Professional Documents

Culture Documents

WPQ Sample Printout

Uploaded by

Kannan VelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPQ Sample Printout

Uploaded by

Kannan VelCopyright:

Available Formats

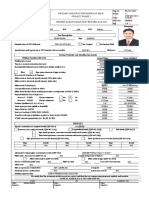

WeldOffice printout sample - ASME WPQ

C-spec

P.O. Box 27604, Concord, California 94527 (877) 977-7999

ASME Section IX - Welder Performance Qualification (WPQ)

Created with WeldOffice WPQ Module

Welder's name Rod Laver Test date 1/6/02

ID Number 5555 WPQ record number 500-5555

Date of birth 4/17/23 Standard test number Rev.

Stamp number 500 WPS record number Rev.

Company name C-spec Qualification code ASME Section IX

Division Concord

BASE METALS (QW-403)

Product form Specification (type or grade) P no. Grp-no. Size Sch. Thick. (in.) Dia. (in.)

Pipe SA-106 (B) 1 1 6 XX 0.864 6.625

Welded to: Pipe SA-106 (B) 1 1 6 XX 0.864 6.625

Joint type Groove

VARIABLES Actual values RANGE QUALIFIED

Type of weld joint Pipe - Groove Groove and Fillet welds

Base metal P1 to P1 P-no./S-no. 1 thru 11, 34, 4X

BASE METAL THICKNESS Groove Fillet Overlay Groove Fillet Overlay

Plate thickness (in.) - - - no limit no limit -

Pipe/tube thickness (in.) 0.864 - - no limit no limit -

Pipe diameter (in.) 6.625 - - 2.875 min no limit -

PROCESS VARIABLES Actual values RANGE QUALIFIED

Welding process SMAW FCAW SMAW FCAW

Type Manual Semi-automatic Manual Semi-automatic

Backing Without With With, without With

Filler metal specification 5.1 5.20 5.xx 5.xx

Filler metal classification E6010 E71T-12M Any Any

Filler metal F-number 3 6 3(1..3 w/backing) 6

Number of layers deposited 2 3 min

Weld deposit thickness (in.) 0.250 0.614 0.5 max no limit

Weld position (Actual position tested) 6G 6G

Groove - Plate & Pipe >24" All All

Groove - Pipe 2.875" to 24" All All

Groove - Pipe < 2.875" - -

Fillet - Plate & Pipe >24" All All

Fillet - Pipe 2.875" to 24" All All

Fillet - Pipe < 2.875" All All

Progression Up Up Up

Backing gas - Without - With, without

GMAW transfer mode (QW-409) - Globular - Spray, pulse, globular

TESTS

Type of test Acceptance criteria Result Comments

4 transverse side bends per QW-161.1 and QW-462.2 QW-163 Acceptable see - ASME IX - QW-452.1 Note (4)

Visual examination per QW-302.4 QW-194 Acceptable see - ASME IX - QW-452.1 Note (8)

Notes

CERTIFICATION

Tests conducted by Nick Mossman Laboratory test number 001

Mechanical tests by Nick Mossman Test file number 001

We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with the requirements of Section IX of the ASME Code.

Welding Engineer QA Manager

Name Signature Name Signature

Nick Mossman Michal Bernasek

Date Date

3/30/01 3/30/01

Signature 3 Signature 4

Name Signature Name Signature

Michele Mossman Charles Foster

Date Date

3/30/01 3/30/01

WeldOffice WPQ (c) Copyright 1985 - 2006 C-spec. All rights reserved worldwide.

Catalog n WPQ00012 Page 1 of 1

You might also like

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoNo ratings yet

- Fillet Weid Break and Macroetch Test PlateDocument1 pageFillet Weid Break and Macroetch Test PlatewijiestNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Sample Welder ID As Per ASME Section IXDocument99 pagesSample Welder ID As Per ASME Section IXVivek Jadhav100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- WPS Format For AWS D1.1 - WPS - SAWDocument1 pageWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- Painting Procedure 4288 Danem 28-04-13Document24 pagesPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Alu WpsDocument4 pagesAlu WpsdselvakuuNo ratings yet

- BOLT Torquing ReportDocument4 pagesBOLT Torquing ReportSumith Kumar S MNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Welding Specification ChartDocument189 pagesWelding Specification ChartVivek SatapathyNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Ami-001 WPSDocument2 pagesAmi-001 WPSPramod Athiyarathu100% (1)

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíDocument3 pagesSuscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíadelNo ratings yet

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- Section 4.3: Solving Friction Problems: Tutorial 1 Practice, Page 174Document10 pagesSection 4.3: Solving Friction Problems: Tutorial 1 Practice, Page 174Nagma AhmedNo ratings yet

- Head Loss Calculator by Fadi YasinDocument8 pagesHead Loss Calculator by Fadi YasinYasser ShehataNo ratings yet

- 018 10Document3 pages018 10ilkerkozturkNo ratings yet

- Performance of Cyclic Cone Penetration Tests in ChalkDocument8 pagesPerformance of Cyclic Cone Penetration Tests in ChalkSam HuckleNo ratings yet

- Heat Transfer & ThermodynamicsDocument194 pagesHeat Transfer & ThermodynamicsBetty Blue100% (1)

- Graphs in Physics PDFDocument2 pagesGraphs in Physics PDFVishalNo ratings yet

- Endress-Hauser Proline Prowirl F 200 7f2c en Vortex Flowmeter BiogasDocument13 pagesEndress-Hauser Proline Prowirl F 200 7f2c en Vortex Flowmeter Biogashk168No ratings yet

- Prestressed Concrete: Masood Khan B. Arch. 4 Year (DayDocument15 pagesPrestressed Concrete: Masood Khan B. Arch. 4 Year (Daymasood khanNo ratings yet

- Casting Process and Different Types of CastingsDocument31 pagesCasting Process and Different Types of CastingsTejas KumarNo ratings yet

- Ch09-Distributed Forces (Moments of Inertia)Document44 pagesCh09-Distributed Forces (Moments of Inertia)mantaptoNo ratings yet

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaNo ratings yet

- Refrigiration and Aircondition NotesDocument18 pagesRefrigiration and Aircondition NotesSiddhu SiddhuNo ratings yet

- Fluid Mechanics II (MEng 3306)Document2 pagesFluid Mechanics II (MEng 3306)Addisu DagneNo ratings yet

- Solar Cells ReviewDocument7 pagesSolar Cells ReviewAlanNo ratings yet

- Made Easy Civil TestDocument11 pagesMade Easy Civil TestLokesh PanwarNo ratings yet

- Space Heating Handbook (Reznor)Document76 pagesSpace Heating Handbook (Reznor)txagusNo ratings yet

- Numerical Simulation of Two-Dimensional Laminar Slot-Jet Impingement Flows Confined by A Parallel WallDocument19 pagesNumerical Simulation of Two-Dimensional Laminar Slot-Jet Impingement Flows Confined by A Parallel WallAENo ratings yet

- Energy Efficient Design For Hotels in The Tropical Climate Using ModelicaDocument8 pagesEnergy Efficient Design For Hotels in The Tropical Climate Using ModelicaLasandu WanniarachchiNo ratings yet

- PVC PDFDocument15 pagesPVC PDFsrabon1059No ratings yet

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument13 pagesAluminium Alloy - Wikipedia, The Free EncyclopediajishnuNo ratings yet

- Slope Stability AnalysisDocument68 pagesSlope Stability AnalysisKingshuk JanaNo ratings yet

- (W Ni Fe) Re CoDocument9 pages(W Ni Fe) Re CoSiddharthNo ratings yet

- Testing of The Mechanical Properties For 15mo3 SteelDocument2 pagesTesting of The Mechanical Properties For 15mo3 SteelavenclNo ratings yet

- Silicon CarbideDocument5 pagesSilicon Carbiderockeysuseelan100% (2)

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed Steelsssip officeNo ratings yet

- Sedimentation Behavior of A Fine Kaolinite in The Presence of Fresh Fe ElectrolyteDocument7 pagesSedimentation Behavior of A Fine Kaolinite in The Presence of Fresh Fe ElectrolytedongngoNo ratings yet

- BL Skill CH 3 Notes and TFDocument5 pagesBL Skill CH 3 Notes and TFapi-329922192No ratings yet

- Sec-Butyl Alcohol Sec-Butyl Acetate N, N-Dimethyl FormamideDocument22 pagesSec-Butyl Alcohol Sec-Butyl Acetate N, N-Dimethyl FormamideCorona MarcUsNo ratings yet

- Structural BehaviourDocument43 pagesStructural BehaviourDr RajeevNo ratings yet

- Normal Modes of Vibration: One-Dimensional Model # 1Document51 pagesNormal Modes of Vibration: One-Dimensional Model # 1Edgar PuenteNo ratings yet