Professional Documents

Culture Documents

BFNS Cheek Sheets Jindal

Uploaded by

Shekher NikhilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BFNS Cheek Sheets Jindal

Uploaded by

Shekher NikhilCopyright:

Available Formats

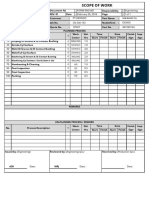

CENTRE GIRDER

RDSO Drawing No :- WD-98057-S-6A_It.No-2_Alt-6

Centre Girder Sl No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

1 Fitment of all components

1.1 Welding

1.2 Dressing

2 Dimensions As follows

Nominal Actual Dimension

Dimensions &

Location Remarks

Allowable Works Inspection RDSO Inspection

Deviation

A1

i Over All Length 13716, +7,-3

A2

Distance of Web plate from B1

ii 45, 1

End of Top pl B2

C1

iii Bolster Centre Distance 9144, +5,-2

C2

Width of Centre Girder Top D1

iv 437, 2

Pl D2

v Draft Gear Pocket E 327, +3,-0

F1

Height of Centre Girder 327, 1.5

vi F2

Height of Centre Girder at G1

vii 177, 1.5

Section ZZ G2

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 3 of 15

HEAD STOCK

RDSO Drawing No :- WD-98057-S-5_ It.No.-3_ Alt-5

Headstock No :-

DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

Fitment of all

1

components

1.1 Welding/Riveting

1.2 Dressing

2 Dimensions As follows

Nominal Dimensions Actual Dimension

Location & Remarks

Allowable Deviation Works Inspection RDSO Inspection

i Over All Length A 2827, 2

ii Over All Height B 549, 1

Distance of Top flange C1

iii from end of Headstock 73, 1

web C2

iv Inside Dimension D 347, +2,-0

v Height E 307, +2,-0

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 4 of 15

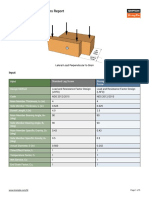

BOLSTER

RDSO Drawing No :- WD-98057-S-5_ It.No.-2_ Alt-5

Bolster No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

Fitment of all

1

components

1.1 Welding/Riveting

1.2 Dressing

2 Dimensions As follows

Actual Dimension

Nominal Dimensions &

Location Remarks

Allowable Deviation Works Inspection RDSO Inspection

i Over All Length A 2827 2

ii Over All Height B 549, 1

Width of Bolster Over

iii C 640, 1

Top Pl

Distance of Top flange D1

iv from end of Bolster 73, 1

web D2

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 5 of 15

CROSS BAR (INNER) CENTRE

RDSO Drawing No :- WD-98057-S-06_It.No.-1_Alt-4

Cross bar (Inner) Centre No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

1 Fitment of all components

1.1 Welding

1.2 Dressing

2 Dimensions As follows

Nominal Actual Dimension

Dimensions &

Location Works RDSO Remarks

Allowable

Deviation Inspection Inspection

i Length Over Cross Member A 558.5, +0,-2

ii Height at End B 530, +0,-2

iii Height at Center Girder Inner C 159, +0,-2

Distance of Top Flange at Top

iv D 45, 1

from Center Girder Inner pl

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 6 of 15

CROSS BAR (OUTER)

RDSO Drawing No :- WD-98057-S-06_It.No.-2_Alt-4

Cross bar (Outer) No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

1 Fitment of all components

1.1 Welding

1.2 Dressing

2 Dimensions As follows

Nominal Actual Dimension

Dimensions &

Location Works RDSO Remarks

Allowable

Deviation Inspection Inspection

i Overall Length A 671.5, +0,-2

ii Overall Height B 539, +0,-2

Distance of Top Flange at top

iii C 80, +2,-0

from Crossbar web end

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 7 of 15

CROSS BAR (OUTER) SHORT

RDSO Drawing No :- WD-98057-S-06_It.No.-10_Alt-4

Cross bar Short (Outer) No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

1 Fitment of all components

1.1 Welding

1.2 Dressing

2 Dimensions As follows

Nominal Actual Dimension

Dimensions &

Location Works RDSO Remarks

Allowable

Deviation Inspection Inspection

i Length Over Cross Member A 671.5, +0,-2

ii Height at End B 339, +0,-2

Distance of Top Flange at Top

iii C 80, +2,-0

from Longitudinal Pl (End)

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 8 of 15

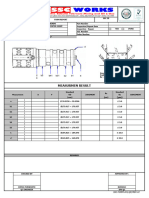

UNDERFRAME

RDSO Drawing No :- WD-98057-S-04_Alt-5

Underframe No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

1 Fitment of all components

1.1 Welding

1.2 Dressing

2 Dimensions As follows

Actual Dimension

Nominal Dimensions &

Location RDSO Remarks

Allowable Deviation Works Inspection

Inspection

A1

i Length over Head stock 13716, +7,-3

A2

B1

ii Width over Solebar 2845, 3

B2

Distance between Bolster / C1

iii Bogie Centers 9144, +5,-2

C2

Diagonal Difference over D1

iv 5

Head Stock D2

Distance between Side E1

v 1474, 2

Bearers E2

vi Camber 9, 2

All dimensions are in mm.

FIXED END

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 9 of 15

RDSO Drawing No :- WD-98057-S-16_Alt-2

Fixed End No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

1 Fitment of all components

1.1 Welding

1.2 Dressing

2 Dimensions As follows

Actual Dimension

Nominal Dimensions &

Location RDSO Remarks

Allowable Deviation Works Inspection

Inspection

Width over corner bend

i A 2845 3

angle

B1

ii End Wall overall Height 1145 3

B2

Distance between Inner

iii to Inner Stanchion C 580 2

Distance between inner to D1

iv 222.5 2

Outer Stanchion D2

Distance between corner E1

v 545 2

Angle to Outer Stanchion E2

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 10 of 15

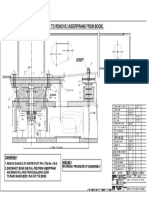

FINAL ASSEMBLY

Wagon No:- U/F No :- DATE :-

Sl.

Stage Works Inspection RDSO Inspection Remarks

No.

1 Fitment of all components

2 Riveting / Lock Bolting

3 Welding

4 Operation of Couplers

Operation of Fabricated

5

Stanchion

6 Under Gear Examination

Brake Test (i) Air Brake

7

(ii) Hand Brake

8 Painting

9 Lettering

10 Dimensions As follows

Nominal Dimensions & Actual Dimension

Location Remarks

Allowable Deviation Works Inspection RDSO Inspection

A1

i Length over Head Stock 13716, +7,-3

A2

B1

ii Coupler height from R.L 1105, +0,-5

B2

Width over Stanchion

iii Bracket C 3045 3

iv Side Bearer Clearance Nil

All dimensions are in mm.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 11 of 15

FINAL WAGON

1. Wagon No. 2. Date of offer

Name of the Wagon

3. Underframe No. 4.

Manufacturer:

Contract/P.O. no. and

5. Contract/P.O. placed by 6.

date and D.P. (Upto)

7. Running Gear

a) Bearing Make Serial Nos.

b) Wheel Make Serial Nos.

c) Axle Make Serial Nos.

d) Bogie Make & Sr. nos. e) Coupler make & Sr. Nos.

Draft Gear make, Model

f) g) Air brake make

& Sr. Nos.

Brake Cylinder make &

h) DV Make & Sr. No. i)

Sr. Nos.

j) Aux. Reservoir Make k) Date of air brake testing

Date of SWTR

l) 8. Lock Bolt Make

Calibration

9. Paint make 10. Tare Weight

11

Shot Blasting 12. D.M. Issue date

.

13

TXR fit memo issue date

.

14. RAD

availed_________________________________________________________________________________________

_

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 12 of 15

15. Defect

Observed______________________________________________________________________________________

Other Attributes

Wagon No.: U/F No.: Date:

SL. WORKS

ATTRIBUTES ACCEPTANCE LIMIT RDSO INSPN.

NO. INSPN.

Mild steel 40microns after primer and

1. Check for paint. Thickness & 80 microns after finish paint. Paint

Finish surface to be free from blistering &

peeling

Lettering & marking for size.

2. As per Drg No. WD-98057-S-17 Alt.6

Location & punch mark.

3. Coupler

Ht. from rail level

1105 +0

3.1 -5

Operating of knuckle with

Full knuckle throw lock to lock

operating handle

3.2 Articulation of coupler body Free movement

4. Hand Brake

Apply hand brake (by one person

4.1 only and strike all wheels with There should not be ringing sound.

hammer)

Release the hand brake and apply All brake block must be released Gap

4.2 crow bar on one end brake block to between the brake and wheel thread

take up all slack not be less than 23.6 min (5.9x4)

Empty tie rod and loaded tie rod must

Empty Load Box. engage. In loaded position the empty

5. Operate the mechanism from any tie rod pins must be loose. In empty

end in empty and loaded positions position loaded tie rod pins must be

loose.

6. Air Brake and Slack Adjuster

Distance between the control rod Must be 70 +2

6.1

head and adjuster barrel (A) -0

Dimension (E) i.e. the distance 575 25 mm

between the end of protection tube

6.2

and a fixed mark on the slack

adjuster pull rod

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 13 of 15

Apply Air Brake and then release the Gap should not be less than 23.6 mm

same. Apply crow bar as one end of (5.9 x 4)

6.3

brake block to take up all slack

SL. WORKS

ATTRIBUTES ACCEPTANCE LIMIT RDSO INSPN.

NO. INSPN.

Rotate the barrel slack adjuster in Gap between the brake block and

clockwise direction (looking from the wheel tread as measured should be

6.4 control rod end) to decrease the 23.6 +1

slack. Apply and release the Air -0

Brake twice

Now rotate the barrel in anticlockwise - do -

6.5 direction. Apply and release the Air

Brake once

Air Brake Equipment

7.

Full service application

Pressure in B.P. 5 0.1 kg/cm2

7.1

Pressure in F.P. 6 0.1 kg/cm2

7.2

Pressure in A.R. 6 0.1 kg/cm2

7.3

Leakage from the system 0.1 kg/cm2 in 1 minute

7.4

B.C. filling time in empty condition Empty 18 to 30 sec.

(pressure rise from 0 to 2.1 kg/ cm2)

7.5 B.C. filling time in loaded condition Loaded 18 to 30 sec.

(pressure rise from 0 to 3.6 kg/ cm2)

Maximum B.P. Pressure in Kg/ cm2 Empty 2.2 0.25 Kg/ cm2

7.6 Loaded 3.8 0.1 Kg/ cm2

Depression in B.P. Pressure

Required for full service application 1.3 to 1.6 Kg/ cm2

7.7

Release after full Service

8.

Application

Draining time B.C. pressure to fall

Empty 45 to 60 sec.

from 2.2 0.25 to 0.4 kg/ cm2

8.1

Draining time B.C. pressure to fall

Loaded 45 to 60 sec.

from 3.8 0.1 to 0.4 kg/ cm2

Piston stroke in mm (a) Empty 85 10

9. (b) Loaded 120 10

10. Emergency application

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 14 of 15

Emergency application BC filling time (a) Empty 18 to 30 sec.

Empty- Pressure Rise from 0 2.1

10.1 kg/ cm2

Loaded- Pressure Rise from 0 3.6 (b) Loaded 18 to 30 sec.

kg/ cm2

SL. WORKS

ATTRIBUTES ACCEPTANCE LIMIT RDSO INSPN.

NO. INSPN.

(a) Empty 2.2 0.25 kg/ cm2

10.2 Maximum B.C. Pressure In kg/ cm2

(b) Loaded 3.8 0.1 kg/ cm2

10.3 Leakage from B.C. 0.1 kg/cm2 in 5 minutes

11. Sensitivity of brakes:

Isolate brake pipe from main line. Brake should apply within 6 seconds.

Check the response of brakes when

11.1 brake pipe pressure is reduced at the

most equal to 0.6 kg/ cm2 in 6

seconds.

12. Insensitivity of brakes

Isolate brake pipe from mainline. Brake should not apply

Check the pressure of brakes when

12.1 brake pipe pressure is reduced at

least equal to 0.3 kg/ cm2 in 60

seconds.

13. Quick Release & Isolation

After emergency brake application Brake cylinder and control reservoir

13.1 operate quick release valve should exhaust automatically.

Bring isolating valve of distributor to

13.2 Auxiliary reservoir should also exhaust.

off position

AR charging time Pressure rise from 17530 Sec. for C3W DV

14

0 to 5.0 kg/ cm2 60 to 120 Sec. for KEO DV

CR charging time Pressure rise from 16520 Sec. for C3W DV

15

0 to 4.8 kg/ cm2 160 to 210 Sec. for KEO DV

Both legs of cotter are split at 90 deg.

(approx.). Split Pin legs are opened at

Check any twenty number of APD

180 deg. (approx.). Tack welding of

16 fittings (refer RDSO Drg. No.

cotter/split pin with washer/nut with

4020/24)

bolts is adequate.

Works Inspector RDSO Inspector

Signature: Signature:

Name Name

Designation Designation

Date Date

Page 15 of 15

You might also like

- Honda StandardDocument4 pagesHonda StandardBjorn Fejer67% (6)

- Basic Stress Calculation 30-Aug-2016Document80 pagesBasic Stress Calculation 30-Aug-2016anandmoon273100% (3)

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDocument1 pageQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- 1 - Gulfstream Park RetrospectoDocument12 pages1 - Gulfstream Park RetrospectoYoandri JoseNo ratings yet

- Report On TransformerDocument20 pagesReport On TransformerNpface100% (1)

- Chambers BrochureDocument11 pagesChambers BrochureonozeanNo ratings yet

- Coal Handling Plant Maintenance and Operation PhilosophyDocument31 pagesCoal Handling Plant Maintenance and Operation PhilosophyJitu Jena100% (1)

- WD CS 01 BFNS22.9 2018Document15 pagesWD CS 01 BFNS22.9 2018Dipanjan chakrabortyNo ratings yet

- Indian Railways: FOR BOGIE COVERED WAGON (91.6 Tonnes)Document14 pagesIndian Railways: FOR BOGIE COVERED WAGON (91.6 Tonnes)Rakesh JainwalNo ratings yet

- Boxnhl MBS (Design-D) Check SheetDocument13 pagesBoxnhl MBS (Design-D) Check SheetKumari SanayaNo ratings yet

- Bvzi (Design-C) Check SheetDocument13 pagesBvzi (Design-C) Check SheetManoj BairwaNo ratings yet

- BVCM (Design-B) Checksheet PDFDocument13 pagesBVCM (Design-B) Checksheet PDFVijay KumarNo ratings yet

- Indian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Document15 pagesIndian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Pratap Singh GangwarNo ratings yet

- Machining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingDocument3 pagesMachining Cyl Surface 1 Sisi & Skim 1 Sisi Machining ID Groove & ID Contact BushingEngineering ProductionNo ratings yet

- Bearing LSS CoverDocument2 pagesBearing LSS CoverRagul0042No ratings yet

- J-A1 Ds-02.pautDocument2 pagesJ-A1 Ds-02.pautKuppan Srinivasan100% (1)

- QC 64256-1 Ring Spacer Inspection ReportDocument1 pageQC 64256-1 Ring Spacer Inspection ReportSenthil KumarNo ratings yet

- Inspection Report: L/S Set Up For Main Shell Seam No - LS1, LS2Document1 pageInspection Report: L/S Set Up For Main Shell Seam No - LS1, LS2Sales Creative EngineeringNo ratings yet

- Snap Head RivetDocument1 pageSnap Head RivetVilasNo ratings yet

- H.M.W.S. & S.Board: Stores IndentDocument3 pagesH.M.W.S. & S.Board: Stores IndentMir AliNo ratings yet

- Ppe MatrixDocument3 pagesPpe MatrixABHISHEK PANDEYNo ratings yet

- DPR-C8MFP - LTS3000 - 004 Dated On 07.03.2020Document1 pageDPR-C8MFP - LTS3000 - 004 Dated On 07.03.2020KRISHNAN ELANGOVANNo ratings yet

- ITEM NO. (Service) : Inspection Report Hot Oil Heater (Vertical On Ground)Document2 pagesITEM NO. (Service) : Inspection Report Hot Oil Heater (Vertical On Ground)Alif Rahmat FebriantoNo ratings yet

- Layout InspectionDocument1 pageLayout InspectionKalki KalkiNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Compressive Strength of Concrete Core BS EN 12504-1: Project InformationDocument2 pagesCompressive Strength of Concrete Core BS EN 12504-1: Project Informationraja qammarNo ratings yet

- Test Result: Sample 1 Sample 2Document14 pagesTest Result: Sample 1 Sample 2yogi arohmanNo ratings yet

- DWG No: UCTC-ALM-ISO-161701: Building ADocument1 pageDWG No: UCTC-ALM-ISO-161701: Building AIzaaz AhamedNo ratings yet

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- External Safety Audit Check-List For Onshore Drilling RigsDocument30 pagesExternal Safety Audit Check-List For Onshore Drilling RigsSiddhartha ChakradharNo ratings yet

- Construction Check Sheet Orifice Plate Pre-Installation Check I-005ADocument1 pageConstruction Check Sheet Orifice Plate Pre-Installation Check I-005AKailash PandeyNo ratings yet

- Roundness Shell # 1 - 1-Tank - 011 BEFORE WELD: Project MTPP66 TK-011 Cyanide Adsorpion TankDocument8 pagesRoundness Shell # 1 - 1-Tank - 011 BEFORE WELD: Project MTPP66 TK-011 Cyanide Adsorpion TankyuwantoniNo ratings yet

- Dimension & Visual Check ReportDocument1 pageDimension & Visual Check Reporteliiiiii50% (2)

- Fastener Designer: Solutions Report: InputDocument5 pagesFastener Designer: Solutions Report: InputVinoth KumarNo ratings yet

- IRDocument1 pageIRflowdewiceNo ratings yet

- SA-6416 Shaft OutputDocument4 pagesSA-6416 Shaft OutputEngineering ProductionNo ratings yet

- Analysis For Increased Defect RateDocument6 pagesAnalysis For Increased Defect RateFaiz IshakNo ratings yet

- Is 8422-7 - 1977 - 5Document1 pageIs 8422-7 - 1977 - 5Svapnesh ParikhNo ratings yet

- Layout Inspection Result Sheet: PQE:01:F07 (PG 1 /)Document3 pagesLayout Inspection Result Sheet: PQE:01:F07 (PG 1 /)Fortune FireNo ratings yet

- Set-Up Approval Report-Bar Comp PillionDocument1 pageSet-Up Approval Report-Bar Comp Pillionswaran autoqaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkartik_harwani4387No ratings yet

- Layout Inspection Report: M/s Pricol LTDDocument35 pagesLayout Inspection Report: M/s Pricol LTDPrakash kumarTripathiNo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

- 1F - P6 Manifold Hubs Heights Survey For Correction (04.12.2022)Document1 page1F - P6 Manifold Hubs Heights Survey For Correction (04.12.2022)chancele nguepdjopNo ratings yet

- Inprocess Check Sheet - Bar Comp.Document1 pageInprocess Check Sheet - Bar Comp.swaran autoqaNo ratings yet

- Date NPS (Inch) No - of Weld Joints Visual AcceptedDocument19 pagesDate NPS (Inch) No - of Weld Joints Visual AcceptedPrasan SJNo ratings yet

- Eye Bolt Inspection Report: Last of ExaminationDocument7 pagesEye Bolt Inspection Report: Last of ExaminationRonniNo ratings yet

- Spindle Center JointDocument2 pagesSpindle Center JointIrwanto ManafNo ratings yet

- NSL West Levee and Flood Wall Hoquiam, WA - DESIGNDocument47 pagesNSL West Levee and Flood Wall Hoquiam, WA - DESIGNk08ivanNo ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- WS09TZ200052Document11 pagesWS09TZ200052sudeepNo ratings yet

- UntitledDocument5 pagesUntitledNithin GNo ratings yet

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- 2F - P6 Manifold Hubs Positions Survey For Correction (04.12.2022)Document1 page2F - P6 Manifold Hubs Positions Survey For Correction (04.12.2022)chancele nguepdjopNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- FM-D-01 Steel Structure ErectionDocument1 pageFM-D-01 Steel Structure ErectionG Vamsi ChandNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Marking & CuttingDocument1 pageMarking & CuttingMohammad FereidNo ratings yet

- Structural Steel Fabrication and Inspection ReportsDocument1 pageStructural Steel Fabrication and Inspection ReportsManoj PrabakaranNo ratings yet

- Elevator Maintenance Inspection Wear DataDocument4 pagesElevator Maintenance Inspection Wear Dataleonardo.mottaNo ratings yet

- 06 R 435 Bow Rod Trail ES To ES ReportDocument4 pages06 R 435 Bow Rod Trail ES To ES ReportPrabhakaran CHNQualityNo ratings yet

- Storage Tank F-9026 Stone Column No SC-9026-52Document1 pageStorage Tank F-9026 Stone Column No SC-9026-52engmaar201037No ratings yet

- BBS - Concrete Block JettyDocument4 pagesBBS - Concrete Block Jettyrony 2222No ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Assey. & Dess - Bogie DrawingDocument1 pageAssey. & Dess - Bogie DrawingShekher NikhilNo ratings yet

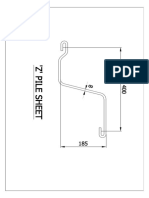

- Z Pile ProfileDocument1 pageZ Pile ProfileShekher NikhilNo ratings yet

- Certificate of Excellence: #1 of 36 Things To Do in UjjainDocument15 pagesCertificate of Excellence: #1 of 36 Things To Do in UjjainShekher NikhilNo ratings yet

- 10 Degree Carb PDFDocument1 page10 Degree Carb PDFShekher NikhilNo ratings yet

- Proforma For Single Wagon Test For Boxnhl For Twin PipeDocument2 pagesProforma For Single Wagon Test For Boxnhl For Twin PipeShekher NikhilNo ratings yet

- BCACBMDocument1 pageBCACBMShekher NikhilNo ratings yet

- 07 Beware of Good ParentsDocument3 pages07 Beware of Good ParentsShekher NikhilNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilNo ratings yet

- BTPGLN 65 MM Plate PDFDocument1 pageBTPGLN 65 MM Plate PDFShekher NikhilNo ratings yet

- WDM-0001 On 15.6Document174 pagesWDM-0001 On 15.6Shekher NikhilNo ratings yet

- Single Pipe Graduated Release Air Brake System.: Difrence For BTPGLN Wagon Variant - A & B Variant - ADocument3 pagesSingle Pipe Graduated Release Air Brake System.: Difrence For BTPGLN Wagon Variant - A & B Variant - AShekher NikhilNo ratings yet

- BCNHL Design e Pipe DRGDocument1 pageBCNHL Design e Pipe DRGShekher NikhilNo ratings yet

- BTPGLN 65 MM PlateDocument1 pageBTPGLN 65 MM PlateShekher NikhilNo ratings yet

- Bosths WagonDocument1 pageBosths WagonShekher NikhilNo ratings yet

- Gerenal Item Bu ItemDocument3 pagesGerenal Item Bu ItemShekher NikhilNo ratings yet

- DUCT (DRG - NO. 1-48-462-40878) Item No Description Length Width Thick Qty. PLATE 7mmDocument17 pagesDUCT (DRG - NO. 1-48-462-40878) Item No Description Length Width Thick Qty. PLATE 7mmShekher NikhilNo ratings yet

- DB Schenker Rail Flyer SteelSolutionDocument2 pagesDB Schenker Rail Flyer SteelSolutionShekher NikhilNo ratings yet

- 4264 Erection Offer - 24.12.10Document6 pages4264 Erection Offer - 24.12.10Shekher NikhilNo ratings yet

- Comp. Bost WagonDocument1 pageComp. Bost WagonShekher NikhilNo ratings yet

- Offset Curve ModelDocument1 pageOffset Curve ModelShekher NikhilNo ratings yet

- BTPN Store PDocument2 pagesBTPN Store PShekher NikhilNo ratings yet

- Bobyn WagonDocument1 pageBobyn WagonShekher NikhilNo ratings yet

- Way Wise AreaDocument2 pagesWay Wise AreaShekher NikhilNo ratings yet

- Bobsn Rivet ListDocument2 pagesBobsn Rivet ListShekher NikhilNo ratings yet

- List of Bought Out Compt.Document5 pagesList of Bought Out Compt.Shekher NikhilNo ratings yet

- WD-12027-S-16 ModelDocument1 pageWD-12027-S-16 ModelShekher NikhilNo ratings yet

- 4264 Supply OfferDocument7 pages4264 Supply OfferShekher NikhilNo ratings yet

- List of Bending FixturesDocument2 pagesList of Bending FixturesShekher NikhilNo ratings yet

- Balancing of Rotating MassesDocument29 pagesBalancing of Rotating Masseskumar kmNo ratings yet

- Class V - Eng - Key - Modules 1 To 12Document8 pagesClass V - Eng - Key - Modules 1 To 12Srinivasa Reddy KarriNo ratings yet

- APE Clinics Manila Location MapDocument12 pagesAPE Clinics Manila Location MapJanice Esguerra-CasaloNo ratings yet

- Systems For Rail Vehicles - by Dr. Jonathan Paddison - Knorr BremseDocument37 pagesSystems For Rail Vehicles - by Dr. Jonathan Paddison - Knorr BremsewmplgrcfNo ratings yet

- ATO SubsetsDocument2 pagesATO SubsetsBrik MalekNo ratings yet

- Tunnel Emer Egress & Mid-Train Fire - R3Document15 pagesTunnel Emer Egress & Mid-Train Fire - R3corson42100% (2)

- Main PaperDocument66 pagesMain PaperAkash MajjiNo ratings yet

- Chap 1 .Ppt. 2012Document68 pagesChap 1 .Ppt. 2012Philimond SegieNo ratings yet

- Cyralie B. Maglipac m3 AnswerDocument2 pagesCyralie B. Maglipac m3 AnswerCyralie MaglipacNo ratings yet

- 09 Manual ReluxSuiteDocument81 pages09 Manual ReluxSuitemtipladyNo ratings yet

- Various Allowances Referred To 7th CPCDocument73 pagesVarious Allowances Referred To 7th CPCGiri KumarNo ratings yet

- Trainz 2004 DRAFT Content Creation ProceduresDocument101 pagesTrainz 2004 DRAFT Content Creation ProceduresAndrei Chirilescu100% (1)

- Catb 2013 eDocument32 pagesCatb 2013 eMohan DakshinaNo ratings yet

- 2014 EMI Conveyor CatalogDocument148 pages2014 EMI Conveyor CatalogcorciniNo ratings yet

- Darjeeling Toy TrainDocument2 pagesDarjeeling Toy TrainAngelina ConnerNo ratings yet

- Advantages: Undergrounding Undergrounding Is The Replacement of Overhead Cables Providing ElectricalDocument5 pagesAdvantages: Undergrounding Undergrounding Is The Replacement of Overhead Cables Providing ElectricalAnonymous GYG8WaiTJNo ratings yet

- Income Tax Jurisdictions Chart - New Revised On 2015Document6 pagesIncome Tax Jurisdictions Chart - New Revised On 2015Ca T.SANKARAMURTHYNo ratings yet

- Psi SpecDocument645 pagesPsi SpecManickavasagam Sadasivam100% (3)

- Cat Rail EN-ENDocument68 pagesCat Rail EN-ENfeltofsnakeNo ratings yet

- 1574 03 Vol 2B DS PackageDocument69 pages1574 03 Vol 2B DS PackageZahoor AhmedNo ratings yet

- MRCB George Kent SDN BHD: Document / Drawing Review Comment Sheet (DRS)Document1 pageMRCB George Kent SDN BHD: Document / Drawing Review Comment Sheet (DRS)Wan Mohamad Noor Hj IsmailNo ratings yet

- Urea Market in Brazil PDFDocument11 pagesUrea Market in Brazil PDFgabydel74No ratings yet

- Medium Voltage Switchgear ProductsDocument32 pagesMedium Voltage Switchgear ProductsdfgNo ratings yet

- OSHA Fixed Ladders DesignDocument7 pagesOSHA Fixed Ladders Designken910076No ratings yet

- Metro Line 4 (Wadala To Kasarvadavali)Document462 pagesMetro Line 4 (Wadala To Kasarvadavali)Anonymous wrHR1JlNo ratings yet

- Introduction For Isbt PatialaDocument8 pagesIntroduction For Isbt Patialaਬਲਦੀਪ ਸਿੰਘ ਸੈਣੀNo ratings yet