Professional Documents

Culture Documents

Tips Wps Format

Uploaded by

Waqas WaqasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tips Wps Format

Uploaded by

Waqas WaqasCopyright:

Available Formats

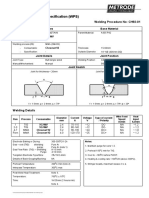

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

WPS

Company Name Precision profiles india , Chennai.

WPS No. PPI/L&T/WPS/013 Rev 0 Date 10/14/2013

PQR No. PPI/L&T/PQR/013 Date

Welding Process GMAW Type: MANUVAL

Scope

JOINTS (QW-402)

Joint Design SINGLE "V "GROOVE JOINT

Root Space (A) 1.5-3MM

Root land (B) 1.5-3MM

Bevel Angle 605

Backing YES

Backing Material P.NO.8

Retainer NIL

BASE METALS (QW-403)

P. No. 8 Group No. 1

Material Specification ASTM A351 GR CF3M/CF8M

Chemical Analysis AS PER SPECIFICATION

Mechanical Properties AS PER SPECIFICATION

Base Metal 20THK Fillet ALL SIZE

Thickness Range

Pipe Diameter Groove:N.A Fillet ALL DIA

Weld pass thickness < 13 mm YES

FILLER METALS (QW-404)

Specification No. (SFA) A5.9

AWS No. (Classification) ER316L

F-No. 6

A-No. 8

Size of Electrode / Filler Metal 1.2mm

Filler Metal Product Form WIRE

Supplemental Filler Metal N.A

Weld Metal Thickness Range 20 mm MAX Fillet NA

Electrode Flux (Classification) N.A

Consumable Insert N.A

Powder Feed Rate N.A

Change of Alloy Element N.A

(Note: Welding Consumables manufacturer shall be as per L&T Approved List )

POSITIONS (QW-405) PREHEAT (QW-406)

Position 1G Preheat Temperature, min. 30C

Welding Progression NA Interpass Temperature, max. 150C

Position(s) of Fillet NA Preheat Maintenance NIL

POST WELD HEAT TREATMENT (QW-407)

Type

Temperature Range Nil

Time Range, min N.A

Time Range, max N.A

Cooling N.A Rate of Heating Max. N.A

Loading / Unloading N.A Rate of Cooling Max. N.A

Temperature, Max N.A

GAS (QW-408)

Gas % Composition / Mixture Flow Rate(lpm)

Shielding Gas ARGON

10 _ 15

Trailing Gas NA Welding Grade (no mixture)

Backing Gas NA

Form No: QP-051-R0

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

WPS

ELECTRICAL CHARACTERISTICS (QW-409)

Filler Metal Current Travel

Volt Speed Heat Input

Weld Pass Process Amps

Classification Diameter (mm) Type Polarity (Range) (range) (max) (kJ/mm)

(Range) (mm/min.)

All Pass GMAW ER316L 1.2 DC RP 140 - 170 25-30 150-230 1.9

Pulsing Current NA

Heat input (max) Ref Table Above

Tungsten Electrode Size & Type NA

Mode of metal transfer Globular

Electrode wire feed speed range 4 - 6 m/min

TECHNIQUE (QW-410)

String or Weave Bead Both(Weave width not more than 12mm)

Oriffice, Nozzle and Gas cup size 10 - 12 mm

Initial and interpass cleaning method wire Brushing and Grinding

Method of back gouging Grinding

Oscillation NA

Multiple or single pass (per side) Multiple pass

Multiple or single layer Multiple layer

Multiple or single electrode Single

Electrode Spacing NA

Welding Process GMAW

Peening Not allowed

Use of thermal process Nil

Note:

The filler metal shall be stored, issued and controlled as per manufacturer's recommendation / L&T procedures.

Prepared by Reviewed & Approved by

Rajesh. O E.X.Xavier

PPI, Quality Assurance PPI, Quality Manger

Form No: QP-051-R0

WELDING PROCEDURE QUALIFICATION RECORD

(PQR) (QW-483)

In accordance with QW-200.2, Section IX, ASME BPVC

PQR

Company Name Larsen & Toubro Limited, Valve Manufacturing Unit, Coimbatore.

PQR No. Date

WPS No. Date

Welding Process Type

Date of Welding Weld Shop

JOINTS (QW-402)

Joint Design

Root gap / Space

Root land

Backing

Backing Material

Retainer

Bevel Angle

BASE METALS (QW-403) PREHEAT (QW-406)

Material Specification Preheat temperature

Grade Interpass temperature

. Preheat Maintenance

P.No 8 Gr. No. 1 to P.No 0 Gr. No. 1 POST WELD HEAT TREATMENT (QW-407)

Thickness of test coupon Temperature

Diameter of test coupon Time

Size (l x w x t) (mm) Cooling

Weld pass thickness Rate of Heating

Refer MTC enclosed for plates bearing Heat No 2N020 Rate of Cooling

Plates of 40 mm used for qualification. Loading / Unloading Temperature (max.)

FILLER METALS (QW-404) GAS (QW-408)

SFA Specification Flow Rate

Gas Mixture composition(%)

AWS Classification (lpm)

Filler Metal F-No. Shielding Gas

Weld Metal Analysis A-No. Trailing Gas Welding Grade (no mixture) 0

Filler Metal Product Form Backing Gas 0 0

Size of Filler metal ELECTRICAL CHARACTERISTICS (QW-409)

Weld metal thickness Current (AC or DC)

Refer Test Certificate. Batch No. C10074641 & Polarity

C05072705 of D&H Heat Input,

Amps (A) Volts (V)

kJ/mm.

POSITION (QW-405) Root Passes

Position Other Passes

Tungsten Electrode

Weld Progression

size

. Other Heat Input

TECHNIQUE (QW-410)

Travel Speed

String or Weave Bead

Initial and interpass cleaning

Method of back gouging

Oscillation

Multiple or single pass (per side)

Multiple or single layer

Multiple or single electrode

Electrode spacing

Welding Process

Peening

Use of thermal process

Form No: QP-051-R0

WELDING PROCEDURE QUALIFICATION RECORD

(PQR) (QW-483)

In accordance with QW-200.2, Section IX, ASME BPVC

PQR

TENSILE TEST (QW-150)

Ultimate total Type of failure

Specimen No. Width, mm Thickness, mm Area, mm2 Ultimate unit stress, MPa

load, kN & location

GUIDED-BEND TESTS (QW-160)

Specimen Size (l x w x t) (mm) 300 x 40 x 10.0

Specimen Type and Figure No. Bend Angle Diameter of roller (mm) Result

TOUGHNESS TESTS (QW-170)

Specimen Size

Notch Impact Values, Joules ( for ref only )

Specimen No. Location / Test Temperature Lateral expansion, mm Remarks

Orientation 1 2 3 Average

FILLET-WELD TESTS (QW-180)

Results

Penetration into parent metal

Macro - Results

OTHER TESTS

Acceptance Standard /

Sl. No Type of Examination Results of Examination

Requirement

1 Visual Examination QW-302.4

Liquid Penetrant

2

Examination

Radiographic

3

Examination

Hardness (HV10)

As per NACE MR0175/

ISO 15156-2

Base 248 HV / 237 HB max Average

4

Average

Weld 248 HV / 237 HB max

(weld top surface)

HAZ 248 HV / 237 HB max Average

Shall be free from

5 Macro Examination

defects

Welder's Name Identification No.

Test Conducted by

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in

accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Prepared By Reviewed & Approved By

Velusamy P C.Raja

L&T Valves, Quality Assurance L&T Valves, Quality Assurance

Form No: QP-051-R0

WELDER PERFORMANCE QUALIFICATION

(WPQ) (QW-484A)

In accordance with QW-301, Section IX, ASME BPVC

WPQ

WPQ No. Date

Welder's Name Identification No.

Weld Shop .

TEST DESCRIPTION

Identification of WPS followed

Test Coupon or Production Weld

Material Specification Grade

Base Metal Thickness

Date of Welding

TESTING VARIABLES AND QUALIFICATION LIMITS

Welding Variables (QW-350) Actual Values Range Qualified

Welding Process(es)

Type (i.e.; manual, semi-automatic) used

Backing (with / without)

Plate or Pipe (enter diameter if pipe or tube)

Base metal P-Number to P-Number

Filler metal or electrode specification(s) (SFA) (info. only)

Filler metal or electrode classification(s) (info. only)

Filler metal F-Number(s)

Consumable insert (GTAW or PAW)

Filler Metal Product Form (solid/metal or flux cored/powder)

(GTAW or PAW)

Deposit thickness for each proces , mm

Deposit thickness for each process (3 layers min)

Position qualified (1G, 6G, 3F, etc.)

Vertical progression (uphill or downhill)

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Transfer mode(spray/globular or pulse to short circuit-GMAW)

Current type/polarity (AC, DCEP, DCEN)

RESULTS

Visual Examination Results (QW-302.4)

Liquid Penetrant Examination results(QW-195.2)

Radiographic Examination results (QW-190)

Mechanical Test conducted by

Hardness Test conducted by

Macro Examination conducted by

Bend test results (QW-462.2)

Type Result Type Result Type Result

- - - -

Welding qualification conducted by --

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and

tested in accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Prepared by Reviewed & Approved by

Velusamy P C Raja

Quality Assurance Quality Assurance

Form No: QP-051-R0

You might also like

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Document23 pagesTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNo ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Inspection RoleDocument18 pagesInspection Rolesribd9128No ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- Inspection Report - ValvesDocument2 pagesInspection Report - ValvesJaspal KaurNo ratings yet

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandeNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- REV 0 Material Selection Diagram MSD Blueprint IncDocument5 pagesREV 0 Material Selection Diagram MSD Blueprint IncJohn Patrick Sanay NunezNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- JIMT Visual Inspection ReportDocument1,913 pagesJIMT Visual Inspection Reportgomathyselvi100% (1)

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- Lalitpur Power Generation Company Limited - Welding & PWHT RequirementsDocument7 pagesLalitpur Power Generation Company Limited - Welding & PWHT RequirementsNavneet SinghNo ratings yet

- LTH Iea 1048Document349 pagesLTH Iea 1048malina1709No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- SS Pipe Welding ProcedureDocument5 pagesSS Pipe Welding Procedureamit rajputNo ratings yet

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDocument28 pagesSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenNo ratings yet

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- Saudi Aramco WPS Procedure ApprovalDocument7 pagesSaudi Aramco WPS Procedure ApprovalAkansha SharmaNo ratings yet

- 8615 Nozzle Orientation Report 01Document4 pages8615 Nozzle Orientation Report 01Bsc Aditya Singh Dinkar100% (1)

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- WQT Parameter Sheet - WPS 29 Ni To NiDocument12 pagesWQT Parameter Sheet - WPS 29 Ni To NiSankar KrishnanNo ratings yet

- Asme P NumberDocument1 pageAsme P NumberSebastian RajeshNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- Amendments To DEP 61.40.20.30 Welding Pipelines Related FacilitiesDocument21 pagesAmendments To DEP 61.40.20.30 Welding Pipelines Related FacilitiesAtul ChaturvediNo ratings yet

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDocument1 pageASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechNo ratings yet

- PDS Na GTS65 PDFDocument2 pagesPDS Na GTS65 PDFMoaatazz NouisriNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- PMI Ferrite Measurement ProcedureDocument7 pagesPMI Ferrite Measurement ProcedureAbd Rahman AliasNo ratings yet

- Specification For Carbon Steel Pipes & FittingsDocument27 pagesSpecification For Carbon Steel Pipes & FittingsNoor Anter100% (1)

- Materials WQTDocument2 pagesMaterials WQTZohaib AnserNo ratings yet

- Liquid Penetrant Testing Report SummaryDocument1 pageLiquid Penetrant Testing Report SummaryAbdul NaveedNo ratings yet

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Welder Visual Inspection ReportsDocument24 pagesWelder Visual Inspection ReportsKyNo ratings yet

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamedNo ratings yet

- Welding Inspection Consumables PDFDocument28 pagesWelding Inspection Consumables PDFJoseph PeterNo ratings yet

- Piping Test Pack Clearance ReportDocument2 pagesPiping Test Pack Clearance ReportKarthikNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Modul Tambahan Kualifikasi Las (KL)Document27 pagesModul Tambahan Kualifikasi Las (KL)Nurhamsyah Susianto0% (1)

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- A106 Pipe Spec SheetDocument7 pagesA106 Pipe Spec SheetyanurarzaqaNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Radiograph Acceptance Criteria ChartDocument1 pageRadiograph Acceptance Criteria ChartTURNO100% (2)

- Coded Marking Procedure - CM-01Document7 pagesCoded Marking Procedure - CM-01carlosNo ratings yet

- 8 - Welding Procedures SummaryDocument12 pages8 - Welding Procedures SummaryHaleemUrRashidBangashNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- W1 Material and Welding For Gas Tankers W1Document13 pagesW1 Material and Welding For Gas Tankers W1AlbertNo ratings yet

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFTanah Tak BertuanNo ratings yet

- Tap & DrillDocument1 pageTap & DrillWaqas WaqasNo ratings yet

- Auditing Welds Under ASME IX PDFDocument21 pagesAuditing Welds Under ASME IX PDFkbldamNo ratings yet

- Tensile TestDocument1 pageTensile TestWaqas WaqasNo ratings yet

- Bolt TighteningDocument1 pageBolt TighteningWaqas WaqasNo ratings yet

- ASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingDocument27 pagesASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingPacifier Nothingface0% (1)

- ASME BPVC.IX-2017 welding standardsDocument1 pageASME BPVC.IX-2017 welding standardsWaqas WaqasNo ratings yet

- Technical Specification for Purchase Requisition TubesDocument1 pageTechnical Specification for Purchase Requisition TubesWaqas WaqasNo ratings yet

- Weld Overlay Obtained by FCAW ProcessDocument2 pagesWeld Overlay Obtained by FCAW ProcessWaqas WaqasNo ratings yet

- Face & Root BendDocument1 pageFace & Root BendWaqas WaqasNo ratings yet

- QW 381Document1 pageQW 381Waqas WaqasNo ratings yet

- Auditing Welds Under ASME IX PDFDocument21 pagesAuditing Welds Under ASME IX PDFkbldamNo ratings yet

- ISO IQA For DDFC by AJMAL29-04-14Document52 pagesISO IQA For DDFC by AJMAL29-04-14Waqas WaqasNo ratings yet

- ISO IQA For DDFC by AJMAL29-04-14Document52 pagesISO IQA For DDFC by AJMAL29-04-14Waqas WaqasNo ratings yet

- Welding Procedure SummaryDocument1 pageWelding Procedure SummaryWaqas WaqasNo ratings yet

- RFI Inspection Request for ProjectDocument1 pageRFI Inspection Request for ProjectWaqas WaqasNo ratings yet

- Reduced Sec. Tensile TestDocument1 pageReduced Sec. Tensile TestWaqas WaqasNo ratings yet

- Procedure For Tank Shell To AnnularDocument1 pageProcedure For Tank Shell To AnnularWaqas WaqasNo ratings yet

- Procedure For Tank Shell To AnnularDocument1 pageProcedure For Tank Shell To AnnularWaqas WaqasNo ratings yet

- ISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesDocument2 pagesISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesWaqas WaqasNo ratings yet

- Welding API TankDocument1 pageWelding API TankWaqas WaqasNo ratings yet

- Changing AIADocument1 pageChanging AIAWaqas WaqasNo ratings yet

- Dimensional Inspection Report: 175mm 150mm 55 29Document3 pagesDimensional Inspection Report: 175mm 150mm 55 29Waqas WaqasNo ratings yet

- 9.3 Qualification of WeldersDocument1 page9.3 Qualification of WeldersWaqas WaqasNo ratings yet

- WPSDocument25 pagesWPSWaqas WaqasNo ratings yet

- 2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)Document6 pages2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)kangsungjinNo ratings yet

- ASME MTC Types & Verification GuideDocument47 pagesASME MTC Types & Verification GuideSULTAN100% (1)

- Codes & Standards For Natural GasDocument13 pagesCodes & Standards For Natural Gasharikrishnanpd3327No ratings yet

- Practical 2 GuideDocument2 pagesPractical 2 GuideJeffrey PiggottNo ratings yet

- Evaluating Wetting Agents Using Student ExperimentsDocument2 pagesEvaluating Wetting Agents Using Student ExperimentsKrupali Umeshkumar KapadiyaNo ratings yet

- Mud Pump F-1000 - BPMMP - Baoji Shaanxi China - Parts ManualDocument103 pagesMud Pump F-1000 - BPMMP - Baoji Shaanxi China - Parts ManualAbdelhamid HaramiNo ratings yet

- Tutorial - Underfloor Air-ConditioningDocument8 pagesTutorial - Underfloor Air-ConditioningJasper_HVACNo ratings yet

- LTE Subframe Number, SFN and HFNDocument2 pagesLTE Subframe Number, SFN and HFNZteTems OptNo ratings yet

- Chapter 7: Communication Elements and Features: 701 GeneralDocument30 pagesChapter 7: Communication Elements and Features: 701 GeneralawasthyNo ratings yet

- Ubuntu Admin Account UtilitiesDocument2 pagesUbuntu Admin Account UtilitiesAnonymous fs4s0hNo ratings yet

- 4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor TestsDocument4 pages4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor Testsmandadi_sailesh50% (2)

- Outlook TroubleshootingDocument17 pagesOutlook TroubleshootingYokesh ElangovanNo ratings yet

- Fundamentals of Electric Vehicles Lecture on Vehicle DynamicsDocument15 pagesFundamentals of Electric Vehicles Lecture on Vehicle DynamicsaerovinuNo ratings yet

- ODROID Magazine 201408Document49 pagesODROID Magazine 201408L0ck0utNo ratings yet

- Panel Rymsa TUU-AT15-250Document1 pagePanel Rymsa TUU-AT15-250Hector CardosoNo ratings yet

- IEC 61892-1 - Mobile and Fixed Offshore Units - Electrical Installations - Part 1 General Requirements and Conditions PDFDocument26 pagesIEC 61892-1 - Mobile and Fixed Offshore Units - Electrical Installations - Part 1 General Requirements and Conditions PDFmauricio_rodrigues09100% (1)

- Hanoi TowersDocument33 pagesHanoi TowersChandan Sharma100% (1)

- Rosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & MunicipalitiesDocument12 pagesRosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & Municipalitiesdiegoh_silvaNo ratings yet

- Lift Car Hidrolis Dan SelingDocument32 pagesLift Car Hidrolis Dan SelingMuhammad Arief PrasetyaNo ratings yet

- Chapter 3-PIC IO Port ProgrammingDocument36 pagesChapter 3-PIC IO Port Programmingouterrace67% (3)

- VG7 Maintenance ManualDocument18 pagesVG7 Maintenance ManualGustavo RodriguezNo ratings yet

- From An Idea To A Minimum Viable ProductDocument44 pagesFrom An Idea To A Minimum Viable ProductGeorge Krasadakis100% (5)

- OMC-138 Wind Display Specs and FeaturesDocument2 pagesOMC-138 Wind Display Specs and FeaturesAjayNo ratings yet

- Liste de Prix BCM Juin 2010Document4 pagesListe de Prix BCM Juin 2010bakzazamNo ratings yet

- How-To Guide - A Quick Guide To B2B XCM ConfigurationDocument45 pagesHow-To Guide - A Quick Guide To B2B XCM Configurationrobi_kren0No ratings yet

- Bosch P-Pump Fuel Injection - Diesel Tech - Diesel Power MagazineDocument2 pagesBosch P-Pump Fuel Injection - Diesel Tech - Diesel Power Magazinerxhughes100% (3)

- DKG-117 Synchroscope and Check Synch RelayDocument12 pagesDKG-117 Synchroscope and Check Synch RelaySaid TouhamiNo ratings yet

- Introduction To X-Ray Fluorescence XRFDocument62 pagesIntroduction To X-Ray Fluorescence XRFMohammad Youssefi100% (1)

- Sensor 120 PDFDocument147 pagesSensor 120 PDFzikri100% (1)

- Grosvenor Full Product Range & Technical Nformation CatalogueDocument87 pagesGrosvenor Full Product Range & Technical Nformation CatalogueDylan LopezNo ratings yet

- Function of The Operating System BS41 Q (HIMA CPU) PDFDocument36 pagesFunction of The Operating System BS41 Q (HIMA CPU) PDFsendutdut100% (1)