Professional Documents

Culture Documents

Techniques For Reducing NOx Emissions From Industrial Boilers

Uploaded by

Naveen ChodagiriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Techniques For Reducing NOx Emissions From Industrial Boilers

Uploaded by

Naveen ChodagiriCopyright:

Available Formats

Techniques for Reducing NOx

Emissions from Industrial Boilers

More than 60,000 industrial boilers exist in the United States. In contrast to

large utility boilers, industrial boilers have received little focus for NOx

emission reductions. However, several alternatives to reduce NOx emissions

currently are available, and others are under development.

Most NOx emissions are derived from nitrogen in the fuels used or from

nitrogen in the combustion air (thermal NOx). For natural gas-red and No. 2

oil-red boilers, thermal NOx represents the majority of NOx produced from

industrial boilers. Thermal NOx emissions increase with increasing peak

ame temperatures and are affected by oxygen availability in the boiler

combustion zone. Several measures to reduce NOx emissions in industrial

boilers are listed in Table 1 and discussed below.

Tune-up and Burner System

Table 1

Modications. Any prudent

NOx reduction measures NOx Reduction Approximate

should begin with a boiler tune- Technique NOx

up to verify and optimize Reduction

current boiler operating Potential

parameters. The ne-tuning of

oxygen and fuel content in the Tune-up and Burner 10-30%

combustion zone can improve System Modications

eciency and reduce NOx

emissions. Beyond simple tune- Burners Out of Service 10-40%

ups, systems can be installed to

Boiler De-rating Up to 30%

automatically monitor and trim

oxygen and fuels for peak Low Excess Air 10-25%

performance. These procedures

must be performed by a Stage Combustion Up to 50+%

qualied individual because

serious hazards can result if Low NOx Burners 40-60%

controls are applied

inappropriately. Alternate Fuels Up to 50%

Burners Out of Service (BOOS). Boilers with multiple burners sometimes

can use BOOS techniques to reduce NOx. By taking one or more burners out

of service, peak ame temperature and the resulting NOx emissions are

reduced by a number of combustion mechanisms.

Boiler De-rating. In some instances, when a facilitys steam demand has

dropped because of phased-out equipment or the implementation of more

energy ecient processes, a boiler can be de-rated to re at lower loads.

Under these circumstances, lowering the ring rate will effectively reduce

NOx emissions.

Low Excess Air. For boilers that use ring or spud

burners, several modications can be made that

control ame length, delay combustion, delay

fuel/air mixing, and reduce peak ame

temperature to reduce NOx. Sometimes air

registers around the burner can be adjusted to

also help reduce NOx.

Stage Combustion. Usually stage combustion can

be achieved only in boilers with large furnace

volumes. Stage combustion allows air and fuel to

react in multiple zones or stages instead of at

once. This process produces lower peak ame

temperatures and other combustion properties

favorable for low NOx emissions.

Low NOx Burners. Available for both new and retrot applications, all low

NOx burners use staged combustion techniques and can reduce NOx

emissions 20 to 40 percent.

Alternate Fuels. Many facilities have modied their boilers to burn natural

gas, which generates less NOx than fuel oils. Methanol and ethanol are other

alternative fuels that can reduce NOx. Also, they may be used as back-up fuels

during natural gas supply shortages. Figure A ranks the NOx emissions for

several fuels.

When considering any measure to reduce boiler NOx emissions, follow these

guidelines: 1) select a qualied consultant, vendor, or service provider, 2)

conduct a boiler characterization, 3) perform the lowest-cost procedures rst,

4) select appropriate NOx reduction measures, 5) implement measures, 6)

retest boiler, and 7) continue proper operation and maintenance.

Return to Focus Index

You might also like

- KTPS V - Review of Forced Outages in Thermal Power PlantDocument24 pagesKTPS V - Review of Forced Outages in Thermal Power PlantNaveen ChodagiriNo ratings yet

- Od Ops Syst 001Document5 pagesOd Ops Syst 001VIBHAVNo ratings yet

- KPIs of Thermal Power Plants (TPPS)Document41 pagesKPIs of Thermal Power Plants (TPPS)Naveen Chodagiri100% (2)

- Design Specifications & THR DeviationsDocument1 pageDesign Specifications & THR DeviationsNaveen ChodagiriNo ratings yet

- 201907171026purchase - Manual PDFDocument165 pages201907171026purchase - Manual PDFRãjendrã Rãjü100% (1)

- Maintenance Planning: SL - No. Description DateDocument2 pagesMaintenance Planning: SL - No. Description DateNaveen ChodagiriNo ratings yet

- BHEL Technical Circulars X-133Document2 pagesBHEL Technical Circulars X-133Naveen Chodagiri100% (1)

- U#09 COH and R&M - LDO ConsumptionDocument4 pagesU#09 COH and R&M - LDO ConsumptionNaveen ChodagiriNo ratings yet

- Unbalance: Dew/Cbpm Lab/JvDocument27 pagesUnbalance: Dew/Cbpm Lab/JvNaveen ChodagiriNo ratings yet

- Vib AnalysisDocument125 pagesVib AnalysisFaruque Khan Yumkhaibam100% (2)

- Sub Outage Managers and Committee Nomination - Reg.: Outage Manager Dy - Outage ManagerDocument1 pageSub Outage Managers and Committee Nomination - Reg.: Outage Manager Dy - Outage ManagerNaveen ChodagiriNo ratings yet

- EmhvDocument1 pageEmhvNaveen ChodagiriNo ratings yet

- Ferrography PresentationDocument56 pagesFerrography PresentationNaveen Chodagiri100% (1)

- SPM TrainingDocument106 pagesSPM TrainingNaveen ChodagiriNo ratings yet

- Relationship Among Displacement, Velocity, Frequency, and Acceleration During Sinusoidal MotionDocument4 pagesRelationship Among Displacement, Velocity, Frequency, and Acceleration During Sinusoidal MotionNaveen ChodagiriNo ratings yet

- Vibration MathDocument4 pagesVibration Mathyianisr5990No ratings yet

- BalancingDocument15 pagesBalancingNaveen ChodagiriNo ratings yet

- BalancingDocument15 pagesBalancingNaveen ChodagiriNo ratings yet

- Training Program On Machine AlignmentDocument42 pagesTraining Program On Machine AlignmentNaveen ChodagiriNo ratings yet

- QuickGuide Vibration Testing MachinesDocument2 pagesQuickGuide Vibration Testing MachinesMiulenNo ratings yet

- Kothagudam: Operation & Maintenance Instruction ManualDocument1 pageKothagudam: Operation & Maintenance Instruction ManualNaveen ChodagiriNo ratings yet

- Vibration Control Unit Conversion Charts and ConstantsDocument7 pagesVibration Control Unit Conversion Charts and ConstantsNaveen ChodagiriNo ratings yet

- Journal-Bearing Fault Detection Based On Vibration Analysis Using Feature Selection and Classification TechniquesDocument4 pagesJournal-Bearing Fault Detection Based On Vibration Analysis Using Feature Selection and Classification TechniquesNaveen ChodagiriNo ratings yet

- Kothagudam: 1 X 500 MW BoilerDocument1 pageKothagudam: 1 X 500 MW BoilerNaveen ChodagiriNo ratings yet

- Job Safety AnalysisDocument30 pagesJob Safety AnalysisNaveen ChodagiriNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Env PresentationDocument11 pagesEnv PresentationNaveen ChodagiriNo ratings yet

- Power Plant ChemistryDocument101 pagesPower Plant ChemistryNaveen ChodagiriNo ratings yet

- TS BSRP Study 2017Document13 pagesTS BSRP Study 2017Naveen ChodagiriNo ratings yet

- Black Start Restoration (BSR) : SRLDC, BangaloreDocument36 pagesBlack Start Restoration (BSR) : SRLDC, BangaloreNaveen ChodagiriNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hope Hospital Self Assessment ToolkitDocument120 pagesHope Hospital Self Assessment Toolkitcxz4321No ratings yet

- 107 2021 High Speed Rail Corridor RegDocument3 pages107 2021 High Speed Rail Corridor Rega siva sankarNo ratings yet

- Making Creams With Olive M 1000Document28 pagesMaking Creams With Olive M 1000Nicoleta Chiric0% (1)

- SanMilan Inigo Cycling Physiology and Physiological TestingDocument67 pagesSanMilan Inigo Cycling Physiology and Physiological Testingjesus.clemente.90No ratings yet

- Updoc - Tips Dictionar Foraj e RDocument37 pagesUpdoc - Tips Dictionar Foraj e RDaniela Dandea100% (1)

- K EtaDocument14 pagesK EtaJosue Teni BeltetonNo ratings yet

- Latest Low NOx Combustion TechnologyDocument7 pagesLatest Low NOx Combustion Technology95113309No ratings yet

- Sanctuary Policy PomonaDocument3 pagesSanctuary Policy PomonaGabriel EliasNo ratings yet

- Solar Refrigeration: Prepared by M.DevakumarDocument21 pagesSolar Refrigeration: Prepared by M.DevakumarEasy StudyNo ratings yet

- Sav4747 PDFDocument49 pagesSav4747 PDFAndres Antonio Moreno CastroNo ratings yet

- Cargador de BateríaDocument34 pagesCargador de BateríaBenNo ratings yet

- EXP 2 - Plug Flow Tubular ReactorDocument18 pagesEXP 2 - Plug Flow Tubular ReactorOng Jia YeeNo ratings yet

- Join Our Telegram Channel: @AJITLULLA: To Get Daily Question Papers & SolutionsDocument24 pagesJoin Our Telegram Channel: @AJITLULLA: To Get Daily Question Papers & SolutionsNaveen KumarNo ratings yet

- Gendec - Inbound HS-HTNDocument1 pageGendec - Inbound HS-HTNKhalidNo ratings yet

- Flame Retardant and Fire Resistant Cable - NexansDocument2 pagesFlame Retardant and Fire Resistant Cable - NexansprseNo ratings yet

- Class Two Summer Vacation AssignmentDocument1 pageClass Two Summer Vacation AssignmentshahbazjamNo ratings yet

- Riber 6-s1 SP s17-097 336-344Document9 pagesRiber 6-s1 SP s17-097 336-344ᎷᏒ'ᏴᎬᎪᏚᎢ ᎷᏒ'ᏴᎬᎪᏚᎢNo ratings yet

- Pay Details: Earnings Deductions Code Description Quantity Amount Code Description AmountDocument1 pagePay Details: Earnings Deductions Code Description Quantity Amount Code Description AmountVee-kay Vicky KatekaniNo ratings yet

- Guides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IDocument136 pagesGuides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IdaggaboomNo ratings yet

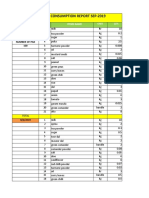

- Daily Staff Food Consumption Reports Sep-2019Document4 pagesDaily Staff Food Consumption Reports Sep-2019Manjit RawatNo ratings yet

- 2 Dawn150Document109 pages2 Dawn150kirubelNo ratings yet

- Soil Biotechnology (SBT) - Brochure of Life LinkDocument2 pagesSoil Biotechnology (SBT) - Brochure of Life Linkiyer_lakshmananNo ratings yet

- SGT PDFDocument383 pagesSGT PDFDushyanthkumar DasariNo ratings yet

- ASOTDocument4 pagesASOTemperors_nestNo ratings yet

- AMS 48 - 2000-n - D0114354 - 055 - 00Document116 pagesAMS 48 - 2000-n - D0114354 - 055 - 00wanhall100% (1)

- Report On Analysis of TSF Water Samples Using Cyanide PhotometerDocument4 pagesReport On Analysis of TSF Water Samples Using Cyanide PhotometerEleazar DequiñaNo ratings yet

- Chapter 2 and 3 ImmunologyDocument16 pagesChapter 2 and 3 ImmunologyRevathyNo ratings yet

- G103 Remov Waste Dust Extraction UnitDocument2 pagesG103 Remov Waste Dust Extraction UnitJoseCRomeroNo ratings yet

- User ManualDocument21 pagesUser ManualKali PrasadNo ratings yet

- HVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionsDocument1 pageHVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionssoftallNo ratings yet