Professional Documents

Culture Documents

Model 4WG 100-800 HP Boilers Relief Valve Sizing Tables

Uploaded by

sebaversaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model 4WG 100-800 HP Boilers Relief Valve Sizing Tables

Uploaded by

sebaversaCopyright:

Available Formats

Model 4WG 100 800 HP Boilers

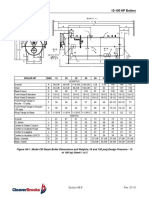

Table A3-13. Model 4WG Hot Water Relief Valve Outlet Size

VALVE SETTING 30 PSIG HW 125 PSIG HW 150 PSIG HTHW

NO. OF NO. OF NO. OF

OUTLET SIZE OUTLET SIZE OUTLET SIZE

BOILER HP VALVES VALVES VALVES

(IN.) (IN.) (IN.)

REQ'D REQ'D REQ'D

100 1 2-1/2 1 1-1/4 1 2

(1) 1-1/2

125 1 2-1/2 1 1-1/4 2

(1) 2

(1) 1-1/2

150 1 2-1/2 1 2 2

(1) 2

(1) 2-1/2

200 2 1 2 2 2

(1) 1-1/4

(1) 2 (1) 2

250 2 1 2 2

(1) 2-1/2 (1) 2-1/2

300 2 2-1/2 1 2-1/2 2 2-1/2

(2) 2-1/2 (1) 2-1/2

350 3 1 2-1/2 2

(1) 1 (1) 3

(1) 2 (1) 2-1/2

400 3 1 2-1/2 2

(2) 2-1/2 (1) 3

(1) 1 (1) 1

500 4 2 3

(3) 2-1/2 (1) 2-1/2

(3) 2-1/2 (1) 1-1/4 (2) 3

600 4 2 3

(1) 2 (1) 2-1/2 (1) 2-1/2

(1) 1 (1) 2-1/2

700, 800 5 2 3 3

(4) 2-1/2 (1) 2

NOTE: Relief valve is Kunkle #537 for 30# & 125#(Section IV) boiler and is Kunkle #927

Table A3-14. 4WG Recommended Steam Nozzle Size

OPERATING PRESSURE BOILER HP

PSIG 100 125 150 200 250 300 350 400 500 600 700 800

15 8 8 8 10 10 12 12 12 12 12 12 12

30 6 6 6888 10 10 10 12 12 12

40 6 6 6688 8 10 10 10 12 12

50 4 6 6668 8 8 10 10 10 12

75 4 4 4666 8 88 8 10 10

100 4 4 4666 6 68 8 8 10

125 4 4 4466 6 68 8 88

150 2.5 3 3446 6 66 6 88

200 2.5 2.5 3 444 4 66 6 66

250 2 2.5 3 344 4 46 6 66

NOTES:

1. Steam nozzle sizes given in inches.

2. Recommended steam nozzle sizes based on 4000 to 5000 fpm steam velocity.

3. All standard steam nozzle sizes for 150 psig design pressure or greater are the same as 125 psig operating pressure on

the above table. To increase or decrease the standard size, request the change with your local Cleaver-Brooks authorized

representative.

4. Shaded area denotes special surge load baffles must be installed to avoid possible water carryover.

5. For incremental operating pressure, see Table I3-1 Steam System Fundamentals.

Section A3-20 Rev. 09-09

Model 4WG 100 800 HP Boilers

Table A3-15. 4WG Recommended Non-Return Valve Size

BOILER CAPACITY OPERATING PRESSURE (PSIG)

BOILER HP

(LBS/HR) 50 75 100 125 150 175 200 250

100 3450 2-1/2 2-1/2 NA NA NA NA NA NA

125 4313 3 2-1/2 2-1/2 2-1/2 NA NA NA NA

150 5175 3 3 2-1/2 2-1/2 2-1/2 2-1/2 NA NA

200 6900 3* 3 3 3 3 2-1/2 2-1/2 2-1/2

250 8625 4 3* 3 3 3 3 33

300 10350 4 4 4 3* 3 3 33

350 12025 4 4 4 4 4 3* 3 3

400 13800 5 4 4 4 4 4 4 3*

500 17210 6 5 5 4 4 4 44

600 20700 6 6 5 5 5 4 44

700 24150 6 6 6 5 5 5 54

800 27600 6 6 6 6 6 5 55

NOTE: Valve sizes (300 # Flanges) given in inches.

Standard Non-Return valve selections limited to a maximum 2 to 1 turndown (50% of full load); selections based on typical

non-return valve sizing recommendations. For final valve selection contact your C-B authorized representative. For high

turndown applications see Boiler Book Section I3, Table I3-3.

* Indicates pressure drop of less than 7.5 psig. All other selections are less than 6 psig pressure drop.

Table A3-16. Altitude Correction for Gas

ALTITUDE CORRECTION ALTITUDE CORRECTION

(FT) FACTOR (FT) FACTOR

1000 1.04 6000 1.25

2000 1.07 7000 1.3

3000 1.11 8000 1.35

4000 1.16 9000 1.4

5000 1.21 - -

To obtain minimum required gas pressure at altitudes above 700

feet, multiply the pressure by the listed factors:

Inches WC x 0.577 = oz/sq-in.

oz/sq-in x 1.732 = inches WC.

Inches WC x 0.0361 = psig.

oz/sq-in x 0.0625 = psig.

psig x 27.71 = Inches WC.

psig x 16.0 = oz/sq-in.

Section A3-21 Rev. 09-09

Model 4WG 100 800 HP Boilers

Table A3-17. Model 4WG, Standard and Low NOx (30 ppm), Minimum Required Gas Pressure at Entrance

to Standard, FM and IRI Gas Trains (Upstream of Gas Pressure Regulator)

STD PIPE PRESSURE REQUIRED-STD PRESSURE REQUIRED-30 PPM

BOILER HP SIZE ("WC) ("WC)

(Inches) GPR* Minimum Maximum GPR* Minimum Maximum

100 2 RV91 9 27.7 RV91 12.3 27.7

125 2 RV91 16.6 27.7 RV91 21.6 27.7

150 2 RV91 23.2 27.7 RV91 21.9 27.7

200 2.5 210G 20.7 277 210G 28.5 277

250 2.5 210G 29.9 277 210G 29 277

300 2.5 210G 40.8 277 210G 39.5 277

350 3 210G 42.7 277 210G 40.7 277

1.5-2 S 130 208 S 130 208

2-2.5 S 89 130 S 89 130

400

2.5 S 64 89 S 64 89

3 S 39 64 S 39 64

1.5-2.5 S 183 277 S 175 277

2-2.5 S 130 183 S 125 175

500

2.5 S 89 130 S 83 125

3 S 50 89 S 44 83

2-1.5-2.5 S 233 277 S 241 277

2-2.5 S 177 233 S 186 241

600 2.5 S 119 177 S 127 186

2.5-3 S 100 119 S 108 127

3 S 61 100 S 69 108

2-3 S 222 277 S 213 277

2.5-3 S 133 222 S 125 213

700

3 S 83 133 S 75 125

4 S 55 83 S 44 75

2-3 S 255 277 S 260 277

2.5-3 S 152 255 S 155 260

800

3 S 94 152 S 94 155

4 S 53 94 S 55 94

NOTE: Where multiple gas train sizes are shown, the shaded row indicates standard size. For altitudes above 700 feet,

contact your local Cleaver-Brooks authorized representative.

* GPR Gas Pressure Regulator

S-Siemens regulating actuator.

Section A3-22 Rev. 09-09

Model 4WG 100 800 HP Boilers

Figure A3-8. Typical Fuel Oil Supply Arrangement

Section A3-23 Rev. 09-09

You might also like

- Model ICB 100-800 HP Boilers Safety Valve and Relief Valve SizingDocument4 pagesModel ICB 100-800 HP Boilers Safety Valve and Relief Valve SizingsebaversaNo ratings yet

- Model CBLE 125-800 HP Boilers: Table A1-14. Steam Boiler Safety Valve OpeningsDocument4 pagesModel CBLE 125-800 HP Boilers: Table A1-14. Steam Boiler Safety Valve OpeningssebaversaNo ratings yet

- Air Line Pipe Size Chart for Compressed Air SystemsDocument1 pageAir Line Pipe Size Chart for Compressed Air SystemsTiến Hà VũNo ratings yet

- CU AL Ampacity Chart FinalDocument1 pageCU AL Ampacity Chart FinalRobertoHerediaJacoboNo ratings yet

- Ansi B16 Valve Face To Face Dimensions: Ball ValvesDocument3 pagesAnsi B16 Valve Face To Face Dimensions: Ball ValvesAslam ShaikhNo ratings yet

- 8.13 - Glycol Heat Tracing 11Document1 page8.13 - Glycol Heat Tracing 11Greg EverettNo ratings yet

- MSDS TCS TrichlorosilaneDocument4 pagesMSDS TCS Trichlorosilanemoku_mokuNo ratings yet

- Air Line Pipe Size: Length of Run - FeetDocument1 pageAir Line Pipe Size: Length of Run - FeetbiondavNo ratings yet

- 爱途牌MT05I电喷诊断系统服务手册Document13 pages爱途牌MT05I电喷诊断系统服务手册张连杉No ratings yet

- Current Api Thread Standards: Size IN MM O.D. Pipe Tubing & CasingDocument5 pagesCurrent Api Thread Standards: Size IN MM O.D. Pipe Tubing & CasingJohan LinggaNo ratings yet

- Ansi Valve DimensionsDocument1 pageAnsi Valve Dimensionsbkm dizaynNo ratings yet

- Automobile Repair Shop Scheduling OptimizationDocument59 pagesAutomobile Repair Shop Scheduling OptimizationitzgayaNo ratings yet

- Optimize Your Boiler Room with Model 4WI DimensionsDocument4 pagesOptimize Your Boiler Room with Model 4WI DimensionssebaversaNo ratings yet

- GWL Performance DataDocument1 pageGWL Performance DatabcombuysaleNo ratings yet

- Torque ValuesDocument6 pagesTorque ValuesMark Darrel AranasNo ratings yet

- Bolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronDocument1 pageBolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronGiorgi KOGOSHVILINo ratings yet

- Pipe Size Schedule Wall Thickness ID Threadolet LG Max Length CL LengthDocument2 pagesPipe Size Schedule Wall Thickness ID Threadolet LG Max Length CL LengthapgoslingNo ratings yet

- Captura de Pantalla 2023-09-21 A La(s) 5.32.58 P.M.Document2 pagesCaptura de Pantalla 2023-09-21 A La(s) 5.32.58 P.M.Richard CarvajalNo ratings yet

- Matriz Inversa - Gauss JordanDocument4 pagesMatriz Inversa - Gauss JordanKevinrichard MendozayunesNo ratings yet

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocument11 pagesThermoplastic Flanges: Technical Information Weights & DimensionsANDERSON NERESNo ratings yet

- What Is The Difference Between Lateral Tee and True WyeDocument11 pagesWhat Is The Difference Between Lateral Tee and True WyeYaneYangNo ratings yet

- 3B6 Load Moment Indicator (Lmi) FOR Telescopic HandlersDocument33 pages3B6 Load Moment Indicator (Lmi) FOR Telescopic HandlersStefan RzepkaNo ratings yet

- Kata LogDocument13 pagesKata LogFarshad MahmoudiNo ratings yet

- ACTIVITY-4-7X7-DETERMINANT-USING-GAUSS-JORDANDocument8 pagesACTIVITY-4-7X7-DETERMINANT-USING-GAUSS-JORDANjlnadua23No ratings yet

- Equivalencia CIs Fontes ChaveadasDocument14 pagesEquivalencia CIs Fontes ChaveadasRobmixNo ratings yet

- NEMA FrameDocument1 pageNEMA Frameriff100% (9)

- Sistemas Con El Método GaussDocument11 pagesSistemas Con El Método GaussRuby RamírezNo ratings yet

- Okta Briyanti Mila Sari - A1E016043 (Index Miler)Document4 pagesOkta Briyanti Mila Sari - A1E016043 (Index Miler)okta briyanti mila sariNo ratings yet

- Elbows, Couplings & NipplesDocument8 pagesElbows, Couplings & NipplesimranNo ratings yet

- Abhishek Yadav RAS Paper 4th 128 MarksDocument46 pagesAbhishek Yadav RAS Paper 4th 128 MarksYOGENDRANo ratings yet

- Electrical Motors - Frame Sizes PDFDocument5 pagesElectrical Motors - Frame Sizes PDFGustavo CuatzoNo ratings yet

- Class 300 Flange Bolt Pattern & SizesDocument1 pageClass 300 Flange Bolt Pattern & SizesRyan SolomonNo ratings yet

- NFPA20 Minimum Pipe SizesDocument1 pageNFPA20 Minimum Pipe SizesMollick Mahfuzur RhmanNo ratings yet

- Stok Opnam 01-31 JanuariDocument4 pagesStok Opnam 01-31 JanuariAtas Nama TraumaNo ratings yet

- 2. 18 07 24 01 დევნილთა სამეწარმეო საქმიანობის ხელშეწყობა 1Document11 pages2. 18 07 24 01 დევნილთა სამეწარმეო საქმიანობის ხელშეწყობა 14w6cszvpdcNo ratings yet

- Fabrikasi Cabang SP Lantai Typical 11: NO Ukuran Pipa Panjang (CM) Jumlah (BTG)Document2 pagesFabrikasi Cabang SP Lantai Typical 11: NO Ukuran Pipa Panjang (CM) Jumlah (BTG)tantan aliansyahNo ratings yet

- Table - Grease Lubrication ScheduleDocument1 pageTable - Grease Lubrication ScheduleXiangYou ChenNo ratings yet

- Calculating motor parameters for star delta startersDocument6 pagesCalculating motor parameters for star delta startersGanesh GawdeNo ratings yet

- Bapa Adi 1Document10 pagesBapa Adi 1herysuria81No ratings yet

- FY8-31DU-001: Service InformationDocument287 pagesFY8-31DU-001: Service Informationadhari rachmanNo ratings yet

- 900# RF Flange Rating: Dimensions Are in Inches. Weights Are in PoundsDocument1 page900# RF Flange Rating: Dimensions Are in Inches. Weights Are in PoundsNILTON BERNALNo ratings yet

- Pipe Nominal DiameterDocument1 pagePipe Nominal DiameterSreejeshPremrajNo ratings yet

- Weights SS FlangesDocument4 pagesWeights SS FlangesMarine SleimanNo ratings yet

- Book 1Document14 pagesBook 1Wan AzriNo ratings yet

- Flange dimensions by pipe size and pressure classDocument19 pagesFlange dimensions by pipe size and pressure classHarish PothepalliNo ratings yet

- Class 150 Flange Bolt Pattern & Sizes ChartDocument1 pageClass 150 Flange Bolt Pattern & Sizes ChartRyan SolomonNo ratings yet

- Pipe Size (Inches) Pipe Inside Diameter (Inches) No. of Bolt Holes Flange Outside Diameter (Inches)Document2 pagesPipe Size (Inches) Pipe Inside Diameter (Inches) No. of Bolt Holes Flange Outside Diameter (Inches)JM MagayanesNo ratings yet

- 4d84e-5 Sebm035103Document197 pages4d84e-5 Sebm035103PHÁT NGUYỄN THẾ100% (11)

- Pipe Beam SizesDocument262 pagesPipe Beam SizesjoehodohNo ratings yet

- Piping Spec Book 1Document259 pagesPiping Spec Book 1interx00No ratings yet

- Bleed Ring - ANSI Class 150-2500 (In)Document2 pagesBleed Ring - ANSI Class 150-2500 (In)ulfatNo ratings yet

- Flanges and Bolt Dimensions ASME/ANSI B16.5 - Class 150 To 2500Document9 pagesFlanges and Bolt Dimensions ASME/ANSI B16.5 - Class 150 To 2500daveNo ratings yet

- Finite Difference Coefficients-How To Calculate CoefficientsDocument4 pagesFinite Difference Coefficients-How To Calculate CoefficientsRMolina65No ratings yet

- Rt38jhrbdsl CL 01Document8 pagesRt38jhrbdsl CL 01Lendys DnielNo ratings yet

- Bridas Slip On Grandes b16.47Document1 pageBridas Slip On Grandes b16.47Nilton Inca TitoNo ratings yet

- Series 30, 31 & 32 Three Way Valves SpecificationsDocument6 pagesSeries 30, 31 & 32 Three Way Valves SpecificationsJovenal TuplanoNo ratings yet

- Leading Provider of Energy Efficient Industrial MotorsDocument1 pageLeading Provider of Energy Efficient Industrial MotorsrsanjuanNo ratings yet

- TexasFlange - Bolt and Stud Dimensions ASME B16.5Document2 pagesTexasFlange - Bolt and Stud Dimensions ASME B16.5cristinelbNo ratings yet

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Corbel Design Based On 2018 IBC / ACI 318-14: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesCorbel Design Based On 2018 IBC / ACI 318-14: Project: Client: Design By: Job No.: Date: Review bycurlyjockey100% (1)

- Roads Division KasaragodDocument142 pagesRoads Division KasaragodShameer UppalaNo ratings yet

- Katmon Tree - : Trees For Noise CancellingDocument7 pagesKatmon Tree - : Trees For Noise CancellingJashley RoviraNo ratings yet

- Noise Control Buildings-Seminar ReportDocument29 pagesNoise Control Buildings-Seminar ReportVîkÅš VìČký69% (13)

- Code Cases Boilers and Pressure VesselsDocument994 pagesCode Cases Boilers and Pressure VesselsmateoNo ratings yet

- PCI 6th Edition OverviewDocument36 pagesPCI 6th Edition Overviewandrej2112No ratings yet

- Structural Analysis ReportDocument53 pagesStructural Analysis ReportNabin AcharyaNo ratings yet

- Plumbing Review: DAY 1: 29 May 2016 Danilo V. RavinaDocument93 pagesPlumbing Review: DAY 1: 29 May 2016 Danilo V. RavinaELArChick100% (2)

- Experiment 6 Forces in A Roof TrussDocument5 pagesExperiment 6 Forces in A Roof Trusshafiey89No ratings yet

- Petrofast MTC 3.1 PO-400234 Anchor Bolts - Option FDocument2 pagesPetrofast MTC 3.1 PO-400234 Anchor Bolts - Option Fحسن صالح حسن المياحيNo ratings yet

- Perancangan Struktur Baja 1Document53 pagesPerancangan Struktur Baja 1Saya BimaNo ratings yet

- Design of Rigid Pavement CC Road With M25Document5 pagesDesign of Rigid Pavement CC Road With M25pravincs_007No ratings yet

- Works) : SABS 1200Document10 pagesWorks) : SABS 1200Palesa TshetlanyaneNo ratings yet

- 45-144 - A505 - Elevator Details (Version)Document1 page45-144 - A505 - Elevator Details (Version)Parth DaxiniNo ratings yet

- Vulkem NEM - Data SheetDocument2 pagesVulkem NEM - Data SheetRobertNo ratings yet

- Wall Cladding & PanelsDocument18 pagesWall Cladding & PanelsSubrata DeyNo ratings yet

- PIP PCECV001 Guidelines For Application of Control ValvesDocument39 pagesPIP PCECV001 Guidelines For Application of Control ValvesAndresNo ratings yet

- Mat UrbanismDocument11 pagesMat UrbanismBadr ZeinaNo ratings yet

- Base Isolation of Structure SystemDocument33 pagesBase Isolation of Structure SystemHaris Alam100% (2)

- Sika PDS - E - SikaGrout - 214-11 PDFDocument3 pagesSika PDS - E - SikaGrout - 214-11 PDFlwin_oo2435No ratings yet

- Yamuna Sports ComplexDocument37 pagesYamuna Sports ComplexHimanshu GoodwaniNo ratings yet

- SplicingDocument4 pagesSplicinghakim2020No ratings yet

- Contract Labour in NepalDocument33 pagesContract Labour in NepalVijay AgrahariNo ratings yet

- (Act 487) Quantity Surveyors Act 1967Document44 pages(Act 487) Quantity Surveyors Act 1967AlasnuyoNo ratings yet

- Wiring Design & CalculationsDocument36 pagesWiring Design & CalculationsSerrano Ivan Jasper100% (1)

- Modified Guidelines For Geopolymer Concrete Mix Design Using Indian StandardDocument13 pagesModified Guidelines For Geopolymer Concrete Mix Design Using Indian StandardDl Divakar LNo ratings yet

- Silt Control GuideDocument32 pagesSilt Control GuidePcEngNo ratings yet

- Protection Board PDFDocument2 pagesProtection Board PDFmilanbrasinaNo ratings yet

- Bison Hollowcore Brochure 2019Document9 pagesBison Hollowcore Brochure 2019Joao AlvesNo ratings yet

- Mannum Report - WordDocument26 pagesMannum Report - WordajNo ratings yet