Professional Documents

Culture Documents

Improving Steam Turbine Blade Design for Increased Efficiency

Uploaded by

easy_astronautOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Improving Steam Turbine Blade Design for Increased Efficiency

Uploaded by

easy_astronautCopyright:

Available Formats

Conference Session B6 2214

Steam Turbine Blade Design

Zachary Stuck (zas31@pitt.edu), Stanley Schurdak (sas312@pitt.edu)

Abstract- This paper addresses the issue of steam turbine energy being produced by steam turbine generators, it is in

efficiency by discussing the overall design of steam turbine the best interest of society to make these generators as

blades with a specific focus on blade aerodynamics, efficient and as sustainable as possible. One of the key

materials used in the production of steam turbine blades, factors influencing the efficiency of these turbines is the

and the factors that cause turbine blade failure and design of the turbine blades. It was through a century of

therefore the failure of the turbine itself. This paper development and advancement in steam turbine blade design

enumerates and describes the currently available that steam turbine efficiency rose from a mere 60% to 90%

technologies that enhance the overall efficiency of the or better [2]. Thus, the better the design of the blade, the

generator and prevent turbine failure due to blade erosion more efficient the turbine will be; and the more efficient the

and blade cracking. In particular, this paper evaluates the turbine is, the more efficient the generator is and the better

effectiveness of certain titanium alloys and steels in resisting off society is. Therefore, it is beneficial to society to

creep and fracture in turbine blades. The effectiveness of implement advanced blade technology that enhances turbine

chemical and thermal coatings in protecting the blade efficiency.

substrate from corrosion when exposed to wet steam will

also be addressed. The stresses developed in the blade as a BLADE MATERIALS

result of steam pressure, steam temperature, and the

centrifugal forces due to rotational movement are The type of material used for turbine blades is based on the

delineated; current designs calculated to counter the fatigue stage of the turbine in which the blades will operate. There

caused by these stresses are presented. The aerodynamic are three such stages: high-pressure (HP), intermediate-

designs of both impulse and reaction turbine blades are pressure (IP), and low-pressure (LP), which are named

compared and contrasted, and the effect that these designs according to the relative pressure of the steam in the stage.

have on turbine efficiency are discussed. The pressures and temperatures of each stage limit the kinds

Based on the research presented herein, this paper of materials that may be used in them. For instance, HP and

presents a detailed summary of what modifications to IP stage blades are generally made from 12Cr martesitic

existing steam turbine generator blades can be made to stainless steels [3]. However, blades used in high-

increase turbine efficiency. Finally, the overall sustainability temperature (> 450 C) HP or IP applications may be made of

of steam turbine generators is discussed and the impact that austenitic stainless steels because they have better

the design of the blades has on the sustainability of these mechanical properties at high temperatures [3]. For example,

generators is presented. stainless steel type AISI 422 (a martensitic stainless steel) is

commonly used for HP and IP turbine sections, while AISI

Key words- Blade, efficiency, corrosion, design, failure, series 300 steels (austenitic) are used for high-temperature

steam turbine, stress applications [3]. LP blades are often, but not exclusively,

made from 12Cr stainless steels also. Common types of

INTRODUCTION stainless steel used in LP sections include AISI types 403,

410, 410-Cb, and 630; the exact type of steel chosen for a

Electrical power has become an essential facet of life in all particular LP application depends on the strength and

spheres of modern society. In the home, electricity is used to corrosion resistance required. Since the 1960s, titanium

power water pumps that provide running water, and heating alloys, especially Ti-6Al-4V, have also been used for LP

and air conditioning systems that provide a comfortable turbine stages [3]. These alloys are particularly suited to LP

atmosphere; electricity is used to power the network of stages for a number of reasons. First, the densities of

computer systems used extensively in commercial inventory titanium alloys are generally less than the density of steels;

organization, and in the computerized mechanisms that for example, Ti-6Al-4V has a density of only 4.43 g/cc

govern manufacturing processes in the manufacturing while stainless steel type AISI 410S has a density of 7.8 g/cc

industry. These are just a few examples that indicate how [4, 5]. This lower density makes it possible to lengthen the

much modern society relies on electrical power and how LP blades and thereby increase turbine efficiency without

important it is to society that a reliable source of electricity increasing stresses in the blades due to centrifugal forces.

be established. Second, titanium alloys have greater corrosion resistance

Currently, nearly 90% of the electricity produced in the than steels; this makes titanium alloys ideal for use in LP

United States is generated using steam turbines, while about stages where there are greater levels of moisture. Finally,

80% of that produced worldwide comes from steam titanium alloys are resistant enough to water droplet erosion

generators [1]. With such a substantial amount of electrical

Twelfth Annual Freshman Conference 1 April 14, 2012

Conference Session B6 2214

!

that they can be used without erosion protection in certain of rotation in the direction away from the center of rotation

applications. of the mass m. The multiplication of m with the second cross

Overall, it is the material properties that make a blade product returns a vector whose magnitude is equal to the

reliable or doomed to failure. The yield strength, tensile second cross product multiplied by the scalar m and whose

strength, corrosion resistance, and modulus of elasticity all direction is the same as that of the second cross product.

play a role in determining whether or not a blade will fail This product is equal to the force vector F. This indicates

under operating loads. that the centrifugal force F acts on the point mass m in a

direction radially outward from the center of rotation.

BLADE LOADING Although this equation is reliable only for point masses, it

helps to illustrate the fact that centrifugal forces tend to

Steam turbines operate at similar speeds, usually in the range pull the objects out of their path of rotation. Figure 1

of 3000-3600 rpm for fossil-fired plants and 1500-1800 rpm illustrates this point. If a turbine blade is thought of as a

for nuclear-powered plants [3]. Because the speeds are finite collection of point masses, then the previous equation

similar, the stresses in the turbine blades, which arise may be applied to each point mass to find the resultant

because of their movement, are also similar. There are two centrifugal force acting on the blade. Thus, the centrifugal

main categories of stress that the blades experience: static force creates an overall tensile stress in the blade by

stresses, consisting of centrifugal tensile stresses, centrifugal pulling on the blade as it rotates [3].

bending stresses, and steam bending loads, and dynamic

stresses, arising from non-uniform steam flows and

synchronous resonance of the blade with the operating speed

of the turbine. However, the majority of blade stresses are

due to centrifugal forces [3].

Centrifugal Tensile Stress

Centrifugal tensile stress is the tensile stress induced in the

blade as a result of its rotational movement. According to

McCloskey [3], the magnitudes of these stresses are

proportional to the square of the speed:

!ct = ("op/"100)2 !100ct

where !ct is the centrifugal tensile load, "op is the rotational

speed of the blade, "100 is the design rotational speed, and

!100ct is the centrifugal tensile stress in the blade at the

design rotational speed. However, blades in the HP and IP

stages are shorter than blades in the LP stage; therefore, the Fig. 1 Centrifugal Force Illustration

centrifugal stresses in the HP and IP stages are relatively

small. Centrifugal forces have a greater effect on the LP !

stage blades due to the longer blade length. According to Centrifugal Bending Stresses

McCloskey, the steady-stresses in the last-row LP blades are

typically 0.5!y for about 50% of the blade length, and Centrifugal bending stresses arise if the centers of gravity

greater than or equal to 0.25!y for 80% of that length, where (centroids) of the blade cross-sectional areas at different

!y is the yield stress of the material [3]. heights do not lie in a straight line with the blade roots

To clarify the action of centrifugal forces, consider the center of gravity. Because the centrifugal force acts on the

simple equation for the centrifugal force, F, acting on a point centroid of the area and in a direction radially outward,

mass m that is rotating with an angular velocity " in a bending moments are produced where the centroids do not

circular path described by the vector r, whose magnitude r lie on the blades center of gravity line. This causes tensile

equals the radius of the path around a certain fixed point: stresses on one side of the blades center of gravity line and

compressive stresses on the other. However, blade designers

F = m"!("!r) [6] have exploited the effects of centrifugal bending to counter

the effect of steam bending. For example, if a steam-bending

The result of the first cross product, ("!r), is a vector in the load tends to bend the blade axially in the direction of steam

direction perpendicular to the plane of rotation. The result of flow, a blade designer can intentionally offset the centroids

of the blade areas that lie towards the tip of the blade in the

the second cross product, "!("!r), is a vector in the plane

direction of the steam load. The centrifugal force acting on

Twelfth Annual Freshman Conference 2 April 14, 2012

Conference Session B6 2214

!

the centroids would then create a bending moment that tends small, and the stress does not exceed the yield stress of the

to bend the blade in the direction opposite that of the steam- material at a given amplitude, the blades experience high-

bending load [3]. Fig. 2 helps to illustrate this point [3]. cycle fatigue causing them to fail suddenly after a large

number of cycles. Larger amplitudes of stress fluctuations

will result in greater stresses in the blades and cause low-

cycle fatigue with blade failure occurring only after a

relatively small number of cycles. Blade vibrations are most

dangerous when the frequency of vibrations coincides with

the natural frequency of the blades [3]. When this occurs, the

blades resonate and fail from high-cycle fatigue in a short

period of time.

Creep

Turbine blades are constantly subject to high temperatures,

predominantly in the HP and IP stages, which tend to soften

the blade material. This, in combination with the centrifugal

forces exerted on the blades, serves to deform the blades,

and cause creep (the slow and continuous deformation of a

Fig. 2 Steam-Bending and Centrifugal Bending

material over time) [3, 7]. The rate of material deformation

(rate of creep) is highly dependent on both the temperature

of the material and the applied stress [7]. This is a

Steam Bending Loads particularly dangerous phenomenon because the blades are

manufactured according to stringent specifications based on

the loading and environment that the blades will operate

As the steam flows through the turbine blades, the steam

under. Any change in the geometry of the blade due to creep

pushes on the blades causing them to bend, thus creating

can result in catastrophic failure due to blade degradation or

what is known as steam bending. Like centrifugal bending,

sudden cracking. This is why it is imperative that the

steam bending causes the blades to be bent lengthwise,

materials chosen for the HP and IP blades retain high yield

creating regions of tensile and compressive stress in the

strengths at elevated temperatures.

blade. Although the movement of the steam does induce

The above information applies mostly to reaction turbine

blade bending, the effect of steam bending in moving blades

blading. Impulse turbines differ from reaction turbines in the

is not as pronounced as the effects of centrifugal forces. In

way that the blades are moved, which results in different

fact, steam-bending stresses are typically only about 10% of

the centrifugal stresses [3]. The stationary blades of a stresses in the different kinds of blades. In a reaction turbine,

the steam flows through fixed blades with no pressure drop

reaction turbine are more affected by the moving steam

and then flows through the moving blades that are shaped so

because the force of the steam on the stationary blades tends

as to form nozzles that serve to increase the velocity of the

to move the blades in the direction of the force. Because the

steam as it passes through the rotor and in doing so cause the

blades cannot be displaced by the applied force of the steam,

rotor to turn. In an impulse turbine, the steam is directed

they instead bend in reaction. Steam bending occurs in HP,

onto the rotor blades from fixed nozzles. The steam hits the

IP, and LP stages, but it is most pronounced in the HP stage

blade creating an impulse and causing the rotor to turn [8].

where the pressure difference across the blades is greatest.

However, it must be noted that in practice, there are no pure

However, steam bending is also significant in LP stage

impulse turbines, but only some considered low-reaction

blades because the LP blades are much longer than HP or IP

turbines [9]. Hence, with the possible exception of steam

blades [3].

bending stresses, the stresses found in impulse turbine blades

Dynamic Stresses may be assumed to be similar to stresses in reaction turbine

blades.

All of the stresses listed above will propagate cracks in

Dynamic stresses are induced in turbine blades when there is

the material, if there are any to begin with, or they will tend

some exciting force that causes the blades to vibrate.

to form cracks from dislocations in the material if there are

Exciting forces can arise from sources of non-uniform flows

no cracks initially present. This is dangerous not only

such as nozzle-wake interactions and structural features that

because it damages the structural integrity of the blade, but

interfere with the steam flow, as well as turbine operating

also because cracks serve as repositories for condensed

speeds [3]. Blade vibrations lead to fluctuations of stress in

steam, which can then react with the blade materials and

the blades, sometimes exceeding the yield strength of the

cause corrosion of the blade [10].

blade material. If the amplitude of the stress fluctuations is

Twelfth Annual Freshman Conference 3 April 14, 2012

Conference Session B6 2214

!

BLADE CORROSION formed surface crack provides an area for condensed steam

to accumulate and a place for impurities carried by the steam

Blade fractures and surface roughness, even on a to concentrate. The concentration of impurities, if high

microscopic scale, provide areas where deposits of highly enough, will corrode the material, thereby lessening the

concentrated aggressive solutions of admixtures [11] can be contiguous area of the blade. This will not only weaken the

formed. The subsequent reaction of blade materials with overall strength of the blade, but it will also increase the

these admixtures is extremely detrimental to the blade local stresses at the edge of the crack, thus propagating the

structure. These reactions propagate cracks by corroding the crack even further and presenting new areas for corrosion.

material around existing cracks and in doing so weaken the Eventually, if the crack grows to a critical size, the blade

blade. In essence, corrosion only occurs because of the will split at the crack location and fail. This example

presence of blade surface cracks. Furthermore, corrosion is illustrates the interconnectedness of stress, corrosion, and

accelerated by impurities in the steam. According to fatigue, and indicates that the effects of crack and defect

Ryuichiro Ebara, in his paper Corrosion Crack Initiation in accumulation are not insignificant.

12% Chromium Stainless Steel, over eighty different

compounds including oxide, silicate, and sulfide have been ACCUMULATION FAILURES

found in deposits on turbine blades [12]. These impurities,

depending on their nature and concentration, can lead to a Over the course of a turbines active lifetime, the cyclic

drastic decrease in blade fatigue strength. Ebara has shown loading experienced by its components will build up areas of

that NaCl and NaOH are very corrosive compounds and defects that can severely affect the integrity of the

therefore very effective in reducing blade fatigue strength. components. Such accumulations of defects increase the

For example, Ebara showed in his study, that even in small possibility of component failure and, if accumulation of

(3%-3x10-2%) concentrations of NaCl solutions the fatigue defects occurs rapidly, the operating lifetime of the turbine

strength of steel is greatly (~75%) reduced. will be significantly shortened. A peer-reviewed case study

Corrosion is of major concern mostly in the LP stage of describes the failure of an 8.25-MW capacity steam turbine

the turbine because of the lower temperatures, but it is an [14]. Although the turbine was designed to operate for years,

issue in any area where there is a phase transition it failed within three months of operation. A thorough

(condensation) of the steam. This is especially harmful examination of the turbine components revealed the

during turbine downtime when high-temperature stages of presence of macropores and extended cavities having

the turbine begin to cool, providing favorable conditions for branched cracks at their ends [14], as well as a build up of

condensation. When the steam condenses on the blade salt deposits in these cavities. From this investigation, the

surface, corrosion pits and dimples are formed. These are cause of failure was surmised to be a combination of

particularly harmful to the blade because they serve as stress corrosion, from the concentration of salt in the macropores,

concentrators. In the presence of normal loading and stress and stress corrosion cracking due to the concentration of

conditions, these concentrators often increase the local stress in the blade defects. In order to increase the reliability

stresses to many times the overall stress of the blade [13]. of turbine components, this study recommended that the

These localized increases in stress provide a means by which steam be regulated to ensure a minimum level of impurities,

dislocations in the materials crystal structure can be moved, especially chlorides, and that the manufacturing process be

resulting in blade deformation and crack propagation. improved to reduce macroporosities, segregate

Ultimately, stress, fatigue, and corrosion are inherently microporosities, and increase micro-structure uniformity

related: Stress induces dislocation movement in the blades throughout the material.

crystal structure; fatigue fluctuates the levels of stress in the Such catastrophes as this indicate the necessity of

blade, causing material dislocations to accumulate and form improved component designs to ensure component

cracks, thereby increasing local stress concentrations; reliability and improve turbine efficiency.

corrosion propagates cracks by reacting with blade material

around existing cracks, thus increasing the crack size, BLADE DESIGN

spreading the stress concentrations, and lessening the blades

overall strength [13]. Under constant cyclical loading, these Based on the information provided in the previous sections,

three factors combine to cause blade failure. For example, a an efficient and reliable blade design will satisfy the

blade experiencing cyclic loading and centrifugal force F, following requirements:

will have a stress of !tot, equal to the sum of all the stresses

(centrifugal, centrifugal-bending, steam-bending, and 1. The blade material must have a sufficient yield

dynamic stresses) acting on the blade. The stress !tot will strength to resist plastic deformation, and must be

tend to move dislocations in the material in the same able to retain such yield strength, or at least most of

direction. As the number of cycles increase, more and more it, at elevated temperatures.

dislocations are moved, and eventually a crack forms as the 2. The blade material must be able to be processed

dislocations reach the surface of the blade. This newly and worked with easily (this is one of the

Twelfth Annual Freshman Conference 4 April 14, 2012

Conference Session B6 2214

!

downsides of Titanium alloys as they are not easily presence or formation of cracks that allow corrosion is

welded and they are expensive to produce). practically inevitable. To this end, studies have been

3. Blade materials must exhibit a moderate elastic conducted to determine whether certain chemical coatings,

modulus so that the blade neither deforms when deposited on turbine blades, are effective in preventing

exceedingly nor breaks suddenly under normal blade corrosion [17]. E. K. Sevidova, et al, determined that

operating stresses. among three coatings (Ti+TiN, Cr+CrN, Cr+(CrTi)N) tested

4. Preferably, blade materials should be low-density in on 20X13 steel, the Cr+CrN coating proved to be most

order to decrease the centrifugal forces, and effective in resisting corrosion when exposed to a 3% NaCl

therefore centrifugal stresses, on the blades. solution [17].

5. The blades must be corrosion-resistant, even in the Water droplet erosion is also an issue in steam turbines.

presence of aggressive ionic solutions formed by Erosion of blade materials will distort the geometry of the

impurities in the steam. blade and cause a decrease in efficiency due to aerodynamic

6. Blades must be manufactured in such a way as to losses. In order to improve erosion resistance, coatings that

minimize initiation of cracks during the harden the surface of the blade have been investigated.

manufacturing process. Shun-sen Wang, et al, tested five different boride coatings,

three ion-plating CrN coatings, and three thermal-spray

Kiyoshi Segawa, et al, have developed a new rotor blade coatings on five different substrate steels [18]. They

for steam turbine plants [15]. The new blade design concluded that the thermal coatings had negligible effects on

optimized blade aerodynamics near the root section of the protecting the blade substrate from erosion when compared

blade, thus decreasing both profile and endwall losses. to the other coatings tested; that the protective coating must

Based on the results of 3-D stage and air turbine tests, the be a at least equal to some minimum critical value in order

new rotor blade was found to increase stage efficiency by to effectively protect the substrate from erosion; that

about 0.3%. In addition, the new blade design was found to improving coating thickness reduces the erosion rate of the

improve internal efficiency and reduce manufacturing costs coating; and that the erosion resistance of the coating is

by reducing the blade number by 15% [15]. strongly dependent on temperature.

Walker and Hesketh have determined that improvements Overall, an improved blade design consisting of strong,

in efficiency can be realized by the optimization of erosion and corrosion-resistant materials with optimized

aerodynamic parameters including stage heat-drop, blade aerodynamic parameters will result in a more efficient

velocity distribution, surface finish, and three-dimensional turbine.

design [9]. However, in order to optimize these parameters

the constraints imposed by manufacturing costs and TURBINE EFFICIENCY

mechanical limitations must be considered. For example,

reduction of blade stress can be realized with the Turbine efficiency is lost through defects accumulating in

implementation of lighter-weight materials, such as turbine components. As the turbine blades significantly

Titanium alloys. However, such alloys are not suitable for impact the overall efficiency of the turbine [2], defects that

use in regions of elevated temperatures and they are neither accumulate in theses components dramatically reduce the

easily nor cheaply manufactured. Thus, in order to improve efficiency of the turbine. At the worst, these defects can

turbine efficiency, a happy medium between cost and cause the failure of the turbine and necessitate the shutdown

performance must be established. of the generator; at best, these defects will increase turbine

A new blade design developed by Hideo Nomoto, et al, maintenance costs. When defects arise, such as blade

allows steam turbine blades to be more resistant to cracking and blade corrosion, the aerodynamic designs of

temperatures up to six hundred and thirty degrees Celsius the blades are severely compromised leading to inefficient

[16]. Thanks to advancements in computer fluid dynamics, interactions between the steam and the blades. This

blade design has allowed for a more efficient steam path. consequently increases the amount of fuel consumed to

The blade is now designed to optimize root and tip area, produce the steam, which increases operating costs, which

which in turn minimizes leakage from the steam path to the ultimately reflects increased the costs to the consumer.

blade. This allows for a more efficient system where steam Hence, to avoid, or at least diminish, elevated energy costs,

is not lost throughout. The introduction of integral snubbing the implementation of an improved blade design in existing

at the tip connects the blades circularly. This new blade turbines, consistent with the findings of this paper, should be

design aspect also reduces leakage, as well as vibration considered.

control. Both add to the efficiency of the steam turbine An increase in fuel consumption necessarily increases

system. This new blade design reduces the impact of thermal the amount of emissions from the generator plant. In the case

stress because of the improved efficiency of the system [16]. of fossil fuel-burning power plants, this indicates elevated

Effective corrosion resistance is key in improving blade amounts of carbon dioxide emissions. However, improved

design. Although the materials currently used in turbine turbine technologies that utilize cleaner, renewable fuels

blades have some degree of corrosion resistance, the have been developed, thereby lessening unwanted emissions.

Twelfth Annual Freshman Conference 5 April 14, 2012

Conference Session B6 2214

!

TURBINE SUSTAINABILITY with the incineration of garbage. Most prominent among the

problems resulting from the burning of trash is the release of

Sustainability, the ability of a technology to perform while toxins to the atmosphere. This not only pollutes the air, but

conserving natural resources and having no significant also poses serious health risks to humans. It has been found

adverse environmental impact, has become a major concern that waste incineration produces dangerous compounds such

as reserves of fossil fuels (on which modern society heavily as dioxin, sulfur dioxide, and nitrogen dioxide as well as

relies) begin to fall. Steam turbines have become a very many other substances of varying toxicity [21]. This has led

sustainable technology due to advances in cogeneration and to strict emission-level requirements which, whether

renewable fuel technologies. Cogeneration, the sequential intentionally or not, has caused the shutdown of some such

generation of two different forms of useful energy, typically facilities [22]. However, advancements in emission control

mechanical and thermal, from a single fuel input, [19] has technologies and incineration techniques have reopened the

been utilized by various manufacturing industries across the door to the possibility of using waste as a major source of

globe [19]. This utilization not only reduces operating costs energy production [21].

due to smaller amounts of electricity consumed by the The implementation of robust turbine blades, designed in

manufacturer from the grid, but it also lessens the accordance with the latest material technologies and able to

manufacturers impact on the environment. Coupled with the withstand the most trying of circumstances, in combination

use of renewable fuels, cogeneration provides an even more with the use of clean, renewable fuels presents an efficient

sustainable technology, sometimes with additional benefits method of generating substantial amounts of electricity. An

over and above a smaller environmental impact. For improved blade design, focused on resisting the effects of

example, M. A. Mujeebu, et al, conducted a case study on stresses, corrosive agents, and creep-inducing temperatures,

the utilization of a rice paddy husk-fueled cogeneration will elevate the turbine efficiency, consequently leading to

system in a South Indian rice mill [19]. It was found that if an increase in the power plants overall efficiency, a

such a system were implemented rice production would reduction of the amount of fuel consumed, and ultimately a

increase by at least 30 tons per day and that the system could decrease in operating costs. The use of renewable fuels, such

yield an annual savings of $0.12 million [19]. Aside form as waste, in addition to a more efficient blade design, will

the immediate monetary and manufacturing benefits of this serve to reduce operating costs even further and lessen the

system, additional benefits could be gained from the burning environmental impacts of steam turbines. Overall, such a

of the husk. As the content of the husk is mostly (91%) combination of technologies would benefit society by

silica, amorphous silica can be retained if the burnt husk is providing an efficient, viable, and sustainable means of

heated up to 700 C [19]. From this, pure silicon, which is generating electrical energy.

used extensively in computer chips and other electronic

devices, can be obtained. Additionally, sodium and REFERENCES

potassium silicate, used in adhesive and detergent

applications, and furfural, used in pharmaceutical products,

[1] U.s. Energy Information Administration (October 2011) Total Energy

can be obtained from burnt husk. Moreover, it was found Annual Energy Review [Online Article] Available:

that 1 kg of paddy husk could produce the equivalent energy http://www.eia.gov/totalenergy/data/annual/showtext.cfm?t=ptb0804b

of 1.5 kg of coal and 1.0 kg of oil [19]. This example [2] H. Termuehlen, W. Emsperger. (2003). Steam Turbine Technology in

serves to show that steam-powered generators, whether they Clean and Efficient Coal-Fired Power Plants. New York NY: ASME Press.

pp. 60-62

are used industrially or commercially, can be classified as [3] T. H. McCloskey (2003) Steam turbines [Online Article] Available:

some of the most sustainable energy-generating http://www.mathpages.com/home/kmath633/kmath633.htmhttp://www.scri

technologies. bd.com/doc/66454959/27/Turbine-Blade-Stresses

The combination of the two technologies (renewable [4] Matweb Material Property Data [Website] Available:

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MTP641

fuels and improved turbine blade design) presents a notably [5] Matweb Material Property Data [Website] Available:

efficient and sustainable method of generating electrical http://www.matweb.com/search/DataSheet.aspx?MatGUID=170de3eaaff34

energy in modern society. If this combination could be ee29e74a8f3323cdf10

implemented in generating plants around the globe, the [6] Centripetal and Centrifugal Forces [Online Article] Available:

http://www.mathpages.com/home/kmath633/kmath633.htm

respective operating costs would consequently be reduced, [7] M. Ashby, H. Shercliff, D. Cebon Materials engineering, science,

as smaller amounts of more expensive fuels would be processing and design 2nd Edition North American Edition Oxford UK:

consumed. Ultimately, this decrease in operating costs Elsevier Ltd. pg. 276

would reflect in a decrease in energy costs for consumers. In [8] Q & A Steam Turbines [Website] Available:

http://massengineers.com/Documents/QASteamturbines.htm

fact, technologies of this kind, such as waste-to-energy (the [9] P.J. Walker, J.A. Hesketh Design of Low-Reaction Steam Turbine

incinerating of commercial and industrial waste to generate Blades. (Feb 1998) Proceedings of the Institution of Mechanical

energy), have already been implemented in steam turbines Engineers, Part C: Journal of Mechanical Engineering [Online Article]

located in Europe [20]. pages: 157-174 [Online Article] Available:

http://pic.sagepub.com/content/213/2/157

Despite the convenience and relative cheapness of using [10] J. Zachary, D. Koza. (Nov/Dec 2006). Steam Turbines. Power,

waste for fuel, there are some serious drawbacks associated

Twelfth Annual Freshman Conference 6 April 14, 2012

Conference Session B6 2214

!

Volume 150, Issue 9. pp. 40-52. [Online Article]. Available:

http://libproxy.mst.edu:2048/login?url=http://search.proquest.com.libproxy.

ADDITIONAL RESOURCES

mst.edu/docview/232492382?accountid=14594

[11] Yu. Ya. Kachuriner, V. G. Orlik Specifics of Initial Steam Bureau of Labor Statistics, U.S. Department of Labor, Occupational

Condensation and Its Influence on Corrosion Damage in Turbines. Outlook Handbook, 2010-11 Edition, Engineers, 18 November 2011.

Thermal Engineering, 2007, Vol. 54, No. 2, pp. 118122 [Online Article]. <http://www.bls.gov/oco/ocos027.htm>.

Available: Curtis Laws Wilson Library, Missouri University of Science and

https://sremote.pitt.edu/content/2414788412286717/,DanaInfo=www.spring Technology (February 9, 2012). [Website]

erlink.com+ D. G. Zill (2009) A First course in Differential Equations Brooks/Cole

[12] Saeki-ku, Miyake. "Corrosion Fatigue Crack Initiation in 12% Publishing Company

Chromium Stainless Steel ." Department of Mechanical System "Materials Engineer Job Description, Salary, and Training Information."

Engineering, Hiroshima Institute of Technology 468-470 (2007): 109-113. 300+ Job Descriptions: Find Your Dream Job in 2011. N.p., n.d. Web. 19

[Online Article] Available: Nov. 2011. <http://www.jobdescriptions.net/engineering/materials-

https://sremote.pitt.edu/science/article/pii/,DanaInfo=www.sciencedire engineer/>.

ct.com+S0921509307003218. Web. 27 Jan. 2012. "Materials Engineers :: Summary." MyPlan.com :: Home. N.p., n.d. Web.

[13] L. A. Zhuchenko, V. V. Kortenko, Yu. A. Sakhnin, and V. V. 18 Nov. 2011. <http://www.myplan.com/careers/materials-

Ermolaev. Reconditioning of Steam Turbine Blades And Rotor Disks. engineers/summary-17-2131.00.html>.

Power Technology and Engineering, Vol. 36, No. 2, 2002 [Online Article] "Metallurgy." Science Daily: News & Articles in Science, Health,

Available: Environment & Technology. N.p., n.d. Web. 19 Nov. 2011.

https://sremote.pitt.edu/content/j17535820453h334/,DanaInfo=www.spring <http://www.sciencedaily.com/articles/m/metallurgy.htm>.

erlink.com+ S. J. Ghosh, A. Srivastava (2005, June). Cracks in Steam Turbine

[14] Batra, Uma. (2010). "Failure Analysis of Steam Turbine Rotor Disk." Components. Russian Journal of Nondestructive Testing, 2006, Vol. 42,

Journal of Failure Analysis and Prevention Volume 10 Issue 3. pp. 178- No. 2. [Online Article]. pp. 134146. Available:

182. [Online Journal Article]. Available: http://www.springerlink.com.libproxy.mst.edu/content/v7x0r67504506407/

https://sremote.pitt.edu/content/c520730w19773644/,DanaInfo=www.sprin

gerlink.com+. Web. 27 Jan. 2012.

[15] Kiyoshi Segawa, Yoshio Shikano, Kuniyoshi Tsubouchi and Naoaki ACKNOWLEDGEMENTS

Shibashita. Development of a Highly Loaded Rotor Blade for Steam

Turbines. JSME International Journal Series B, Vol. 45, No. 4 (2002),

pp.881-890. We would like to thank Lauren Schmeer from the writing

[16] Hideo Nomoto, Yoshikazu Kuroki, Masafumi Fukuda, and Shinya center, the staff members at the Hillman Library, and friend

Fujitsuka. Recent Development of Steam Turbines with High Steam Austin OKeane who have all helped us in our research and

Temperatures. JSME International Journal Series B, Vol. 49, No. 2

(2006), pp.218-223. [Online Journal Article]. Available:

composition of this paper.

http://www.jstage.jst.go.jp/article/jsmeb/49/2/49_218/_article

[17] E. K. Sevidova, V. M. Matsevityi, I. B. Kazak, and K. V. Vakulenko.

(2007, July). Evaluation of the Protective Properties of Multilayer

Coatings for Steam Turbine Blades. Surface Engineering and Applied

Electrochemistry, 2007, Vol. 43, No. 6, pp. 409414. [Online Journal

Article]. Available:

http://www.springerlink.com/content/t606326001257424/

[18] S. Wang, G. Liu, Q. He, Z. Feng. (2009, November). Effects of

Coating Thickness, Test Temperature, and Coating Hardness on the Erosion

Resistance of Steam Turbine Blades. Journal of Engineering for Gas

Turbines Power, February 2010, Volume 132, Issue 2. [Online Article].

Available:

http://scitation.aip.org.libproxy.mst.edu/getabs/servlet/GetabsServlet?prog=

normal&id=JETPEZ000132000002022102000001&idtype=cvips&gifs=yes

[19] M. A. Mujeebu, M. Z. Abdulla, S. Ashok. (2011, February). Husk-

Fueled Steam Turbine Cogeneration For a Rice Mill with Power Export - A

Case Study. Energy Sources, Part A: Recovery, Utilization and

Environmental Effects, January 2011, Volume 33, Issue 8. [Online Article].

Available:

https://sremote.pitt.edu/doi/abs/10.1080/,DanaInfo=www.tandfonline.com+

15567030903226298

[20] Lynne Anderson. Reheat Steam Turbines for Sustainable Energy

Solutions. [Online Article]. Available:

http://www.engineerlive.com/Power-

Engineer/Engines_Turbines/Reheat_steam_turbines_for_sustainable_energ

y_solutions/17623/

[21] Grover, Velma I. "Waste Incineration." Encyclopedia of Environment

and Society. Ed. . Thousand Oaks, CA: SAGE, 2007. 1911-12. SAGE

Reference Online. Web. 28 Mar. 2012.

[22] Ginger, Brad. "Waste to energy: air pollution control strategies and

equipment can have a major impact on waste-to-energy projects." Pollution

Engineering Mar. 2011: 20+. Academic OneFile. Web. 28 Mar. 2012.!

Available:!

http://go.galegroup.com/ps/i.do?id=GALE%7CA252848269&v=2.1&u=upi

tt_main&it=r&p=AONE&sw=w

Twelfth Annual Freshman Conference 7 April 14, 2012

You might also like

- BBC Last Stage Blades DesignDocument12 pagesBBC Last Stage Blades Designantoniomambro100% (1)

- Curtis TurbineDocument18 pagesCurtis TurbineDivya Prakash SrivastavaNo ratings yet

- Finite Element Analysis of Steam Turbine Rotor of 210 MW Power PlantDocument13 pagesFinite Element Analysis of Steam Turbine Rotor of 210 MW Power PlantEditor IJRITCCNo ratings yet

- Everything About Steam TurbinesDocument27 pagesEverything About Steam Turbinesbauskarm1100% (1)

- Troubleshooting Turbine Steam Path Damage MechanismsDocument40 pagesTroubleshooting Turbine Steam Path Damage MechanismsMas Zuhad100% (1)

- Steam Turbine Rotor CrackDocument11 pagesSteam Turbine Rotor Crackpoloko7100% (1)

- Steam Path Audit of Steam TurbineDocument38 pagesSteam Path Audit of Steam TurbineAnonymous a19X9GHZ100% (6)

- Steam Turbine Materials For Advanced AUSC COAL POWER PLANTS PDFDocument29 pagesSteam Turbine Materials For Advanced AUSC COAL POWER PLANTS PDFJuveNo ratings yet

- Turbine MannualDocument154 pagesTurbine MannualnogeshwarNo ratings yet

- Procedure Repair Diaphragm PDFDocument37 pagesProcedure Repair Diaphragm PDFGian Pratama100% (1)

- Study of Steam TurbineDocument3 pagesStudy of Steam TurbineJohn FredyNo ratings yet

- Steam Turbine Q & ADocument47 pagesSteam Turbine Q & Asrikanth9555100% (1)

- MHPS Jac GTDocument7 pagesMHPS Jac GTkp pkNo ratings yet

- Comparison Between Single&multi Shaft Turbine PDFDocument12 pagesComparison Between Single&multi Shaft Turbine PDFcobrasrkNo ratings yet

- Steam Turbine Rotor Rub DiagnosisDocument4 pagesSteam Turbine Rotor Rub DiagnosisSantosh Kale100% (1)

- Steam Turbine Vibration Characteristics AnalysisDocument24 pagesSteam Turbine Vibration Characteristics AnalysisVirgilio100% (1)

- Steam Turbine Thermal Stress Online Monitoring Technology - EPRI PDFDocument84 pagesSteam Turbine Thermal Stress Online Monitoring Technology - EPRI PDFChetan Atrai100% (1)

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument25 pagesCondition Monitoring of Steam Turbines by Performance Analysisabuhurairaqazi100% (1)

- STEAM TURBINES: UNDERSTANDING CONFIGURATIONS AND APPLICATIONSDocument25 pagesSTEAM TURBINES: UNDERSTANDING CONFIGURATIONS AND APPLICATIONSVishal DhimanNo ratings yet

- KWU Steam Turbine Module DesignDocument14 pagesKWU Steam Turbine Module Designbhaskar100% (1)

- Steam Turbine Design Project 2011Document34 pagesSteam Turbine Design Project 2011Armand du RandtNo ratings yet

- Turbine LossDocument31 pagesTurbine LossGourav Choudhuri100% (1)

- Steam TurbineDocument46 pagesSteam TurbinePOWERBOOKONE100% (2)

- Turbine CourseDocument137 pagesTurbine Courseknx175100% (8)

- Steam Purity Considerations For New TurbinesDocument46 pagesSteam Purity Considerations For New Turbinesomertrik100% (1)

- Steam TurbinesDocument27 pagesSteam Turbinesm_mukbel8752100% (1)

- Steam TurbineDocument10 pagesSteam TurbineAmeya Ranade100% (1)

- Turbine QuestionsDocument64 pagesTurbine QuestionsLyn Serwaah Gorni100% (1)

- Steam Turbine - Q & A 1Document104 pagesSteam Turbine - Q & A 1rahul_choubey_9100% (6)

- Siemens Steam TurbinesDocument3 pagesSiemens Steam TurbinesEdgar Segovia100% (1)

- In Situ Repair Welding of Steam Turbine ShroudDocument7 pagesIn Situ Repair Welding of Steam Turbine ShroudClaudia MmsNo ratings yet

- Thermodynamic Analysis of A Steam TurbineDocument3 pagesThermodynamic Analysis of A Steam TurbinePhil Engel100% (1)

- Turbine Gland Seal Steam SystemDocument15 pagesTurbine Gland Seal Steam SystemFahad Khalil75% (8)

- Steam Turbine Theory ExplainedDocument17 pagesSteam Turbine Theory ExplainedbhaskarNo ratings yet

- Compounding of Steam TurbinesDocument6 pagesCompounding of Steam TurbinesGolak Mahanta100% (1)

- Steam TurbineDocument8 pagesSteam TurbinepearlcityrjtNo ratings yet

- Ansaldo - Steam - TurbinesDocument8 pagesAnsaldo - Steam - TurbinesPratama Trendy LeoNo ratings yet

- Lesson Turbine Mainte0Ance ProgramDocument2 pagesLesson Turbine Mainte0Ance Programmister pogiNo ratings yet

- D-11 Chapter 9 Turb Alignment and S P ClearancesDocument17 pagesD-11 Chapter 9 Turb Alignment and S P ClearancesHernan Giraut100% (2)

- Steam TurbineDocument4 pagesSteam TurbineRowin Mark Sabornido100% (1)

- Steam Turbine and Deposits Problems and SolutionsDocument18 pagesSteam Turbine and Deposits Problems and Solutionsjerezg25100% (2)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- The Steam Engine and Turbine - A Text Book for Engineering CollegesFrom EverandThe Steam Engine and Turbine - A Text Book for Engineering CollegesNo ratings yet

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionFrom EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryRating: 4 out of 5 stars4/5 (5)

- Structural_modification_of_a_steam_turbine_bladeDocument7 pagesStructural_modification_of_a_steam_turbine_bladeEMS CommerceNo ratings yet

- Design and analysis of steam turbine bladesDocument7 pagesDesign and analysis of steam turbine bladesaliNo ratings yet

- Critical Review Paper of Steam Turbine Blades Corrosion and Its SolutionsDocument9 pagesCritical Review Paper of Steam Turbine Blades Corrosion and Its Solutionsijsret100% (1)

- Modeling and Analysis of Steam Turbine Blade-Ijaerdv05i0451562n PDFDocument11 pagesModeling and Analysis of Steam Turbine Blade-Ijaerdv05i0451562n PDFGuruvenu KamanuruNo ratings yet

- A Research Paper On Design and Analysis of Shaftless Steam TurbineDocument5 pagesA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDNo ratings yet

- journalsresaim,+IJRESM V3 I8 104Document4 pagesjournalsresaim,+IJRESM V3 I8 104077bme030No ratings yet

- Fatigue Analysis of Simple and Advanced Hoop Pelton Turbine BucketsDocument8 pagesFatigue Analysis of Simple and Advanced Hoop Pelton Turbine BucketsAliNo ratings yet

- Steam Turbine Basic TheoryDocument34 pagesSteam Turbine Basic TheoryEliyanto E BudiartoNo ratings yet

- Failure Analysis of A Gas Turbine BladeDocument10 pagesFailure Analysis of A Gas Turbine BladeJoao Vitor de Almeida SoaresNo ratings yet

- The Design and Analysis of Gas Turbine Blade: Research PaperDocument3 pagesThe Design and Analysis of Gas Turbine Blade: Research PaperSai SushmaNo ratings yet

- Design and Modal Analysis of Turbine Compressor BladeDocument8 pagesDesign and Modal Analysis of Turbine Compressor BladeReynaldi PrakasaNo ratings yet

- Structural Design and Analysis of Gas Turbine Blade Using Cae Tools IJERTV3IS100482Document6 pagesStructural Design and Analysis of Gas Turbine Blade Using Cae Tools IJERTV3IS100482Sai SushmaNo ratings yet

- An Investigation of Transient Thermal Analysis of 1 Stage Gas Turbine Blade Manufactured by Directional Solidification and Mechanically Alloyed Nickel-Based SuperalloysDocument12 pagesAn Investigation of Transient Thermal Analysis of 1 Stage Gas Turbine Blade Manufactured by Directional Solidification and Mechanically Alloyed Nickel-Based SuperalloyshidaiNo ratings yet

- Design and Analysis of Steam Turbine Blade Using FEA: K. S N D, D - P. H. V. S T SDocument5 pagesDesign and Analysis of Steam Turbine Blade Using FEA: K. S N D, D - P. H. V. S T SShanker PandeyNo ratings yet

- Appleton Right BrainDocument13 pagesAppleton Right Braineasy_astronautNo ratings yet

- Information Theory Paper Explores Digital RevolutionDocument27 pagesInformation Theory Paper Explores Digital RevolutionidayacgNo ratings yet

- A Comparison of Five Business PhilosophiesDocument13 pagesA Comparison of Five Business PhilosophiesCK LimNo ratings yet

- 75 Things To Do With Your MenteesDocument16 pages75 Things To Do With Your Menteeseasy_astronautNo ratings yet

- Transactions of The Association For COmputational Linguistics PDFDocument14 pagesTransactions of The Association For COmputational Linguistics PDFeasy_astronautNo ratings yet

- How To Take Yourself Lightly PDFDocument2 pagesHow To Take Yourself Lightly PDFeasy_astronautNo ratings yet

- IPFS - The Distributed, Versioned P2P File System (DRAFT 3Document11 pagesIPFS - The Distributed, Versioned P2P File System (DRAFT 3easy_astronautNo ratings yet

- Min Os BookDocument78 pagesMin Os BookstevenjaganNo ratings yet

- The Philosophy of Creativity - GautDocument13 pagesThe Philosophy of Creativity - GautDavid Chak100% (3)

- Systems Leadership IntroDocument9 pagesSystems Leadership Introeasy_astronautNo ratings yet

- Being A Mentee - How To Get The Most From MentoringDocument17 pagesBeing A Mentee - How To Get The Most From Mentoringeasy_astronautNo ratings yet

- The Characteristics of Mathematical Creativity PDFDocument16 pagesThe Characteristics of Mathematical Creativity PDFeasy_astronautNo ratings yet

- A Comparison of Five Business PhilosophiesDocument13 pagesA Comparison of Five Business PhilosophiesCK LimNo ratings yet

- The Philosophy of Creativity - GautDocument13 pagesThe Philosophy of Creativity - GautDavid Chak100% (3)

- The Human Side of Enterprise PDFDocument11 pagesThe Human Side of Enterprise PDFeasy_astronautNo ratings yet

- Trig Cheat SheetDocument4 pagesTrig Cheat Sheetapi-284574585No ratings yet

- Being A Mentee - How To Get The Most From MentoringDocument17 pagesBeing A Mentee - How To Get The Most From Mentoringeasy_astronautNo ratings yet

- Study of Manufacturing of Steam Turbine Blade PDFDocument54 pagesStudy of Manufacturing of Steam Turbine Blade PDFeasy_astronaut67% (6)

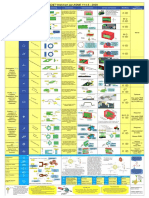

- GDT Wall Chart 2009 Arch - D PDFDocument1 pageGDT Wall Chart 2009 Arch - D PDFeasy_astronautNo ratings yet

- Supercritical Power Generation-Experiences, Issues & ChallengesDocument85 pagesSupercritical Power Generation-Experiences, Issues & ChallengesVeda SiddharthNo ratings yet

- GDand TDocument0 pagesGDand TKaliya PerumalNo ratings yet

- GDand TDocument0 pagesGDand TKaliya PerumalNo ratings yet

- Using Custom Classes in Scripts - CATIA V5 AutomationDocument9 pagesUsing Custom Classes in Scripts - CATIA V5 Automationeasy_astronautNo ratings yet

- GDT Wall Chart 2009 Arch - D PDFDocument1 pageGDT Wall Chart 2009 Arch - D PDFeasy_astronautNo ratings yet

- Brief, Horrible MomentsDocument51 pagesBrief, Horrible Momentseasy_astronaut100% (1)

- Groupthink - WikipediaDocument13 pagesGroupthink - Wikipediaeasy_astronautNo ratings yet

- Study of Manufacturing of Steam Turbine Blade PDFDocument54 pagesStudy of Manufacturing of Steam Turbine Blade PDFeasy_astronaut67% (6)

- NEi L1Document4 pagesNEi L1easy_astronautNo ratings yet

- GD&T Symbols Reference GuideDocument2 pagesGD&T Symbols Reference Guidecreating_24No ratings yet

- 750-91 CB - CBLE 250-350 HP (Rev 1997)Document166 pages750-91 CB - CBLE 250-350 HP (Rev 1997)Jonathan GarciaNo ratings yet

- VENTURIMETERDocument10 pagesVENTURIMETERKrishan PrajapatiNo ratings yet

- Eclate 719520-51100 2tne68-ErDocument10 pagesEclate 719520-51100 2tne68-ErTheo HuqueleuxNo ratings yet

- Piping Bulk MTO Input TemplateDocument5 pagesPiping Bulk MTO Input TemplateShankar KumarNo ratings yet

- 200aetl 2000Document0 pages200aetl 2000Ray Cepeda MenaNo ratings yet

- Ships: Related Commercial ResourcesDocument5 pagesShips: Related Commercial ResourcesMinhSon HaNo ratings yet

- Pumping Unit C-640D-305-168Document51 pagesPumping Unit C-640D-305-168EdinsonUribeTorres100% (1)

- General Physics 1 Week 3Document5 pagesGeneral Physics 1 Week 3Levi AckermanNo ratings yet

- 1955 3 EngDocument21 pages1955 3 EngTateNo ratings yet

- Refrigeration (Kylteknik) : 2. Vapour-Compression Refrigeration ProcessesDocument36 pagesRefrigeration (Kylteknik) : 2. Vapour-Compression Refrigeration ProcessesiJeng RalluNo ratings yet

- Process Engineering Manual 005 IIDocument29 pagesProcess Engineering Manual 005 IIzoeNo ratings yet

- Lateral Earth Pressure Due To Vibratory Rollers PDFDocument11 pagesLateral Earth Pressure Due To Vibratory Rollers PDFchutton681No ratings yet

- ABB LV Motor ManualDocument16 pagesABB LV Motor Manualleeyuen_aNo ratings yet

- Service N ValveDocument30 pagesService N ValvesenamotoNo ratings yet

- Bai 2023 J. Phys. Conf. Ser. 2478 122027Document15 pagesBai 2023 J. Phys. Conf. Ser. 2478 122027Persian GulfNo ratings yet

- Vibratoin Severity - ISO 2372Document1 pageVibratoin Severity - ISO 2372HARSHANo ratings yet

- Refrigeration TutorDocument7 pagesRefrigeration TutorTejas Vibhandik100% (2)

- Ge Frame 3 Gas Turbine Compressor Drive Application Control PackageDocument3 pagesGe Frame 3 Gas Turbine Compressor Drive Application Control PackagehasnaNo ratings yet

- NPTEL Fluid Mechanics MCQDocument14 pagesNPTEL Fluid Mechanics MCQVijayan SnNo ratings yet

- FSNF ActuatorsDocument4 pagesFSNF Actuatorssbalan6949No ratings yet

- FH100 FH120 FH135 FH160: EU Stage 4 EngineDocument16 pagesFH100 FH120 FH135 FH160: EU Stage 4 EngineSabah100% (1)

- Triplex Pump Part 1Document30 pagesTriplex Pump Part 1Rodolfo Castro86% (7)

- Rough Terrain Crane Specifications and CapacitiesDocument12 pagesRough Terrain Crane Specifications and CapacitiesKpChua0% (1)

- Electric Drives Nen 701Document2 pagesElectric Drives Nen 701sriharshitha vegesnaNo ratings yet

- GSE EnVision ProcessFund Sim IDocument2 pagesGSE EnVision ProcessFund Sim IFungky KingNo ratings yet

- Site Bumi Barito equipment status and repair updatesDocument1 pageSite Bumi Barito equipment status and repair updatesYulian GalihNo ratings yet

- Solar Energy Week 8 Assignment (Due: November 13)Document3 pagesSolar Energy Week 8 Assignment (Due: November 13)batlax0000No ratings yet

- Thermodynamics Solutions Manual for Gaskell 6th EditionDocument228 pagesThermodynamics Solutions Manual for Gaskell 6th Editionhamed pirboneh75% (4)

- Fisica 2Document3 pagesFisica 2Saul TicsihuaNo ratings yet

- Mechanic FractureDocument9 pagesMechanic Fracturehengki wibowoNo ratings yet