Professional Documents

Culture Documents

pr1169 1170 PDF

Uploaded by

rahulmuleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pr1169 1170 PDF

Uploaded by

rahulmuleCopyright:

Available Formats

PD-5 2nd

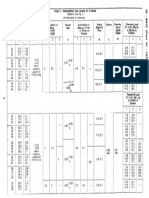

TECHNICAL DATA TECHNICAL DATA

SURFACE ROUGHNESS BY DIFFERENT PROCESSING METHODS INDICATIONS OF GEOMETRICAL TOLERANCE ON DRAWINGS Excerpt from

JIS B 0021(1984)

Arithmetical mean roughness IKinds and symbols of geometrical tolerances

0.025 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100

Ra Kind of tolerance Symbol Definition of tolerance zone Examples of diagrammatical indication and its interpretation

0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100 200 400 Where symbol F is attached before the Where a tolerance frame is

Max. height F0.08

of surface roughness

Former designations

numerical value indicating a tolerance connected to the dimension showing

Rmax. -S -S -S -S -S -S -S -S -S -S -S -S -S Straightness zone, this tolerance zone is a zone in a the diameter of a cylinder, the axis of

tolerance

F

cylinder of diameter t. the cylinder shall be contained a

Ft

Standard values of cylinder of 0.08mm diameter.

0.25 0.8 2.5 8 25

standard length(mm) The tolerance zone is a zone held This surface shall be contained between

between two parallel planes a distance t two parallel planes 0.08mm apart.

Flatness

llll lll ll l

Triangular indication - apart.

0.08

tolerance

Forging Precision

t

Casting Precision t The tolerance zone in the considered 0.1 The circumference in any section normal

plane is a zone between two concentric to the axis shall be contained between

Circularity

Die casting circles a distance t apart. two concentric circles 0.1mm apart on

Form tolerance

tolerance the same plane.

Hot rolling

The tolerance zone is a zone contained The considered surface shall be

t

Cold rolling between two coaxial cylinder surfaces a 0.1 contained between two coaxial cylinder

Cylindricity

distance t apart. surfaces 0.1mm apart.

Drawing tolerance

Extruding

The tolerance zone is a zone held In any cross-section parallel to the

0.04 projection plane the considered profile

Tumbling Profile tolerance between two lines enveloping circles of shall be contained between two lines

t

F

diameter t, the centers of which are enveloping circles of 0.04mm in

Sandblasting of line situated on a theoretically exact profile diameter, the centers of which are

situated on a surface having the

line. theoretically exact profile.

Rolling

The tolerance zone is a zone held The considered surface shall be contained

between the two surfaces enveloping the 0.02 between two surfaces enveloping the

Face cutter grinding Precision Profile tolerance

spheres of diameter t, the centers of spheres of diameter 0.02mm, the centers

of surface which are situated on a theoretically of which are situated on a surface having

Planing SFt

exact profile surface. the theoretically exact profile.

Carving( Slotting) The tolerance zone is a zone held 0.01 A The surface shown by the arrow of the

between two parallel planes parallel to leader line shall be contained between

Precision Parallelism

t

Cutter grinding the datum plane and a distance t apart two planes parallel to the datum plane A

tolerance from each other. and 0.01mm apart from each other in the

Orientation tolerance

Precision boring A direction of the arrow of the leader line.

Filing Precision Ft Where symbol F is attached before the F The axis of the cylinder shown by the

Working method

F0.01 A

numerical value indicating the tolerance, arrow of the leader line shall be

Perpendicularity

Round grinding Precision Fine Medium Rough the tolerance zone is a zone within a contained within a cylinder of

tolerance cylinder of diameter t perpendicular to diameter 0.01mm perpendicular to

Boring Precision the datum plane. A the datum plane A.

t The tolerance zone is a zone held 0.08 A The surface shown by the arrow of the

Drilling between two parallel planes inclined at

leader line shall be contained between two

Angularity parallel planes which are inclined at 40B

the specified angle to the datum plane 40B with theoretical exactness to the datum

Reaming Precision tolerance and a distance t apart from each other. plane A and which are 0.08mm apart from

each other in the direction of the arrow of

Broach grinding Precision A the leader line.

The tolerance zone is a zone within a B F0.03 AB The point shown by the arrow of the

leader line shall be contained within a

Shaving circle or sphere of diameter t having its

t

circle of 0.03mm diameter having its

Positional center at the true location 60mm and

center at the theoretically exact location,

60

100mm apart, respectively, from the

Grinding Precision Fine Medium Rough tolerance True hereinafter referred to as the ""true datum straight line A and from the

location 100 datum straight line B.

A

Location tolerance

location"".

Hone finishing Precision Where symbol F is attached before the

A F0.01 A The axis shown by the arrow of the

Coaxiality tolerance numerical value indicating the tolerance, leader line shall be contained

Ft

Super finishing Precision

or the tolerance zone is a zone within a within a cylinder of 0.01mm

Precision concentricity tolerance cylinder of diameter t whose axis agrees diameter whose axis agrees with

Buffing

with the datum axial straight line. the datum axial straight line A.

Paper finishing Precision The tolerance zone is a zone held The median surface shown by the arrow of

A 0.08 A

between two parallel planes a distance t the leader line shall be contained between

Symmetry

t

Lapping Precision apart from each other and arranged two parallel planes 0.08mm apart form

tolerance symmetrically about the datum median each other and arranged symmetrically

Liquid honing Precision plane. about the datum median plane A.

The tolerance is a zone between two The run-out in the radial direction of the

Burnishing Measuring plane concentric circles whose centers agree 0.1 A-B

Circular with the datum axial straight line on any

cylinder surface shown by the arrow of the

leader line shall not exceed 0.1mm on any

Run-out tolerance

t

measuring plane normal to the datum

F

run-out

F

measuring plane normal to the datum axial

Surface rolling axial straight line and

which are a distance t apart straight line when the cylinder is rotated by

tolerance Tolerance surface from each other in the radial one rotation about the datum axial straight

Electric discharge carving direction. A B line A-B.

The tolerance zone is a zone between The total radial run-out of the cylinder

0.1 A-B surface shown by the arrow of the leader line

Wire cut electric spark two coaxial cylinders having axes

Total run-out shall not exceed 0.1mm at any point on the

F

agreeing with the datum axial straight cylinder surface when the cylinder part is

Chemical polishing Precision tolerance line and a distance t apart from each rotated about the datum axial straight line

A-B with a relative movement in the axial

other in the radial direction. A B direction.

Electrolytic abrasion Precision

Lines used in the drawings in the column of ""definition of tolerance zone"" indicate the following meanings:

Thick solid line or broken line:Feature Thin alternate long and short dash line:Center line

Thick alternate long and short dash line:Datum Thin alternate long and two short dashes line:Supplementary projection plane or sectional plane.

Thin solid line or broken line:Tolerance zone Thick alternate long and two short dashes line:Projection of a feature to supplementary

Projection plane or sectional plane

1169 1170

You might also like

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Surface Roughness ChartDocument1 pageSurface Roughness ChartdmayhillNo ratings yet

- Surface Texture SymbolDocument1 pageSurface Texture SymbolSrinivas RaoNo ratings yet

- Surface Roughness Drawing Indications of Surface TextureDocument1 pageSurface Roughness Drawing Indications of Surface TextureSIVA 1010No ratings yet

- Regular Machining Dimension ToleranceDocument1 pageRegular Machining Dimension ToleranceSIVA 1010No ratings yet

- FTD00325 - EN - Standardized Representation For Technical DrawingDocument2 pagesFTD00325 - EN - Standardized Representation For Technical DrawingMai TuanNo ratings yet

- Surface RoughnessDocument1 pageSurface RoughnesswholenumberNo ratings yet

- Iso 1101 - 15-12-04Document63 pagesIso 1101 - 15-12-04gkhn100% (1)

- Scutarus Schiavo M. - 06 APR 2023 IssuedDocument1 pageScutarus Schiavo M. - 06 APR 2023 Issuedrajitkumar.3005No ratings yet

- Is 8422-5 - 1977 - 2Document1 pageIs 8422-5 - 1977 - 2Svapnesh ParikhNo ratings yet

- Surface Roughness JIS B 0601 (1994)Document1 pageSurface Roughness JIS B 0601 (1994)Tú Nguyễn MinhNo ratings yet

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- ERA Series Thin-Film Chip Resistors: Line ExtensionDocument1 pageERA Series Thin-Film Chip Resistors: Line ExtensionlalithkumartNo ratings yet

- SOLIDWORKS Educational Product. For Instructional Use Only.: .XX .02 .XXX .005 Angles 1Document1 pageSOLIDWORKS Educational Product. For Instructional Use Only.: .XX .02 .XXX .005 Angles 1DavidNo ratings yet

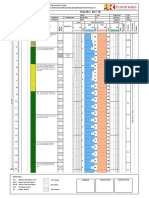

- Hole No.: Borehole Log BDRS.1: Secondary Canals and Drains Rentang Irrigation Modernization Project Icb Package Lss-08Document2 pagesHole No.: Borehole Log BDRS.1: Secondary Canals and Drains Rentang Irrigation Modernization Project Icb Package Lss-08radixkusumaNo ratings yet

- Me 359 HW 03 P 10 DRW 2Document2 pagesMe 359 HW 03 P 10 DRW 2api-576392651No ratings yet

- Backgro Und PressureDocument2 pagesBackgro Und PressureNader HemayaNo ratings yet

- QuickGuide Roundtest PDFDocument2 pagesQuickGuide Roundtest PDFArvin BabuNo ratings yet

- 300x200x8.0 RHSDocument1 page300x200x8.0 RHSwaynectwNo ratings yet

- SiC Activities 2022 - v8MADocument1 pageSiC Activities 2022 - v8MAKonstantinos ZekentesNo ratings yet

- Bourns 3224Document2 pagesBourns 3224didier.cauvetNo ratings yet

- Framing Channels - Heavy Duty Framing System: Halfen Industrial TechnologyDocument2 pagesFraming Channels - Heavy Duty Framing System: Halfen Industrial TechnologyJake GoodmanNo ratings yet

- TCJ Series: TCJ Series - Standard and Low Profile - J-LeadDocument14 pagesTCJ Series: TCJ Series - Standard and Low Profile - J-LeadgpremkiranNo ratings yet

- Catalog Sistem Parcare Klaus g82Document5 pagesCatalog Sistem Parcare Klaus g82Mihai Ștefan100% (1)

- GD&T Basics Wall ChartDocument1 pageGD&T Basics Wall ChartShahzad KhanNo ratings yet

- Hole No.: Borehole Log BDWS.1: Secondary Canals and Drains Rentang Irrigation Modernization Project Icb Package Lss-08Document2 pagesHole No.: Borehole Log BDWS.1: Secondary Canals and Drains Rentang Irrigation Modernization Project Icb Package Lss-08radixkusumaNo ratings yet

- Rheology Applications Note: Automatic Gap ClosureDocument3 pagesRheology Applications Note: Automatic Gap ClosuretadirambabuNo ratings yet

- Iso 3601-1-2002Document12 pagesIso 3601-1-2002TK DanielNo ratings yet

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDocument1 pageSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiNo ratings yet

- Cet - Section Properties of Plate GirderDocument6 pagesCet - Section Properties of Plate GirderEngDbtNo ratings yet

- T BEAM Rectangular Beam 3sections FinalDocument24 pagesT BEAM Rectangular Beam 3sections FinalDipanjan MitraNo ratings yet

- Week 7 Geometric Dimenisoning and Tolerancing by Olaf Pippel of HYDACDocument40 pagesWeek 7 Geometric Dimenisoning and Tolerancing by Olaf Pippel of HYDACZubairAhmedNo ratings yet

- Plano Eléctrico - TRACTOR D10T PDFDocument4 pagesPlano Eléctrico - TRACTOR D10T PDFHéctorReyesPinedaNo ratings yet

- Geometric Dimensioning and Tolerancing - WikipediaDocument4 pagesGeometric Dimensioning and Tolerancing - WikipediaEdryle AtanacioNo ratings yet

- Prediction of Stiffness and Damping of Gas Foil Journal Bearing For High-Speed RotorDocument11 pagesPrediction of Stiffness and Damping of Gas Foil Journal Bearing For High-Speed RotorBiren Kumar PradhanNo ratings yet

- Datasheet PDFDocument10 pagesDatasheet PDFHank SvensonNo ratings yet

- RME Data Sheet - RUSSELL Mill Relining MachineDocument1 pageRME Data Sheet - RUSSELL Mill Relining MachineСергейNo ratings yet

- Monorail Beam Additional Check - HB1Document7 pagesMonorail Beam Additional Check - HB1AmolTarallkarNo ratings yet

- Fund 944 Answer Guide 2nd-Ed-9th-PrintDocument21 pagesFund 944 Answer Guide 2nd-Ed-9th-PrintAckshayaNo ratings yet

- Hole No.: Borehole Log BLT 1A: Secondary Canals and Drains Rentang Irrigation Modernization Project Icb Package Lss-08Document2 pagesHole No.: Borehole Log BLT 1A: Secondary Canals and Drains Rentang Irrigation Modernization Project Icb Package Lss-08radixkusumaNo ratings yet

- 735 Articulated Truck Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pages735 Articulated Truck Electrical System: Electrical Schematic Symbols and DefinitionsNorman CoetzeeNo ratings yet

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- Mechanical PropertiesDocument2 pagesMechanical Propertiesadarsh29adityaNo ratings yet

- 322C Excavator Electrical System: Area DDocument2 pages322C Excavator Electrical System: Area Dمهدي شقرونNo ratings yet

- Toggle SpringDocument1 pageToggle Springrohit negiNo ratings yet

- Opex and CapexDocument5 pagesOpex and CapexATM Shafiq Ul AlamNo ratings yet

- Lecture5 PDE 2016Document22 pagesLecture5 PDE 2016isele1977No ratings yet

- Arts6,4, Week2, Module 2V4Document24 pagesArts6,4, Week2, Module 2V4Loreen Pearl MarlaNo ratings yet

- Complete Processing Lines For Extruded Pet FoodDocument13 pagesComplete Processing Lines For Extruded Pet FoodденисNo ratings yet

- #Dr. Lora Ecg PDFDocument53 pages#Dr. Lora Ecg PDFمحمد زينNo ratings yet

- SP 73Document105 pagesSP 73Rodrigo Vilanova100% (3)

- Procter and Gamble-1Document5 pagesProcter and Gamble-1Abegiel MendozaNo ratings yet

- Rankine-Hugoniot Curve: CJ: Chapman JouguetDocument6 pagesRankine-Hugoniot Curve: CJ: Chapman Jouguetrattan5No ratings yet

- A Presentation On-: Dr. Nikhil Oza Intern BvdumcDocument43 pagesA Presentation On-: Dr. Nikhil Oza Intern BvdumcMaheboob GanjalNo ratings yet

- Igcse Revision BookDocument23 pagesIgcse Revision BookJo Patrick100% (2)

- Imbinari Teava Fibra de Sticla PDFDocument1 pageImbinari Teava Fibra de Sticla PDFplex015No ratings yet

- Mpfic54 PDFDocument201 pagesMpfic54 PDFAmy100% (1)

- Reactive Dyes For Digital Textile Printing InksDocument4 pagesReactive Dyes For Digital Textile Printing InksDHRUVNo ratings yet

- Contact Inform 2002 PDFDocument24 pagesContact Inform 2002 PDFFrank AlmeidaNo ratings yet

- Communication Guide: For Vita 62 Compliant VPX Power SuppliesDocument8 pagesCommunication Guide: For Vita 62 Compliant VPX Power Suppliesk.saikumarNo ratings yet

- BS746 2014Document22 pagesBS746 2014marco SimonelliNo ratings yet

- Factors Affecting Physical FitnessDocument7 pagesFactors Affecting Physical FitnessMary Joy Escanillas Gallardo100% (2)

- Inform LetterDocument2 pagesInform LetterMc Suan75% (4)

- Material Requirement Planning (MRP)Document55 pagesMaterial Requirement Planning (MRP)Lisa CarlsonNo ratings yet

- Report - IvatanDocument28 pagesReport - IvatanJohara Winel PerezNo ratings yet

- Antoine Constants PDFDocument3 pagesAntoine Constants PDFsofiaNo ratings yet

- Active Faults in MalaysiaDocument52 pagesActive Faults in MalaysiaHazim HaNo ratings yet

- Chapter 10 - The Mature ErythrocyteDocument55 pagesChapter 10 - The Mature ErythrocyteSultan AlexandruNo ratings yet

- Bio (RocessDocument14 pagesBio (RocessVijay SansanwalNo ratings yet

- 1ST SUMMATIVE TEST FOR G10finalDocument2 pages1ST SUMMATIVE TEST FOR G10finalcherish austriaNo ratings yet

- Sudip Praposal - 1Document20 pagesSudip Praposal - 1Usha BbattaNo ratings yet

- A Textual Introduction To Acarya Vasuvan PDFDocument3 pagesA Textual Introduction To Acarya Vasuvan PDFJim LeeNo ratings yet

- VTA28-G5: Fuel OptimizedDocument3 pagesVTA28-G5: Fuel OptimizedIslam HemdanNo ratings yet

- ChipmunkDocument19 pagesChipmunkema.nemec13No ratings yet