Professional Documents

Culture Documents

Office furniture testing standards BIFMA ANSI

Uploaded by

Ritesh BijawatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Office furniture testing standards BIFMA ANSI

Uploaded by

Ritesh BijawatCopyright:

Available Formats

What standards are used to test office furniture?

The most common standards used, in Canada and the United States are the BIFMA

standard. BIFMA is the Business and Institutional Furniture Manufacturer's Association.

When applying for a Canadian NMSO or QPL, these standards will be called up in the

applicable CAN/CGSB standard or GPD.

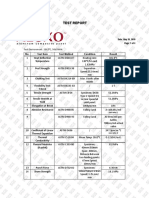

Here is a table detailing the ANSI/BIFMA standards required by each CAN/CGSb and

GPD specification.

Government ANSI/BIFMA

Product

document (current)

Can/CGSB 44.227 Freestanding Furniture X5.5-1998

Can/CGSB 44.229 Panel system X5.6-2003

CAN/CGSB 44.232 Task chair X5.1-2002

GPD-2 Desking system X5.5-1998

GPD-6 Side chair X5.1-2002

GPD-10 Metal filing & storage X5.3-1997 or X5.9-2004

GPD-12 Cafeteria seating X5.1-2002

GPD-13 Lounge seating X5.4-2005

The following is a ,ore exhausitve list of office furniture testing standards we use

(excluding the finish testing standards such as ASTM D-3363)

• ANSI/BIFMA X5.1-2002: Office Chairs

• ANSI/BIFMA X5.2-1997: Lateral Files (Now obsolete and replaced by 5.9)

• ANSI/BIFMA X5.3-1997:Vertical Files

• ANSI/BIFMA X5.4-2005: Lounge Seating

• ANSI/BIFMA X5.5-1998: Desk Products

• ANSI/BIFMA X5.6-2003: Panel Systems

• ANSI/BIFMA X5.9-2004: Storage Units

• ANSI/SOHO S6.5-2001: Home office, small office furniture

Climate exposure and accelerated ageing

Micom Laboratories Inc. offers tests for climate exposure and accelerated ageing.

• Environmental testing (Humidity, temperature cycling)

(-73°C à +150°C, 10 – 95% RH)

• Weatherometry, U.V. exposure (ASTM G 155)

• Salt spray (ASTM B-117)

• Accelerated ageing by temperature

• Reconstruction in a laboratory environment of ageing problems

• Thermal shocks

• High and low temperature tensile and compression tests.

Our testing services allow you to simulate conditions of useage and ageing of your

products thereby allowing you to minimize any medium to long term risks associated

with your products being used in a given environment.

Corrugated board testing

Micom offers a wide range of testing for corrugated board, listed below.

• Abrasion Taber (T 426)

• Board Analysis (T 410)

• Board Quality Analysis (T 410)

• Board Thickness (T 411)

• Boat Method (T 819)

• Burst (Mullen) (T 807,810)

• Cobb

• Coefficient of Friction (T 815)

• Construction

• Edge Crush Test (T 811)

• Flat Crush (T 825)

• Float Curl (T 832)

• Manufacturer’s Joint Tensile Test (T 813)

• Moisture Content at Equilibrium (T 412)

• Pin Adhesion (T 821)

• Score Quality Test (T 829)

• Tear Resistance (T 414)

• Tensile Strength (T 494)

• Thickness (T411)

• Water Absorption of Corrugated Medium

• Water Drop (T 835)

We also offer box compression, moisture adhsive test (regular, moisture resistant and

waterproof) as well as testing related to the transport of Dangerous Good regulations.

Material testing

From compressive strength to UV exposition, Micom offers a wide range of material

testing services.

• Environmental Exposure

• Temperature & humidity cycling

• Ultraviolet exposure

• Weatherometry

• Xenon Arc

• Mechanical properties (tensile, compression, flexural)

• Surface finishes

• Corrosion resistance

• Salt spray tester

This is a partial list of the tests available:

• Tensile Strength (ASTM D-638, D-1623, D-2990, D-5574)

• Compressive Strength (ASTM D-695, D-2990, D-4762)

• Flexural Strength (ASTM D-790, D3043, D-5616)

• Taber Abrasion (ASTM D-4060)

• Foam (ASTM D-3574)

• Heat resistance ASTM D-790, II-B @ 180¾ F

• Moisture Absorption ASTM D-570

• Specific Gravity ASTM D-792

• Particle Board Testing ASTM D-1037

• Weatherometry (U.V. exposure) (ASTM G-26, G53)

• High Pressure Decorative Laminates ANSI/NEMA LD3

• Adhesives (ASTM C-297)

• Corrosion Resistance (ASTM B-117)

• Coefficient of Friction

• Hardness

• Specific Gravity

• Tear and Shear Strength

Packaging testing

Micom now offers the packaging testing services listed below. Our packaging lab is

ISTA accredited (International Safe Transit Association).

These tests are included by ISTA and NMFTA (National Motor Freight Transport

Association) in their test plans:

• ISTA 1a, 1b, 1c, 1d, 1e, 2a, 2b, 2c, 2d, 2e, 3a, 3e, 3f, 4ab, 5b, 7a, 7b, 7c, 7d

• NMFTA rule 180, 181

• Transportation of Dangerous Goods Regulation (UN, CAN/CGSB-43.150 &

43.146)

• Vibration (ASTM D 999, A1, A2)

• Drop (ASTM D 5276)

• Compression (ASTM D 642)

• Incline Impact (ASTM D 880)

• Atmospheric Conditioning (ASTM D4332) (-73°C to +150°C, 10–95% RH)

• Bridge Test (ASTM D-5265)

• Thermal Insulation Quality of Packages (ASTM D-3103)

• Rotational Drop (ASTM D-6179)

• Random vibration (ASTM D-4728)

• Performance Testing of Shipping Containers and Systems (ASTM D-4169)

• Packaging design & optimization

A proper packaging design will allow you to achieve the following:

• Efficiently protect the package contents

• Minimize rate of product return due to transport & handling failures

• Increase customer satisfaction

• Increase profitability

You might also like

- Crush Tester (RCT Ect FCT Pat)Document1 pageCrush Tester (RCT Ect FCT Pat)Rohit ChawlaNo ratings yet

- Boe Linien en 090616onlinedoppelseite PDFDocument19 pagesBoe Linien en 090616onlinedoppelseite PDFxavicojmNo ratings yet

- Nanocellulose Film ProductionDocument1 pageNanocellulose Film ProductiongoldennanukNo ratings yet

- Packing Standard PDFDocument9 pagesPacking Standard PDFMuthuswamyNo ratings yet

- Metal Bearing Waste Streams: Minimizing, Recycling and TreatmentFrom EverandMetal Bearing Waste Streams: Minimizing, Recycling and TreatmentNo ratings yet

- World standards for testing corrugated board propertiesDocument14 pagesWorld standards for testing corrugated board propertiesCesar NietoNo ratings yet

- Surface Contamination: Proceedings of a Symposium Held at Gatlinburg, Tennessee, June 1964From EverandSurface Contamination: Proceedings of a Symposium Held at Gatlinburg, Tennessee, June 1964B. R. FishNo ratings yet

- Packaging TermsDocument32 pagesPackaging TermsAbhineet Shrivastava100% (1)

- Boxes - Performance - Mullen Test and ECT - Richmond Corrugated Box CompanyDocument4 pagesBoxes - Performance - Mullen Test and ECT - Richmond Corrugated Box CompanysatyamedNo ratings yet

- ISTA GuidelinesDocument16 pagesISTA GuidelinestairelkNo ratings yet

- General Issues and The Recommended StandardsDocument60 pagesGeneral Issues and The Recommended StandardsTomislav RogićNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- Scratch Resistance Test BSENISO15182001Document14 pagesScratch Resistance Test BSENISO15182001Jose Antonio Lucero CruzNo ratings yet

- Containerization and Palletization in Rail TransportDocument42 pagesContainerization and Palletization in Rail TransportFahmi_mukhtarNo ratings yet

- Film Test ValidationDocument19 pagesFilm Test Validationjerobu100% (1)

- Medical Coating Innovations - NEW PDFDocument2 pagesMedical Coating Innovations - NEW PDFleonardq1No ratings yet

- Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesDocument8 pagesBurst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesraulNo ratings yet

- Ista 3eDocument4 pagesIsta 3eduygu9merve100% (1)

- Formula For Plastic ProductsDocument6 pagesFormula For Plastic ProductsRRSNo ratings yet

- D 2578 - 04 - Rdi1nzgDocument4 pagesD 2578 - 04 - Rdi1nzgaless2056100% (1)

- Technical Explanation of Corrugated Board Structure and PropertiesDocument2 pagesTechnical Explanation of Corrugated Board Structure and PropertiesCraig DaughertyNo ratings yet

- Test Report: Page: 1 of 4 Date: May 26, 2010Document4 pagesTest Report: Page: 1 of 4 Date: May 26, 2010rqfsiypisnvabmtusrNo ratings yet

- ASTM F 382 Experiment - 1 - FoyDocument2 pagesASTM F 382 Experiment - 1 - FoyLucas MlbNo ratings yet

- Packaging Test RequirementDocument54 pagesPackaging Test Requirementjinmao100% (1)

- Mould Sandwich Mould PDFDocument5 pagesMould Sandwich Mould PDFSamir KhNo ratings yet

- Kevlar Cut Protection TestingDocument6 pagesKevlar Cut Protection Testingalvares90No ratings yet

- Ista 6aDocument17 pagesIsta 6aduygu9merve100% (2)

- Film and Flexible Packaging Materials CharacterizationDocument5 pagesFilm and Flexible Packaging Materials CharacterizationsggdgdNo ratings yet

- ESCRDocument3 pagesESCRAvelino Sobrevega Pinuela Jr.No ratings yet

- Everything about plastic filmsDocument16 pagesEverything about plastic filmspraveenNo ratings yet

- Box Compression TestDocument4 pagesBox Compression TestJoan Vidal-KempisNo ratings yet

- 3 A Overview ISTADocument8 pages3 A Overview ISTApbipkgNo ratings yet

- Standard Packing Guideline JICADocument146 pagesStandard Packing Guideline JICAYul Aryono S.No ratings yet

- Charpy ASTM and ISO TestsDocument2 pagesCharpy ASTM and ISO TestsPrashant PuriNo ratings yet

- PKG Materials Standards IIP A A JoshiDocument45 pagesPKG Materials Standards IIP A A JoshiDeepak VermaNo ratings yet

- Astm D494Document3 pagesAstm D494Jony Gutiérrez Abanto0% (1)

- Adsyl and Clyrell Advantage: Boost Performance With Advanced Sealing Resins From Industry Leader LyondellbasellDocument6 pagesAdsyl and Clyrell Advantage: Boost Performance With Advanced Sealing Resins From Industry Leader Lyondellbasellnouman ashrafNo ratings yet

- Paper for medical packaging sterilizationDocument26 pagesPaper for medical packaging sterilizationtruong271230% (1)

- Film Coextrusion Troubleshooting 7832Document28 pagesFilm Coextrusion Troubleshooting 7832Almir MachadoNo ratings yet

- Gloss MeterDocument2 pagesGloss Meterravi00098No ratings yet

- ANSYS Seal Evaluation of EPB Actuator DesignsDocument24 pagesANSYS Seal Evaluation of EPB Actuator Designssvk_ntNo ratings yet

- Iso 3005Document4 pagesIso 3005Pedro Perez La RosaNo ratings yet

- Ista 3aDocument8 pagesIsta 3aduygu9merve33% (3)

- Quality Control - Laser Plastic Welding, Impossibly ConsistentDocument5 pagesQuality Control - Laser Plastic Welding, Impossibly ConsistentJosh BrownNo ratings yet

- 99MAD014M4 Digimatic CaliperDocument2 pages99MAD014M4 Digimatic CaliperermankurNo ratings yet

- Bioplastics: DOI: 10.1002/0471238961.koe00006Document41 pagesBioplastics: DOI: 10.1002/0471238961.koe00006annahiazNo ratings yet

- F 2252 - 03 - RjiyntiDocument2 pagesF 2252 - 03 - RjiyntiAndres Camilo Benitez100% (1)

- Bopp-Busch Quality ManualDocument50 pagesBopp-Busch Quality ManualJOECOOL67No ratings yet

- Sheehan 06 PDFDocument8 pagesSheehan 06 PDFpalani.djpNo ratings yet

- Genset Load Bank Test Fuel TestDocument10 pagesGenset Load Bank Test Fuel TestGautham Raavo PainaiduNo ratings yet

- ASTM D 529 - 00 Enclosed Carbon-Arc Exposures of Bituminous MaterialsDocument3 pagesASTM D 529 - 00 Enclosed Carbon-Arc Exposures of Bituminous Materialsalin2005No ratings yet

- Iso 8096Document28 pagesIso 8096Nasir MajeedNo ratings yet

- D 5628 - 96 R01 - Rdu2mjg - PDFDocument10 pagesD 5628 - 96 R01 - Rdu2mjg - PDFJuan Pablo ApazaNo ratings yet

- ASTM Volume 04.10, July 2016 Wood: Standard Number TitleDocument3 pagesASTM Volume 04.10, July 2016 Wood: Standard Number TitleVila Marchant CristianNo ratings yet

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGMaey AkimNo ratings yet

- MSDS Magnesium Nitrate HexahydrateDocument4 pagesMSDS Magnesium Nitrate HexahydrateCarmen M AvinazarNo ratings yet

- Bilirubin-D Mindray bs-300Document1 pageBilirubin-D Mindray bs-300neofherNo ratings yet

- Army Public School Bhopal: TOPIC:-" "Document20 pagesArmy Public School Bhopal: TOPIC:-" "Gourav Pathariya100% (1)

- Module 6Document104 pagesModule 6rabih87No ratings yet

- Design of Machine Elements GateDocument4 pagesDesign of Machine Elements GateshashankNo ratings yet

- Hydrometallurgical Process For TheDocument11 pagesHydrometallurgical Process For ThemanzoorNo ratings yet

- App1Document12 pagesApp1Diastari KusumawatiNo ratings yet

- 05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesDocument14 pages05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesGirma FikreNo ratings yet

- Rr322105-High Speed AerodynamicsDocument8 pagesRr322105-High Speed AerodynamicsSRINIVASA RAO GANTANo ratings yet

- Astm C 473-03 Standard Test Methods For Physical Testing ofDocument13 pagesAstm C 473-03 Standard Test Methods For Physical Testing ofCharwin Picao100% (1)

- Paint Failures Library - PPT (Read-Only)Document75 pagesPaint Failures Library - PPT (Read-Only)Elhusseiny FoudaNo ratings yet

- Tool Wear MechanismDocument9 pagesTool Wear MechanismDevansh AgrawalNo ratings yet

- Separating Mixtures Summative TestDocument4 pagesSeparating Mixtures Summative TestMisael GregorioNo ratings yet

- Toluene: Safety Data SheetDocument10 pagesToluene: Safety Data SheetLiaHerlianaNo ratings yet

- JR Elite& AIIMS S60 NEET WET - 14 (14-11-23) SyllabusDocument1 pageJR Elite& AIIMS S60 NEET WET - 14 (14-11-23) SyllabussindhukarnikapNo ratings yet

- ActivityDocument1 pageActivityTomy GeorgeNo ratings yet

- Raptor Defender® Fixed Plant LWP PDFDocument20 pagesRaptor Defender® Fixed Plant LWP PDFBorisRakelaGonzalezNo ratings yet

- PDF Kroma 2Document6 pagesPDF Kroma 2Apriani SimaNo ratings yet

- Filled Bulb Temperature Sensors Learning Instrumentation and Control EngineeringDocument4 pagesFilled Bulb Temperature Sensors Learning Instrumentation and Control Engineeringmohamed abourayaNo ratings yet

- Chemistry Aqa A Level AlkenesDocument21 pagesChemistry Aqa A Level AlkenesAttec OinotnaNo ratings yet

- Unit 10 Packet 3 AnswersDocument4 pagesUnit 10 Packet 3 AnswersBrandon BaxterNo ratings yet

- Hello - Bioclad ASTMDocument4 pagesHello - Bioclad ASTMgrrcNo ratings yet

- Cylinder Design Standards WSNZDocument5 pagesCylinder Design Standards WSNZjamilNo ratings yet

- CaseStudy2 WindmillDocument8 pagesCaseStudy2 WindmillAnthony BergemannNo ratings yet

- Basic Hydraulics Bench: Page 1/3 05/2008Document3 pagesBasic Hydraulics Bench: Page 1/3 05/2008brianlaksonoNo ratings yet

- Atomoxetine HydrochlorideDocument3 pagesAtomoxetine Hydrochlorideehsan050628No ratings yet

- Flujo de Caja - Costos de ProducciónDocument11 pagesFlujo de Caja - Costos de ProducciónDanielIgnacioLuengoCordovaNo ratings yet

- Alloy 286Document6 pagesAlloy 286shivam.kumarNo ratings yet

- Engineering Design Guideline Separator Vessel Rev01Document28 pagesEngineering Design Guideline Separator Vessel Rev01Yan Laksana50% (4)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItFrom EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItRating: 4 out of 5 stars4/5 (16)

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Building Construction and DrawingFrom EverandBuilding Construction and DrawingRating: 2.5 out of 5 stars2.5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Residential Construction Performance Guidelines, Contractor ReferenceFrom EverandResidential Construction Performance Guidelines, Contractor ReferenceNo ratings yet