Professional Documents

Culture Documents

Model 4WI 100 - 800 HP Boilers: Figure A2-7. No. 2 Oil Piping, Multiple Boiler Installation

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model 4WI 100 - 800 HP Boilers: Figure A2-7. No. 2 Oil Piping, Multiple Boiler Installation

Uploaded by

sebaversaCopyright:

Available Formats

Model 4WI 100 800 HP Boilers

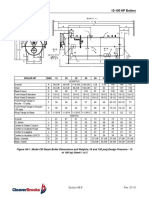

Figure A2-7. No. 2 Oil Piping, Multiple Boiler Installation

ITEM SIZE DESCRIPTION

Connection to oil level

A 1/2" NT

switch

B See Note Return line to tank

Oil supply connection

C See Note

from transfer pump

1/2" NPT

D Tank drain connection

E See Note FOS connection

Oil level test valve

F 1/8" NPT

connection

G See Note FOR connection

H

No.80 Oil level switch

McD

NOTE: Connections should be sized using

recommended sizes in oil line sizing

instructions.

Figure A2-8. No. 2 Oil Transfer Tank Detail (For consideration with elevated boiler rooms)

Section A2-24 Rev. 09-09

Model 4WI 100 800 HP Boilers

Note: Observe all local and national (eg. Fire underwriters) code requirements governing the

installation of fuel oil storage tanks and supply systems.

Figure A2-9. Typical Fuel Storage Tank Arrangement

General Boiler Information

Table A2-24 shows blowdown tank sizing information.

Table A2-25 provides heating surface information.

Table A2-26 provides steam volume and disengaging area information

Table A2-27 provides recommended steam nozzle sizes.

Table A2-28 provides recommended non-return valve sizes.

Boiler Room Information

Figure A2-10 shows typical boiler room length requirements.

Figure A2-11 shows typical boiler room width requirements.

Figure A2-12 shows typical breeching arrangements.

Stack Support Capabilities

All standard Cleaver-Brooks Firetube Boilers can support up to 2,000 lbs without

additional support.

Boilers 250 hp through 800 hp can be reinforced to support 3,000 lbs.

Stack/Breeching Size Criteria

The design of the stack and breeching must provide the required draft at each boiler flue

gas outlet. Proper draft is critical to burner performance.

Although constant pressure at the flue gas outlet is not required, it is necessary to size

the stack/breeching to limit flue gas pressure variation. The allowable pressure range is

0.25" W.C. to +0.25" W.C.

Boiler Room Combustion Air

When determining boiler room air requirements, the size of the room, air flow, and

velocity of air must be reviewed as follows:

1. Size (area) and location of air supply openings in boiler room.

A. Two (2) permanent air supply openings in the outer walls of the boiler room

are recommended. Locate (1) at each end of the boiler room, preferably

below a height of 7 feet. This allows air to sweep the length of the boiler.

Section A2-25 Rev. 09-09

Model 4WI 100 800 HP Boilers

B. Air supply openings can be louvered for weather protection, but they should

not be covered with fine mesh wire, as this type of covering has poor air flow

qualities and is subject to clogging by dust or dirt. A vent fan in the boiler

room is not recommended, as it could create a slight vacuum under certain

conditions and cause variations in the quantity of combustion air. This can

result in unsatisfactory burner performance.

C. Under no condition should the total area of the air supply openings be less

than (1) square foot.

D. Size the openings by using the formula: Area (sq-ft) = CFM/FPM

2. Amount of air required (cfm).

A. Combustion Air = Rated bhp x 8 cfm/bhp.

B. Ventilation Air = Maximum bhp x 2 cfm/bhp

C. Total recommended air = 10 cfm/bhp - up to 1000 feet elevation. Add 3

percent more per 1000 feet of added elevation.

3. Acceptable air velocity in Boiler Room (fpm).

A. From floor to (7) foot height - 250 fpm

B. Above (7) foot height - 500 fpm

Example: Determine the area of the boiler room air supply openings for (1) 300 hp boiler

at 800 feet altitude. The air openings are to be 5 feet above floor level.

Air required: 300 x 10 = 3000 cfm (from 2B above).

Air velocity: Up to 7 feet = 250 fpm (from 3 above).

Area Required: Area = cfm = 3000/250 = 12 sq-ft total.

Area/Opening: 12/2 = 6 sq-ft/opening (2 required).

Notice

Consult local codes, which may supersede these requirements.

Table A2-24. Blowdown Tank Sizing Information

BOILER HP WATER (GAL)

100 85

125 104

150 102

200 131

250 145

300 169

350 178

400 198

500 233

600 278

700 286

800 286

NOTE: Quantity of water removed from boiler by lowering normal water line 4".

Section A2-26 Rev. 09-09

Model 4WI 100 800 HP Boilers

Table A2-25. Heating Surface

BOILER HEATING SURFACE (SQ-FT)

HP FIRESIDE WATERSIDE

100 500

125 625 679

150 750 820

200 1000 1092

250 1250 1346

300 1500 1623

350 1750 1932

400 2000 2151

500 2500 2691

600 3000 3262

700 & 800 3500 3810

Table A2-26. Steam Volume Disengaging Area

STEAM VOLUME CU-FT STEAM RELIEVING AREA SQ-IN

BOILER HP HIGH PRESSURE LOW PRESSURE HIGH PRESSURE LOW PRESSURE

(A) (B) (A) (B)

100 16.5 22.3 4565 4954

125 20.3 27.4 5587 6077

150 19.9 26.8 5443 5918

200 25.7 34.6 7013 7632

250 34.8 49.5 7790 8597

300 40.6 57.9 9115 10051

350 51.3 69.6 9734 10570

400 57.2 77.5 10843 11779

500 83.6 107.6 12874 13781

600 100 128.6 15394 16474

700 115.6 144.9 15826 16819

800 115.6 144.9 15826 16819

NOTE:

1. Based on normal water level.

A. Based on 150 psig design pressure.

B. Based on 15 psig design pressure.

Section A2-27 Rev. 09-09

You might also like

- Model 4WG 100 - 800 HP Boilers: Fuel Connections - OilDocument4 pagesModel 4WG 100 - 800 HP Boilers: Fuel Connections - OilsebaversaNo ratings yet

- CBEX Elite 100-800 HP: Burner CharacteristicsDocument4 pagesCBEX Elite 100-800 HP: Burner CharacteristicssebaversaNo ratings yet

- CBEX Elite Boilers 1300-2200HP Engineering DataDocument4 pagesCBEX Elite Boilers 1300-2200HP Engineering DatasebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Genset Installation Recommendation: A LocationDocument27 pagesGenset Installation Recommendation: A LocationShiv Kumar VermaNo ratings yet

- Model 4WI Boilers Oil-Fired Burners and Gas Train ComponentsDocument4 pagesModel 4WI Boilers Oil-Fired Burners and Gas Train ComponentssebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: Performance DataDocument4 pagesModel ICB 100-800 HP Boilers: Performance DatasebaversaNo ratings yet

- Dokumen - Tips - Cbex de Boiler Book Cbex de Features and Benefits 3 The Cleaver Brooks Cbex deDocument19 pagesDokumen - Tips - Cbex de Boiler Book Cbex de Features and Benefits 3 The Cleaver Brooks Cbex decarlosNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model 4WG Boiler Dimensions and SpecificationsDocument4 pagesModel 4WG Boiler Dimensions and SpecificationssebaversaNo ratings yet

- Modul Air Fluid Coolers 1800Document12 pagesModul Air Fluid Coolers 1800Roger AklNo ratings yet

- Model 4WG 100 - 800 HP Boilers: Figure A3-9. Boiler Room Length (Typical Layouts) - Model 4WGDocument4 pagesModel 4WG 100 - 800 HP Boilers: Figure A3-9. Boiler Room Length (Typical Layouts) - Model 4WGsebaversaNo ratings yet

- An Introduction To High Temperature Water Heating Plants R1Document39 pagesAn Introduction To High Temperature Water Heating Plants R1Kenn WahhNo ratings yet

- Cleaver Brooks - Boiler Book 2011Document1,140 pagesCleaver Brooks - Boiler Book 2011kennnyp1100% (1)

- 2 Smoke Calculation r4.Document11 pages2 Smoke Calculation r4.muhammed sabir v aNo ratings yet

- CBEX Elite 1300-2200HP Boiler BookDocument15 pagesCBEX Elite 1300-2200HP Boiler Bookfauzi endraNo ratings yet

- Chapter 9 Lecture - RADIATORDocument37 pagesChapter 9 Lecture - RADIATORSabree AbdullahNo ratings yet

- Approved by The Engineer: Item Description Unit Qty Rate US$Document6 pagesApproved by The Engineer: Item Description Unit Qty Rate US$febousNo ratings yet

- Bentone BG 100Document22 pagesBentone BG 100mechanicalNo ratings yet

- Bentone ST133 ManualDocument14 pagesBentone ST133 ManualAsron Ferdian FalaahNo ratings yet

- Operation PaperDocument5 pagesOperation PaperpragyanNo ratings yet

- An Atmospheric Crude Tower RevampDocument6 pagesAn Atmospheric Crude Tower Revampniladri_paulNo ratings yet

- Field-Erected Fire Tube Boiler SpecificationsDocument7 pagesField-Erected Fire Tube Boiler SpecificationsMomar Talla DiawNo ratings yet

- Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document4 pagesSection A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)sebaversaNo ratings yet

- Trends in Packaged Boiler Design PDFDocument10 pagesTrends in Packaged Boiler Design PDFpertspyNo ratings yet

- Radiator CoolingDocument4 pagesRadiator Coolingvishal.nithamNo ratings yet

- 6890 GC Site Preparation ChecklistDocument4 pages6890 GC Site Preparation Checklistigor_239934024No ratings yet

- Juhas ENGLISHDocument14 pagesJuhas ENGLISHghiocel apinteiNo ratings yet

- MEP Design ParametersDocument9 pagesMEP Design ParameterstogirishsharmaNo ratings yet

- Generators & UPSDocument15 pagesGenerators & UPSgopalraojiNo ratings yet

- Providing Sustainable Energy Solutions Worldwide: Installation-And Maintenance InstructionDocument20 pagesProviding Sustainable Energy Solutions Worldwide: Installation-And Maintenance Instructioncristian villegasNo ratings yet

- Installation and maintenance guide for B70-2FH oil burnerDocument15 pagesInstallation and maintenance guide for B70-2FH oil burneranweshaccNo ratings yet

- Series 1: Forced Draft Dual Fuel BurnersDocument4 pagesSeries 1: Forced Draft Dual Fuel Burnersdiogenes torresNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Rah 563 Ce Heating Element 35 Non Enamelled 1566626618Document4 pagesRah 563 Ce Heating Element 35 Non Enamelled 1566626618Senthil KumarNo ratings yet

- Instr Bentone B40a en 0 PDFDocument13 pagesInstr Bentone B40a en 0 PDFमेनसन लाखेमरूNo ratings yet

- Design Practices of Solid Fuel BoilersDocument16 pagesDesign Practices of Solid Fuel BoilersKaza ShanthiNo ratings yet

- Design Practices of Solid Fuel BoilersDocument16 pagesDesign Practices of Solid Fuel BoilersKaza ShanthiNo ratings yet

- Ace3 1122.03 GB PDFDocument16 pagesAce3 1122.03 GB PDFArpit VermaNo ratings yet

- 959 TP Severe Service Power Applications Handbook Low ResDocument52 pages959 TP Severe Service Power Applications Handbook Low Respneuma110No ratings yet

- 1000CUM Main Fuel Storage Tanks SepchDocument3 pages1000CUM Main Fuel Storage Tanks SepchBTENo ratings yet

- Annexure - I Fuel Oil Handling SystemDocument12 pagesAnnexure - I Fuel Oil Handling SystemjayarajNo ratings yet

- Tip Sheet Nov10Document1 pageTip Sheet Nov10Tom BorkowskiNo ratings yet

- Bfit Model BFIT Condensing Hot Water Boiler SpecificationDocument8 pagesBfit Model BFIT Condensing Hot Water Boiler SpecificationjoeNo ratings yet

- High Temperature Hot Water BoilersDocument4 pagesHigh Temperature Hot Water BoilersRibhi HamdanNo ratings yet

- Bentone Burner Operating InstructionsDocument20 pagesBentone Burner Operating InstructionsVikk Suriya100% (2)

- Detroit Diesel Training Manual Fans and Fan Shrouds AbbyDocument11 pagesDetroit Diesel Training Manual Fans and Fan Shrouds AbbyMohamed Abo elkhairNo ratings yet

- Pages From HVAC Design Handbook (301 450)Document150 pagesPages From HVAC Design Handbook (301 450)zaffar731No ratings yet

- Installation Manual EiDocument13 pagesInstallation Manual Eithanh thien nguyenNo ratings yet

- An Atmospheric Crude Tower RevampDocument6 pagesAn Atmospheric Crude Tower RevampMarlon ArteagaNo ratings yet

- Boiler SpecificationDocument15 pagesBoiler Specificationjrri16No ratings yet

- Operating and Maintenance Manual: Model "SRN and HRN" Atmospheric Steam BoilerDocument116 pagesOperating and Maintenance Manual: Model "SRN and HRN" Atmospheric Steam BoilerAntonio MoralesNo ratings yet

- CHAPTER 6 COMBUSTION CHAMBERSDocument31 pagesCHAPTER 6 COMBUSTION CHAMBERSmustafaxdar4No ratings yet

- AIA Boiler Specification CM2 v1.2 Master Spec PDFDocument11 pagesAIA Boiler Specification CM2 v1.2 Master Spec PDFbotosionNo ratings yet

- SPEC ModelCBR Steam Mar4Document10 pagesSPEC ModelCBR Steam Mar4Jason PoloNo ratings yet

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocument10 pagesModel CB Boilers 15-100 HP: Dimensions and Ratingsleonel lopezNo ratings yet

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocument9 pagesModel CB Boilers 15-100 HP: Dimensions and RatingsMauricio RojasNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Topsoe Ammonia 4 Start Up Worlds Largest Ammonia PlantDocument13 pagesTopsoe Ammonia 4 Start Up Worlds Largest Ammonia PlantSyariful Maliki NejstaršíNo ratings yet

- Condensate Pumps and Energy Recovery PDFDocument17 pagesCondensate Pumps and Energy Recovery PDFPhani Raj MNo ratings yet

- AR #02: Inspection and Maintenance of Steam Traps: Recommended ActionDocument4 pagesAR #02: Inspection and Maintenance of Steam Traps: Recommended ActionJUAN CAMILO EspindolaNo ratings yet

- Amol Jadhav ResumeDocument15 pagesAmol Jadhav ResumeamolNo ratings yet

- Online Steam Purity Analysis For Geothermal Power GenerationDocument11 pagesOnline Steam Purity Analysis For Geothermal Power GenerationrizkiNo ratings yet

- Etd 2mark With AnswerDocument16 pagesEtd 2mark With AnswerERKATHIR100% (1)

- Index to Co-Generator Gas Turbine Cause Code TablesDocument59 pagesIndex to Co-Generator Gas Turbine Cause Code TablessamsNo ratings yet

- 15TPD Palm Oil, Cottonseed Oil and Canola Oil Refining LineDocument15 pages15TPD Palm Oil, Cottonseed Oil and Canola Oil Refining LineMuhammad aliNo ratings yet

- PRESSURE Relief Valve EXCEL SHEETSDocument9 pagesPRESSURE Relief Valve EXCEL SHEETSsathishNo ratings yet

- DNVGL Ru Inv Pt4ch2Document29 pagesDNVGL Ru Inv Pt4ch2mustafa meseliNo ratings yet

- What Is The Boiler Cool Down ProcedureDocument2 pagesWhat Is The Boiler Cool Down ProcedureRitche Lim BragaisNo ratings yet

- Typical Turbine System and DescriptionDocument85 pagesTypical Turbine System and DescriptionManjunath AithalNo ratings yet

- Flowchart Proses Pks PT - TPP Flowchart Proses Pks Pt. TPP: SterilizerDocument1 pageFlowchart Proses Pks PT - TPP Flowchart Proses Pks Pt. TPP: SterilizerArifalNo ratings yet

- Thermal Engineering - IIDocument54 pagesThermal Engineering - IIMARSHALNo ratings yet

- Steam Boiler Operating AND Maintenance Manual: Prepared by Meksis A.Ş. Service and R&D DepartmentDocument19 pagesSteam Boiler Operating AND Maintenance Manual: Prepared by Meksis A.Ş. Service and R&D DepartmentShambhu Mehta100% (1)

- Energizing Experience at Thermax Babcock & WilcoxDocument1 pageEnergizing Experience at Thermax Babcock & Wilcoxankit7329No ratings yet

- Unit4 - NotesDocument38 pagesUnit4 - NotesKrishna AgarwalNo ratings yet

- Steam Traps Heat Railcars Faster for Asphalt TerminalsDocument2 pagesSteam Traps Heat Railcars Faster for Asphalt TerminalsAnonymous v5uipHNo ratings yet

- Appendix 16 Emergency Shutdown Procedure Potential Abnormal Operating Conditions Furnace Start-Up and Shutdown ProceduresDocument10 pagesAppendix 16 Emergency Shutdown Procedure Potential Abnormal Operating Conditions Furnace Start-Up and Shutdown ProceduresSubburajMechNo ratings yet

- Engineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemDocument23 pagesEngineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemInemie-ebi NiweighaNo ratings yet

- 08-Falling Film Evaporator - by Bma GermanyDocument30 pages08-Falling Film Evaporator - by Bma GermanyFarooq Ameer Jordan Wala100% (1)

- P&ID NotesDocument17 pagesP&ID Notesnokaraju100% (1)

- Melag Vacuklav 24B+, 30B+ Autoclave - User ManualDocument61 pagesMelag Vacuklav 24B+, 30B+ Autoclave - User ManualLuciano Andres Villarroel Muñoz0% (1)

- Ammonia ManualDocument389 pagesAmmonia Manualahmed100% (3)

- Non-Conventional Energy Resources Unit-III: By:Deepak PandeyDocument8 pagesNon-Conventional Energy Resources Unit-III: By:Deepak Pandeyshylaja9No ratings yet

- Steam power plants explainedDocument38 pagesSteam power plants explainedsrihari_bhadabhagniNo ratings yet

- Handbook of Thermo 00 LuckDocument264 pagesHandbook of Thermo 00 LuckAlvaroJoseMauroNo ratings yet

- Steam Bowing Procedure of Stage # 1Document18 pagesSteam Bowing Procedure of Stage # 1Waleed HashimNo ratings yet

- 040 550GBDocument18 pages040 550GBGil DulayNo ratings yet

- Process Safety Leading and Lagging Metrics - CCPS - 2011Document44 pagesProcess Safety Leading and Lagging Metrics - CCPS - 2011Haribo1962No ratings yet