Professional Documents

Culture Documents

Rolling Element Bearing Problem

Uploaded by

Anibal QuezadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rolling Element Bearing Problem

Uploaded by

Anibal QuezadaCopyright:

Available Formats

Rolling element bearing problem

The vibrations caused by bearings are called bearing tones. All antifriction bearings generate

more or less high levels of lagertoner. The more worn the bearing becomes the higher the

levels of the bearing tones are.

An incorrect bearing generates vibrations not exact multiples of 1xRPM, i.e. asynchronous

vibration components. Except these components bearing faults can also generate a broad

banded noise.

There are four different types of bearing tones:

Fundamental Train Frequency (FTF) = The rotational speed of the train, usually 0.4

multiplied with the rotational speed. FTF seldom appears in vibration spectrums as the train

hardly carry any load.

Ball rotation frequency (BSF) = The balls or rollers rotaional speed. A hole in a ball/roller

causes BSP to appear in the frequency spectrum.

Ball passage frequency, outer race (BPFO) = The rate of which the ball/roller passes a

defect in the outer race. This frequency is estimated as:

the number of rollers x rotational speed x 0.4.

Ball passage frequency, inner race (BPFI) = The rate of which a ball/roller passses a defect

in the inner race. The level of BPFI is often slightly lower than BPFO as the vibration is

generated further away from the transducer. The vibration has to pass through the roller and

the outer rece before it is registrated. BPFI is estimated as

the number of rollers x rotational speed x 0.6.

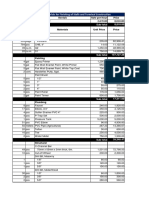

Source of Exciting Dominating Spectral

Amplitude Comments

vibration frequency direction characteristic

Defect inner ring, Bpfi, multiples Asynchronous

Radial Constant Radial load

small single defect on bpfi peaks

Bpfi, with

Defect inner ring, Asynchronous

multiples and Amplitude Radial load increase

increased single Radial peaks with

side band on 1 modulated level

defect sideband on 1 X

X

Bpfi and

Defect inner ring, two High, broadband noise,

significant Radial Broadband

or three small defects constant increase in level

multiples

Defect inner ring many

Bpfi and

small defects with High, Asynchronous Broadband noise,

significant Radial

damage all around the constant peaks increase in level

multiples

bearing race

Multiples have higher

Defect outer ring, Bpfo and Asynchronous

Radial Constant level than basic

small single defect multiples peaksr

frequrncy

Defect outer ring,

Bpfo and Increased broaband

increased single Radial Constant Broad band

multiples noise level

defect

Defect ball or roller, Bsf and

Radial Constant Narrow band

single ball defect multiples

Bsf and High, Increased broaband

More defect balls Radial Narrow band

multiples constant noise level

Damaged fundamental

Broadband

train, broken at one Radial Broad band Low level on noise

noise

place

Fundamental train Broadband Noise due to fragments

Radial Broad band

broken in pieces noise from FTF in the bearing

High frequency

Bad pretension or oil Natural bearing

noise Radial Broad band

film frequency

haystack

Number of multiples

Loose bearing, and the amplitude is a

1 X multiples Radial Narrow band

rotation around shaft measure of how loose

the bearing is.

Loose mount in Increased low

1X, 2X, 4X Radial Narrow band

bearing house frequency noise floor.

Severe looseness or 0,5 X and 4X to 8X and/or 7X to

Radial

bearing fault multiples 15X

180 degrees phase

1X, 2X bearing High difference at the axial

Cocked bearing Axial, radial Narrow band

frequences constant direction at each side

of the bearing house.

Note:

X = speed (RPM)

ftf = fundamental train frequency (approx. = 0,38X to 0,42X)

bsf = ball rotation frequency (approx. = 1,5X to 3X)

bpfi = ball pass frequency, inner ring (approx. = 4X to 10X)

bpfo = ball pass frequency, outer ring (approx. = 2X to 7X)

http://www.vtab.se/training/vibration-school/rolling-element-bearing-problem/?lang=en

You might also like

- Condition Monitoring of Centrifugal Blower Using Vibration AnalysisDocument10 pagesCondition Monitoring of Centrifugal Blower Using Vibration AnalysismustafaNo ratings yet

- Identification of Bearing Defects by Spectral AnalysisDocument6 pagesIdentification of Bearing Defects by Spectral AnalysisShashankSharmaNo ratings yet

- Frequency Transformation in Digital DomainDocument5 pagesFrequency Transformation in Digital DomainNguyen Si PhuocNo ratings yet

- Theory of Machines - I: Question Bank (Numericals) Velocity and Acceleration Analysis of Mechanisms: Graphical MethodsDocument18 pagesTheory of Machines - I: Question Bank (Numericals) Velocity and Acceleration Analysis of Mechanisms: Graphical Methodsvijaykumar327No ratings yet

- Dynamic Signal Analysis BasicsDocument18 pagesDynamic Signal Analysis BasicsDina ArzinaNo ratings yet

- Pump Vibration Monitoring InstrumentsDocument4 pagesPump Vibration Monitoring Instrumentssubramanyanvenkat6185No ratings yet

- Ultraprobe 2000: The Ultimate Analog Ultrasonic Inspection System For Predictive MaintenanceDocument2 pagesUltraprobe 2000: The Ultimate Analog Ultrasonic Inspection System For Predictive MaintenanceMuhammad YahyaNo ratings yet

- A Textbook of Machine Design by R.S.khurMI and J.K.guptADocument17 pagesA Textbook of Machine Design by R.S.khurMI and J.K.guptAVikas SharmaNo ratings yet

- Vibration AnalysisDocument4 pagesVibration Analysisrishan33100% (1)

- 802 Baikeling BWTDocument3 pages802 Baikeling BWTRifat AzadNo ratings yet

- Rolling Element Bearings Vibration AnalysisDocument10 pagesRolling Element Bearings Vibration AnalysisSiva Kulanji100% (1)

- Infrared Thermography Inspection - Electrical Case Study of MCC DisconnectDocument9 pagesInfrared Thermography Inspection - Electrical Case Study of MCC DisconnectRajib100% (1)

- Up9000 ManualDocument33 pagesUp9000 Manualho-faNo ratings yet

- IRTLevel1 3TrainingBrochureDocument12 pagesIRTLevel1 3TrainingBrochuregedearthanaNo ratings yet

- THERMAL AND HEAT CONCEPTS - Modified PPTDocument54 pagesTHERMAL AND HEAT CONCEPTS - Modified PPTKwame DowridgeNo ratings yet

- Low Frequency EvaluationDocument13 pagesLow Frequency EvaluationthrillerxNo ratings yet

- 2 - Slow Speed Vibration Signal AnalysisDocument9 pages2 - Slow Speed Vibration Signal AnalysisSasi NimmakayalaNo ratings yet

- Vibration Analysis Rolling Element BearingDocument20 pagesVibration Analysis Rolling Element BearingmilaNo ratings yet

- Problemas Rotor UTDocument35 pagesProblemas Rotor UTClaudio PinoNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Detecting Rolling Element Bearing Faults With Vibration AnalysisDocument20 pagesDetecting Rolling Element Bearing Faults With Vibration AnalysiscatraioNo ratings yet

- CM3146 en FRF Testing-How Select Correct HammerDocument8 pagesCM3146 en FRF Testing-How Select Correct HammerLuisSilvaNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- T19101 118Document18 pagesT19101 118Chintan Raval100% (1)

- Fundamentals of VibrationDocument99 pagesFundamentals of Vibrationjide.atolagbe3737No ratings yet

- Signal Processing Dan Analisis Vibrasi: Januari 2021Document19 pagesSignal Processing Dan Analisis Vibrasi: Januari 2021Fifth AnalistNo ratings yet

- Vib1 by IjazDocument162 pagesVib1 by IjazAbdul Raheman Mohammed100% (2)

- A Review of Enveloping and Demodulation TechniquesDocument6 pagesA Review of Enveloping and Demodulation TechniquesMohamed WahidNo ratings yet

- Making The Case For Plant-Wide Condition MonitoringDocument8 pagesMaking The Case For Plant-Wide Condition MonitoringAbdulrahman Alkhowaiter100% (1)

- Vibration & Fault DiagnosisDocument4 pagesVibration & Fault DiagnosisSheraNo ratings yet

- CM3152 en SKF Idler Sound MonitorDocument4 pagesCM3152 en SKF Idler Sound MonitorLuisSilvaNo ratings yet

- Vibration Assessment Quiz To Determine Entry Vs Analysis IDocument2 pagesVibration Assessment Quiz To Determine Entry Vs Analysis IAhmad DanielNo ratings yet

- Seismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationFrom EverandSeismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationNo ratings yet

- Vibration Analysis of Turbo Machines - Case Studies - Murilo CamisãoDocument67 pagesVibration Analysis of Turbo Machines - Case Studies - Murilo Camisãojoao batista alvesNo ratings yet

- Maintworld 4 - 2017Document52 pagesMaintworld 4 - 2017Yassine MESSAOUDNo ratings yet

- Motors:: The Past Is PresentDocument6 pagesMotors:: The Past Is Presenteko bagus sunaryoNo ratings yet

- Nico International: Hazards Identification & Risk AssessmentDocument4 pagesNico International: Hazards Identification & Risk AssessmentkazishahNo ratings yet

- About The Infrared Training CentreDocument8 pagesAbout The Infrared Training CentreAleksandar StojanovicNo ratings yet

- 03 IR Camera OperationDocument10 pages03 IR Camera OperationAleksandar StojanovicNo ratings yet

- 10 - 01 - 2007 - Kochanek - The Importance of Spatial Resolution in Infrared Thermography Temperature Measurements - 3 Brief Case StudiesDocument9 pages10 - 01 - 2007 - Kochanek - The Importance of Spatial Resolution in Infrared Thermography Temperature Measurements - 3 Brief Case Studieslbk50No ratings yet

- FFTDocument2 pagesFFTgoharmahmoodkhokharNo ratings yet

- High Frequency Vibration AnalysisDocument22 pagesHigh Frequency Vibration AnalysisMohamed BelallNo ratings yet

- SPM Bearing Checker InstructionDocument42 pagesSPM Bearing Checker Instructionmilos dzinoNo ratings yet

- Acceleration Enveloping - Higher Sensitivity, Earlier DetectionDocument10 pagesAcceleration Enveloping - Higher Sensitivity, Earlier Detectionsureshkumar908No ratings yet

- CAT II - EMMU 7241 - Machine Tool Vibrations and Cutting Dynamics-Marking SchemeDocument14 pagesCAT II - EMMU 7241 - Machine Tool Vibrations and Cutting Dynamics-Marking SchemeCharles OndiekiNo ratings yet

- 71951B LeonovaDiamond SpreadDocument8 pages71951B LeonovaDiamond SpreadRajesh BeheraNo ratings yet

- iLearnVibration SubjectsDocument10 pagesiLearnVibration SubjectsalcaboneNo ratings yet

- Tutorial Diagnostics Randall PDFDocument84 pagesTutorial Diagnostics Randall PDFkfathi55No ratings yet

- Basic Vibration Signal Processing For Bearing Fault DetectionDocument8 pagesBasic Vibration Signal Processing For Bearing Fault DetectionGuru PrakashNo ratings yet

- MH pgs0700Document15 pagesMH pgs0700Hamza Nouman100% (1)

- Basics of Turbomachinery BalanceDocument14 pagesBasics of Turbomachinery BalanceSuthan RNo ratings yet

- Temperature Effects On DC Motor Performance 1Document10 pagesTemperature Effects On DC Motor Performance 1BabuNo ratings yet

- SDT Success StoriesDocument112 pagesSDT Success StoriesPablo LazoNo ratings yet

- Vibration SensorsDocument93 pagesVibration Sensorsthai huynh leNo ratings yet

- Basic-Engineering - Electrical EngineeringDocument227 pagesBasic-Engineering - Electrical EngineeringE-m FunaNo ratings yet

- Harmonics Training May 2012 WebinarDocument35 pagesHarmonics Training May 2012 WebinarMarvin TejerinaNo ratings yet

- Shock Pulse MeasuringDocument4 pagesShock Pulse MeasuringyancNo ratings yet

- Propeller Shaft EarthingDocument1 pagePropeller Shaft EarthingclinthenNo ratings yet

- Laplace Transform Review: ExampleDocument3 pagesLaplace Transform Review: ExampleSandhyaNo ratings yet

- Using PeakVue Plus Technology For Detecting Anti Friction Bearing FaultsDocument11 pagesUsing PeakVue Plus Technology For Detecting Anti Friction Bearing Faultseko bagus sunaryo100% (1)

- 0-WD170-EP442-C0001 - Rev.f - Manual Valve Datasheet & Drawings (Page 53)Document1 page0-WD170-EP442-C0001 - Rev.f - Manual Valve Datasheet & Drawings (Page 53)Anibal QuezadaNo ratings yet

- SS 65TSW16P SwagelokCompany 05-20-2018Document1 pageSS 65TSW16P SwagelokCompany 05-20-2018Anibal QuezadaNo ratings yet

- 2996Document1 page2996Anibal QuezadaNo ratings yet

- 26.bills of Material and Drawings (Page 625)Document1 page26.bills of Material and Drawings (Page 625)Anibal QuezadaNo ratings yet

- PR GDF Suez UruguayDocument2 pagesPR GDF Suez UruguayAnibal QuezadaNo ratings yet

- Transportes Reyes Meza Eirl (August 2014)Document2 pagesTransportes Reyes Meza Eirl (August 2014)Anibal QuezadaNo ratings yet

- 9.steam Seal (Pages 234-303)Document70 pages9.steam Seal (Pages 234-303)Anibal QuezadaNo ratings yet

- Siemens Security Advisory Ssa-945660Document2 pagesSiemens Security Advisory Ssa-945660Anibal QuezadaNo ratings yet

- NO.46 392 CTV Casting Valves KUMWOO (Page 200)Document1 pageNO.46 392 CTV Casting Valves KUMWOO (Page 200)Anibal QuezadaNo ratings yet

- Daihatsu Terios II J200, J210, J211 2006-2014 Air ConditionerDocument68 pagesDaihatsu Terios II J200, J210, J211 2006-2014 Air ConditionerBadis Ait HammouNo ratings yet

- Civic Turbo DieselDocument202 pagesCivic Turbo DieselLuciano PereiraNo ratings yet

- Skoda Fabia 1.4Document2 pagesSkoda Fabia 1.4wnsdNo ratings yet

- FAD Calculation For CompressorDocument2 pagesFAD Calculation For CompressorDurjoy ChakrabortyNo ratings yet

- Dept. Technical Reference Created by Approved byDocument1 pageDept. Technical Reference Created by Approved byakshatNo ratings yet

- College of Engineering - UOZ Department of Petroleum Engineering Reservoir Fluid Properties Stage: Three Student NamesDocument20 pagesCollege of Engineering - UOZ Department of Petroleum Engineering Reservoir Fluid Properties Stage: Three Student NamesShaaban HassanNo ratings yet

- Compound CylinderDocument11 pagesCompound CylinderLiliana Ara GubanNo ratings yet

- Mechanical OperationsDocument3 pagesMechanical Operationstrades korNo ratings yet

- Sinamics Perfect Harmony enDocument16 pagesSinamics Perfect Harmony ensykimk8921No ratings yet

- Mech ANM 2019R1 WS04D-Anisotropic HyperelasticityDocument14 pagesMech ANM 2019R1 WS04D-Anisotropic HyperelasticityDong LINo ratings yet

- 3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionDocument2 pages3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionKris Aileen CortezNo ratings yet

- E Beam WeldingDocument2 pagesE Beam WeldingDhilip DanielNo ratings yet

- Refrigerator: Service ManualDocument19 pagesRefrigerator: Service ManualCesar Calderon GrNo ratings yet

- Cooling System MechanicallDocument23 pagesCooling System MechanicallStuart FerreiraNo ratings yet

- Turbo Machines Lab: Centrifugal and Reciprocating CompressorsDocument38 pagesTurbo Machines Lab: Centrifugal and Reciprocating CompressorsUpendra SravanNo ratings yet

- Flexible Design - Geo Synthetic LCR MethodDocument14 pagesFlexible Design - Geo Synthetic LCR MethodartiNo ratings yet

- Manual March Te-7k-MdDocument2 pagesManual March Te-7k-MdjoseNo ratings yet

- Copeland PDFDocument1 pageCopeland PDFEdwin GallegosNo ratings yet

- Refresher No.4 (Pipe)Document5 pagesRefresher No.4 (Pipe)chyno.kang08No ratings yet

- Simplified Analysisof Continuous BeamsDocument8 pagesSimplified Analysisof Continuous BeamsMin Thiha NaingNo ratings yet

- Fluid Lab Report 1Document7 pagesFluid Lab Report 1TamaraTwal100% (1)

- Nissan RB Engine - WikipediaDocument60 pagesNissan RB Engine - WikipediaZedrick Nell100% (2)

- Scheda Tecnica: IT-T1S Itb-T1SDocument1 pageScheda Tecnica: IT-T1S Itb-T1SITALFIL S.p.A.No ratings yet

- Axera D07Document79 pagesAxera D07Percy Chero100% (2)

- Testing and Adjusting: Troubleshooting Problem ListDocument101 pagesTesting and Adjusting: Troubleshooting Problem ListJose DarioNo ratings yet

- BR Cat VF-W STD Eng r07 1Document268 pagesBR Cat VF-W STD Eng r07 1Brian LeslieNo ratings yet

- Overcoming Pipeline Access ConstraintsDocument12 pagesOvercoming Pipeline Access ConstraintsDheeraj Chowdary DhanekulaNo ratings yet

- Orientation Syllabus Thermo 2Document16 pagesOrientation Syllabus Thermo 2Kenneth Rodriguez HerminadoNo ratings yet

- King Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerDocument4 pagesKing Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerMikeNo ratings yet

- DepbDocument65 pagesDepbomkarniranjanNo ratings yet