Professional Documents

Culture Documents

19.station - Service Transformer

Uploaded by

Thameemul BuhariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

19.station - Service Transformer

Uploaded by

Thameemul BuhariCopyright:

Available Formats

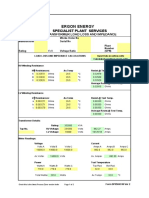

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 1 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

1. MECHANICAL CHECK AND VISUAL INSPECTION

S. NO: DESCRIPYION DONE REMARKS

Check impact recorder for any abnormal impacts during transit (if

1

applicable).

Check for LV Side Air Circuit Breaker before cable at transformer side. If

2

applicable.

3 Check for Danger Plate Warning installation.

Check earthing, color, painting, external damage, oil leakage, wheel

4

stopper, cable connection and bolt tightness, etc.

5 Check Name Plate information for correctness

6 Perform all special checks according to the manufacturers instructions.

7 Check oil level in HV side cable box and its oil level indicator or HV

fuses ( if applicable)

8 Check that the off load tap-changer is set at the nominal voltage tap.

9 Check all devices are labeled correctly as per drawing.

2. ELECTRICAL TESTS:

S. NO: DESCRIPYION DONE REMARKS

1 Check LV side MCB setting as per transformer current rating.

Ratio Test (all taps), Insulation resistance measurement test on all windings

2

and polarization index (P.I.) test

3 Polarity and Vector Group symbols confirmation Test.

4 Check oil level and its indicator alarms.

5 Check oil temperature gauge by oil bath method and its alarms.

6 Check LV and HV side phases match with the LV bus bar phasing in the

S. NO: distribution panels and withDESCRIPYION

the main transformer phases. DONE REMARKS

7 Check phasing

Perform at the

functional testsautomatic transferdevices

of all auxiliary switch(as

(asapplicable)

applicable )

11

8 Winding

Oil resistance

dielectric measurement

test at site shall not be(at allthan

less taps).

50KV at 2.5mm gap.

12

9 Excitation current

Insulating oil tests : test (all taps).

10 Prior

Back to energization,

energization testthe

at contractor

rated voltageshould submit

for 15 insulating oil test

minutes.

reports tested at an independent laboratory, for the following.

a. Dielectric strength

1. ASTM D 877 (2.5 mm) gap for unprocessed oil.

2. ASTM D 1816 (1.0 mm) gap for oil in main tank

TEST DATE: b.

TESTNeutralization Number (ASTM

EQUIPMENT CALIB.DATE & DETAILD 974)

c. Interfacial Tension (ASTM D 971)

TESTING ENGINEER CSD- Engineer

13 d. Color (ASTM D 1500)

e. Moisture Content (ASTM D 1533)

f. Power factor test(ASTM D 924)

Signature: ________________

g. Dissolved Gas in Oil Analysis (ASTM Signature:

D3 612)________________

Name h. (Dielectric Dissipation factor, Resistivity,

: ________________ Name Sediment and/or

: ________________

Perceptible sludge)

Another oil sample shall be given to SEC transmission for their own

analysis & comparison purposes. A syringe oil sample shall be taken by

contractor.

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 2 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

TRANSFORMER NAME PLATE DETAILS:

Make :

Type of cooling :

Number of Phases :

Rated Frequency :

Rated KVA :

Vector Group :

% Impedance :

DIAGRAM :

Year of Manufacture :

Primary Current :

Secondary Current :

Primary :

Secondary :

Serial No :

Total Weight :

Temp.Rise of OIL :

Temp Rise Wdg :

Maximum withstands operating pressure :

Maximum withstands capability :

TAP POSITION HV LV

1

VOLT 2

AGE 3

(volts) 4

5

1. LV side MCB setting as per transformer current rating.

Current Applied Trip Time in Sec Contact

Device No. of

Sr. No Type Rating (A) Current (A) From Status

Location poles Actual

In 3x In Curve Check

1

2

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 3 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

3

10

2. WINDING INSULATION RESISTANCE AND POLARIZATION INDEX

Instrument : Insulation Resistance Tester

Make :

Model No. / Sr. No. :

Voltage Applied : 1000 V / 500 V DC

Ambient Temperature = ________ C Humidity = _______%

OTI = ______ C Acceptable Criteria : Comparison with Factory results

MEASURED INSULATION RESISTANCE

VALUE (M )

HV-Earth 10 (min.) Polarization Index

1 (min.) 5 (min.)

(LV Guarded)

LV- Earth

(HV Guarded)

HV-LV

(Tank

Guarded)

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 4 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

CRITERIA: PI > 1.25

TURNS RATIO TEST

Instrument : TURNS RATIO METER

Make :

Model No. / Sr.No. :

Criteria : Error in ratio to be less than 0.5% of

Nominal ratio

Ratio measured % Error

Rated

Tap

HV (V) LV (V) ratio A-B B-C C-A

No. A B C

a-b b-c c-a

1

2

3

4

5

3. VECTOR GROUP SYMBOLS CONFORMATION TEST

Test Instrument :

Make / Model No. :

Vector Group of Transformer :

Transformer was excited from H.V. winding with a suitable Low three phase power supply and

Vector Group checked.

Test connections:

Test Results:

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 5 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

Relationship required:

Field Measurements:

Result :

4. Check oil level and its indicator alarms.

Make : Type:

FUNCTIONAL TEST

OPERATION

DEVICE FUNCTION SETTING REMARKS

PICK UP DROP OUT

Alarm

OTI

Criteria : Pickup & Dropout values shall be within 1%

5. Calibration test of Oil temperature gauge by oil bath method and its alarms.

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 6 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

TEMPERATURE SETTING

Increase

Temp:

Gauge C

Decrease

6. Check LV and HV side phases match with the LV bus bar phasing in the distribution panels and with the main

transformer phases.

7. Check phasing at the automatic transfer switch (as applicable)

8. WINDING RESISTANCE MEASUREMENT.

OTI = ______ C Amb: ______ C

WINDING RESISTANCE (HV)

Tap PHASE- CAL: at PHASE- CAL: at PHASE- CAL: at

FACT: FACT: FACT:

Position A 75 C B 75 C C 75 C

1

2

3

4

5

LV WINDING RESISTANCE MEASUREMENT.

OTI =Temp: C Amb: C

WINDING RESISTANCE (LV)

CAL: at CAL: at CAL: at

TEST 2u1-2n FACT: 2v1-2n FACT: 2w1-2n FACT:

75 C 75 C 75 C

1

Formula to convert winding resistance to reference temperature at 75 C for copper winding.

NOTE: 1.

Rc = Calculated value at 75 C

Rm = Measurement value which contained a measurement cable.

NOTE: 2

Calculated 75 C Rc = (Rm-Rx) x (234.5+75)

(234.5+Ta)

Rx = Resistance value of the measurement cable. Ta = Oil Temperature ____ C

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 7 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

NOTE: 3

Resistance value of measurement cable Rx = _______

9. EXCITATION CURRENT MEASUREMENT

Excitation current was measured by applying three phase source to H.V. side, keeping L.V. side

Open.

Instrument : Multimeter (Current)

Make :

Model No. :

Sl. No. :

Multimeter (Voltage Range)

Criteria : 10 % of factory test report

Test connection

Tap Positions A-B B-C C-A

Phase Result

On all taps Applied Voltage (V)

Excitation Current (mA)

10. BACK ENERGISATION TEST (15 minutes)

Test Instrument

a. 3 Phase supply

b. Multimeter (as Volt Meter) :

Make :

Sr. No. :

Calibration Certificate :

Procedure:

Three phase 380 V source is applied for 15 minutes to the secondary of Transformer keeping primary

open ( 34.5kV ). The condition of Transformer is observed.

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 8 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

Result:

11. Perform functional tests of all auxiliary devices (as applicable)

12. DIELECTRIC BREAKDOWN TEST FOR OIL:

Test Instrument : OIL TESTER

Make :

Model / Sr.No. :

The transformer insulating oil was tested for Dielectric strength using oil tester (ASTM Std.)

1. Test after filling : 50kV or above

Dielectric strength required :

Oil Temp. Deg. C

Result

Dielectric Strength ( kV ) ELECTR

No. Test Points Average

Number of Tests -ODE

GAP

13. CHARECTERISTICS OF INSULATING OIL:

Items Measured value

D.2.a Acid Neutralization number (ASTM D 974)

D.2.b. Interfacial tension (ASTM D 971)

D.2.c Color (ASTM D 1500)

D.2.d. Moisture content PPM water (ASTM D 1533)

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractors name: Advance Energy

Client: NG - SA

Company(AECC)

SEC EOA Contract No. :

Name of substation: 115/13.8KV Khafji Substation - 5 31131152/00

Page 9 of 9

STATION SERVICE TRANSFORMER

P/TR.No.: Vector Group: HV Voltage: LV Voltage:

Make: MVA Capacity: HV Current: LV Current:

D.2.e Kind of gas Gas content ( ppm )

CO2

CO

H2

CH4

C2H4

Respon C2H6

C2H2

sibilities Total gas

Legend

CSD Note: The tests for characteristics of oil as above will be carried out in an independent laboratory and test results will

be submitted.

14. TEST EQUIPMENT USED:

Item Description Make Equipment Sl. No Calibration Date Calibration Due Date

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

You might also like

- Prophetic Dance - Mary JonesDocument7 pagesProphetic Dance - Mary Jonesm28181920No ratings yet

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocument8 pagesNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamNo ratings yet

- 9 LorDocument2 pages9 LorThameemul BuhariNo ratings yet

- 9 LorDocument2 pages9 LorThameemul BuhariNo ratings yet

- Handouts For Madina Book1Document39 pagesHandouts For Madina Book1Bilal Shahid100% (1)

- CB Test ReportDocument2 pagesCB Test ReportLingga SuhadhaNo ratings yet

- Mvaj101 - Trip RelayDocument2 pagesMvaj101 - Trip RelayratheeshkumardNo ratings yet

- Arabic Tutor (Arabi Ka Muallim) Part-4 by Shaykh Abdus Sattar KhanDocument528 pagesArabic Tutor (Arabi Ka Muallim) Part-4 by Shaykh Abdus Sattar Khanabdussamad6544% (9)

- Arabic Tutor (Arabi Ka Muallim) Part-4 by Shaykh Abdus Sattar KhanDocument528 pagesArabic Tutor (Arabi Ka Muallim) Part-4 by Shaykh Abdus Sattar Khanabdussamad6544% (9)

- Testing of Power and Distribution TransformerDocument82 pagesTesting of Power and Distribution Transformeramulya sNo ratings yet

- Test Procedure CVT Bus 1 Phase R & TDocument4 pagesTest Procedure CVT Bus 1 Phase R & TLeonardo layNo ratings yet

- Iso 27001 Auditor TrainingDocument19 pagesIso 27001 Auditor TrainingITOPS TeamNo ratings yet

- Site Test Report AnalysisDocument32 pagesSite Test Report AnalysisThameemul BuhariNo ratings yet

- Site Test Report AnalysisDocument32 pagesSite Test Report AnalysisThameemul BuhariNo ratings yet

- Modern Automatic Bus Transfer Scheme Using IEDsDocument10 pagesModern Automatic Bus Transfer Scheme Using IEDsnitinpeNo ratings yet

- GT Relay Testing FormatDocument7 pagesGT Relay Testing FormatVk Sumanth100% (1)

- Surge Arrestor Commissioning ChecklistDocument7 pagesSurge Arrestor Commissioning ChecklistSyed Abbas100% (1)

- Checklist For Auxiliary Transformer Rev00Document4 pagesChecklist For Auxiliary Transformer Rev00Santhosh Kumar VinayagamNo ratings yet

- Power Transformer TestDocument27 pagesPower Transformer Testm khNo ratings yet

- Promoting Gusaling Museo Through ModernizationDocument15 pagesPromoting Gusaling Museo Through Modernizationdesiree choi100% (1)

- Protectionofpowertransformer 130727035128 Phpapp02 PDFDocument19 pagesProtectionofpowertransformer 130727035128 Phpapp02 PDFKarthik Kumar100% (1)

- PSGDocument13 pagesPSGya vikaNo ratings yet

- Bet VT Test ReportDocument2 pagesBet VT Test ReportSathi Reddy ThondapuNo ratings yet

- 220v DC SystemDocument16 pages220v DC SystemsanjeevchhabraNo ratings yet

- Line Protection: Mahendra S Hada PowergridDocument48 pagesLine Protection: Mahendra S Hada PowergridshashankaumNo ratings yet

- Theories & Models of LearningDocument33 pagesTheories & Models of LearningAna Paulina Suárez CervantesNo ratings yet

- Tested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureDocument2 pagesTested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureRK KNo ratings yet

- On Load Tap Changers Abb PDFDocument12 pagesOn Load Tap Changers Abb PDFKushtrim MalaNo ratings yet

- HV Pressure Tests Document SummaryDocument4 pagesHV Pressure Tests Document SummaryssNo ratings yet

- Tinh Dong Ngan Mach Va Ton That Co TaiDocument3 pagesTinh Dong Ngan Mach Va Ton That Co TaiNga VũNo ratings yet

- Substation Commissioning Test Report - SAMPLEDocument1 pageSubstation Commissioning Test Report - SAMPLEArun MuthuramanNo ratings yet

- Power Transformer Maintenance and CommissioningDocument79 pagesPower Transformer Maintenance and CommissioningAdnann NurdinNo ratings yet

- TSS SP/SSP: Testing of Equipment at Traction SubstationDocument2 pagesTSS SP/SSP: Testing of Equipment at Traction Substationrajni1239No ratings yet

- Schematic Wiring Diagram GuideDocument6 pagesSchematic Wiring Diagram GuideramyapothurNo ratings yet

- 16 MVTPDocument3 pages16 MVTPjayabalNo ratings yet

- Busbar Protection Philedelphia Edu LibreDocument90 pagesBusbar Protection Philedelphia Edu Libreprakasa88No ratings yet

- Ac Panel Test ReportDocument14 pagesAc Panel Test ReportUtku Can KılıçNo ratings yet

- Subject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheDocument22 pagesSubject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheChetan KotwalNo ratings yet

- GAS INSULATED SWITCHGEAR - Rev 2Document33 pagesGAS INSULATED SWITCHGEAR - Rev 2Essam AlBannaNo ratings yet

- Site Testing Pre Commissioning PDFDocument2 pagesSite Testing Pre Commissioning PDFadi nugrohoNo ratings yet

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- HV Cable Commissioning ReportDocument10 pagesHV Cable Commissioning Reportvo100% (1)

- MN000301R171Document24 pagesMN000301R171juancgr77No ratings yet

- EE2036 Flexible AC Transmission Systems Two Mark Question and AnswersDocument15 pagesEE2036 Flexible AC Transmission Systems Two Mark Question and Answersanshuman nayakNo ratings yet

- A. Wound Type:: 1. What Are The Types of CT? Example?Document8 pagesA. Wound Type:: 1. What Are The Types of CT? Example?deltavijayakumarNo ratings yet

- General Data and InformationDocument5 pagesGeneral Data and InformationSunil SinghNo ratings yet

- Pedro Flores El Chapo TrialDocument19 pagesPedro Flores El Chapo TrialChivis MartinezNo ratings yet

- High Voltage SwitchgearDocument10 pagesHigh Voltage SwitchgearMATHANKUMAR.SNo ratings yet

- MV Transformer Testing (7200DB1001Document4 pagesMV Transformer Testing (7200DB1001sulthanabdulNo ratings yet

- PM Check List - CB & BusbarDocument7 pagesPM Check List - CB & BusbarRizky VidiyanaNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- 01 CB-Design PDFDocument21 pages01 CB-Design PDFaaaygugNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDocument11 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDinesh PitchaivelNo ratings yet

- LV Test Plan - ErgonDocument1 pageLV Test Plan - ErgonrezadNo ratings yet

- Voltage Transformer TestingDocument19 pagesVoltage Transformer TestingAfrin HossainNo ratings yet

- VC-6000 Monitoring SystemDocument8 pagesVC-6000 Monitoring Systemahwaz89No ratings yet

- Variable Voltage Variable Frequency Motor Drive ManualDocument11 pagesVariable Voltage Variable Frequency Motor Drive ManualKhaled ZakariaNo ratings yet

- Engine Generator Set Inspection Checklist: Section A - Customer DataDocument2 pagesEngine Generator Set Inspection Checklist: Section A - Customer Datasri_lntNo ratings yet

- IOC Tr. Oil Test ReportDocument3 pagesIOC Tr. Oil Test ReportMalini VenkatesanNo ratings yet

- Check List For Testing: Equipment Needed To Be TestedDocument2 pagesCheck List For Testing: Equipment Needed To Be TestedKarthik EvilordNo ratings yet

- ADR233BDocument19 pagesADR233BNamrata ShettiNo ratings yet

- ADR245BDocument19 pagesADR245BNamrata ShettiNo ratings yet

- Qc-Qcr-Ele-24 Power CircuitDocument1 pageQc-Qcr-Ele-24 Power CircuitRoderick HipolNo ratings yet

- Magnetic Balance TestDocument3 pagesMagnetic Balance Testrasheed313No ratings yet

- Unit-6 Circuit Breakers (Switchgear and Protection)Document84 pagesUnit-6 Circuit Breakers (Switchgear and Protection)sujithNo ratings yet

- VVVF v1.3 Operators ManualDocument26 pagesVVVF v1.3 Operators ManualyounesNo ratings yet

- CMA9 MOTOR DRIVE ManualDocument29 pagesCMA9 MOTOR DRIVE ManualAshraf NazifNo ratings yet

- Atvus PRVDocument6 pagesAtvus PRVvipulpanchotiyaNo ratings yet

- SIPROTEC Numerical Protection Relays Catalog Features 7RW600 UV/OV & Frequency ProtectionDocument20 pagesSIPROTEC Numerical Protection Relays Catalog Features 7RW600 UV/OV & Frequency Protectionrajinipre-1No ratings yet

- Respon Sibilities Legend CSD: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document2 pagesRespon Sibilities Legend CSD: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1jayabalNo ratings yet

- Potential TransformerDocument8 pagesPotential TransformerSyed AbbasNo ratings yet

- Service ManualDocument106 pagesService ManualThameemul BuhariNo ratings yet

- Steve and JohnDocument57 pagesSteve and JohnThameemul BuhariNo ratings yet

- SF6 Leak Repairs Without Pressure ReductionDocument3 pagesSF6 Leak Repairs Without Pressure ReductionThameemul BuhariNo ratings yet

- DC Oprtd Relay Auto RXEMDocument2 pagesDC Oprtd Relay Auto RXEMThameemul BuhariNo ratings yet

- Deabb 5171 16 enDocument2 pagesDeabb 5171 16 enThameemul BuhariNo ratings yet

- DC Oprtd Relay Auto LSDocument2 pagesDC Oprtd Relay Auto LSThameemul BuhariNo ratings yet

- 3 Rxba4Document2 pages3 Rxba4Thameemul BuhariNo ratings yet

- DC Oprtd Electr Relay RXMD1Document2 pagesDC Oprtd Electr Relay RXMD1Thameemul BuhariNo ratings yet

- MicroTAPP OperDocument22 pagesMicroTAPP OperThameemul BuhariNo ratings yet

- Critical-Power Automatic Transfer Systems - Design and ApplicationDocument18 pagesCritical-Power Automatic Transfer Systems - Design and ApplicationRazvan Mares100% (1)

- PCO Improve Method Measuring c1 Power Factor PDFDocument7 pagesPCO Improve Method Measuring c1 Power Factor PDFThameemul BuhariNo ratings yet

- Considerations and Methods For An Effective Fast Bus Transfer SystemDocument12 pagesConsiderations and Methods For An Effective Fast Bus Transfer SystemThameemul BuhariNo ratings yet

- JHJJKDocument2 pagesJHJJKThameemul BuhariNo ratings yet

- Numbers PDFDocument6 pagesNumbers PDFThameemul BuhariNo ratings yet

- Transformer Basics and COPQ AnalysisDocument59 pagesTransformer Basics and COPQ AnalysisThameemul BuhariNo ratings yet

- NWsu04Fea DuarteDocument5 pagesNWsu04Fea DuarteThameemul BuhariNo ratings yet

- Arabic-Weekly Course-Flyer PDFDocument1 pageArabic-Weekly Course-Flyer PDFThameemul BuhariNo ratings yet

- TTR300 UG en V02Document64 pagesTTR300 UG en V02Thameemul BuhariNo ratings yet

- Helpsheet FAQDocument11 pagesHelpsheet FAQThameemul BuhariNo ratings yet

- Forms Design Fa QDocument20 pagesForms Design Fa QThameemul BuhariNo ratings yet

- SweptfrequencyresponseanalysistodetectpowertransformersshippingdamageDocument17 pagesSweptfrequencyresponseanalysistodetectpowertransformersshippingdamagepoeta_oscuroNo ratings yet

- Topic 2Document6 pagesTopic 2Vince Diza SaguidNo ratings yet

- Dslam Commissioning Steps Punjab For 960 PortDocument8 pagesDslam Commissioning Steps Punjab For 960 Portanl_bhn100% (1)

- 1) How Are Lakes Classified in Regards To Trophic Status? 2) What Is Cultural Eutrophication?Document31 pages1) How Are Lakes Classified in Regards To Trophic Status? 2) What Is Cultural Eutrophication?Enzo TapingNo ratings yet

- Past Paper 1 Ibsl: Phone: 7514251,0816930718Document4 pagesPast Paper 1 Ibsl: Phone: 7514251,0816930718santhiNo ratings yet

- Urea CycleDocument2 pagesUrea CycleyoungdandareNo ratings yet

- History of Technical Writing HardDocument4 pagesHistory of Technical Writing HardAllyMae LopezNo ratings yet

- Socsci 032 Midterm Compilation NotesDocument12 pagesSocsci 032 Midterm Compilation NotesCarla AbalaNo ratings yet

- Clare Redman Statement of IntentDocument4 pagesClare Redman Statement of Intentapi-309923259No ratings yet

- Thesis NewDocument55 pagesThesis NewHasan juwelNo ratings yet

- Sample Problems Part FormDocument4 pagesSample Problems Part FormkenivanabejuelaNo ratings yet

- ICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseDocument8 pagesICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseZayd Iskandar Dzolkarnain Al-Hadrami100% (1)

- Anuj Singh ResumeDocument4 pagesAnuj Singh ResumeAnuj BaghelNo ratings yet

- Business Analytics ModuleDocument22 pagesBusiness Analytics ModuleMarjon DimafilisNo ratings yet

- Deepali Bhartiya: TCI Express Limited Gurgaon Assistant Manager Prateek Group Noida Senior ExecutiveDocument3 pagesDeepali Bhartiya: TCI Express Limited Gurgaon Assistant Manager Prateek Group Noida Senior ExecutiveThe Cultural CommitteeNo ratings yet

- 09-04-2023 - Plumbing BOQ Without RatesDocument20 pages09-04-2023 - Plumbing BOQ Without RatesK. S. Design GroupNo ratings yet

- En GBDocument4 pagesEn GBahmedNo ratings yet

- Embodied experience at the core of Performance StudiesDocument10 pagesEmbodied experience at the core of Performance StudiesVictor Bobadilla ParraNo ratings yet

- Metaswitch Datasheet Network Transformation OverviewDocument5 pagesMetaswitch Datasheet Network Transformation OverviewblitoNo ratings yet

- SYKES Home Equipment Agreement UpdatedDocument3 pagesSYKES Home Equipment Agreement UpdatedFritz PrejeanNo ratings yet

- 100 Seniman Yang Membentuk Sejarah DuniaDocument134 pages100 Seniman Yang Membentuk Sejarah DuniaIBRAHIM S.Sos,INo ratings yet

- Gee1-Lp1 2022-2023Document18 pagesGee1-Lp1 2022-2023Sherrizah AlidoNo ratings yet

- What Is A Dry Well?Document4 pagesWhat Is A Dry Well?eullouNo ratings yet

- Current Electricity O LevelDocument59 pagesCurrent Electricity O LevelNoah OkitoiNo ratings yet

- Visvesvaraya Technological University BelagaviDocument148 pagesVisvesvaraya Technological University BelagavichetanbvNo ratings yet

- DHRM 3 SyllabusDocument10 pagesDHRM 3 SyllabusCherokee Tuazon RodriguezNo ratings yet