Professional Documents

Culture Documents

C20R Optimized Start Technique For C20 and C20R

Uploaded by

EstevamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C20R Optimized Start Technique For C20 and C20R

Uploaded by

EstevamCopyright:

Available Formats

Tech-Center

----... - --- ra,. COMMERCIAL SERVICE LETTER

Allison GAS TURBINE DIVISION General Motors Corporation

TECHNICAL ASPECTS ARE FAA APPROVED

SUBJECT: OPTIMIZED START TECHNIQUE FOR ALLISON 250-C20 SERIES AND C20R SERIES

ENGINES

Various misconceptions exist about what is a good start and how to obtain an

optimal start for an Allison 250-C20 or C20R Series engine. This service

letter addresses Bendix controlled engines specifically, but most of the

principles expressed also apply to engines utilizing CECO controls. Allison

recommends judging starts by the performance of a first start of the day

situation utilizing a fully charged battery. Do not attempt to adjust fuel

control systems based on cold soaked engines in low ambient temperatures or

by using an APU/GPU power source. An optimized start primarily focuses on

starting in the least possible time without exceeding any temperature

limits.

Allison defines a good first start as one taking less than 25 seconds from

the introduction of fuel until the engine reaches ground idle. To obtain an

optimized start, move the throttle to the ground idle position to begin fuel

flow as the Nl RPM accelerates through 12-15% Nl. Do ng1 wait for Nl RPM to

peak out before initiating fuel flow, as this will unnecessarily utilize

battery capacity early in the start cycle. Peak observed turbine outlet

temperature may reach 820C for C20 Series engines or 860C for C20R Series

engines during the optimized start. However, start temperature limits

remain as defined in the appropriate Operation and Maintenance Manual, not

to exceed 810C for more than 10 seconds and never to exceed 927C.

During starts Pilots should note temperature peaks, the drop between the

peaks as well as the total start time. This information will assist

maintenance personnel in making appropriate fuel control adjustments.

It does not matter which observed peak is the higher. At times the two

peaks may be so close together that they appear as one peak. In an

optimized start the temperature drop between the two peaks, known as the

start notch, is usually 50C or less. However, the prime determinant of the

quality of the start is the length of time from introduction of fuel to

attaining 58% NI and releasing starter assist. Flight personnel should

provide maintenance personnel with accurate time and temperature information

in order to exact the most effective start adjustments.

December 15, 1992 2S0-C20 Series

2S0-C20R Series

CSL 1176

CSl 4050

ALLISON GAS TURBINE

Commercial Service Letter

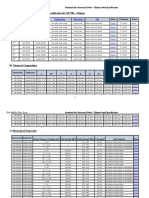

There are two adjustments to balance starting on current Bendix systems;

start derichment and start/acceleration adjust.ent (tweeter). (See Figure

1). To affect start temperatures or stagnation below 301 NI, start

derichment should be adjusted. Start/acceleration adjustment is to be used

to remedy stagnation above 301 NI or regulate the start ta.perature above

301 NI. The start/acceleration adjust .. nt affects the entire start

schedule. It is possible that in adjusting the start/acceleration

adjustment, an additional adjustment of the start derichlent ~ be required

1

because of the startl acceleration adjustment influence on the entire engine

fuel schedule. Adjustments to the fuel control unit are considered normal

maintenance allowing compensation for wear or atmospheriC 'change. All fuel

control adjustments should be .ade only by qualified personnel familiar with

the adjustments and should always be accomplished in accordance with the

appropriate Allison Operation and Maintenance Mandal.

START DERICHMENT AD.lJSTMENT

Start/Acceleration and Start-Derichment Adjustments

Figure I

December 15, 1992 2S0-C20 Series

2S0-C20R Series

CSl 1176

CSL 4050

Page 2 of 3

ALLISON GAS TURBINE

Commercial Service Letter

If adjustments defined in the applicable Operation and Maintenance Manual do

not improve the start characteristics within a few attempts, the fuel

control may have been maladjusted previously and require returning both

start-derichment and start/acceleration settings to the nominal or neutral

position. Should this be required, uke a fuel flow (baby bottle) check

using a vessel calibrated in CCs to capture and .aasure initial fuel flow.

The Operation and Maintenance Manuals specify the procedure, define nominal

settings, and 1ndicatedesired fuel quantity to accomplish the fuel flow

test. Once proper fuel flow is attained, proceed with proper adjustment to

optimize the start. If correct fuel flow or starts cannot be atta1ned, the

fuel control.., be out of calibration. Return any out of calibration fuel

control unit to an authorized facility for adjustlent or repair.

Consistent long, cool starts (35 seconds or more) can be detrimental to the

gas producer turbine life. Remember that the temperatures indicated on the

TOT gauge are interturbine, between the gas producer and power turbine, and

m~ not reflect the temperatures being experienced by the first stage

turbine nozzle and first stage turbine wheel. The quick, warm starts

recommended by Allison actually increase cooling air flow in the combustion

section to help insulate the gas producer turbine.

This CSL outlines the Allison Gas Turbine philosophy on proper starting of

250-C20 Series and C20R Series engines. While it has been stated that

starting procedures and adjustments are helpful to C20 Series operators,

they are even more important to C20R Series operators. As stated by Allison

in C20R Series CSL 4031, a C20R Series engine start takes a few seconds

longer and will atta1n a higher peak TOT than its C20 Series counterpart,

installed in the same aircraft, in the same ambient conditions. It is these

start characteristics that make proper fuel control adjustments imperative

to optimize starts on C20R Series engines.

Fuel control adjustment may be required seasonally to compensate for ambient

change or if operational location MOves result in significant altitude

variation. Contact your authorized 250 Distributor or AMOC for assistance

if you do not feel confident in making the fuel control adjustment discussed

here, as defined in the Operation and Maintenance Manual, for each series

engine.

CUSTOMER SUPPORT

ALLISON GAS TURBINE DIVISION

GENERAL MOTORS CORPORATION

Page 3 of 3

EXPORT CONTROLLED Rolla-Royce

250-C30 SERIES OPERATION AND MAINTENANCE

2

.lIem Trouble

4 {cont) Engine lights off but will not

accelerate to idle speed at a

normal rate. (cont)

5

6

Engine lights off but flames

out during ground starts at

high altilude, especially above

5000 feet (1524 meters). during

cold ambient conditions.

Acceleration temperarure too

high during start.

TABLE 101 (cont)

Troubleshooting

probable Cause

Fuel nozzle

panlally ctogged

with carbon.

Remedy

Clean fuel nozzle. (Reter to Clean

ing. para 3., 73-10-03.)

Fuel nozzle valve stuck par- Rep'ace fuel nozzle.

tially open.

Start derichment adjustment Make start derichment adjustment.

too low. (Refer to Start Derichment Adjustment.

para 3.0.(1), 73-20-02.)

Gas producer fuel control in- Replace control.

correcdy adjusted or calibration

has shifted.

Antt-iclng valve open and cabin

heat on. .

Foreign object damage or ero

sion to compressor.

Faulty power tUrWIe governor.

Fuel nozzle partially clogged.

, Start derichment adjustment

too low.

Insu1ficient time allowed for

draining after an unsuccessful

starting attempt.

Reduced battery capacity.

This can produce low cranking

speed.

Close anti-iclng valve and turn off

cabin heat.

Inspect compressor

Replace governor.

Inspect fuel nozzle for carbon buildup.

Clean or reDlace as necessary.

Uake start derichment adjustment.

(Refer to Start Derichment Adjustment,

para 3.C. (1). 73-20-02).

Purge tt'le ellatneby motoring with

the gas producer lever and ignition

switch in OFF for approximately 10

3

sec before attempting a second start.

Recharge or replace battery.

High residua! TOT in excess Motor engine with starter leaving gas

of , SOOC (302~F). producer lever and ignition OFF.

Depreciated starter which is Replace starter.

not capable of dry motoring

gas producer (N1) above 15

percent.

72-00-00

Page 103

Jul1192

EXPORT CONTROlLED Rolis-Royce

25O-C30 SERIES OPERATION AND MAINTENANCE

START/ACCElERA 1100 --,

ADJUSTMENT

START DERICHMEliT ADJUSTMENT

Start/Acceleration and Stan Derlchment Adjustments

Figure 204

73-20-02

Page 209

Jul1192

You might also like

- Installation and Rigging ProceduresDocument15 pagesInstallation and Rigging ProceduresRene QueirozNo ratings yet

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsFrom EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo ratings yet

- Ceb 73 6048Document5 pagesCeb 73 6048turboshaftNo ratings yet

- CSL 1060Document6 pagesCSL 1060oscar horacio floresNo ratings yet

- SL162B Helicoil PDFDocument2 pagesSL162B Helicoil PDFjeffrey_fay100% (2)

- C47B OmmDocument12 pagesC47B OmmturboshaftNo ratings yet

- Ceb A 72-3247Document4 pagesCeb A 72-3247turboshaftNo ratings yet

- X30011 - C90 Parts Catalog ContinentalDocument54 pagesX30011 - C90 Parts Catalog ContinentalLeonardo Martedi100% (1)

- Airworthiness LimitationsDocument5 pagesAirworthiness LimitationsCharles PereiraNo ratings yet

- Commercial Engine Bulletin: Engine - Power Turbine With Improved Airflow CharacteristicsDocument4 pagesCommercial Engine Bulletin: Engine - Power Turbine With Improved Airflow Characteristicsturboshaft0% (1)

- TM 1-1500-204-23-1, Change 5Document448 pagesTM 1-1500-204-23-1, Change 5"Rufus"No ratings yet

- Model 250 C40BDocument2 pagesModel 250 C40Bsnappish1No ratings yet

- Subject: Revision C-12 To St-Un-M001 TO: All Holders of Sa227 Airframe Airworthiness Limitations ManualDocument89 pagesSubject: Revision C-12 To St-Un-M001 TO: All Holders of Sa227 Airframe Airworthiness Limitations ManualOficina Tecnica100% (1)

- Special Airworthiness Information Bulletin: Federal Aviation AdministrationDocument3 pagesSpecial Airworthiness Information Bulletin: Federal Aviation Administrationrnordell0% (1)

- CAMP Status CessnaDocument95 pagesCAMP Status CessnaKritz FritzNo ratings yet

- Service Letter Cessna (CAL-79-02)Document16 pagesService Letter Cessna (CAL-79-02)anon_847285754No ratings yet

- Note 8Document7 pagesNote 8Alberto MolinaNo ratings yet

- 2007 04 19R1Document24 pages2007 04 19R1Yaşar AkyıldızNo ratings yet

- 250-C30R3, - C30R3M Engine Illustrated Parts CatalogDocument240 pages250-C30R3, - C30R3M Engine Illustrated Parts Catalogp letsonNo ratings yet

- Flysimware's CESSNA 441 ManualDocument19 pagesFlysimware's CESSNA 441 ManualJosé A. Montiel QuirósNo ratings yet

- Al 250Document25 pagesAl 250EstevamNo ratings yet

- FSX/P3D Cessna T206H Soloy Turbine Pac Mark 2 V1.0 Operating ManualDocument26 pagesFSX/P3D Cessna T206H Soloy Turbine Pac Mark 2 V1.0 Operating ManualrodolfoaznarNo ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument5 pagesService Bulletin: Piper Considers Compliance MandatoryJean AbrialNo ratings yet

- EASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Document24 pagesEASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Ken VanNo ratings yet

- 55 1520 214 PMSDocument47 pages55 1520 214 PMSmdhelicopters100% (1)

- Beech 200/300 King Air Type Acceptance ReportDocument19 pagesBeech 200/300 King Air Type Acceptance Reportanantia100% (1)

- Model FR172 Reims Rocket 1968 Thru 1976 Service Manual DEC 2011Document226 pagesModel FR172 Reims Rocket 1968 Thru 1976 Service Manual DEC 2011Paul100% (1)

- Enstrom 280FX RFM Rev.05 (2007)Document158 pagesEnstrom 280FX RFM Rev.05 (2007)JeremiahJohnson100% (1)

- SBFA2100CVR022Document16 pagesSBFA2100CVR022pathy_ameNo ratings yet

- Inspect Shur-Lok Nut on Tail Rotor Drive FlangeDocument31 pagesInspect Shur-Lok Nut on Tail Rotor Drive FlangeRaymond ZamoraNo ratings yet

- H7EU Rev 25Document43 pagesH7EU Rev 25Emanuel PerezNo ratings yet

- CSP Hmi 3Document722 pagesCSP Hmi 3Channy Kim100% (3)

- Contact and Order Info for Bell Helicopter PartsDocument10 pagesContact and Order Info for Bell Helicopter PartsEagle1968No ratings yet

- DHC-6-100-200-300-400 - Rev 14Document111 pagesDHC-6-100-200-300-400 - Rev 14Patrick MbunguNo ratings yet

- Sid97 3GDocument28 pagesSid97 3GdzakubNo ratings yet

- 412 MM CH04 PDFDocument16 pages412 MM CH04 PDFlalo7772No ratings yet

- Ipc 33 590011 3Document500 pagesIpc 33 590011 3LeandroCamposNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00Document62 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00anony8103No ratings yet

- A-65 & A-75 SeriesDocument77 pagesA-65 & A-75 SeriesRicardo UrioNo ratings yet

- ASBAS350620042ENR0Document23 pagesASBAS350620042ENR0Dinesh Bandara100% (1)

- Specs DHC6-msn-846Document10 pagesSpecs DHC6-msn-846Bob DENARDNo ratings yet

- MMsDocument3 pagesMMsJaze JamaludinNo ratings yet

- LYCOMING O & LO-360 (76 Series) Parts Catalog PC-123 PDFDocument29 pagesLYCOMING O & LO-360 (76 Series) Parts Catalog PC-123 PDFBrunoNo ratings yet

- Ad 72-03-03Document3 pagesAd 72-03-03Jonathan PatlanNo ratings yet

- LAPEC - ProductApplicationReference-wm Starter - Generator LibraryDocument104 pagesLAPEC - ProductApplicationReference-wm Starter - Generator Libraryqingtao50% (2)

- X30532Document84 pagesX30532FoxTheHunterNo ratings yet

- Asb 407-04-62Document5 pagesAsb 407-04-62turboshaftNo ratings yet

- Thrust Data For Performance CalculationDocument10 pagesThrust Data For Performance CalculationAnoob Narayanan0% (1)

- HeliSAS POH - 4th Edition PDFDocument44 pagesHeliSAS POH - 4th Edition PDFNickNo ratings yet

- 407 MM CH10Document8 pages407 MM CH10Bruno Alonso PachecoNo ratings yet

- The Australian Air Transport Pilot Licence (Helicopter) S76 Performance and Operations HandbookDocument75 pagesThe Australian Air Transport Pilot Licence (Helicopter) S76 Performance and Operations Handbookgreg mNo ratings yet

- Airborne Fuel Pump 2Document1 pageAirborne Fuel Pump 2Luis Martinez GerdingNo ratings yet

- Allison 250 c20rDocument2 pagesAllison 250 c20rOleksandr BalychevNo ratings yet

- RR250 - C30 OmmDocument16 pagesRR250 - C30 OmmturboshaftNo ratings yet

- Shadin PDFDocument35 pagesShadin PDFAndrea VCorroNo ratings yet

- CESSNA 560 ENCORE Contiuous Airworthinnes ProgramDocument4 pagesCESSNA 560 ENCORE Contiuous Airworthinnes ProgramHaile DinisNo ratings yet

- Se72 2Document2 pagesSe72 2Arturo Israel Sanchez Miranda100% (1)

- RR M250-Siv Ceb 73 - 6048Document6 pagesRR M250-Siv Ceb 73 - 6048turboshaft100% (1)

- Rb211 Fan Blade Failure Tr200200646 - 001Document22 pagesRb211 Fan Blade Failure Tr200200646 - 001EstevamNo ratings yet

- Reciprocating Engine TS TipsDocument5 pagesReciprocating Engine TS TipsEstevamNo ratings yet

- Common Maintenance Events On The M250C20 EnginesDocument11 pagesCommon Maintenance Events On The M250C20 EnginesEstevamNo ratings yet

- Common Maintenance Events On The M250C20 EnginesDocument11 pagesCommon Maintenance Events On The M250C20 EnginesEstevamNo ratings yet

- TMC Annual ChecklistDocument26 pagesTMC Annual ChecklistEstevamNo ratings yet

- A 04 P 0142Document11 pagesA 04 P 0142EstevamNo ratings yet

- TMC Annual ChecklistDocument26 pagesTMC Annual ChecklistEstevamNo ratings yet

- Anac CF34 Engine PDFDocument10 pagesAnac CF34 Engine PDFEstevamNo ratings yet

- Al 250Document25 pagesAl 250EstevamNo ratings yet

- Rolls-Royce Corporation CEBsDocument24 pagesRolls-Royce Corporation CEBsEstevamNo ratings yet

- m250 Lessons LearnedDocument6 pagesm250 Lessons LearnedEstevamNo ratings yet

- Turbine Tips - M250C20 SeriesDocument3 pagesTurbine Tips - M250C20 SeriesEstevamNo ratings yet

- Bell Engine Tooling PDFDocument8 pagesBell Engine Tooling PDFEstevamNo ratings yet

- Overhaul Manual for Jabiru 2200 & 3300 Aircraft EnginesDocument200 pagesOverhaul Manual for Jabiru 2200 & 3300 Aircraft EnginesEstevam Gomes de Azevedo100% (1)

- BE20 FS Technical ManualDocument342 pagesBE20 FS Technical ManualTiago Dreyer100% (3)

- m250 First Network PDFDocument140 pagesm250 First Network PDFEstevam100% (1)

- Embraer ERJ145EPDocument8 pagesEmbraer ERJ145EPTechcenter AssessoriaNo ratings yet

- ABT Station Capability ListDocument1 pageABT Station Capability ListEstevam Gomes de AzevedoNo ratings yet

- AAK Newsletter-June-2016 N°1Document4 pagesAAK Newsletter-June-2016 N°1EstevamNo ratings yet

- Bager Mini JCB 1cxDocument24 pagesBager Mini JCB 1cxZoricaNo ratings yet

- Furniture Locksand CatchesDocument15 pagesFurniture Locksand CatchesNishant DeoNo ratings yet

- Plastic AnalysisDocument23 pagesPlastic AnalysisPraveen Kumar R100% (1)

- Standard Specification For GB 700Document12 pagesStandard Specification For GB 700Ma'arif Nuzul AddibNo ratings yet

- Painting Specification for Aegean Refinery ProjectDocument18 pagesPainting Specification for Aegean Refinery Projectraluca_19735597No ratings yet

- NGK Spark Plug SchemeDocument1 pageNGK Spark Plug Schemeiskra vasileva100% (1)

- Chapter 2 (Lecture 3)Document25 pagesChapter 2 (Lecture 3)SchaieraNo ratings yet

- Glo Brochure Sikagard 555 W ElasticDocument4 pagesGlo Brochure Sikagard 555 W ElasticYasndra AbeygunewardhaneNo ratings yet

- Install Guide Spunlite Poles 2015Document6 pagesInstall Guide Spunlite Poles 2015Balaji PalaniNo ratings yet

- Corporate Image enDocument8 pagesCorporate Image enDanfert PinedoNo ratings yet

- Blown Film CatalogueDocument12 pagesBlown Film CatalogueMohammad-reza NabavinezhadNo ratings yet

- RY780030A Parts ManualDocument4 pagesRY780030A Parts ManualAntonio MartinoNo ratings yet

- Cleaner Production of Essential Oils by Steam DistillationDocument7 pagesCleaner Production of Essential Oils by Steam Distillationhagung100% (1)

- Sony Dsc-w630 Ver1.1 Level2Document25 pagesSony Dsc-w630 Ver1.1 Level2Alberto MorenoNo ratings yet

- Warning: Keystart 9620/9621Document4 pagesWarning: Keystart 9620/9621John GarnetNo ratings yet

- Color Coding On Ships: Trainees DigestDocument2 pagesColor Coding On Ships: Trainees DigestmmakdNo ratings yet

- CanningDocument39 pagesCanningvalerieNo ratings yet

- Aama 501.2-83Document3 pagesAama 501.2-83Abdul Raqeeb67% (3)

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDocument40 pagesJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemNo ratings yet

- Flexible grid coupling selection guideDocument18 pagesFlexible grid coupling selection guidechavico113No ratings yet

- 32LC818 Lcd26v88amDocument53 pages32LC818 Lcd26v88amDaniel AvecillaNo ratings yet

- Powder Metallurgy LabDocument8 pagesPowder Metallurgy Labשירי חדדNo ratings yet

- Experimental Investigation of Resistance Spot Welding of Duplex Stainless SteelDocument5 pagesExperimental Investigation of Resistance Spot Welding of Duplex Stainless SteelM.SoundarrajanNo ratings yet

- Roof Truss Design LoadsDocument51 pagesRoof Truss Design LoadsFeigyl Miro100% (4)

- CHP SopDocument26 pagesCHP Sopkalyanm20351550% (2)

- Aci 318R 08Document1 pageAci 318R 08Sayed Diab AlsayedNo ratings yet

- Pressure-Temperature-Ratings of Flanges As Per ASME B16.5 PDFDocument1 pagePressure-Temperature-Ratings of Flanges As Per ASME B16.5 PDFPawan Patil100% (1)

- Manganese Steel 3401Document1 pageManganese Steel 3401kazdoelahNo ratings yet

- CNC Instructables PDFDocument13 pagesCNC Instructables PDFNadim AhmedNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilFrom EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilNo ratings yet

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsFrom EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNo ratings yet

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet