Professional Documents

Culture Documents

Lifting Lug Calculations

Uploaded by

shazanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Lug Calculations

Uploaded by

shazanCopyright:

Available Formats

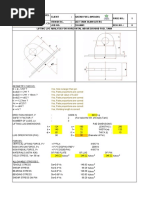

Lifting Lug Calculations

As per Pressure Vessel Design Manual by Deniss Moss

ErectionWeightoftheequipment We = 497.3 kgs

= 4878.51 N

Angleoflift = 45 degree

Nooflugs n = 2

Impactfactor I.F. = 2

Loadperlug P = We*I.F./n*sin()

= 6899.26 N

Materialoflug = SA516Gr.485(70)

YieldStress Sy = 260 N/mm2

Allowabletensilestress(Sect.IIPartD) Sta = 138 N/mm3

Allowableshearstress(0.4Sy) Ssa = 104 N/mm4

Allowablebendingstress(0.67Sy) Sba = 174.2 N/mm5

Max.allowableHertzianstress(2*Sy) Sha = 520 N/mm2

Lugthickness t = 10 mm

Widthofthelug A = 80 mm

Distanceofholefromlug B = 60 mm

Weldsize w1 = 8 mm

ModulusofElasticityofmaterial E = 210000 N/mm2

Diameterofholeforpin d = 30 mm

Diameterofpin R2 = 25 mm

Actualbendingstress Sb = 6*P*B/A^2*t

= 38.81 N/mm2

Actualshearstress Ss = P/(AD)*t

= 13.8 N/mm2

Actualtensilestress St = P/(Ad)*t

= 13.8 N/mm2

Hertzianstressduetobearing Sh = 0.418*(E*P/t*(dR2))/d*R2)^0.5

= 410.81 N/mm2

Actualshearstressinweld Sww = 6*P*B/A^2*tw*0.707

= 68.61 N/mm2

Sincetheactualstressesarelessthantheallowablestressesthedesignissafe.

You might also like

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Calc. Fillet Weld Transverse Load-Jacket ClosureDocument6 pagesCalc. Fillet Weld Transverse Load-Jacket ClosureAsep MulyadiNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- SA 516 Gr. 70 Lifting Lug Material Stress AnalysisDocument2 pagesSA 516 Gr. 70 Lifting Lug Material Stress Analysismiteshpatel191100% (2)

- Tailing LugDocument12 pagesTailing LuguvarajmecheriNo ratings yet

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- Davit Design Calculation: L 1 D V H V H V DDocument2 pagesDavit Design Calculation: L 1 D V H V H V DSiva baalanNo ratings yet

- Saddle Road Transportation Analysis 1Document2 pagesSaddle Road Transportation Analysis 1vpjagannaathNo ratings yet

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDocument4 pagesLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Calculation For Quick Opening Closure: Design ConditionDocument5 pagesCalculation For Quick Opening Closure: Design ConditionA.K.100% (3)

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghNo ratings yet

- Cover Plate CalculationDocument1 pageCover Plate CalculationSachin5586No ratings yet

- Saddle CalculationDocument10 pagesSaddle Calculationpharis_chrisNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisAntonio Perez ZornozaNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocument10 pagesFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNo ratings yet

- WRC-107 Lifting Lugs - Vert. Vessel Vertical LiftDocument5 pagesWRC-107 Lifting Lugs - Vert. Vessel Vertical LiftManoj MulikNo ratings yet

- Vessel Allowable LoadingsDocument50 pagesVessel Allowable LoadingsfahadfiazNo ratings yet

- Calculation of left and right saddle supports for offshore tankerDocument12 pagesCalculation of left and right saddle supports for offshore tankerrustamriyadiNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program Descriptionnamasral100% (3)

- Lug - On - FlangeDocument17 pagesLug - On - Flangeshaishav100% (1)

- Curb AngleDocument1 pageCurb Angle940623015859No ratings yet

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm Calculationnitin400No ratings yet

- Design of Saddle Supported VesselsDocument10 pagesDesign of Saddle Supported Vesselsvikas100% (1)

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Lifting Lug Design CalculationsDocument17 pagesLifting Lug Design CalculationsSiva baalan100% (1)

- Tema ChecklistDocument2 pagesTema ChecklistAdrian Stoicescu100% (1)

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 pagesPipe Cap Thickness Calculation for ASME Section VIIILcm TnlNo ratings yet

- Design of base plate for columnDocument6 pagesDesign of base plate for columnsoumyaNo ratings yet

- Saddle Stresses On Shell During Transportation: Equipment NoDocument5 pagesSaddle Stresses On Shell During Transportation: Equipment NoshazanNo ratings yet

- Studding Flange Calculations Gasket SelectionDocument6 pagesStudding Flange Calculations Gasket SelectionDarshan PanchalNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Rectangular Tank CalculationDocument28 pagesRectangular Tank CalculationMohammed EljammalNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- TubesheetDocument8 pagesTubesheetVaibhavNo ratings yet

- Saddle-Design-Operating - FinalDocument17 pagesSaddle-Design-Operating - FinalSiva baalan75% (4)

- Davit Arm CalculationDocument4 pagesDavit Arm Calculationjoeriji0% (1)

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Eccentric and Moment Connections (Fillet Weld) : DATE: 24-SEP-2020 Gurram Vinay (L&T Wet Ic (CMPC)Document6 pagesEccentric and Moment Connections (Fillet Weld) : DATE: 24-SEP-2020 Gurram Vinay (L&T Wet Ic (CMPC)vinayNo ratings yet

- SPLICEDocument11 pagesSPLICEAgus SholehudinNo ratings yet

- General Data: Bending StessesDocument8 pagesGeneral Data: Bending Stessesprajakt_pieNo ratings yet

- Bolt torque calculation for sealing flangesDocument6 pagesBolt torque calculation for sealing flangessouren1975No ratings yet

- Pin StressesDocument5 pagesPin Stressesprajakt_pieNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- Design Calculation For Bolted Splice For NPB SectionsDocument9 pagesDesign Calculation For Bolted Splice For NPB SectionsAtul WanodeNo ratings yet

- Lifting Lug Excel SheetDocument8 pagesLifting Lug Excel Sheetshazan67% (3)

- Rotor Clip - Wave Spring FormulasDocument1 pageRotor Clip - Wave Spring Formulasهندسة الإنتاج والتصميم الميكانيكيNo ratings yet

- Cleat Summary Excel SheetDocument4 pagesCleat Summary Excel SheetshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Flange Details & DrawingsDocument338 pagesFlange Details & DrawingsshazanNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Weld CalculationsDocument12 pagesWeld Calculationshakr5100% (1)

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Manhole MH PDFDocument1 pageManhole MH PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Clearance Calculation For Skirt OpeningDocument3 pagesClearance Calculation For Skirt OpeningshazanNo ratings yet

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Gasket Selection GuideDocument6 pagesGasket Selection GuiderezaNo ratings yet

- Welding EngineeringDocument1 pageWelding EngineeringshazanNo ratings yet

- Static Equipment A Look Inside The How and Why of SpecificationDocument19 pagesStatic Equipment A Look Inside The How and Why of SpecificationshazanNo ratings yet

- Seismic Calculation IS 1893 - RSMDocument3 pagesSeismic Calculation IS 1893 - RSMshazanNo ratings yet

- Test Flange TypeDocument1 pageTest Flange TypeshazanNo ratings yet

- MN-V-02 Sump - NozDocument1 pageMN-V-02 Sump - NozshazanNo ratings yet

- Midrex Case StudyDocument1 pageMidrex Case StudyshazanNo ratings yet

- Flange GeometryDocument1 pageFlange GeometryshazanNo ratings yet

- MN-V-02 M-01 - NozDocument1 pageMN-V-02 M-01 - NozshazanNo ratings yet

- Test Ring1 ModelDocument1 pageTest Ring1 ModelshazanNo ratings yet

- Lecture2 (Petrochemical)Document12 pagesLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- Saddle DrawingDocument1 pageSaddle DrawingshazanNo ratings yet

- ASME BPVC Latest Edition Design and FabricationDocument2 pagesASME BPVC Latest Edition Design and Fabricationshazan100% (1)

- Andritz Salem HaplDocument2 pagesAndritz Salem HaplRajkumar ASNo ratings yet

- Introduction To Well TestingDocument39 pagesIntroduction To Well TestingzazoNo ratings yet

- Best of Class Noti Log For SionsDocument16 pagesBest of Class Noti Log For SionsDolly GuptaNo ratings yet

- Myoglobin & Hemoglobin: Essential Oxygen Transport ProteinsDocument53 pagesMyoglobin & Hemoglobin: Essential Oxygen Transport ProteinsAgnetasia PriscilliaNo ratings yet

- Advanced Steam System Optimization Program PDFDocument5 pagesAdvanced Steam System Optimization Program PDFRobert MontoyaNo ratings yet

- Beer-Lambert Law Explains Light AbsorptionDocument11 pagesBeer-Lambert Law Explains Light AbsorptionJonathan CookNo ratings yet

- Cutting FluidsDocument4 pagesCutting FluidsChandaKundaNo ratings yet

- Nicofer Alloy625 PDFDocument13 pagesNicofer Alloy625 PDFbigsteve9088No ratings yet

- Quick Guide to Operating TA Instruments Discovery DSC 250Document9 pagesQuick Guide to Operating TA Instruments Discovery DSC 250Nguyễn Phương ThoaNo ratings yet

- Design For Reliability and Quality: IIT, BombayDocument12 pagesDesign For Reliability and Quality: IIT, Bombaytejap314No ratings yet

- Y7 Particle Models and Physical PropertiesDocument29 pagesY7 Particle Models and Physical Propertiesjamie_venning_1No ratings yet

- Using Jmol To Help Students Better Understand Fluxional ProcessesDocument1 pageUsing Jmol To Help Students Better Understand Fluxional Processesdevy ridaNo ratings yet

- 2012 f5 Identifying VariablesDocument8 pages2012 f5 Identifying Variableszalifah74No ratings yet

- BCS theory explains superconductivityDocument3 pagesBCS theory explains superconductivitySobuj RajNo ratings yet

- Wilson - PhysioEx Exercise 1 Activity 5Document3 pagesWilson - PhysioEx Exercise 1 Activity 5Hulwah ShalihahNo ratings yet

- VSU Lab Report on Alkyl Halide PreparationDocument5 pagesVSU Lab Report on Alkyl Halide PreparationShella Mare CanizaresNo ratings yet

- Automotive - Brochure - BluestarDocument20 pagesAutomotive - Brochure - BluestarAlexandreNo ratings yet

- Soil Electrical Conductivity - WebDocument9 pagesSoil Electrical Conductivity - WebDr. Ranjan BeraNo ratings yet

- Optimal AgricultureDocument9 pagesOptimal AgriculturesamNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument11 pagesSafety Data Sheet: 1. Product and Company IdentificationAdelaida CruzNo ratings yet

- CB - n990 Epdm ProfilesDocument3 pagesCB - n990 Epdm ProfilesMartha GuzmanNo ratings yet

- SBI4U0 Exam Review GuideDocument6 pagesSBI4U0 Exam Review GuideSukhvir AujlaNo ratings yet

- AIS - Plasmair C2010 Brochure - Ed01 - EN - Oc10Document4 pagesAIS - Plasmair C2010 Brochure - Ed01 - EN - Oc10Valentin MalihinNo ratings yet

- Human Skin Temperature CalculationDocument14 pagesHuman Skin Temperature CalculationRaymond FuentesNo ratings yet

- ES HS QTSteamMaxDocument4 pagesES HS QTSteamMaxWattsNo ratings yet

- Cover EssayDocument23 pagesCover EssayAstha MishraNo ratings yet

- Starch Gel Electrophoresis of Conifer Seeds: A Laboratory ManualDocument23 pagesStarch Gel Electrophoresis of Conifer Seeds: A Laboratory ManualPACIFIC SOUTHWEST RESEARCH STATION REPORTNo ratings yet

- DiscussionDocument2 pagesDiscussionKelvin liew100% (1)

- Project Report On Phthalic AnhydrideDocument8 pagesProject Report On Phthalic AnhydrideEIRI Board of Consultants and PublishersNo ratings yet

- 2017 - Water Sampling Protocols and HandlingDocument61 pages2017 - Water Sampling Protocols and HandlingaseascanNo ratings yet