Professional Documents

Culture Documents

GB 17107 Part4

Uploaded by

Imran Ishak0 ratings0% found this document useful (0 votes)

230 views4 pagesOriginal Title

GB_17107_part4

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

230 views4 pagesGB 17107 Part4

Uploaded by

Imran IshakCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

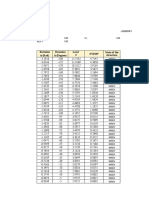

Table 4.

Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 1/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m㎡) (N/m㎡) (%) of area (%) energy (J) Hardness

≥ ≥ ≥ ≥ ≥

thermal ≤100 685 440 15 50 - -

30Mn2 28Mn6

refining 100∼300 635 410 16 45 - -

normalizing+ ≤100 620 315 18 45 - 207∼241

35Mn2 36Mn6 tempering 100∼300 580 295 18 43 23 207∼241

thermal ≤100 745 590 16 50 47 229∼269

refining 100∼300 690 490 16 45 47 229∼269

normalizing+ ≤100 690 355 16 38 - 187∼241

45Mn2 42Mn6 tempering 100∼300 670 335 15 35 - 187∼241

≤600 470 265 15 30 39 -

20SiMn - normalizing+ 600∼900 450 255 14 30 39 -

tempering 900∼1200 440 245 14 30 39 -

≤300 490 275 14 30 27 -

normalizing+ 300∼500 470 265 13 28 23 -

20SiMn - tempering 500∼750 440 245 11 24 19 -

750∼1000 410 225 10 22 19 -

≤100 785 510 15 45 47 229∼286

35SiMn - thermal 100∼300 735 440 14 35 39 271∼265

refining 300∼400 685 390 13 30 35 215∼255

400∼500 635 375 11 28 31 196∼255

≤100 785 510 15 45 31 229∼286

42SiMn - thermal 100∼200 735 460 14 35 23 217∼269

refining 200∼300 685 440 13 30 23 217∼255

300∼500 635 375 10 28 20 196∼255

thermal ≤100 835 540 15 40 39 229∼286

50SiMn - refining 100∼200 735 490 15 35 39 217∼269

200∼300 685 440 14 30 31 207∼255

≤300 500 305 14 40 39 -

20MnMo - thermal 300∼500 470 275 14 40 39 -

refining ≤300 500 305 14 32 31 -

300∼500 470 275 13 30 31 -

thermal 100∼300 635 490 15 45 47 187∼229

20MnMoNb -

refining 300∼500 590 440 15 45 47 187∼229

thermal 500∼800 490 345 15 45 39 -

20MnMoNb - refining 100∼300 610 430 12 32 31 -

300∼500 570 400 12 30 24 -

thermal 100∼300 765 590 12 40 31 241∼286

42MnMoV - refining 300∼500 705 540 12 35 23 229∼269

500∼800 635 490 12 35 23 217∼241

thermal 100∼300 885 735 12 40 31 269∼302

50SiMnMoV - refining 300∼500 885 635 12 38 31 255∼286

500∼800 835 610 12 35 23 241∼286

thermal 100∼200 865 685 14 40 31 269∼302

37SiMn2MoV - refining 200∼400 815 635 14 40 31 241∼286

400∼600 765 590 14 40 31 229∼269

normalizing+ ≤100 390 195 26 50 39 111∼156

15Cr tempering 100∼300 390 195 23 45 35 111∼156

normalizing+ ≤100 430 215 19 40 31 123∼179

20Cr 20Cr4 tempering 100∼300 430 215 18 35 31 123∼167

thermal ≤100 470 275 20 40 35 137∼179

refining 100∼300 470 245 19 40 31 137∼197

30Cr 34Cr4 therm.ref. ≤100 615 395 17 40 43 187∼229

35Cr 34Cr4 therm.ref. 100∼300 615 395 15 35 39 187∼229

≤100 735 540 15 45 39 241∼286

40Cr 41Cr4 thermal 100∼300 685 490 14 45 31 241∼286

refining 300∼500 685 440 10 35 23 229∼269

500∼800 590 345 8 30 16 217∼255

thermal ≤100 835 540 10 40 - 241∼286

50Cr -

refining 100∼300 785 490 10 40 - 241∼286

normalizing+ ≤100 440 275 20 50 55 ≤159

12CrMo -

tempering 100∼300 440 275 20 45 55 ≤159

quenching ≤100 440 275 20 - 55 116∼179

15CrMo - + 100∼300 440 275 20 - 55 116∼179

tempering 300∼500 430 255 19 - 47 116∼179

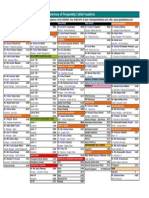

Table 4. Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 2/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m㎡) (N/m㎡) (%) of area (%) energy (J) Hardness

≥ ≥ ≥ ≥ ≥

thermal 17∼40 780 600 14 55 - -

25CrMo - refining 40∼100 690 450 15 60 - -

100∼160 640 400 16 60 - -

thermal ≤100 620 410 16 40 49 196∼240

30CrMo 1 2

refining 100∼300 590 390 15 40 44 196∼240

≤100 735 540 15 45 47 207∼269

35CrMo 34Cr4 thermal 100∼300 685 490 15 40 39 207∼269

refining 300∼500 635 440 15 35 31 207∼269

500∼800 590 390 12 30 23 -

thermal 100∼300 635 440 11 30 27 -

35CrMo 34Cr4 refining 300∼500 590 390 10 24 24 -

500∼800 540 345 9 20 20 -

≤100 900 650 12 50 - -

thermal 100∼160 800 550 13 50 - -

42CrMo 42CrMo4 refining 160∼250 750 500 14 55 - -

250∼500 690 460 15 - - -

500∼750 590 390 16 - - -

≤100 900 700 12 50 - -

thermal 100∼160 850 650 13 50 - -

50CrMo - refining 160∼250 800 550 14 50 - -

250∼500 740 540 14 - - -

500∼750 690 490 15 - - -

100∼300 765 590 15 40 47 -

34CrMo1 - thermal 300∼500 705 540 15 40 39 -

refining 500∼750 665 490 14 35 31 -

750∼1000 635 440 13 35 31 -

case hardening+ ≤30 780 590 10 40 - -

16CrMn - quenching+

tempering 30∼63 640 440 11 40 - -

case hardening+ ≤30 980 680 8 35 - -

20CrMn 20MnCr5 quenching+

tempering 30∼63 790 540 10 35 - -

20CrMnTi - therm.ref. ≤100 615 395 17 45 47 -

case hardening+ ≤30 1080 785 7 40 - -

20CrMnMo - quenching+

30∼100 835 490 15 40 31 -

tempering

thermal 100∼300 785 590 14 45 43 207∼269

35CrMnMo - refining 300∼500 735 540 13 40 39 207∼269

500∼800 685 490 12 35 31 207∼269

≤100 885 735 12 40 39 -

40CrMnMo - thermal 100∼250 835 640 12 30 39 -

refining 250∼400 785 530 12 40 31 -

400∼500 735 480 12 35 23 -

≤100 900 785 13 40 39 277∼331

100∼300 880 735 13 40 39 225∼302

20CrMnMoB - thermal 300∼500 835 685 13 40 39 241∼286

refining 500∼800 785 635 13 40 39 241∼286

100∼300 845 735 12 35 39 269∼302

300∼600 805 685 12 35 39 255∼286

thermal 100∼300 880 715 12 40 31 225∼302

30CrMn2MoB - refining 300∼500 835 665 12 40 31 225∼302

500∼800 785 615 12 40 31 241∼286

thermal 100∼300 830 685 14 45 59 255∼302

32Cr2MnMo - refining 300∼500 785 635 12 40 49 255∼302

500∼750 735 590 12 35 30 241∼286

30CrMnSi - thermal ≤100 735 590 12 35 35 235∼293

refining 100∼300 685 460 13 35 35 228∼269

35CrMnSi - thermal ≤100 785 640 12 35 31 241∼293

refining 100∼300 685 540 12 35 31 223∼269

12CrMoV - normalizing+ ≤100 470 245 22 48 39 143∼179

tempering 100∼300 430 215 20 40 39 123∼167

Table 4. Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 3/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m㎡) (N/m㎡) (%) of area (%) energy (J) Hardness

≥ ≥ ≥ ≥ ≥

≤100 440 245 19 50 39 123∼167

12Cr1MoV - normalizing+ 100∼300 430 215 19 48 39 123∼167

tempering 300∼500 430 215 18 40 35 123∼167

500∼800 430 215 16 35 31 123∼167

thermal 100∼300 735 590 16 - 47 -

24CrMoV -

refining 300∼500 685 540 16 - 47 -

thermal 100∼200 880 745 12 40 47 -

35CrMoV -

refining 200∼240 860 705 12 35 47 -

thermal ≤150 830 735 15 50 47 219∼277

30Cr2MoV - refining 150∼250 735 590 16 50 47 219∼277

250∼500 635 440 16 50 47 219∼277

thermal ≤100 835 735 15 50 47 269∼302

28Cr2Mo1V - refining 100∼300 735 635 15 40 47 269∼302

300∼500 685 565 14 35 47 269∼302

≤100 735 590 14 45 47 223∼277

40CrNi SNC236 thermal 100∼300 685 540 13 40 39 207∼262

refining 300∼500 635 440 13 35 39 197∼235

500∼800 615 395 11 30 31 187∼229

≤80 980 835 12 55 78 -

quenching+ 80∼100 980 835 11 50 74 -

40CrNiMo - tempering 100∼150 980 835 10 45 70 -

150∼250 980 835 9 40 66 -

thermal 100∼300 785 640 12 38 39 241∼293

refining 300∼500 685 540 12 33 35 207∼262

≤100 850 735 15 45 55 277∼321

34CrNi1Mo - thermal 100∼300 765 635 14 40 47 262∼311

refining 300∼500 685 540 14 35 39 235∼277

500∼800 635 490 14 32 31 212∼248

≤100 900 785 14 40 55 269∼341

34CrNi3Mo - thermal 100∼300 850 735 14 38 47 262∼321

refining 300∼500 805 685 13 35 39 241∼302

500∼800 755 590 12 32 32 241∼302

case hardening+ ≤30 880 640 9 40 - -

15Cr2Ni2 - quenching+

30∼63 780 540 10 40 - -

tempering

thermal

20Cr2Ni4 -

refining

φ15 1175 1080 10 45 62 -

case hardening+ ≤30 1080 790 8 35 - -

17Cr2Ni2Mo - quenching+

30∼63 980 690 8 35 - -

tempering

≤100 1100 900 10 45 - -

thermal 100∼160 1000 800 11 50 - -

30Cr2Ni2Mo - refining 160∼250 900 700 12 50 - -

250∼500 830 635 12 - - -

500∼1000 780 590 12 - - -

thermal ≤100 1000 800 11 50 - -

34Cr2Ni2Mo - refining 100∼160 900 700 12 55 - -

160∼250 800 600 13 55 - -

thermal 250∼500 740 540 14 - - -

34Cr2Ni2Mo -

refining 500∼1000 690 490 15 - - -

thermal 100∼300 685 585 15 60 110 190∼240

15CrNiMoV -

refining 300∼500 635 535 14 55 100 190∼240

≤100 900 785 14 40 47 269∼321

34CrNi3MoV - thermal 100∼300 855 735 14 38 39 248∼311

refining 300∼500 805 685 13 33 31 235∼293

500∼800 735 590 12 30 31 212∼262

≤100 900 785 13 40 47 269∼321

37CrNi3MoV - thermal 100∼300 855 735 12 38 39 248∼311

refining 300∼500 805 685 11 33 31 235∼293

500∼800 735 590 10 30 31 212∼262

Table 4. Mechanical properties of alloy steel (Chinese standard: GB/T 17107-1997) 4/4

Mechanical properties

Heat Dimension Tensile strength Yield point Elongation Reduction Absorption Brinell

Chinese symbol (ISO)

treatment (e.g.length) (N/m㎡) (N/m㎡) (%) of area (%) energy (J) Hardness

≥ ≥ ≥ ≥ ≥

100∼300 1000 870 12 45 70 -

24Cr2Ni4MoV - thermal 300∼500 950 850 13 50 70 -

refining 500∼750 900 800 15 50 65 -

750∼1000 850 750 15 50 65 -

≤80 1180 835 10 45 78 -

18Cr2Ni4W - quenching+ 80∼100 1180 835 9 40 74 -

tempering 100∼150 1180 835 8 35 70 -

150∼250 1180 835 7 30 66 -

You might also like

- Steel grade 12Х1МФDocument6 pagesSteel grade 12Х1МФHussien AlsadyNo ratings yet

- Von MisesDocument4 pagesVon Misesmohanad tariqNo ratings yet

- Resistance To Pitting and Crevice CorrosionDocument6 pagesResistance To Pitting and Crevice CorrosionsuiafwgehjdfNo ratings yet

- DIWA 373: Weldable Fine Grained Steel For Higher Temperature ServiceDocument4 pagesDIWA 373: Weldable Fine Grained Steel For Higher Temperature ServiceRam KadamNo ratings yet

- Consteel Catalogue PLATES ChequeredPlatesDocument3 pagesConsteel Catalogue PLATES ChequeredPlatesrichard richNo ratings yet

- Tugas Uji Tarik FixDocument15 pagesTugas Uji Tarik FixANDINTA MUDA YUSUFNo ratings yet

- Sa283c Stress-Strain CurveDocument7 pagesSa283c Stress-Strain CurveAnonymous AtAGVssJNo ratings yet

- Bus Bar Selection Chart AluminiumDocument1 pageBus Bar Selection Chart AluminiumJit0% (1)

- P355GH boiler plate steel specsDocument1 pageP355GH boiler plate steel specsCommercial MarocNo ratings yet

- Boiling PointDocument3 pagesBoiling PointrusyadNo ratings yet

- Alloy Machining: NickelDocument2 pagesAlloy Machining: Nickeljoko setiawanNo ratings yet

- Tgsno2 Geofisikainversi FatimahNurkhalifahDocument2 pagesTgsno2 Geofisikainversi FatimahNurkhalifahSisilia ElisNo ratings yet

- Radiation ValuesDocument12 pagesRadiation ValuesSameer AmjadNo ratings yet

- Tabela API 6ADocument2 pagesTabela API 6AFeromont KvalitetNo ratings yet

- Quality 39nicrmo3: Lucefin GroupDocument2 pagesQuality 39nicrmo3: Lucefin Groupmarko9292No ratings yet

- Force Deformation and Diameter Testing of Steel RodsDocument18 pagesForce Deformation and Diameter Testing of Steel RodsANDINTA MUDA YUSUFNo ratings yet

- Temp Diff EUDocument3 pagesTemp Diff EUSreeraja SreevilasanNo ratings yet

- Hardy Cross Method Solved ExampleDocument4 pagesHardy Cross Method Solved ExamplejajajajNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Busbar Selection ChartDocument4 pagesBusbar Selection ChartArvind KumawatNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- Alla France ASTM ThermometerDocument3 pagesAlla France ASTM ThermometerPutut WindujatiNo ratings yet

- Brightbar Sae1018 2021Document2 pagesBrightbar Sae1018 2021Mike HeisenbergNo ratings yet

- Rumus CCI 4737Document5 pagesRumus CCI 4737Eko NbsNo ratings yet

- − sin θ − cos θ + sinθ + cosθ = ¨ cos θ − sin θ − cosθ + sinθ = 0Document1 page− sin θ − cos θ + sinθ + cosθ = ¨ cos θ − sin θ − cosθ + sinθ = 0Muhammad FauziNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- Calibration of Thermocouple and RTD: For Platinum: Alpha 0.00385. Reference Temperature 100 CentigradeDocument3 pagesCalibration of Thermocouple and RTD: For Platinum: Alpha 0.00385. Reference Temperature 100 CentigradeBharath kumarNo ratings yet

- Pavsp: 200 F (X) - 0.359129697x 2 + 37.2815284848x - 810.0475454545Document6 pagesPavsp: 200 F (X) - 0.359129697x 2 + 37.2815284848x - 810.0475454545Oscar FernandoNo ratings yet

- GB 5310 Seamless Boiler Pipe SpecificationDocument1 pageGB 5310 Seamless Boiler Pipe SpecificationMujib DerusNo ratings yet

- Chapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopDocument8 pagesChapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopRedzaNo ratings yet

- Horizontal Curve Excel SheetDocument9 pagesHorizontal Curve Excel SheetTarunNo ratings yet

- Calculate Curve Lengths and Superelevation RatesDocument9 pagesCalculate Curve Lengths and Superelevation Ratesrjg_vijayNo ratings yet

- Bakir BaralarDocument1 pageBakir BaralarFurkan TopcuNo ratings yet

- Okada Top SeriesDocument2 pagesOkada Top SeriessinanNo ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Normal Distribution Excel ExampleDocument16 pagesNormal Distribution Excel ExamplehaffaNo ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

- Δ X Δ Y Δ X Δ Y: Calculation Of Closed Traverse (Bowditch Method)Document8 pagesΔ X Δ Y Δ X Δ Y: Calculation Of Closed Traverse (Bowditch Method)Erlita KusumasariNo ratings yet

- Steel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Document1 pageSteel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Kuya Fabio VidalNo ratings yet

- Hoek-Brown rock mass classification parametersDocument8 pagesHoek-Brown rock mass classification parametersCristobal De La GuardaNo ratings yet

- UntitledDocument11 pagesUntitledksarawanNo ratings yet

- 46S20PB - 46SPb20-Nr 1 0757-ENGDocument1 page46S20PB - 46SPb20-Nr 1 0757-ENGVipul SharmaNo ratings yet

- !en 10025Document1 page!en 10025Nguyen Quy DuongNo ratings yet

- CR XP Hit Dice Hit Points XP Armor Class XP Attack Bonus XP Avg Damage XP Level Max XPDocument1 pageCR XP Hit Dice Hit Points XP Armor Class XP Attack Bonus XP Avg Damage XP Level Max XPMike DonovanNo ratings yet

- Singly Reinforced Concrete Beam CapacityDocument16 pagesSingly Reinforced Concrete Beam CapacityWilfredoEnghoyNo ratings yet

- Efficiency vs Temperature Chart for Perovskite Solar Cell with Varying LayersDocument2 pagesEfficiency vs Temperature Chart for Perovskite Solar Cell with Varying Layersramy thaerNo ratings yet

- Toque WrenchDocument7 pagesToque WrenchMohammed SibghatullaNo ratings yet

- Hedonic 1Document262 pagesHedonic 1KaiWenNgNo ratings yet

- Thalachrome Se 500: High Corrosion ResistanceDocument1 pageThalachrome Se 500: High Corrosion ResistancethyskieNo ratings yet

- Table Busbar ArusDocument2 pagesTable Busbar ArusFreddy Suhartono100% (2)

- 070m20 En3a BlackDocument3 pages070m20 En3a BlackmitternpdNo ratings yet

- Volume Per KM S1-4Document15 pagesVolume Per KM S1-4dinal031No ratings yet

- TENDON-PROFILE_BAYUG-BRIDGE-ZMS_TYPE-IV__Span-21Document1 pageTENDON-PROFILE_BAYUG-BRIDGE-ZMS_TYPE-IV__Span-21vfmagallanesNo ratings yet

- Excel de InterracionesDocument3 pagesExcel de InterracionesrudyNo ratings yet

- ACERO DE REFUERZO DIAGRAMASDocument11 pagesACERO DE REFUERZO DIAGRAMASJhon MagañoNo ratings yet

- Tugas Uji Tarik FixDocument255 pagesTugas Uji Tarik FixANDINTA MUDA YUSUFNo ratings yet

- Tugas Plot (Large Deflection)Document3 pagesTugas Plot (Large Deflection)dhiafahheraNo ratings yet

- Welding CablesDocument1 pageWelding CablesanuradhaNo ratings yet

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 pageDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoNo ratings yet

- Intake Sheet SampleDocument1 pageIntake Sheet SampleRochelleNo ratings yet

- Ignition System Spark Test DiagnosisDocument24 pagesIgnition System Spark Test DiagnosisMohamed l'Amine75% (4)

- Cipac MT 185Document2 pagesCipac MT 185Chemist İnançNo ratings yet

- Annex 8 Qualification of BalancesDocument11 pagesAnnex 8 Qualification of BalancesMassimiliano PorcelliNo ratings yet

- Cap 716 PDFDocument150 pagesCap 716 PDFjanhaviNo ratings yet

- Magnetic FieldDocument19 pagesMagnetic FieldNitinSrivastava100% (2)

- Arp0108 2018Document75 pagesArp0108 2018justin.kochNo ratings yet

- Lesson 1 CA 3Document13 pagesLesson 1 CA 3myndleNo ratings yet

- Jairo Garzon 1016001932 G900003 1580 Task4Document12 pagesJairo Garzon 1016001932 G900003 1580 Task4Jairo Garzon santanaNo ratings yet

- EO On Ban of Fireworks (Integrated)Document2 pagesEO On Ban of Fireworks (Integrated)Mario Roldan Jr.No ratings yet

- English III Module 2 Simple Present Job and Job VerbsDocument4 pagesEnglish III Module 2 Simple Present Job and Job VerbsAdrian CortesNo ratings yet

- History of The Stethoscope PDFDocument10 pagesHistory of The Stethoscope PDFjmad2427No ratings yet

- Lease Practice QuestionsDocument4 pagesLease Practice QuestionsAbdul SamiNo ratings yet

- Completed Manuscript 1 5Document52 pagesCompleted Manuscript 1 5SAMANTHA LACABANo ratings yet

- Past The Shallows EssayDocument2 pagesPast The Shallows EssaycaitlinNo ratings yet

- The Impact of StressDocument3 pagesThe Impact of StressACabalIronedKryptonNo ratings yet

- Li Ching Wing V Xuan Yi Xiong (2004) 1 HKC 353Document11 pagesLi Ching Wing V Xuan Yi Xiong (2004) 1 HKC 353hNo ratings yet

- Nutrition During PregnancyDocument8 pagesNutrition During PregnancyHalliahNo ratings yet

- B.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSDocument31 pagesB.Sc. (AGRICULTURE) HORTICULTURE SYLLABUSgur jazzNo ratings yet

- Fuck Your LawnDocument86 pagesFuck Your Lawnhuneebee100% (1)

- Insurance Principles, Types and Industry in IndiaDocument10 pagesInsurance Principles, Types and Industry in IndiaAroop PalNo ratings yet

- Fitness WalkingDocument192 pagesFitness Walkingjha.sofcon5941100% (1)

- SPA For Banks From Unit OwnersDocument1 pageSPA For Banks From Unit OwnersAda DiansuyNo ratings yet

- DR - Hawary Revision TableDocument3 pagesDR - Hawary Revision TableAseel ALshareefNo ratings yet

- Rudraksha - Scientific FactsDocument20 pagesRudraksha - Scientific FactsAkash Agarwal100% (3)

- Iso 28000Document11 pagesIso 28000Aida FatmawatiNo ratings yet

- Material Handling EquipmentsDocument12 pagesMaterial Handling EquipmentsRahul SheelavantarNo ratings yet

- Carpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesDocument105 pagesCarpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesVinod KumarNo ratings yet

- Steam System Design RequirementsDocument29 pagesSteam System Design RequirementsAthirahNo ratings yet