Professional Documents

Culture Documents

Curbe Caracteristice Fibre

Uploaded by

Yvette OrbánCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Curbe Caracteristice Fibre

Uploaded by

Yvette OrbánCopyright:

Available Formats

290 Physical properties of textile fibres

In

0.5

500

Nailon

Bumbac

Mtase

Efort specific [MPa]

400

[GPa]

300

0.25

Mtasea

200 vscoz

Mtasea Ln

acetat

100

0

0 5 10 15 20 25 30 35 40

Deformaie (%)

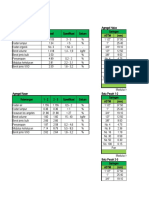

13.11 Stressstrain curves of various fibres tested at 65% r.h., 20 C, 0.15 mN

tex1 s1. From Merediths [2] 1945 data. Note: Durafil is Lilienfeld rayon; Fibro

is staple viscose rayon; Lanital is a casein fibre; acetate rayon is secondary

acetate.

Table 13.1 Tensile properties of fibres at 65% r.h., 20 C, 1 cm test length, 0.15 mN tex1 s1 [2]

Fibre Tenacity Breaking Work of Initial Yield Yield Work

(N/tex) extension rupture modulus stress strain factor

(%) (mN/tex) (N/tex) (mN/tex) (%)

Cotton

St Vincent 0.45 6.8 14.9 7.3 0.49

Upper 0.32 7.1 10.7 5.0 0.46

Bengals 0.19 5.6 5.1 3.9 0.49

Flax 0.54 3.0 8.0 18.0 0.50

Jute 0.31 1.8 2.7 17.2 0.50

Hemp 0.47 2.2 5.3 21.7 0.50

Ramie 0.59 3.7 10.6 14.6 0.47

Viscose rayon 0.18 27.2 30.6 4.8 57 2.0 0.62

Courtaulds

continuous-

filament

Fibro 0.21 15.7 18.8 6.5 68 1.9 0.59

Tenasco 0.27 16.9 19.7 6.0 66 1.6 0.50

Acetate 0.13 23.7 21.6 3.6 75 3.2 0.72

(Celanese)

Fortisan (cellulose) 0.59 6.4 19.1 16.1 113 0.8 0.51

Silk 0.38 23.4 59.7 7.3 156 3.3 0.66

Nylon 0.47 26.0 76.0 2.6 407 16.0 0.61

Wool

Botany 64s 0.11 42.5 30.9 2.3 57 5.0 0.64

Crossbred 56s 0.14 42.9 37.5 2.1 62 5.1 0.62

Crossbred 36s 0.12 29.8 26.6 3.0 74 3.6 0.78

Glass 0.75 2.5 9.8 29.4

Steel wire 0.26 8.0 17.7 28.5

Woodhead Publishing Limited, 2008

You might also like

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- GICO document analyzes soil sample sieving dataDocument1 pageGICO document analyzes soil sample sieving dataKarim IderNo ratings yet

- Spojke Plosnati Remen Klinasti Remen Zupčasti Remen Lančani PrijenosDocument27 pagesSpojke Plosnati Remen Klinasti Remen Zupčasti Remen Lančani PrijenosKarlo KlobučarićNo ratings yet

- Rab DRAINASE LINGKUNGANDocument25 pagesRab DRAINASE LINGKUNGANkesos bojongkembarNo ratings yet

- Laboratory Test Result: Single Sieve For Concrete Materials SpecificationDocument2 pagesLaboratory Test Result: Single Sieve For Concrete Materials SpecificationAndry SetiawanNo ratings yet

- Kelompok 2 Lab. Beton LenturDocument21 pagesKelompok 2 Lab. Beton Lentur1A025D4 Jakon MuhsyahikhanalkahfyNo ratings yet

- Elemental analysis and boiling point characterization of coal tar and biomass tarDocument4 pagesElemental analysis and boiling point characterization of coal tar and biomass tarCesar BerruecoNo ratings yet

- GVT RAW MATERIAL SPECIFICATIONSDocument2 pagesGVT RAW MATERIAL SPECIFICATIONSSaravanan A100% (1)

- Fullerbetonprojete 0000 0Document8 pagesFullerbetonprojete 0000 0Karim IderNo ratings yet

- Fullerbetonprojete 0311 1Document4 pagesFullerbetonprojete 0311 1Karim IderNo ratings yet

- Feed Formulation Chart AnalysisDocument8 pagesFeed Formulation Chart AnalysisJude EnabuluNo ratings yet

- RN 27 Tunnel Bba: FullerDocument3 pagesRN 27 Tunnel Bba: FullerKarim IderNo ratings yet

- Copia de Datos Reologia Prof. LucasDocument34 pagesCopia de Datos Reologia Prof. LucasALEJANDRA GUTIERREZ SAAVEDRANo ratings yet

- Sieve Analysis Test: Astm C 136Document1 pageSieve Analysis Test: Astm C 136Dede NurcahyadiNo ratings yet

- Bahan Baku (Raw Material Feed)Document6 pagesBahan Baku (Raw Material Feed)MFajar FahmiNo ratings yet

- Fullerbetonprojete 1911 1Document1 pageFullerbetonprojete 1911 1Karim IderNo ratings yet

- Fullerbetonprojete 1911 1Document1 pageFullerbetonprojete 1911 1Karim IderNo ratings yet

- Mix Design Using RAP 30Document4 pagesMix Design Using RAP 30Raghav100% (2)

- Akbou (Sable Saoudi) RN 35: FullerDocument2 pagesAkbou (Sable Saoudi) RN 35: FullerKarim IderNo ratings yet

- Fullerakbou 01Document2 pagesFullerakbou 01Karim IderNo ratings yet

- Properties of Natural and Man-Made Fibers ComparededitDocument2 pagesProperties of Natural and Man-Made Fibers Comparededitkate trishaNo ratings yet

- Steel TableDocument6 pagesSteel TableRANJAN PANDEYNo ratings yet

- Bom BoqDocument4 pagesBom BoqRenzel EstebanNo ratings yet

- Fuller: Etrhb Dosage 400KgDocument2 pagesFuller: Etrhb Dosage 400KgKarim IderNo ratings yet

- Etrhb 2Document2 pagesEtrhb 2Karim IderNo ratings yet

- Sieve Analysis 2Document3 pagesSieve Analysis 2A KyariNo ratings yet

- Feed Formulation-DZARCDocument11 pagesFeed Formulation-DZARCanwar kadiNo ratings yet

- Calculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaDocument6 pagesCalculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaMauro DelgadoNo ratings yet

- ENG - C 20 FORMULATION Variante B - 40 sieve size analysisDocument3 pagesENG - C 20 FORMULATION Variante B - 40 sieve size analysisKarim IderNo ratings yet

- M30 Concrete Mix DesignDocument4 pagesM30 Concrete Mix DesignrajupetalokeshNo ratings yet

- Ball Mill SimulatorDocument4 pagesBall Mill SimulatorIrshad HussainNo ratings yet

- Rodsim:: Open Circuit Grinding SimulatorDocument38 pagesRodsim:: Open Circuit Grinding SimulatorJunior Romero ChavezNo ratings yet

- Whatman Filtration Catalog PDFDocument68 pagesWhatman Filtration Catalog PDFJohn E. BeNo ratings yet

- CAlcio Fino y Grueso Polo MatiasDocument2 pagesCAlcio Fino y Grueso Polo MatiasCarlos M. LópezNo ratings yet

- ASME B46.1-2009 Surface Texture (Surface Roughness, Waviness, and Lay) - Part2 PDFDocument62 pagesASME B46.1-2009 Surface Texture (Surface Roughness, Waviness, and Lay) - Part2 PDFR JNo ratings yet

- Combined grading analysis of coarse and fine aggregatesDocument12 pagesCombined grading analysis of coarse and fine aggregatesGaurav SharmaNo ratings yet

- Mechanical Tube - Square: Unit Weight: KG/MDocument1 pageMechanical Tube - Square: Unit Weight: KG/MRisang PamungkasNo ratings yet

- Mix Design Using RAPDocument3 pagesMix Design Using RAPRaghav100% (1)

- JIS G3452: Carbon Steel Pipes For Ordinary PipingDocument1 pageJIS G3452: Carbon Steel Pipes For Ordinary PipingHoJienHauNo ratings yet

- Metode Perhitungan Viscositas Intrinsik: Sample Kode 141 900Document1 pageMetode Perhitungan Viscositas Intrinsik: Sample Kode 141 900A Achyar AlfaNo ratings yet

- Kandungan Unsur Hara Pada Bahan OrganikDocument2 pagesKandungan Unsur Hara Pada Bahan OrganikYusrifar ImanudinNo ratings yet

- Fuller: Graviers ENG Sable Soumame - Boussada Dosage 250KgDocument2 pagesFuller: Graviers ENG Sable Soumame - Boussada Dosage 250KgKarim IderNo ratings yet

- CMT DetailsDocument32 pagesCMT DetailsMerch3 organicNo ratings yet

- Is 19781982Document5 pagesIs 19781982Padakandla SumanNo ratings yet

- Gama PhiDocument2 pagesGama PhiAndres FloresNo ratings yet

- Calcul Composition Beton Selon Bolomey - Lafarge AlgerieDocument1 pageCalcul Composition Beton Selon Bolomey - Lafarge AlgerieLaziz AtmaniNo ratings yet

- Fullerbetonprojete 2011 1Document4 pagesFullerbetonprojete 2011 1Karim IderNo ratings yet

- Sieve Analysis ReportDocument1 pageSieve Analysis ReportBaluku BennetNo ratings yet

- Acoustic analysis of an auditoriumDocument16 pagesAcoustic analysis of an auditoriumRicardo Soto MoscosoNo ratings yet

- Combine CalculationDocument3 pagesCombine CalculationKamran JUTTNo ratings yet

- Mix Desain Bahan Bahu Agregat Kls. S: Proyek: Pelebaran Jalan Maros - Watanpone (Myc)Document59 pagesMix Desain Bahan Bahu Agregat Kls. S: Proyek: Pelebaran Jalan Maros - Watanpone (Myc)Dibakar PutraNo ratings yet

- TABELA Promom 61Document1 pageTABELA Promom 61marantelNo ratings yet

- CableDocument2 pagesCablejay shahNo ratings yet

- Requerimientos Proteicos: Mcal EM/Kg MSDocument10 pagesRequerimientos Proteicos: Mcal EM/Kg MSgcguilhermNo ratings yet

- Back UpDocument4 pagesBack UpWahyu SaputroNo ratings yet

- Analyse CourbesDocument21 pagesAnalyse CourbesOussama ImadNo ratings yet

- ModulusDocument22 pagesModulusYvette OrbánNo ratings yet

- Development of Direct Tension Test Method For Ultra-High-Performance Fiber-Reinforced ConcreteDocument10 pagesDevelopment of Direct Tension Test Method For Ultra-High-Performance Fiber-Reinforced ConcreteYvette OrbánNo ratings yet

- Microstructure of Mortars From Three Egyptian PyramidsDocument10 pagesMicrostructure of Mortars From Three Egyptian PyramidsYvette OrbánNo ratings yet

- Interfacial Bond Between Reinforcing Fibers and Calcium SulfoalumDocument12 pagesInterfacial Bond Between Reinforcing Fibers and Calcium SulfoalumYvette OrbánNo ratings yet

- PP Fiber Reinforced Concrete - ReviewDocument6 pagesPP Fiber Reinforced Concrete - ReviewSubramani PichandiNo ratings yet

- BambooDocument30 pagesBambooYvette OrbánNo ratings yet

- Bamboo Based Biocomposites Material, Design and ApplicationsDocument30 pagesBamboo Based Biocomposites Material, Design and ApplicationsGia Han Hoang HuuNo ratings yet

- Ultra High Performance Concrete Reinforced With SHDocument8 pagesUltra High Performance Concrete Reinforced With SHYvette OrbánNo ratings yet

- Performance of Kevlar Fibre-Reinforced Rubber Composite Armour Against Shaped-Charge Jet PenetrationDocument13 pagesPerformance of Kevlar Fibre-Reinforced Rubber Composite Armour Against Shaped-Charge Jet PenetrationYvette OrbánNo ratings yet

- Lea 201 Coverage Topics in Midterm ExamDocument40 pagesLea 201 Coverage Topics in Midterm Examshielladelarosa26No ratings yet

- A - Bahasa Inggris-DikonversiDocument96 pagesA - Bahasa Inggris-DikonversiArie PurnamaNo ratings yet

- WEEK 8 HW WS - B - Graphs & ChartsDocument6 pagesWEEK 8 HW WS - B - Graphs & Chartsangela trioNo ratings yet

- Intermediate Accounting Testbank 2Document419 pagesIntermediate Accounting Testbank 2SOPHIA97% (30)

- Movie Review TemplateDocument9 pagesMovie Review Templatehimanshu shuklaNo ratings yet

- Introduction to Human Resource Management Functions and Their ImportanceDocument23 pagesIntroduction to Human Resource Management Functions and Their ImportancedhrupaNo ratings yet

- Exercise No. 7: AIM: To Prepare STATE CHART DIAGRAM For Weather Forecasting System. Requirements: Hardware InterfacesDocument4 pagesExercise No. 7: AIM: To Prepare STATE CHART DIAGRAM For Weather Forecasting System. Requirements: Hardware InterfacesPriyanshu SinghalNo ratings yet

- Spain Price List With VatDocument3 pagesSpain Price List With Vatsanti647No ratings yet

- Fundamentals and Applications of Renewable Energy by Mehmet Kanoglu, Yunus Cengel, John CimbalaDocument413 pagesFundamentals and Applications of Renewable Energy by Mehmet Kanoglu, Yunus Cengel, John CimbalaFrancesco Nocera100% (1)

- Scenemaster3 ManualDocument79 pagesScenemaster3 ManualSeba Gomez LNo ratings yet

- The Punjab Commission On The Status of Women Act 2014 PDFDocument7 pagesThe Punjab Commission On The Status of Women Act 2014 PDFPhdf MultanNo ratings yet

- DX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Document6 pagesDX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Welissa ChicanequissoNo ratings yet

- TransformerDocument50 pagesTransformerبنیاد پرست100% (8)

- JRC Wind Energy Status Report 2016 EditionDocument62 pagesJRC Wind Energy Status Report 2016 EditionByambaa BattulgaNo ratings yet

- StrutsDocument7 pagesStrutsBatrisyialya RusliNo ratings yet

- Jenga Cash Flow Solution: InstructionsDocument1 pageJenga Cash Flow Solution: InstructionsPirvuNo ratings yet

- Equity AdvisorDocument2 pagesEquity AdvisorHarshit AgarwalNo ratings yet

- Method StatementDocument11 pagesMethod StatementMohammad Fazal Khan100% (1)

- BUSN7054 Take Home Final Exam S1 2020Document14 pagesBUSN7054 Take Home Final Exam S1 2020Li XiangNo ratings yet

- Hollow lateral extrusion process for tubular billetsDocument7 pagesHollow lateral extrusion process for tubular billetsjoaopedrosousaNo ratings yet

- Coupled Mode TheoryDocument5 pagesCoupled Mode TheoryRahul RoyNo ratings yet

- FOMRHI Quarterly: Ekna Dal CortivoDocument52 pagesFOMRHI Quarterly: Ekna Dal CortivoGaetano PreviteraNo ratings yet

- Renewable and Sustainable Energy ReviewsDocument13 pagesRenewable and Sustainable Energy ReviewsMohammadreza MalekMohamadiNo ratings yet

- GSM Multi-Mode Feature DescriptionDocument39 pagesGSM Multi-Mode Feature DescriptionDiyas KazhiyevNo ratings yet

- User-Centered Website Development: A Human-Computer Interaction ApproachDocument24 pagesUser-Centered Website Development: A Human-Computer Interaction ApproachKulis KreuznachNo ratings yet

- Final Biomechanics of Edentulous StateDocument114 pagesFinal Biomechanics of Edentulous StateSnigdha SahaNo ratings yet

- Upgrade DB 10.2.0.4 12.1.0Document15 pagesUpgrade DB 10.2.0.4 12.1.0abhishekNo ratings yet

- WM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersDocument4 pagesWM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersEdgar JimenezNo ratings yet

- Admission Checklist (Pre-) Master September 2021Document7 pagesAdmission Checklist (Pre-) Master September 2021Máté HirschNo ratings yet

- The Study of Accounting Information SystemsDocument44 pagesThe Study of Accounting Information SystemsCelso Jr. AleyaNo ratings yet