Uk Amateur Radio CallsignsDocument2,930 pagesAnnex List of Uk Amateur Radio CallsignsVerbatimNo ratings yet

- Tromp Value: Feed % Pass Fines % Pass Dim. Rejects % PassDocument5 pagesTromp Value: Feed % Pass Fines % Pass Dim. Rejects % PassThaigroup CementNo ratings yet

- ABC Cooler InletDocument4 pagesABC Cooler InletNaelNo ratings yet

- Cement Manufacturing OverviewDocument20 pagesCement Manufacturing OverviewRaj K SharmaNo ratings yet

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084No ratings yet

- Cement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Document20 pagesCement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Abay ShiferaNo ratings yet

- Department of Chemical EngineeringDocument19 pagesDepartment of Chemical EngineeringPandia RajanNo ratings yet

- Colour Codes, Notes & FAQ: WBCSD Cement Sustainability Initiative CO2 Emissions Inventory Protocol, Version 2.0Document33 pagesColour Codes, Notes & FAQ: WBCSD Cement Sustainability Initiative CO2 Emissions Inventory Protocol, Version 2.0Rodrigo DíazNo ratings yet

- Importance of Dedusting Pipe LayoutDocument4 pagesImportance of Dedusting Pipe LayoutManoj ThakurNo ratings yet

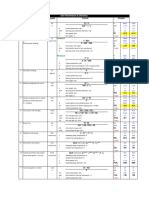

- Psychrometric CalculationDocument7 pagesPsychrometric CalculationAnonymous 3ESYcrKPNo ratings yet

- Cooling TowerDocument3 pagesCooling Toweradearyani4No ratings yet

- VB 29 - 10Document5 pagesVB 29 - 10Kenny RuizNo ratings yet

- (Grate Cooler Assessment) June 2012Document13 pages(Grate Cooler Assessment) June 2012Phillip007No ratings yet

- 09.work Instruction For Operation of Additive Ball MillDocument9 pages09.work Instruction For Operation of Additive Ball MillRahul VermaNo ratings yet

- The Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsDocument31 pagesThe Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsZegera MgendiNo ratings yet

- Comparison of Bricks SpecificationsDocument1 pageComparison of Bricks SpecificationsSaji KumarNo ratings yet

- Bits Ps-II Eos FDBK I Sem 2012-13Document1 pageBits Ps-II Eos FDBK I Sem 2012-13Sai Sricharan ReddyNo ratings yet

- Fls - Cfi SiloDocument4 pagesFls - Cfi SiloNicolás CanelliNo ratings yet

- Heat Balance Cement IndustryDocument1 pageHeat Balance Cement IndustryMin ZayarNo ratings yet

- How To Remove Scrap Materials From A Ball Mill CircuitDocument5 pagesHow To Remove Scrap Materials From A Ball Mill Circuitsafwat hassanNo ratings yet

- Turbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnerDocument4 pagesTurbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnermsvprasadNo ratings yet

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- CFS SiloDocument4 pagesCFS SiloYhaneNo ratings yet

- Dust - and - Meal Presentation PDFDocument27 pagesDust - and - Meal Presentation PDFawwadNo ratings yet

- In VoluteDocument3 pagesIn Voluteds693No ratings yet

- Pre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)Document3 pagesPre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)saji kumarNo ratings yet

- ATEC Splash BoxDocument1 pageATEC Splash BoxBerkan FidanNo ratings yet

- Study On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderDocument4 pagesStudy On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderIJIRST100% (1)

- Process - Operation - Optimization of The ETA Cooler - MugherDocument138 pagesProcess - Operation - Optimization of The ETA Cooler - Mugherzewdu dechasaNo ratings yet

- False Air Sealing Around Vertical Raw Mill and PyroDocument5 pagesFalse Air Sealing Around Vertical Raw Mill and PyroabdulfetahNo ratings yet

- Bypass SystemDocument9 pagesBypass SystemirfanNo ratings yet

- WorkingDocument4 pagesWorkingUsman ZafarNo ratings yet

- Cement Plant VIPDocument51 pagesCement Plant VIPengr kazamNo ratings yet

- Assignment On Fundamental Analysis Acc CompanyDocument5 pagesAssignment On Fundamental Analysis Acc CompanyDevika SuvarnaNo ratings yet

- Horno - QuemadorDocument13 pagesHorno - QuemadorRoberto Alanez EncinasNo ratings yet

- Pyro System - Control Loops V0.0Document2 pagesPyro System - Control Loops V0.0Junaid MazharNo ratings yet

- Process Operation Manual For Clinker Burning SystemDocument109 pagesProcess Operation Manual For Clinker Burning SystemGebrehiwot Esayas100% (1)

- Cement Technology Cement Manufacturing: C E M E N T A D D I T I V E SDocument57 pagesCement Technology Cement Manufacturing: C E M E N T A D D I T I V E Sshani5573No ratings yet

- NM3 To ACTUAL M3Document3 pagesNM3 To ACTUAL M3Vipan Kumar DograNo ratings yet

- Cement Kiln CapacityDocument2 pagesCement Kiln Capacityemad sabriNo ratings yet

- Jetflex - Highlights ArticleDocument2 pagesJetflex - Highlights Articlenagendra51No ratings yet

- Cement Industry: Handy ManualDocument44 pagesCement Industry: Handy ManualMahmoudRadiNo ratings yet

- Calculation of Cement and Sand For Plastering Excel SheetDocument2 pagesCalculation of Cement and Sand For Plastering Excel SheetSonu KumarNo ratings yet

- Review No.145: Keystone S Cross-OverDocument7 pagesReview No.145: Keystone S Cross-Overbasavaraju535No ratings yet

- Cement ManufacturingDocument6 pagesCement ManufacturingMuhammad TausifNo ratings yet

- Performance Evaluation of Hybrid Fiber Reinforced Concrete Using Copper Slag As Replacement Material of Fine AggregateDocument4 pagesPerformance Evaluation of Hybrid Fiber Reinforced Concrete Using Copper Slag As Replacement Material of Fine AggregateEditor IJTSRDNo ratings yet

- Comparison of Short-And Long-Term ASR Test Methods On Cementitious CompositesDocument6 pagesComparison of Short-And Long-Term ASR Test Methods On Cementitious CompositesysrerbsNo ratings yet

- Presentation - Cement - GenDocument40 pagesPresentation - Cement - Genpacoto livingstoneNo ratings yet

- Kiln Feed+ Kiln+ Cooler+ DPC and Clinker Silo Top Daily Check ListDocument12 pagesKiln Feed+ Kiln+ Cooler+ DPC and Clinker Silo Top Daily Check ListVinod Kumar VermaNo ratings yet

- Inspection Form Atox Mill 70000196-1: Measurement of Bottom PlateDocument2 pagesInspection Form Atox Mill 70000196-1: Measurement of Bottom PlatemkpqNo ratings yet

- Ball Mill Volume LoadingDocument2 pagesBall Mill Volume LoadingThaigroup CementNo ratings yet

- PDF Created With Pdffactory Trial VersionDocument8 pagesPDF Created With Pdffactory Trial VersionVisnu SankarNo ratings yet

- Ercom Brief ProfileDocument57 pagesErcom Brief ProfileKarthik DhayalanNo ratings yet

- Ball Charge DesignDocument12 pagesBall Charge DesignPaulo VidasNo ratings yet

- Better Burner Specifications PDFDocument4 pagesBetter Burner Specifications PDFAbdul HayyeNo ratings yet

- Clinker Cooler Queching Best PracticeDocument1 pageClinker Cooler Queching Best PracticeShukor AzNo ratings yet

- L-2 Fans 21.11.11Document5 pagesL-2 Fans 21.11.11Aaron HortonNo ratings yet

- Combustion Studies of Fuel-Rich PropellantsDocument156 pagesCombustion Studies of Fuel-Rich PropellantsĐăng Khôi TrầnNo ratings yet

- Pre Commissioning Checks in Pyro - Pre Heater AreaDocument1 pagePre Commissioning Checks in Pyro - Pre Heater AreaVijay BhanNo ratings yet

- 3D Model ReviewDocument12 pages3D Model ReviewDana GuerreroNo ratings yet

- Maximum Ball Size - Grinding Media - CalculationDocument2 pagesMaximum Ball Size - Grinding Media - CalculationVijay BhanNo ratings yet

- Deposit CalculatorDocument2 pagesDeposit CalculatorVijay Bhan0% (1)

- Ok Mill Interlock ListDocument1 pageOk Mill Interlock ListVijay BhanNo ratings yet

- Specific Stoichiometric - Combustion Air CalculationDocument2 pagesSpecific Stoichiometric - Combustion Air CalculationVijay BhanNo ratings yet

- Rotary Kiln - Burning Zone Load CalculationDocument2 pagesRotary Kiln - Burning Zone Load CalculationVijay Bhan100% (1)

- K - Constant For Cooler Fan FlowsDocument4 pagesK - Constant For Cooler Fan FlowsVijay Bhan100% (1)

- Heat-Up Schedule As Per RequirementDocument1 pageHeat-Up Schedule As Per RequirementVijay BhanNo ratings yet

- MULTICOR Operating PrincipleDocument1 pageMULTICOR Operating PrincipleVijay BhanNo ratings yet

- Kiln Rotation ProcedureDocument1 pageKiln Rotation ProcedureVijay BhanNo ratings yet

- MMTS Train TimingsDocument15 pagesMMTS Train TimingsMohan KrishnaNo ratings yet

- Influence of Sulfur in ClinkerDocument1 pageInfluence of Sulfur in ClinkerVijay Bhan100% (1)

- CORIOLIS PrincipleDocument1 pageCORIOLIS PrincipleVijay BhanNo ratings yet

- Inching Drive - Mechanism For Process FansDocument1 pageInching Drive - Mechanism For Process FansVijay BhanNo ratings yet

- Fan System - Curve Operating RangeDocument1 pageFan System - Curve Operating RangeVijay BhanNo ratings yet

- Fan System - System Resistance PDFDocument1 pageFan System - System Resistance PDFVijay Bhan0% (1)

- Precommissioning Checks in Raw Mill Feed Bin AreaDocument1 pagePrecommissioning Checks in Raw Mill Feed Bin AreaVijay BhanNo ratings yet

- Weigh Feeder MechanicsDocument1 pageWeigh Feeder MechanicsVijay Bhan67% (3)

- Pre Commissioning Checks in Pyro - Pre Heater AreaDocument1 pagePre Commissioning Checks in Pyro - Pre Heater AreaVijay BhanNo ratings yet

- Fan System - System ResistanceDocument1 pageFan System - System ResistanceVijay BhanNo ratings yet

- Precommissioning Checks in Pyro - Instrumentation SectionDocument1 pagePrecommissioning Checks in Pyro - Instrumentation SectionVijay BhanNo ratings yet

- B-W Calibration ProcedureDocument4 pagesB-W Calibration ProcedureVijay Bhan100% (3)

- Pre Commissioning Checks in Major Process FansDocument1 pagePre Commissioning Checks in Major Process FansVijay BhanNo ratings yet

- Building Construction CostDocument3 pagesBuilding Construction CostVijay BhanNo ratings yet

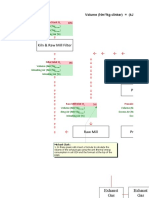

- Pyro-Processing System - MASS & GAS FLOWDocument1 pagePyro-Processing System - MASS & GAS FLOWVijay BhanNo ratings yet

- Reactions of Clinker BurningDocument1 pageReactions of Clinker BurningVijay BhanNo ratings yet

- Hammer MillDocument1 pageHammer MillVijay BhanNo ratings yet

- Fan Curve CalculationsDocument1 pageFan Curve CalculationsVijay BhanNo ratings yet

- Stack MonitoringDocument24 pagesStack MonitoringVijay BhanNo ratings yet

- Kiln Audit - Required Measurement ToolsDocument1 pageKiln Audit - Required Measurement ToolsVijay BhanNo ratings yet

- English Conversation For BeginnersDocument10 pagesEnglish Conversation For BeginnersDede Van Brengosh83% (6)

- Dynamic Learning Plan: Arellano University - Pasig Campus SeniorDocument15 pagesDynamic Learning Plan: Arellano University - Pasig Campus SeniorKim lobreteNo ratings yet

- Rab Interior Hotel FixDocument4 pagesRab Interior Hotel FixDhimas Surya NegaraNo ratings yet

- Young September-October 2011Document4 pagesYoung September-October 2011Straight Talk FoundationNo ratings yet

- Turandot Study GuideDocument37 pagesTurandot Study GuideBoran SavranNo ratings yet

- Ethan Steimel: Lighting DesignDocument1 pageEthan Steimel: Lighting Designetnfret2000No ratings yet

- Edgar Allan Poe - A DreamDocument1 pageEdgar Allan Poe - A DreamItha Shin ChanchythaNo ratings yet

- ArtsDocument16 pagesArtsAndreycarla MerlanNo ratings yet

- Computer NetworksDocument27 pagesComputer NetworksAMITNo ratings yet

- PrintDocument11 pagesPrintMars TinNo ratings yet

- Amadeus Quick Reference - Reservation by Iata Travel ConsultanceDocument6 pagesAmadeus Quick Reference - Reservation by Iata Travel ConsultanceLEO OrtizNo ratings yet

- Descrição Das UM's EnglishDocument6 pagesDescrição Das UM's EnglishPablo CarvalhoNo ratings yet

- Grade 11 HandoutDocument61 pagesGrade 11 Handoutrach.belferarNo ratings yet

- English For KidsDocument5 pagesEnglish For KidsGonzalo HerreraNo ratings yet

- Jason Lamb ResumeDocument1 pageJason Lamb ResumeJason LambNo ratings yet

- Xii Maths Book-1 Based (Solutions) Self-Assessment Tests 2022-23 (Amit Bajaj)Document26 pagesXii Maths Book-1 Based (Solutions) Self-Assessment Tests 2022-23 (Amit Bajaj)Dheeraj SinhaNo ratings yet

- Holy Week Mass Schedule (2023)Document1 pageHoly Week Mass Schedule (2023)joelNo ratings yet

- Openings ListDocument48 pagesOpenings ListJhonny CehNo ratings yet

- Nombre. Leidy Viviana Fajardo Lopez Grupo:1A PAG2: I. Circle The Correct Answers. III. Put in Much or ManyDocument12 pagesNombre. Leidy Viviana Fajardo Lopez Grupo:1A PAG2: I. Circle The Correct Answers. III. Put in Much or ManyLEIDY VIVIANA FAJARDO L�PEZNo ratings yet

- Sims Installation ProcedureDocument1 pageSims Installation ProcedureTHIRU.SNo ratings yet

- QMLDocument410 pagesQMLMani Rathinam RajamaniNo ratings yet

- Summary of Music Time Periods: BAROQUE PERIOD 1600 - 1750Document4 pagesSummary of Music Time Periods: BAROQUE PERIOD 1600 - 1750Isobel WilliamsNo ratings yet

- Fuji Xerox Mono MFP Tel: 63346455 / 63341373 Fax: 63341615 / SMS/Whatsapp - 8777 6955 / Wechat ID - BizgramSG Bizgram Asia Pte Ltd (ROC :200903547Z) Shop & Collection : 1 Rochor Canal Road, # 05-49 / 50 Simlim Square, Singapore 188504.Document10 pagesFuji Xerox Mono MFP Tel: 63346455 / 63341373 Fax: 63341615 / SMS/Whatsapp - 8777 6955 / Wechat ID - BizgramSG Bizgram Asia Pte Ltd (ROC :200903547Z) Shop & Collection : 1 Rochor Canal Road, # 05-49 / 50 Simlim Square, Singapore 188504.Bizgram AsiaNo ratings yet

- Church Mass Songs With ChordsDocument11 pagesChurch Mass Songs With ChordsAdelaide Andre LozadaNo ratings yet

- Name of Exercise Area (S) of Body Imbalance (S) Structures AddressedDocument2 pagesName of Exercise Area (S) of Body Imbalance (S) Structures AddressedBruce HoNo ratings yet

- DCC Patron SunWukong TCDocument9 pagesDCC Patron SunWukong TCTimNo ratings yet