Professional Documents

Culture Documents

10 En-Gb PDF

Uploaded by

Pasa123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 En-Gb PDF

Uploaded by

Pasa123Copyright:

Available Formats

Horticultural Machinery

uality tha t's your

Q

pleasure!

Operating Instructions

for agria Power Hoe Type 6000

3308, 3307

&

Before commissioning the machine, read operating instructions

and observe warnings and safety instructions.

Operating Instructions No. 998 720 11.98

Symbols, Name Plate

Please complete: Symbols

Machine Type No.: .........................

ID/Machine No.: Warning Danger

......................................................

Engine Type: .................................. Important information

Engine No.: ....................................

Date of Purchase: .......................... Choke

For name plate, refer to p5/fig. B/26.

For engine type and number, refer to Fuel

p5/item no. 27.

Please state these data when ordering

spare parts to avoid wrong deliveries. Oil

Only use original agria spare parts!

Specifications, figures and dimensions Hoeing/tilling drive

stated in these instructions are not bind-

ing. No claims can be derived from them.

We reserve the right for improvements

without changing these instructions. Visual check

Open (unlocked)

This delivery comprises:

Closed (locked)

l Operating instructions

l Power hoe

basic machine

steering handle

l Tool kit

2 Power Hoe 6000 Edition 11.98

Designation of Parts

Figure A

Figure B

27

Edition 11.98 Power Hoe 6000 3

Designation of Parts

Figures A and B

1 Steering handle

2 Tensioning lever for steering handle side adjustment

3 Spark plug / spark plug connector

4 Exhaust

5 Fuel tank lid

6 Fuel tank

7 Oil immersed air filter

8 Manual gearbox oil filling control plug

9 Tubes for attachment of guards

10 Hoeing drive

11 Hoeing shaft

12 Hoeing drive lubricant control / filler plug

13 Steering handle height-adjustment hex head bolt

14 Starter handle

15 Carburetor

16 Cooling air-grille

17 Leg

18 Hitch

19 Hoeing leg

20 Hoeing share

21 Clutch / chain-drive housing cover

22 Cover attachment nut

23 Manual gearbox oil drain plug

24 Chain tensioning screw

25 Fuel tap

26 Name plate/I.D. no.

27 Engine type plate

4 Power Hoe 6000 Edition 11.98

Index

Amount of Delivery .......................... 3 4. Commissioning and Operation

Commissioning the Machine ............ 23

Recommendations Starting the Engine ........................... 24

Lubricants, Anti-Corrosive Agents ...... 4 Switching off the Engine ................... 25

Fuel .................................................... 4 Hoeing .............................................. 26

Maintenance and Repair ..................... 4

5. Maintenance

Designation of Parts .................. 5, 35 Engine .............................................. 27

Manual Gearbox ............................... 29

Assembly Instructions ..................... 7 Hoeing Drive .................................... 30

Adjustments on Hand Levers ........... 30

1. Safety Instructions ................. 812

Dead Stop ........................................ 31

General Maintenance ....................... 31

2. Specifications

Cleaning ........................................... 31

Dimensions ...................................... 13

Storage ............................................. 32

Power Hoe ........................................ 13

Noise Level ....................................... 13 Lubricants, Varnishes,

Engine .............................................. 14 Wear Parts ....................................... 33

Operation on Slopes ......................... 14

6. Troubleshooting .................... 3435

3. Devices and

Operating Elements 7. Inspection and

Engine .............................................. 15 Maintenance Chart ......................... 36

Dead Stop Lever ............................... 16

Clutch ............................................... 16 Electric Wiring Diagram ................. 37

Gearbox ........................................... 17

Hitch ................................................. 17 Conformity Declaration .................. 39

Steering Handle ................................ 18

Drive-Wheels .................................... 18

Wheel-Weights ................................. 19

Front support wheel .......................... 20

Hoeing Tools ..................................... 20

Note fold-out pages!

Hoeing Guards ................................. 22

Fig. A + B ........................................... 5

Fig. C ............................................... 38

Edition 11.98 Power Hoe 6000 5

Recommendations

Lubricants and If, for environmental reasons, you use

unleaded petrol, make sure the fuel is

Anti-Corrosive Agents: drained completely when shutting

Use the lubricants specified for engine down the engine for more than 30 days.

and gearbox (see Specifications). This is to prevent resin residue from

depositing in the caburetor, fuel filter,

We recommend using Bio-lubricating and tank. Or add a fuel stabilizing liquid

oil or Bio-lubricating grease for open to the fuel.

lubrication points or nipples (as specified

in the operating instructions). When storing the machine at the end

of the season, also drain leaded fuel

We recommend using Bio-slushing oil completely or add a fuel stabilizing liq-

to preserve machines and attachments uid.

(do not apply on painted covers). You can

brush or spray the oil. For further instructions see Engine

Preservation.

Anti-corrosive agents are environmen-

tally friendly and degrade fast.

Maintenance and

Using ecologically safe Bio-lubricants

and Bio-anti-corrosives, you contribute to Repair:

environmental protection and to the The trained mechanics of your agria

wellbeing of humans, animals and plants. workshop expertly carry out any main-

tenance and repair work.

Fuel You should only carry out major main-

The 2-stroke-engine runs on commer- tenance work and repairs on your own,

cial oil-petrol mixtures (for the specified if you have the proper tools and knowl-

stoichiometric ratio refer to Specifica- edge of machines and internal com-

tions). Unleaded regular and bustion engines.

supergrade petrol as well as leaded Do not hammer against the flywheel

supergrade petrol can be used for the with a hard object or metal tools as it

fuel mixture. However, only use self- might crack and shatter in operation,

mixing special 2-stroke-engine oil (refer causing injuries and damage. Only use

to Specifications, p15). suitable tools to pull off the flywheel.

6 Power Hoe 6000 Edition 11.98

Unpacking and Assembly

l Open the top of the cardboard box.

l Remove tommy nut (2). Take hex head

bolt (5).

l Place the steering handle (1) onto the

locking plate (4) and hold it in place.

Ensure no Bowden cables or electric

cables are twisted or squeezed as you

are doing this.

l Insert the hex head bolt (5) from the

bottom through the joint and the steering

handle.

l Attach the tommy nut (2).

l Move the steering handle until its teeth

engage with the locking plate teeth.

1 Steering handle

Tighten the tommy nut.

2 Tommy nut

l Attach the Bowden cables and elec- 3 Locking plate on steering handle

tric line to the handlebars using the clips. 4 Locking plate on joint

l Steering handle removal is in re- 5 Hex head bolt

verse order.

l To start up, carry out all steps de-

scribed on page 23.

Edition 11.98 Power Hoe 6000 7

1. Safety Instructions

Before starting the engine, read the op- General Instructions

erating instructions and note:

on Safety and

Accident Prevention

Warning Basic Rule:

The standard accident prevention regu-

This symbol marks all paragraphs affect- lations must be adhered to, as well as all

ing your safety. Pass all safety instruc- other generally accepted rules govern-

tions to other users and operators. ing operational safety, occupational

health and road traffic regulations.

Due Use For travelling on public roads, the current

The power hoe has exclusively been traffic code applies.

designed for all common applications and Check the power hoe for road and op-

tasks in agriculture, forestry, horticulture, erational safety each time you take up

grass and park maintenance (due use). operation.

Any other type of use is considered un- Only persons familiar with the power hoe

due. The manufacturer is not liable for any and instructed on the hazards of opera-

damages resulting from undue use, for tion are allowed to use, maintain and

which the risk lies with the user alone. repair the machine.

Due use includes compliance with manu- Teenagers of 16 years or younger may

facturers instructions on operation, main- not operate the power hoe!

tenance and repair. Only work in good light and visibility.

Any unauthorized changes to the power Operators clothes should fit tight. Avoid

hoe render manufacturer liability null and wearing loose fitting clothes. Wear solid

void. shoes.

Note the warning and instruction signs

on the power hoe for safe operation.

Compliance is for your own safety.

When transporting the power hoe on

vehicles or trailers outside the area to be

cultivated, ensure that the engine is

turned off.

Careful with rotating tools keep at a safe

distance!

8 Power Hoe 6000 Edition 11.98

1. Safety Instructions

Beware of coasting tools. Before you start Operation and

any maintenance or repair on them, wait

until tools have come to a complete stop. Safety Devices

Foreign powered parts shear and crush!

Before you start operation

Riding on the attachment during opera-

tion is not permitted. Become familiar with the devices and

operating elements and their functions.

Attachments and their weight affect the

Above all, learn how to turn off the en-

driving, steering, braking, and tip-over

gine quickly and safely in case of an

characteristics of the power hoe. There-

emergency.

fore, ensure steering and braking func-

tions are sufficient. Match operating Ensure that all protective devices are

speed to conditions. mounted and positioned to provide pro-

tection.

Do not change governor settings. High

engine speed increases risk of accidents. With no attachment mounted, make sure

PTO-shaft is covered with the protective

Working Area and cap.

Dangerous Area Starting the engine

The user is liable to third parties working Do not start engine in closed rooms. The

within the power hoes working range. carbon monoxide contained in the ex-

haust fume is extremely toxic when in-

Staying in the hazardous area of the

haled.

power hoe is not permitted.

Before you start the engine set all oper-

Check the immediate surroundings of the

ating elements to neutral or idling posi-

power hoe before you start it. Watch out

tion.

for children and animals.

For starting the engine, do not step in front

Before you start work, clear the area from

of the power hoe and the attachment.

any foreign object. During operation,

always watch out for further objects and Operation

remove them in time.

Never leave the operators position at the

For operation in enclosed areas, ensure

steering handle while power hoe is at

that a safety distance is kept to enclo-

work.

sures to prevent damage to tools.

Never adjust the steering handles during

work danger!

Edition 11.98 Power Hoe 6000 9

1. Safety Instructions

For any operation do not leave the op- Attachments

erators position as defined by the steer-

Only mount attachments with the engine

ing handle, especially not when you turn

and attachment drive switched off.

the machine.

Riding on the attachment during opera- Always use appropriate tools and wear

tion or in transport is not permitted. gloves when changing attachments and

parts thereof.

If clogging occurs in the attachment, turn

off the engine and clean the attachment For mounting and dismounting attach-

with an appropriate tool. ments bring support leg into proper posi-

tion and ensure stability.

In case of damage to the power hoe or to

Secure power hoe and attachments

the attachment, immediately turn off the

against rolling off (wheel wedge).

engine and have it repaired.

Beware of injuries when coupling attach-

If steering causes problems, immediately

ments. Proceed with extreme caution.

bring the power hoe to a halt and turn it

off. Have the malfunction removed without Mount attachments as specified and only

delay. couple at specified points.

To prevent the power hoe from sliding on Secure power hoe and attachment

slopes make sure it is secured by another against unauthorized use and rolling off

person using a bar or a rope. This person when you leave the machine. If neces-

must be located at a higher position than sary, install transport or security devices

the vehicle at a safe distance from the and secure.

attachment at work.

Hoeing Attachment

If possible, always work horizontally to

the slope. Adjust protective hood of hoeing attach-

ment so that only those parts of tools

End of Operation which penetrate the soil are not covered.

Never leave the power hoe unattended When hoeing, make sure hoeing skid is

with the engine running. adjusted properly.

Before you leave the power hoe, turn off

the engine. Then close fuel tap.

Secure power hoe against unauthorized

use remove spark plug connector.

10 Power Hoe 6000 Edition 11.98

1. Safety Instructions

Maintenance Storage

Never carry out any maintenance or It is not allowed to store the power hoe in

cleaning with the engine running. rooms with open heating.

In addition, always remove spark plug Never park the power hoe in closed

connector before you work on the engine. rooms with fuel left in tank. Fuel vapours

Check regularly and, if necessary, re- are hazardous.

place all protecting devices and tools

subject to wear and tear. Engine, Fuel, and Oil

Replace damaged cutting tools. Never let the engine run in closed rooms.

Always wear safety gloves and use Extreme danger of intoxication!

proper tools when exchanging cutting Careful when dealing with fuel. Great

tools. danger of fire! Never refill fuel close to

Do not carry out repairs like welding, open fire, inflammable sparks or hot

grinding, drilling, etc. on structural and engine parts. Do not refill fuel in closed

safety-relevant parts (e.g. coupling de- rooms. Do not smoke when refilling!

vices)! Refill only with the engine switched off

Keep power hoe and attachment clean and cooled down.

to avoid risk of fire. Do not spill any fuel, use a proper filling

Check nuts and screws regularly for tight device.

fit and re-tighten, if necessary. In case of fuel-spillage, push the power

Ensure that you re-install all safety and hoe away from the spillage before you

protective devices and adjust them prop- start the engine.

erly after maintenance and cleaning. Make sure fuel is of specified quality.

Only use original agria spare parts. All Store fuel in approved cans only.

other commercial spare parts must cor-

Store anti-corrosive agents and stabiliz-

respond to quality and technical require-

ing liquids out of reach of children. If sick-

ments specified by agria.

ness and vomiting occur, see a doctor. If

fuel has contacted eyes, rinse them

thoroughly, avoid inhaling of vapours.

Read and observe enclosed instructions.

Edition 11.98 Power Hoe 6000 11

1. Safety Instructions

Before you dispose of opened and seem- Explanation of

ingly empty pressurised tins make sure

they are completely empty. Empty them Warning Signs

in ventilated places safe from spark

formation or flames. If necessary, dispose

of tins in hazardous waste deposits.

Careful when draining hot oil, danger of

burns.

Make sure oil used is of specified quality.

Storage is in approved cans only.

Dispose of oil, greases, and filters

seperately and properly. Before any cleaning, maintenance, and

repair work switch off the engine and pull

Tyres and spark plug connector.

Tyre Air Pressure

When working on tyres, make sure power

hoe is parked properly and secured

against rolling off.

Any repairs are to be carried out by

trained mechanics only and with the

With engine running, keep at a safe dis-

appropriate tools.

tance from hoeing tools.

Regularly check tyre air pressure. Exces-

sive air pressure may cause bursts.

Use appropriate tyre air pressure when

mounting front weight.

Re-tighten attachment bolts of drive-

wheels or check tightness when doing

maintenance work.

Do not work without protective covers

Electrical System and mounted. Before starting the engine, bring

covers into proper position.

Battery

Persons having a pacemaker may not

touch live parts of the ignition system

when the engine is running.

12 Power Hoe 6000 Edition 11.98

2. Specifications

Model designation ..................... 6000

Machine Dimensions:

Gearbox ........ 3-speed manual gearbox

and 1 roller chain driving

hoeing shaft/wheel shaft

Oil filling quantities

Gearbox in engine block

Transmission oil BP TFJD-GL4 ..... 0.30l

in chain drive top

a .......................................... 310 mm Transmission semi-fluid grease .... 350g

b .......................................... 620 mm BP Energrease LS-EP00

c ........................................ 1000 mm in hoeing drive

d .......................................... 890 mm Transmission semi-fluid grease .... 350g

h ............................. ca.700950 mm BP Energrease LS-EP00

l ......................................... 1250 mm

A ................................. 100650 mm Speed steps

(depending on type of tilling attach- Ground speed

ment) Hoeing tool [km/h]

Gear

Manufactured according to [rpm] with 5.0-10

CEN/GS safety standards: tyres fitted

e ....................................... > 150 mm 1 66 6

f ............... > 500 mm at h = 800 mm 2 98 9

3 172 15.7

Hoeing width: ........ Depending on type

of hoeing accessory

Accessories: Tyres: ....................... 5.0-10 (field tyre)

Hoe 34100 cm Tyre pressure: ........................... 1.2bar

Front support wheel ............... 0189 421 Noise levels:

Ridger .................................... 3452 021 In accordance with German 3rd Ordi-

Wheel hubs ........................... 6019 511 nance on machine-safety law:

Drive-wheels ......................... 0190 111 Noise level at operators ear ...... 90dBA

Wheel weights ....................... 0421 011 Sound level ........................... 101.5dBA

Hitch ...................................... 4040 021 (in accordance with regulations of

Conventional plough .............. 3441 021 German Agricultural Association)

Quarter-turn plough ............... 3444 021

Potato raising plough ............. 3443 021 Clutch: ............................ Oil immersed

Spring tine cultivator .............. 3472 021 multi-plate clutch

Combined rotary harrow ........ 3473 021 Weight: .......................... approx. 56kg.

Edition 11.98 Power Hoe 6000 13

2. Specifications

Engine Generator: .............................. 6V A.C.

Fuel tank capacity: ......... approx. 4.5 l

Manufacturer: .............................. agria

Fuel: .................................. Commercial

Type: .................................... 66/6 or 1* petrol/oil mixture 1:30

Version: ........................ Fan-air-cooled octane number min. 90 RON

1-cylinder-2-stroke engine (petrol) and self-mixing

supergrade 2-stroke engine oil, e.g.

Lubrication: ............. Petroil lubrication; Shell: Super T, Super TX;

stoichiometric ratio 1:30 Esso: Exxon Special 2T Engine oil;

BP: 2T Special

Bore: ........................................ 56 mm

(refer to fuel recommendations)

Stroke: ..................................... 58 mm

Air filter: ..................... Oil bath air filter

Cubic capacity: ..................... 150 ccm Engine oil filling

quantity: ......................... approx. 150ml

Compression: .............................. 6 :1

Carburetor: ...... Piston slide carburetor

Output: .................................... 4.8 kW Bing 1/18/31 or 1/18/106

at 4500 rpm Air control screw: ....... in basic setting

Spark plug: ..................... Bosch M10A approx. 1/21 1/2 revs. open

Spark plug gap ................ 0.50.6 mm Main jet: .......................................... 95

Idle jet: ............................................ 45

Ignition system: ................... Flywheel Needle jet: .................................. 1108

magnet ignition Needle setting: ................................. II

Contact clearance ....... 0.350.45 mm

Ignition point ............... 2.5 before u.d.c. Rated speed: ....................... 4800 rpm

radio remote screened according to Top no-load speed: ............. 6300 rpm

VDE 0879

Idling speed: ....................... 1800 rpm

Starter: ........................... Recoil starter

Operability on Slopes:

Stop device: ................. Contact break

via short circuit cable Engine is suited for use on slopes:

Engine-stop-switch on handlebar continuous operation possible

up to .................. 45 inclination (100%)

14 Power Hoe 6000 Edition 11.98

3. Devices and Operating Elements

The power hoe agria 6000 is suited for Cooling System

common horticultural, agricultural, and

The engine is fan-cooled. Therefore keep

forestal operations, and for grass and

screen at recoil starter and cooling ribs

park maintenance.

of cylinder clean and free from sucked-in

The following attachments are available: plant trash.

l Hoeing attachment 34100 cm Always ensure that idling-speed is ad-

l Ridging attachment justed correcty. At low speeds and with

l Draft attachments for soil cultivation the speed control lever set to idle, the

engine is supposed to run smoothly and

without run-out.

Engine

The two-stroke-petrol engine runs on Air Filter

commercial petrol/oil mixture of a stoi- The air filter purifies the air intake. A

chiometric ratio 1:30. For the first tank clogged filter reduces engine output.

filling use a ratio of 1:25.

I

Note! Only use self-mixing spe- Ignition System

cial 2-stroke engine oil (see The engine is equipped with a mainte-

Specifications). nance-free, contactless electronic ignition

Also, refer to fuel recommendations, p4. system. We recommend to have

necessary check-ups done by an expert

During the first 20 operating hours (break-

only.

in period) do not use engine to maximum

power. Speed Control Lever

Even after break-in period never use

The speed control lever (C/8) on the

engine at higher speed than necessary

steering handle is for stepless setting of

for the work in hand.

I

engine speed from min. = idle to max. =

High engine speed is harm- full throttle.

ful to any engine and con-

siderably affects its durability.

This applies especially for no load op-

eration. Any overspeed (have the en-

gine roar) can result in immediate

damage.

Edition 11.98 Power Hoe 6000 15

3. Devices and Operating Elements

Engine-off-switch l Start position: For starting the engine

and for short breaks, pull the hand clutch

The power hoe is equipped with an elec- lever (C/6) and fasten with pawl (C/7).

tric off-switch (C/4). On pressing the l Operating position: To operate the

switch, the ignition is turned off (engine

W

machine press dead stop lever (C/5).

is switched off).

Do not tie down dead stop lever.

I

The dead stop lever also serves

to switch off in an emergency.

Release the dead stop lever for

fast engine switch-off. The lever automati-

cally goes to STOP position.

Position "I" = Operation Clutch

Position "0" = Engine off The power hoe is equipped with a multi

I

The engine-off-switch also plate disk clutch, running in an oil bath.

serves as emengency-off- Clutch is engaged with hand clutch lever

switch. Set the switch to 0 for (C/6).

fast switch-off. The machine is decoupled when you pull

the hand clutch lever. Now, the engine

Dead Stop Lever stops driving the mower. The pulled hand

clutch lever can be

The power hoe is equipped with a safety locked with pawl (C/7).

switch (lever C/5). Upon release of the

To avoid clutch slipping

lever, the ignition system is turned off

away during operation,

(engine is off).

a clutch play of 35 mm

STOP position Operating position is factory-set on the hand lever.

After the first operating hour, the clutch

play has to be checked and, if necessary,

re-adjusted (refer to Maintenance).

Start position

l Stop position: Upon release of the

lever, the ignition system is switched off

(engine is off). Beware engine keeps

running due to centrifugal mass.

16 Power Hoe 6000 Edition 11.98

3. Devices and Operating Elements

Gearbox Coupling Unit

The power hoe has a 3-speed manual The coupling unit (1) is an adapter that

gearbox that drives the wheels and the serves as a link between the hitch and

tiller. the mounted attachments (plough, culti-

vator and combined rotary harrow).

Speed steps These attachments have a coupling pin

Lever (C/3) shifts the that is inserted into the adapter tube (2).

gears on wheel-drive Attach the pin (3) with the locking pin and

and hoeing-drive: lock with R-clip (4).

The crank (5) on the coupling device

allows setting individual working depths.

Set the travel X with the stop bolts 6

I .............................................. 1st gear and 7 to adjust the hoe's steering when

II ............................................ 2nd gear an attachment is mounted.

III ............................................ 3rd gear

0 ................................................ neutral

A roller chain transmits power to the shaft

that drives the wheels and the hoeing unit.

I

Only change gears when clutch

is decoupled. Move shift lever

only with your hand.

Hitch

Trailed implements, for example leg and

plough, are pin-attached (1) to the hitch

(A/18).

1 Coupling unit

2 Adapter tube

3 Locking pin

1 Locking pin 4 R-clip

2 R-clip 5 Crank

Ensure the pin is locked in place with the

R-clip (2) after the implement is attached.

Edition 11.98 Power Hoe 6000 17

3. Devices and Operating Elements

Steering Handle

Steering handle height

adjustment

l Undo hex bolt (13) until the teeth are

exposed.

l Adjust the handlebars to the desired

height and notch the teeth into the

proper teeth of the pivoting joint.

l Tighten the hex bolt.

Steering handle side

adjustment

l Undo tommy screw (1) until the

teeth are exposed.

l Move the handlebars to the proper

position.

Drive-Wheels

A choice of hubs are available to be

mounted to the drive-wheels:

l one pair of wheel hubs to suit a rigid

1 Anchoring bolt

wheel shaft;

2 Wheel hub

l one pair of latch hubs to give easier

3 Locking nut

turns.

One pair of wheel hubs

(rigid version)

Assembly

l Attach wheel hubs (2) to both ends of

the hoeing shaft.

l Guide the anchoring bolt (1) through

the hubs and the shaft as shown in the

illustration.

l Attach locking nut (3) and tighten it

(100Nm).

18 Power Hoe 6000 Edition 11.98

3. Devices and Operating Elements

One pair of latch hubs Fitting the drive-wheels

(assist turning) The drive-wheels can be fitted to the hubs

Assembly in two ways, pointing inside or outside to

l Attach the latch hub (1) together with

give the desired track width.

anchoring bolt to the hoeing shaft, as For full tractive power, mount the wheels

shown in the picture. with the pointed parts of lugs pointing in

travelling direction (wheels seen from

l Attach the latch hub (2) without an- above). Fit the ball spring washers with

choring bolt to the opposite shaft end. the ball side pointing to the recess in the

l Attach locking nut (3) and tighten it disk wheel.

(100Nm).

1 Latch hub with anchoring bolt

2 Latch hub without anchoring bolt

3 Locking nut

On new machines and after each wheel

change retighten the wheel bolts and nuts

Latch hubs can be adjusted as required at 100Nm after the first 2 operating hours,

via the levers. otherwise retighten each time you

l Middle position = rigid connection maintain the machine.

l Forward position = Drive and free-

wheeling for forward operation Wheel-Weights

l Backward position= Drive and free- Wheel weights are available to improve

wheeling for reverse operation traction.

Wheel weight ........... Item no. 3221 011

to be fitted to drive-wheels 5.0-10

Edition 11.98 Power Hoe 6000 19

3. Devices and Operating Elements

Front support wheel Attachment of

(Accessory no. 0189 421) Hoeing Tools

W

For easier transport, use the front sup-

port wheel. Always shut off the engine

and remove the spark plug

Installing the front support wheel connnector before you at-

Push the square pin on the support wheel tach/remove the hoeing tools. Wear

(1) all the way in the rectangular tube and safety gloves.

connect both parts with a linch pin (2) l Assemble the hoeing tools (AC) us-

fitted through the borings. ing distancer sleeves (EG) and guard

discs (D), if necessary, to obtain the

desired working width (see Combina-

tions of hoeing tools, p21) and push them

on the shaft.

l Insert the anchoring bolt (H) through

the tools and shaft.

l Attach locking nut and tighten it at

100Nm.

Guard discs

The discs are to prevent shrubs and

1 Front support wheel bushes from being damaged by the hoe

2 Linch pin and to protect young plants from being

3 Grip screw (clamping screw)

covered with soil.

They also provide protection for the op-

To keep the front support wheel mounted erator when hoeing along headlands or

on the power hoe fold it up for hoeing. fences.

Hoeing position

l Loosen grip screw (3) until the notches

on the beam are released.

l Fold the beam up into a mesh with the

notches and tighten the grip screw.

Transport position

l Fold the support wheel down and

tighten the grip screw.

20 Power Hoe 6000 Edition 11.98

3. Devices and Operating Elements

Hoeing Tools E pair of distancer sleeves

A pair of F pair of distancer sleeves

base hoeing tools

G pair of distancer sleeves

B pair of

add-on hoeing tools H pair of anchoring bolts

C pair of

end hoeing tools

Combinations of hoeing tools

D pair of

Width A B C D E F G H

guard discs

cm mm

34 1 1 350

34/42* 1 1 1 1 400

42 1 1 350

42/50* 1 1 1 1 1 480

52 1 1 1 1 540

52/60* 1 1 1 1 1 585

60 1 2 1 1 540

60/68* 1 2 1 1 1 1 665

70 1 2 2 730

70/78 1 2 1 1 2 780

80 1 3 1 2 730

80/88* 1 3 1 1 1 2 860

90 1 3 3 920

90/98* 1 3 1 1 3 970

100 1 4 3 920

100/100* 1 4 1 1 3 1050

* Total width with guard discs fitted

Edition 11.98 Power Hoe 6000 21

3. Devices and Operating Elements

Hoeing guards Hoeing leg

Assembly l Attach hoeing leg (5) and leg (6) to the

The guards must cover the hoeing tools hitch.

across the whole working width.

W

Always shut off the engine

and remove the spark plug

connnector before you at-

tach/remove the hoeing guards. Wear

safety gloves.

l Fit both hoeing guards (1+2) with

anchoring bolts (3) and tensioning bolts

(4) into the holes (A/9) on the hoeing drive

(see illustration).

W

Before you start hoeing en-

sure guards of the correct

size are mounted to prevent

injuries caused by the rotating hoeing

tools. The hoeing leg slows down the hoes

forward speed. Press the hoeing leg (5)

1 Left hoeing guard into the soil for the desired working depth.

2 Right hoeing guard The deeper you set the leg setting, the

3 Anchoring bolt deeper is the working depth.

4 Tensioning bolt Hoeing leg settings

A = in heavy soil

B = in medium to light soil

C = in sandy soil

A B C

The share (4) is for working in losened

soil only.

22 Power Hoe 6000 Edition 11.98

4. Commissioning and Operation

Commissioning the Each time you take up operation, i.e.

before you start the engine, check

Machine whether

Please note that durability and opera- l the fuel tank contains enough fuel,

tional safety of the engine depend to a l the oil filling mark in the pot of the oil

large extent on its breaking-in. Always bath air filter shows an adequate level of

allow a cold engine to warm up for some engine oil (filling quantity approx. 50 ml).

minutes and never run it at full throttle at

the beginning. Please note: for the first

20 hours of operation (break-in period)

do not use the engine at full power.

I

Make sure you check and

maintain air filters regularly

and use clean fuel. Only use

branded petrol.

Only use fresh, clean fuel (not older than

3 months) and approved fuel cans to be

purchased in special shops. Rusty sheet

metal cans or fuel cans not suited for oil level

petrol are not permitted.

For the first commissioning or after longer l transmission oil level in manual gear-

periods of no operation, fill fuel tank to box reaches the control opening (B/28)

maximum to avoid starting problems. (for checking, bring engine into horizon-

tal position).

W

Do not cause fuel tank to overflow, but

leave a 5 mm margin for the fuel to ex- Only take power hoe into op-

pand. eration with all protective de-

W

vices mounted and positioned

Be careful when dealing with to provide protection!

fuel. Great danger of fire!

Never refill fuel close to open l Careful when starting the engine in

fire, inflammable sparks or hot engine closed rooms!

parts. l Ensure good ventilation and fast

l Do not refill fuel in closed rooms. escape of exhaust fumes. Exhaust

fumes contain carbon monoxide

l Do not smoke when refilling! which acts toxic when inhaled.

l Refill only with the engine switched l Do not touch the hot engine dan-

off and cooled down. ger of burns!

l Do not spill any fuel, use a proper l Do not touch the ignition cable and

filling device. do touch or remove ignition spark

connector while the engine is running.

Edition 11.98 Power Hoe 6000 23

4. Commissioning and Operation

Starting the Engine

l Open fuel tap (B/21)

Engine cold:

l Press tickler (B/23) on carburetor until

fuel overflows.

l Set speed control lever (C/7) to max

(full throttle).

Engine warm:

l Do not actuate tickler on carburetor.

l Set speed control lever (C/7) to

approx. 1/4 throttle. 1/4

l Move engine-off-switch (C/3) to oper-

ating position I.

l Pull hand clutch lever (C/5) and lock

with pawl (C/6) (start position).

l Pull starting-rope on handle (B/29)

until you feel starter clutch engage. Then

pull hard and fast to start the engine.

After the start, let rope glide back. Do not

let snap.

l Once the engine has started, slowly

move speed control lever to centre posi-

tion and let engine warm up for some

time.

24 Power Hoe 6000 Edition 11.98

4. Commissioning and Operation

Switching off Engine

l Move speed control lever to idling gas

position and let engine run idle for

approx.1/2 minute. 6 30 sec

l Move engine-off-switch to position 0.

l Close fuel tap.

I

Note: The engine-off-switch

(C/3) also serves as emer-

gency off-switch. If necessary,

bring switch into position 0 to turn en-

gine off.

I

For longer periods of no opera-

tion, do not switch off engine

with engine-off-switch, but close

fuel tap and let engine run until it slowly

comes to a complete stop due to lack of

fuel. This ensures that carburetor is empty

and no resin residue can deposit.

W

Secure power hoe against

unauthorized use discon-

nect spark-plug connector.

Edition 11.98 Power Hoe 6000 25

4. Commissioning and Operation

Hoeing Hazardous area

W

l Start the engine as described in Start- Staying in the hazardous area

ing the Engine. of the power hoe is not per-

mitted when the power hoe is

l Pull hand clutch lever (C/5). being started or in operation.

l Select proper speed with gear shift

lever (A/3).

Hazardous area

For heavier soil and coarse tilling:

select slow speed I.

For lighter soil and medium tilling:

select medium speed II.

For sandy soil and fine tilling:

select fast speed III.

l Slowly release hand clutch lever while

pressing the throttle the power hoe

moves forward and hoeing tools start

working.

4227

End of Hoeing

W

l Move speed control lever to idling po- Never leave the operators

sition. position at the steering han-

dle while the machine is at

l Pull hand clutch lever and hold.

work.

l Move gear shift lever to position 0

During all operation with the power

(neutral).

I

hoe, especially when turning, the

Before you actuate the shift operator must keep at a safe distance

lever, pull hand clutch lever as defined by the steering handle.

to stop. Only move the shift le-

Do not clean hoeing tools with the en-

ver with your hands.

gine running. Switch off the engine

Change of work-site and remove spark plug connector.

If clogging occurs, turn off the engine

l Turn off the engine.

and clean the attachment with an ap-

l Pull hand clutch lever. propriate tool (wooden stick).

l Turn off hoeing drive (B/19) (position

0).

l If present, fold front support wheel into

travel direction.

26 Power Hoe 6000 Edition 11.98

5. Maintenance

Apart from adhering to operating instruc- diesel fuel several times and rinse

tions for power hoe, it is also important to thoroughly. Spin dry. Screw air filter back

observe the following maintenance into place and fill cleaned filter pot with

instructions. fresh engine oil. Then re-fit filter pot.

W

Warning: Only do mainte- Never wash air filter in petrol, water,

nance work with the engine lye or hot liquids.

turned off and spark plug con-

nector removed. Always wear safety

Cleaning the Cooling System

gloves, when working on hoeing tools. After operation for an extended period of

time, clogging of plants and dust may

Engine occur in the cooling system. Sustained

operation with the cooling system

The oil contained in the fuel mixture lu- clogged lets the engine heat up and

bricates the 2-stroke-engine. Therefore, causes damage.

there is no engine oil filling opening.

l Always check cooling-air screen

Oil Bath Air Filter (B/31) and remove dirt and plant trash

sucked in.

Change oil in oil bath air filter (A/8) after

l Remove fan case at least once per

every 25 operating hours or at least after

year, preferably before the season starts,

3 months. In case of heavy dust

and clean cooling fins on cylinder and

occurence, clean after a few hours

cylinder head, clean guiding plates and

check for proper condition frequently.

cooling-air screen, both serving for good

l Clean air filter and outside surround-

air circulation. For this purpose, contact

ing parts.

your professional agria workshop.

l Open closing bow and remove oil pot.

l Remove old oil (dispose of properly) Cleaning Spark Plug and

and clean oil pot. Setting Spark Plug Gap

l Fill oil pot with engine oil up to oil level

mark (not higher) and re-fit oil pot onto After every 50 operating hours

filter ensure pot fits tight. l remove soot from spark plug elec-

trodes with a steel brush,

l check the gap between electrodes and

Oil bath air filter set to 0.6 mm.

Exchange spark plug after approx. 100

hours of operation.

Oil level

l After repeated oil change or excessive

dirt in the filter remove the oil pot and 0.6 mm ca. 20 Nm

unscrew oil bath air filter. Dip filter into

Edition 11.98 Power Hoe 6000 27

5. Maintenance

Fuel System Idling Speed

l Each time you maintain the machine, Always ensure that idling engine speed

check fuel hose, fuel tank, and carburetor is adjusted correctly. At low speeds, the

for leakages. Repair, if necessary. engine is supposed to run smoothly, with

speed control lever at stop in idling speed.

l Replace fuel hoses after every 2

years, immediately exchange leaking For basic tuning, adjust the slide valve

hoses. adjusting screw (3) on the slide

carburetor. For this purpose, set the throt-

l Always fill correct stoichiometric ratio

tle control cable free of play by turning

of fuel. the adjusting screw on carburetor.

l If engine received too much fuel

For fine tuning, adjust the air control

(flooded), move speed control lever to

screw (2). Adjust only while the engine is

max and crank engine with recoil starter

still warm from operation (also refer to

until engine starts. Or remove spark plug

Specifications). For these adjust-

and clean and dry. With spark plug

ments, contact your professional agria

removed, crank engine a few times with

workshop.

recoil starter. Screw spark plug back in

and re-start engine.

Cleaning Cylinder Head 1 Carburetor

tickler

After every 400 hours of operation take 2 Air control

off cylinder head and remove carbon screw

deposits on cylinder head and exhaust 3 Slide valve

tunnel with a steel brush. Afterwards, adjusting

clean with soft paint brush. Exchange screw

head gasket and reassemble to cylinder

head. Tighten cylinder head screws in

turn at 22 Nm. For this purpose, contact Exhaust

your professional agria workshop.

l Constantly check exhaust system

Carburetor Settings (A/12) for plant trash and clean, if neces-

sary. Otherwise

W

Changes in fuel, temperature, height or

strain can require slight re-adjustments danger of fire!

of carburetor settings. Only let engine run Check before each operation.

with air filter and air filter pot mounted.

l Check exhaust after every 200 oper-

ating hours for oil carbon and, if neces-

sary, clean or burn out.

For this purpose, contact your profes-

sional agria workshop.

28 Power Hoe 6000 Edition 11.98

5. Maintenance

Manual Gearbox Chain Drive

Check the transmission oil level in the The chain drive is filled with transmission

gearbox before you start up the machine oil.

and repeat checks at intervals of 25

operating hours. Refilling is not necessary as long as no

l Park the machine on level ground (see lubricant leaks are spotted on the

illustration). housings and their seals.

The oil level is visible in the opening Checking Lubricants

(B/28) after the Allen head screw has

been removed. Top up transmission oil, if l Open the cover of the housing (A/21).

necessary. l Crank the hoeing shaft at least 6 rota-

tions. Lubrication is fine, if the chains are

wet with transmission oil (visual check).

Top up transmission oil, if necessary.

Oil level

1 Plug

2 O-ring

Change transmission oil after the first

25 operating hours and then at intervals Chain Tension

of 50 operating hours. Ensure oil filler plug The wheel drive chain should neither be

(B/28), drain plug and the surrounding tight nor too slack.

parts are absolutely clean to prevent any l Undo the 3 attachment bolts (1) and

ingress of dirt. the locking nut (3).

For oil filling quantity and quality, see l Set the chain tension via the hex head

Specifications. bolt (2).

l Retighten locking nut (3) and attach-

ment nuts (1).

3 Drain plug

4 O-ring

Edition 11.98 Power Hoe 6000 29

5. Maintenance

Hoeing drive Adjustments on Levers

The hoeing drive is filled with semi-fluid Check play or settings each time before

grease. Refilling is not necessary, if no you operate the machine and readjust

leaks are visible on the housings and their them, if necessary (in particular during

seals. breaking-in after starting up the machine

and after replacing the clutch disks).

Lubrication inspection l Remove retaining spring (2) with a

l Open the plug (A/12) screw driver or a similar tool.

l Crank the hoeing shaft at least 6 ro- l Use set pin (4) to press the cable end

tations. Lubrication is fine, if the chains (3) out of the bracket in the lever.

are wet with transmission oil (visual in- l Adjust the set pin (4) to a play of X.

spection). Top up transmission grease, if (Screw set pin in to reduce the play, screw

necessary. it out to increase the play).

l For inspection, hook the cable end

back into the bracket, using the set pin.

l Fit retaining spring (2).

Clutch lever:

X = 35 mm (Clutch play)

30 Power Hoe 6000 Edition 11.98

5. Maintenance

Dead Stop General

Check the dead stop function each time l Watch out for fuel and oil leaks, and

you maintain the machine. remove them if necessary.

l The engine must automatically come l Check nuts and bolts regularly for tight

to a stop upon release of the lever (C/4) fit and tighten them if necessary.

and clutch engagement. l Grease all gliding and moving parts

l Inspect all electric lines and connec- (e.g. speed control lever, hand lever

tions and replace them if necessary. bearing, etc.) slightly with Bio-lubrication

For this purpose contact your agria grease and Bio-lubrication oil.

workshop.

Cleaning

Stop position After each cleaning (washing with water,

especially with a pressure washer)

lubricate all lubrication points, oil the

machine, and let the power hoe run for a

short time to press the water out.

Apply grease generously and leave a

grease ring around the bearings to pre-

vent water, plant sap, and dirt from pen-

etrating.

Drive-Wheel

Engine

l Check the tyre pressure (1.2 bar) at

regular intervals. Clean the engine only with a cloth. Avoid

spraying with strong jets of water be-

l Fit the wheels with pointed parts of cause water might leak into ignition and

lugs showing in travelling direction fuel system, causing malfunctions.

(wheels seen from above) to provide full

tractive power.

l Retighten wheel nuts and locking bolts

at 100 Nm on the hubs each time you

maintain and service the machine.

Edition 11.98 Power Hoe 6000 31

5. Maintenance

Storage c) Drive-wheels

For longer periods of no operation Support drive-wheels in such a way that

prepare the machine for storage. Pro- tyres have no ground contact. Pneumatic

ceed as follows: tyres are quickly destroyed, if left parked

under load and unsupported.

a) Clean thoroughly

d) Storing the machine

Repair paint coat, lubricate machine and

attachment and operate for a short time. Do not park the machine in humid

Then spray all shining parts, in particular rooms, in rooms where fertilizer is stored,

hoeing tools, with Bio-slushing oil. in stables or adjacent rooms because of

severe corrosion.

b) Engine preservation

e) Protecting the machine

l Drain fuel completely and let the en-

gine run until it comes to stop due to lack Protect machine with cloth or a similar

of fuel or add fuel stabilizer (agria No. 673 cover.

50).

Method: Fill fuel tank, add anti-corrosive

and stabilizing liquid (amount ON

stabilizes 4l of fuel). Let engine run for

approx. 1 minute. (Observe enclosed

instructions).

l Fill a tea-spoon (approx. 0.03l) of

engine oil into spark plug opening. Slowly

crank the engine.

l Set the piston to compression with the

recoil starter to keep the valves closed.

l Slowly crank the engine every 23

week (spark-plug connector is removed).

Then set the piston to compression again.

W

Warning! Keep anti-corrosive

and stabilizer out of reach of

children at all times. Do not

inhale vapours! In case of sickness

and vomiting see a doctor immedi-

ately! In case of eye contact with liq-

uids, rinse eyes thoroughly.

32 Power Hoe 6000 Edition 11.98

Lubricants, Varnishes, Wear Parts

agria Order No.

Lubricants and Anti-Corrosive Agents

690 35 Bio-lubrication grease cartridge 400g

690 36 Bio-Slushing oil bottle 500ml

673 50 Fuel stabilizer bottle 125ml

Please read and observe enclosed instructions!

Varnishes

181 03 Spray varnish birch-green spray tin 400ml

712 98 Spray varnish red, RAL 2002 spray tin 400ml

509 68 Spray varnish black spray tin 400ml

Wear Parts

304 40 Spark plug M 10 A

009 16 O-ring 16x22x2

for gearbox filling opening

009 44 O-ring 8x11x1

for gearbox drain opening

102 53 Cylinder head gasket

241 92 Chain housing seal top, internal

256 45 Chain housing seal top, external

172 22 Hoeing tine, left right

left

172 23 Hoeing tine, right

Spare Parts

997 127 Power Hoe 6000

997 050 agria Engine

Edition 11.98 Power Hoe 6000 33

6. Troubleshooting

W

Problem

Observe safety instructions! Have all serious malfunctions on the machine or engine repaired by your

agria workshop. They have the proper tools. Improper repairs can only add to the damage.

Possible cause Remedy Page

Engine - Spark plug connector not connected Connect spark plug connector

does not start - Engine-off-switch is set to 0 Set engine-off-switch to I 24

- Dead stop lever is not set Set dead stop lever to start position 24

to start position

- Fuel tank empty or poor fuel Fill fresh fuel 23

- Fuel line clogged Clean fuel line 28

- Defective spark plug Clean, adjust or exchange spark plug 27

- Engine too much fuel Dry and adjust spark plug and

(flooded engine) start at full throttle

- Engine-off-line defective Check line and connections

- Inleaked air due to loose caburetor Tighten attachment bolts

Misfirings in - Loose ignition cable Firmly connect spark plug connector to

engine spark plug, fix ignition cable retaining device

- Clogged fuel line Clean fuel line,

or poor fuel fill fresh fuel 23

- Vent opening in fuel tank cap clogged Exchange fuel tank cap

- Water or dirt in fuel system Drain fuel and fill fresh fuel

- Air filter clogged Clean air filter or exchange 27

- Carburetor misadjusted Re-adjust carburetor 28

Excessive - Impaired cooling Clean cooling fan grid,

temperature clean internal cooling ribs 27

in engine - Air filter clogged Clean air filter 27

- Carburetor misadjusted Re-adjust carburetor 28

Misfirings - Short firing intervals Adjust spark plug 27

in engine - Incorrect idle mixture Adjust carburetor 28

at high speeds

Engine - Firing interval too long, Adjust or replace spark plug 27

frequently defective spark plug

stalls - Carburetor misadjusted Re-adjust carburetor 28

in idle - Air filter clogged Clean air filter 27

Engine - Defective engine-stop-line, Check line and connection,

does not stop earth missing check earth contact

when set

to stop

34 Power Hoe 6000 Edition 11.98

6. Troubleshooting

Problem Possible cause Remedy Page

Engine - Loose cylinder head or Tighten cylinder head, 28

output too low damaged sealing exchange sealing

- Poor compression Have engine checked

Clutch does - Hand clutch lever misadjusted Adjust clutch free play 30

not decouple

Clutch slips - Hand clutch lever misadjusted Adjust clutch free play 30

- Worn out clutch linings Exchange clutch linings

Excessive - Loosened bolts Tighten attachment bolts 31

vibration

= For this purpose contact your agria workshop.

Edition 11.98 Power Hoe 6000 35

7. Inspection and Maintenance Chart

After operating hours

min. 3 min.

A 5 25 50 100 200 months yearly B page

Clean engine,

K 31

check bolts and nuts

Check air filter K 27

Air filter oil change, earlier, if required K K 27

Clean air filter totally, earlier, if required W 27

Replace fuel hoses W* 28

Clean cylinder head F 28

Clean cooling-air screen K 27

Clean guide plates, cooling fins

F F 27

earlier, if required

Clean spark plug,

W 27

set spark plug gap

Replace spark plug K 27

Check safety switch function K 31

Check oil level in manual gearbox K 29

First oil change in manual gearbox W 29

subsequent oil changes W W 29

Check lubrication of chain and hoeing drive W 40

Lubricate all gliding parts K K 31

Check clutch free play K 30

A = Each time before you take up operation

B = After each cleaning

K = Checks and maintenance to be executed by operator

W = Maintenance to be executed by professional workshop

F = Maintenance should be carried out by your agria workshop

* = after 2 years

36 Power Hoe 6000 Edition 11.98

Designation of Parts,

Electrical Wiring Diagram

Figure C

1 Hex head bolt for steering handle height adjustment

2 Tommy screw for steering handle side adjustment

3 Gearshift lever

4 Engine shut-off switch

5 Dead stop lever

6 Clutch lever

7 Pawl

8 Speed control lever

Electrical Wiring Diagram

1 Engine

2 Magnet ignition system

3 Engine speed delimiter

4 Switch in dead stop lever

5 Switch in clutch lever

bl = blue

br = brown

Edition 11.98 Power Hoe 6000 37

Designation of Parts

38 Power Hoe 6000 Edition 11.98

EC Conformity Declaration

in accordance with the EC directive machinery 98/37/EC

We, agria-Werke, GmbH

D-74215 Mckmhl/Wrtt.

herewith declare in sole responsibility that the product

Power Hoe, Type 6000

to which this declaration refers, corresponds to

the standard fundamental safety and health requirements

as stipulated in EC directive machinery 98/37/EC

and EMC directive 89/336/EC.

The following harmonized standards have been applied:

EN 709

Mckmhl, 20th May 1997

Gregor Czaja Dipl. Ing. Thomas Ilchmann

Head, Qualitity Control Head, Research and Development

Edition 11.98 Power Hoe 6000 39

Horticultural Machinery

agria-Werke GmbH

D-74215 Mckmhl/Wrtt.

Phone 0049 62 98 39-0

Fax 0049 62 98 39-111

e-mail: info@agria.de

Internet: http://www.agria.de

The Winning Team

Power hoes One-wheel hoes Hobby two-wheelers

AllShredd Cutterbar mowers

Lawn mowers Verticutters All-purpose machines

Contact your authorised agria dealer for service and prompt delivery of spare parts

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- FlexiROC T35 R and T40 RDocument4 pagesFlexiROC T35 R and T40 RalmirNo ratings yet

- Attachment Word MillatDocument26 pagesAttachment Word MillatMian SahibNo ratings yet

- Pertanyaan Tentang SKYWAY PDFDocument74 pagesPertanyaan Tentang SKYWAY PDFCharlusSeptesonNo ratings yet

- Recommended Parts List - GEP50-7 (W)Document2 pagesRecommended Parts List - GEP50-7 (W)sami akermiNo ratings yet

- HX210S HX220S: Standard / OptionDocument10 pagesHX210S HX220S: Standard / OptionKo PhyoNo ratings yet

- Safety Engineering: 1-1/2" BS 336 MaleDocument12 pagesSafety Engineering: 1-1/2" BS 336 Malewalid kawsarNo ratings yet

- Genie S80Document353 pagesGenie S80nelsonyNo ratings yet

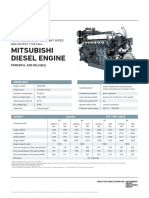

- Mitsubishi Diesel Engine - S16R-PTADocument2 pagesMitsubishi Diesel Engine - S16R-PTAfendynovapamelaNo ratings yet

- Emission M18QTA QSM11 Rev010 Unstampedcommrec USEPADocument20 pagesEmission M18QTA QSM11 Rev010 Unstampedcommrec USEPAOzgur TuncerNo ratings yet

- Wheel Loader ZL55GV - April 2022 - CompressedDocument3 pagesWheel Loader ZL55GV - April 2022 - CompressedRony ZetyawanNo ratings yet

- Genfhfshf 50 TD enDocument152 pagesGenfhfshf 50 TD enbebeusNo ratings yet

- YAK-52 Operating HandbookDocument12 pagesYAK-52 Operating HandbookaturcubbNo ratings yet

- New Holland D180 Service ManualDocument417 pagesNew Holland D180 Service ManualDiego100% (4)

- SYL956H5 SYL956H5: Brand NewDocument12 pagesSYL956H5 SYL956H5: Brand NewGuillermo HerreraNo ratings yet

- Road Roller YL27-3Document4 pagesRoad Roller YL27-3james schembriNo ratings yet

- Ignition Timing - AgonoyDocument2 pagesIgnition Timing - AgonoyRAE ANGELO AGONOYNo ratings yet

- Volume TM Machinery Fire Fighting and Environment Protection Equipment 2012-11-30Document54 pagesVolume TM Machinery Fire Fighting and Environment Protection Equipment 2012-11-30buddhansamrat100% (1)

- JNJNDocument4 pagesJNJNAleksandria Donne D. FernandezNo ratings yet

- Doosan DV250S-7 BrochureDocument9 pagesDoosan DV250S-7 BrochureОлег СкладремонтNo ratings yet

- PipeDocument489 pagesPipeShantle Taciana P. Fabico67% (18)

- Procedure For Me Ae Fifi Steering BTDocument2 pagesProcedure For Me Ae Fifi Steering BTAcank KharismaNo ratings yet

- Re 15190Document24 pagesRe 15190Ahmed Abd ElhakeemNo ratings yet

- Construction Features of Gas Turbine: N.V.S.Murthy Dy. Manager/ BHELDocument67 pagesConstruction Features of Gas Turbine: N.V.S.Murthy Dy. Manager/ BHELSai KrishnaNo ratings yet

- Mitsubishi S6S-Y3T61HF Diesel Engine Service Repair Manual PDFDocument16 pagesMitsubishi S6S-Y3T61HF Diesel Engine Service Repair Manual PDFfjjskekdmmekm0% (1)

- Performance and Emission Testing of Methyl Ester of Aloe Vera Using Metal Oxide As Additive in CI EngineDocument8 pagesPerformance and Emission Testing of Methyl Ester of Aloe Vera Using Metal Oxide As Additive in CI EngineHabtamu AlemnewNo ratings yet

- MINCO F2 Engine Controller Operating Instruction ManualDocument10 pagesMINCO F2 Engine Controller Operating Instruction ManualAnas BasarahNo ratings yet

- Industrial Diesel Generator Set - 50 HZ: General Specifications KOHLER Premium QualityDocument7 pagesIndustrial Diesel Generator Set - 50 HZ: General Specifications KOHLER Premium QualityABCD123655No ratings yet

- Frame: MaintenanceDocument66 pagesFrame: MaintenanceEsjoNo ratings yet

- (Qa7 & Qa1) Machine Inspection Report: Pt. Kalimantan Prima PersadaDocument15 pages(Qa7 & Qa1) Machine Inspection Report: Pt. Kalimantan Prima PersadaDe JavuNo ratings yet

- BE3255 Basic Civil and Mechanical Engineering Important QuestionsDocument6 pagesBE3255 Basic Civil and Mechanical Engineering Important Questionssar019987No ratings yet