Professional Documents

Culture Documents

Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing Machines

Uploaded by

Innovative Research PublicationsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing Machines

Uploaded by

Innovative Research PublicationsCopyright:

Available Formats

International Journal of Engineering Research ISSN:2319-6890 (online),2347-5013(print)

Volume No.6, Issue No.8, pp : 403-405 1 Aug. 2017

Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based

Digital Printing Machines

Dhirender1, Ankit Boora2, Bijender3

1

UFLEX Ltd., Noida, Utter Pradesh, 2,3Deptt. of Printing Tech., GJUS&T, Hisar, Haryana

Email : dhirender.flex@gmail.com

Abstract: Screen printing and digital printing are most

suitable printing process for printing on shorter run jobs at with a master developed specially designed for the above

current time. Aim of this paper is tocomparatively analyse the purpose. Epson liquid toner printer was used to print with digital

quality of screen printing and liquid ink based digital printing medium. Three types of paper; one coated gloss, coated matt,

process on basis of quality parameters such as solid ink and uncoated papers were identified and taken into

density, hue error, greyness and print sharpness. A test chart consideration for printing. 20 sheets were collected from each of

consisting of high quality images and quality control strip was the above speed and the same was repeated for the three types of

printed in local market with the help of both above processes paper. X-Rite Exact spectrodensitometer was used to check the

and prints were tested to analyse print quality. Solid Ink Density, Hue Error and Greyness. Print sharpness was

analysed with visual standard observer method.

Keywords: Screen Printing, Liquid Toner based Digital

Printing, Solid Ink Density, Hue Error, Greyness, Print

Sharpness DATA COLLECTION AND ANALYSIS

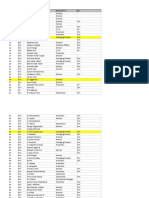

Introduction Table.1. Solid Ink Density Analysis

Quality has been the matter of serious concern among printers.

At one hand screen printing is one of the cheapest printing

process in terms of initial investments, on the other digital

printing came with personalization options with good print

quality. Both printing processes are suitable for short run. So to

compare printing quality among both printing processes is the

need of the hour. A number of quality control parameters are

existing today like solid ink density, dot gain, print contrast, hue

error, greyness, sharpness etc. which are helpful to evaluate

quality of printing. [1],[2],[3].

Research Objectives

Print quality in different printing processes requires different

kind of attention. Objective of project work is:

1. To compare print quality of different paper varieties

printed with screen printing and liquid ink based digital printing

presses.

Research Methodology

Experimentation and comparison work was performed in the

research work.The printing of the test sheets was carried out in

on screen printing machine on the other hand multi-colour liquid

toner based digital presses were available in the local market for

printing work. Gloss coated, matte coated and uncoated paper

stocks weretaken and sample sheets were printed with the help

of printing machine and liquid toner based printing machines. Fig.1. Solid Ink Density Analysis

Finally gloss coated, matte coated and uncoated printed paper

stocks are analyzed to check various quality control parameters.

The printing work of the project was carried out in local market

DOI : 10.5958/2319-6890.2017.00047.2 Page 403

International Journal of Engineering Research ISSN:2319-6890 (online),2347-5013(print)

Volume No.6, Issue No.8, pp : 403-405 1 Aug. 2017

Table.2. Hue Error Analysis

Fig.2. Hue Error Analysis

Fig.4. Print Sharpness Analysis

Table.3. Grayness Analysis

RESULTS AND DISCUSSIONS

Solid Ink Density Analysis

Optimum solid ink density on print is the need of the hour for

printing technocrats. Solid ink density is decided by type of

paper to much extent. Solid ink density was found maximum in

case of screen printing on gloss coated paper as shown in table1

and figure 1. The reason might be very thick layer of around 80

microns in case of screen printing. In case of liquid toner based

printing the solid ink density was found less.

Hue Error Analysis

Hue Error is the evaluation of the larger impurity portion of an

ink. Hue error was found maximum in Magenta color in both

printing processes as shown in Table 2 and Fig. 2. But in case of

screen printing process, hue error was found maximum. Yellow

ink showed minimum hue error in both printing processes.

Greyness Analysis

GreSyness was found more in screen printing process compared

to digital printing process. Black colour showed maximum

grayness compared to other colors. Yellow showed minimum

Fig.3. Grayness Analysis

grayness among all colors. The reason behind more grayness in

Table.4. Print Sharpness Analysis Screen printing is the greater amount of ink being applied in

case of screen printing.

Print Sharpness

DOI : 10.5958/2319-6890.2017.00047.2 Page 404

International Journal of Engineering Research ISSN:2319-6890 (online),2347-5013(print)

Volume No.6, Issue No.8, pp : 403-405 1 Aug. 2017

Digital uncoated paper showed maximum sharpness. Sharpness References

of screen printing process was found less compared to digital

printing, might be due to squeeze pressure being applied on i. Ole Norberg, Patrik Westin, Siv Lindberg, Marianne Klama

stencil. Uncoated paper in screen printing process was least and Lars Eidenval (2001) A Comparison of Print Quality between

Digital and Traditional Technologies, DPP2001: International

sharp.

Conference on Digital Production Printing and Industrial Applications,

page no. 380-385

Conclusion http://www.ami.imaging.org/site/PDFS/Papers/2001/DPP-0-

252/4762.pdf

1. SID of Screen Printing process is more than liquid ii. Robert Chung and Matthew Rees (2007) A Survey of digital

toner based digital printing process. and offset print quality issues Rochester Institute of Technology RIT

2. Hue error of screen printing process is more than that Scholar Work

of liquid toner based digital printing process. http://scholarworks.rit.edu/cgi/viewcontent.cgi?article=1049&context

3. Greyness in ink is more in case of screen printing =books

process. iii. George NubarSirnonian (2003) Comparative Study

4. Print sharpness is more in liquid toner based digital Between Different Digital and Offset Litho Printing Systems

printing process compared to screen printing process. DESIDOC Bulletin of Information Technology, Vol. 23, NO 1. January

2003, pp. 43-55

http://publications.drdo.gov.in/ojs/index.php/djlit/article/view/3590/20

02

DOI : 10.5958/2319-6890.2017.00047.2 Page 405

You might also like

- Durometro - Time - th130 PDFDocument2 pagesDurometro - Time - th130 PDFjoseperezosoNo ratings yet

- Improving Tapping Performance & Increasing Tapping Tool LifeDocument10 pagesImproving Tapping Performance & Increasing Tapping Tool LifeSrikar ShenoyNo ratings yet

- GLIMMDocument22 pagesGLIMMJou RazoNo ratings yet

- ISO 105-E03-2011 Textile Materials. Definition of ResilientDocument12 pagesISO 105-E03-2011 Textile Materials. Definition of ResilientDilhara WickramaarachchiNo ratings yet

- TiN Coating of Tool SteelDocument13 pagesTiN Coating of Tool Steelvitet412759No ratings yet

- Holographic Projection - SahadDocument23 pagesHolographic Projection - SahadSahad MkNo ratings yet

- Fowler Instructions Report EditDocument5 pagesFowler Instructions Report Editapi-550048875No ratings yet

- Tool Wear MechanismDocument8 pagesTool Wear Mechanismnduvu1050% (2)

- Relationship Between Tool Flank Wear Area and Component Forces in Single Point TurningDocument6 pagesRelationship Between Tool Flank Wear Area and Component Forces in Single Point TurningAniruddha GuptaNo ratings yet

- Modeling Flank Wear of Carbide Tool Insert in Metal CuttingDocument12 pagesModeling Flank Wear of Carbide Tool Insert in Metal CuttingBasarabeanuNo ratings yet

- Cash Sorting Cell Stat Bank of PakistanDocument12 pagesCash Sorting Cell Stat Bank of PakistangreathigreatNo ratings yet

- Categories of HologramsDocument2 pagesCategories of HologramsChanNo ratings yet

- Banknotes and Coins March 2015Document11 pagesBanknotes and Coins March 2015Jolina EsmandeNo ratings yet

- CVD 1 PDFDocument11 pagesCVD 1 PDFpichonsisimoNo ratings yet

- AISI Type 430Document3 pagesAISI Type 430Agus MulyadiNo ratings yet

- Gray Scale For Color Change and Gray Scale For Staining: or ISO Test Method 105-X12Document4 pagesGray Scale For Color Change and Gray Scale For Staining: or ISO Test Method 105-X12郭哲宏No ratings yet

- End of Waste - Scrap Metal Case Study: Working DocumentDocument25 pagesEnd of Waste - Scrap Metal Case Study: Working Documentsuresh693sNo ratings yet

- Mil STD 1501bDocument12 pagesMil STD 1501bJuan Pablo ToroNo ratings yet

- XHH03 IntDocument22 pagesXHH03 Intaiurea92No ratings yet

- CH-24-Stainless Steel Notes PDFDocument7 pagesCH-24-Stainless Steel Notes PDFArvind RaguNo ratings yet

- What Is A HologramDocument4 pagesWhat Is A HologramJezibel MendozaNo ratings yet

- About Folded and Crumpled Models in NatureDocument8 pagesAbout Folded and Crumpled Models in NatureWilliam DriepuntnulNo ratings yet

- Holography HistoryDocument27 pagesHolography HistoryasduraiNo ratings yet

- Astm B604 PDFDocument10 pagesAstm B604 PDFcarlosNo ratings yet

- Noida Expressway Properties: By: Sagar SinghDocument19 pagesNoida Expressway Properties: By: Sagar Singhsweetnitzz2183No ratings yet

- Principle of HolographyDocument36 pagesPrinciple of HolographySumanth BodduNo ratings yet

- SW TobaccoDocument8 pagesSW TobaccoMai Hoàng AnhNo ratings yet

- Making Holograms Uniting Art and Science.: by Pearl JohnDocument18 pagesMaking Holograms Uniting Art and Science.: by Pearl Johnepuchulu100% (1)

- Physic Holograms PaperDocument8 pagesPhysic Holograms PaperWesley ShippNo ratings yet

- Indemnity Bond - RatheeDocument2 pagesIndemnity Bond - RatheeGirish SharmaNo ratings yet

- Noida Air Hostess Escorts Services With Hot Young Call GirlsDocument11 pagesNoida Air Hostess Escorts Services With Hot Young Call GirlsmsriyaNo ratings yet

- Is Iso 105 A05 1996Document12 pagesIs Iso 105 A05 1996tramy1413No ratings yet

- Lajpat Nagar ClearoneDocument28 pagesLajpat Nagar ClearoneAmitSamadiyaNo ratings yet

- 2016 Advances in Tool Wear in Turning ProcessDocument14 pages2016 Advances in Tool Wear in Turning ProcessorlandoduranNo ratings yet

- Rockwell Tester 200HRS-150 MFR User GuideDocument21 pagesRockwell Tester 200HRS-150 MFR User GuideuhcmlNo ratings yet

- List of Japanese Company in India PDFDocument42 pagesList of Japanese Company in India PDFVin odNo ratings yet

- Purchae Stationery & Other Store Items PDDLDocument3 pagesPurchae Stationery & Other Store Items PDDLshiekh siddiNo ratings yet

- HolographyDocument7 pagesHolographyAli JahaniNo ratings yet

- UOP952Document12 pagesUOP952goodcharacter1No ratings yet

- Kheadaha2 PDFDocument422 pagesKheadaha2 PDFSukalyan BhadraNo ratings yet

- DIP LucknowDocument20 pagesDIP LucknowParas AgarwalNo ratings yet

- Stationery Catalogue 2011 - FINALDocument18 pagesStationery Catalogue 2011 - FINALAinsley CowellNo ratings yet

- Rohini As A Real EstateDocument23 pagesRohini As A Real EstateSainyam JainNo ratings yet

- DatabaseDocument21 pagesDatabaseMayank AroraNo ratings yet

- Is 278 2009 PDFDocument11 pagesIs 278 2009 PDFjaianit89No ratings yet

- Test Methods For Textile Fibres With Textile LabDocument5 pagesTest Methods For Textile Fibres With Textile LabRezaul Karim TutulNo ratings yet

- JBJBDocument116 pagesJBJBk.saikumarNo ratings yet

- GreenplyDocument8 pagesGreenplyRishi AgarwalNo ratings yet

- InvoicesDocument44 pagesInvoicespavanNo ratings yet

- All India Plastic ManufacturersDocument256 pagesAll India Plastic Manufacturersabhimanyu.xplastNo ratings yet

- Project Report - First PageDocument1 pageProject Report - First PageGirish SharmaNo ratings yet

- Vendor Registration FormDocument3 pagesVendor Registration FormvijaymandiNo ratings yet

- Directory of Its Officers and EmployeesDocument2 pagesDirectory of Its Officers and EmployeespriyakbiswasNo ratings yet

- Muthoot Finance: and The Gold Loan BusinessDocument15 pagesMuthoot Finance: and The Gold Loan BusinessRobbie ShawNo ratings yet

- List of UIDAI Certified Biometric Devices 13072017Document7 pagesList of UIDAI Certified Biometric Devices 13072017kvemanak9733No ratings yet

- Relationship of Solid Ink Density and Dot Gain in Digital PrintingDocument5 pagesRelationship of Solid Ink Density and Dot Gain in Digital PrintingerpublicationNo ratings yet

- IDJ Volume 7 Issue 1 Page 103 107Document5 pagesIDJ Volume 7 Issue 1 Page 103 107Van PhamNo ratings yet

- Digital PrintingDocument14 pagesDigital Printingjoyshree ayekpamNo ratings yet

- Reformatted Paper-2Document4 pagesReformatted Paper-2Bijender KaushikNo ratings yet

- Analysis of Trapping of Color Sequences of Multicolor Offset PrintingDocument7 pagesAnalysis of Trapping of Color Sequences of Multicolor Offset PrintingPavan SamudralaNo ratings yet

- Power Transformer Protection Using Fuzzy Logic Based ControllerDocument5 pagesPower Transformer Protection Using Fuzzy Logic Based ControllerInnovative Research PublicationsNo ratings yet

- 3D Modeling of Complex Structure Based On AutoCAD VBADocument3 pages3D Modeling of Complex Structure Based On AutoCAD VBAInnovative Research PublicationsNo ratings yet

- Case Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageDocument6 pagesCase Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageInnovative Research PublicationsNo ratings yet

- The Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestDocument5 pagesThe Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestInnovative Research PublicationsNo ratings yet

- Computational EconomicsDocument2 pagesComputational EconomicsInnovative Research PublicationsNo ratings yet

- Surveillance NetworksDocument2 pagesSurveillance NetworksInnovative Research PublicationsNo ratings yet

- Wearable ComputingDocument3 pagesWearable ComputingInnovative Research PublicationsNo ratings yet

- Information EngineeringDocument2 pagesInformation EngineeringInnovative Research PublicationsNo ratings yet

- Role of Coaching Institutes in IndiaDocument5 pagesRole of Coaching Institutes in IndiaInnovative Research PublicationsNo ratings yet

- Online Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Document2 pagesOnline Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Innovative Research PublicationsNo ratings yet

- Experimental Study About Soil Improvement With Glass FibersDocument5 pagesExperimental Study About Soil Improvement With Glass FibersInnovative Research PublicationsNo ratings yet

- CFD Analysis of A 210 MW Tangential Fired BoilerDocument6 pagesCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsNo ratings yet

- Computational ElectromagneticsDocument3 pagesComputational ElectromagneticsInnovative Research PublicationsNo ratings yet

- A Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiDocument6 pagesA Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiInnovative Research PublicationsNo ratings yet

- Information Security in Cloud Computing: A Systematic Literature Review and AnalysisDocument6 pagesInformation Security in Cloud Computing: A Systematic Literature Review and AnalysisInnovative Research PublicationsNo ratings yet

- Anilox Offset FirstDocument3 pagesAnilox Offset Firstrafael_faria_4No ratings yet

- Rinoceronte - VitaliStoreDocument13 pagesRinoceronte - VitaliStoreJaimarys RuizNo ratings yet

- Template Extended AbstractDocument3 pagesTemplate Extended AbstractRoy Ruby CaberoyNo ratings yet

- Reading Group Questions For The Rainbow Troops by Andrea HirataDocument2 pagesReading Group Questions For The Rainbow Troops by Andrea HirataRandomHouseAUNo ratings yet

- Entertainment and Media Outlook PDFDocument134 pagesEntertainment and Media Outlook PDFEd NjorogeNo ratings yet

- Projekt 1065 A Novel of World War II by Alan GratzDocument14 pagesProjekt 1065 A Novel of World War II by Alan GratzNoah Glass0% (1)

- Icf 2 Performance Task Portfolio 2023 2024Document7 pagesIcf 2 Performance Task Portfolio 2023 2024marcleonor032No ratings yet

- The Purposeful Millionaire .CUT Final - Redacted PDFDocument281 pagesThe Purposeful Millionaire .CUT Final - Redacted PDFRitu100% (2)

- A Practical Guide To MLADocument13 pagesA Practical Guide To MLADiana Nikkel NanceNo ratings yet

- Polyu Thesis BindingDocument4 pagesPolyu Thesis Bindingmariesmithwilmington100% (1)

- Fr-Covadis Manuel-Conception VRD - CV01 PDFDocument623 pagesFr-Covadis Manuel-Conception VRD - CV01 PDFKesse GblaNo ratings yet

- MIS5010 wk1DBDocument1 pageMIS5010 wk1DBchristiNo ratings yet

- Digizeitschriften: Library Partnership and A Subscription Model For A Journal DatabaseDocument8 pagesDigizeitschriften: Library Partnership and A Subscription Model For A Journal DatabasejengdeleonNo ratings yet

- PRINTERS NotesDocument4 pagesPRINTERS NotesFridah Apondi75% (4)

- The World of BeowulfDocument17 pagesThe World of BeowulfSanti BeuzonNo ratings yet

- History of India TodayDocument13 pagesHistory of India TodayfarromelvynNo ratings yet

- Lincolnshire ObookoDocument27 pagesLincolnshire ObookoAc RaviNo ratings yet

- Repographic ArtDocument7 pagesRepographic Artgemmasitchon1980No ratings yet

- Mla Works Cited FormatDocument4 pagesMla Works Cited FormatCarole Ezell BishopNo ratings yet

- Introduction To Language 10th Edition Fromkin Solutions ManualDocument25 pagesIntroduction To Language 10th Edition Fromkin Solutions ManualEricaGaysoqr100% (63)

- Necip Hablemitoğlu - Çarlık Rusyası'nda Türk Kongreleri by Türkçü Betik - IssuuDocument1 pageNecip Hablemitoğlu - Çarlık Rusyası'nda Türk Kongreleri by Türkçü Betik - IssuuMuhammed Yüksel ÖzgünNo ratings yet

- 09 Lawrence Kramer PDFDocument30 pages09 Lawrence Kramer PDFPaulina SzurgaczNo ratings yet

- University of California Press Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Film QuarterlyDocument3 pagesUniversity of California Press Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Film QuarterlytaninaarucaNo ratings yet

- DirmancukDocument110 pagesDirmancukFigo WinnerkoNo ratings yet

- The Mechanics (And Kinematics) of Web-Work Plot ConstructionDocument44 pagesThe Mechanics (And Kinematics) of Web-Work Plot ConstructionPhilippe Borsky VermeerschNo ratings yet

- A Brief History of NewspapersDocument16 pagesA Brief History of NewspapersAkshay KatiraNo ratings yet

- Ucl Thesis Printing ServicesDocument4 pagesUcl Thesis Printing Servicesgj9zvt51100% (2)

- CSC 101 Introduction To Computer ComsatsDocument3 pagesCSC 101 Introduction To Computer Comsatsbakiz89No ratings yet

- Ebook El Mito Del EmprendedorDocument6 pagesEbook El Mito Del Emprendedordaniel100% (1)

- Handbook Oxford OM PDFDocument27 pagesHandbook Oxford OM PDFSantiago RobledoNo ratings yet